Organic silicon modified epoxy resin for packaging LED (Light Emitting Diode), and preparation method and application thereof

A technology of LED packaging and epoxy resin, applied in the direction of epoxy resin glue, organic chemistry, adhesive type, etc., can solve the problems of epoxy resin performance improvement, lack of organic silicon chain segments, etc., to improve flexibility, improve Anti-yellowing performance, anti-yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

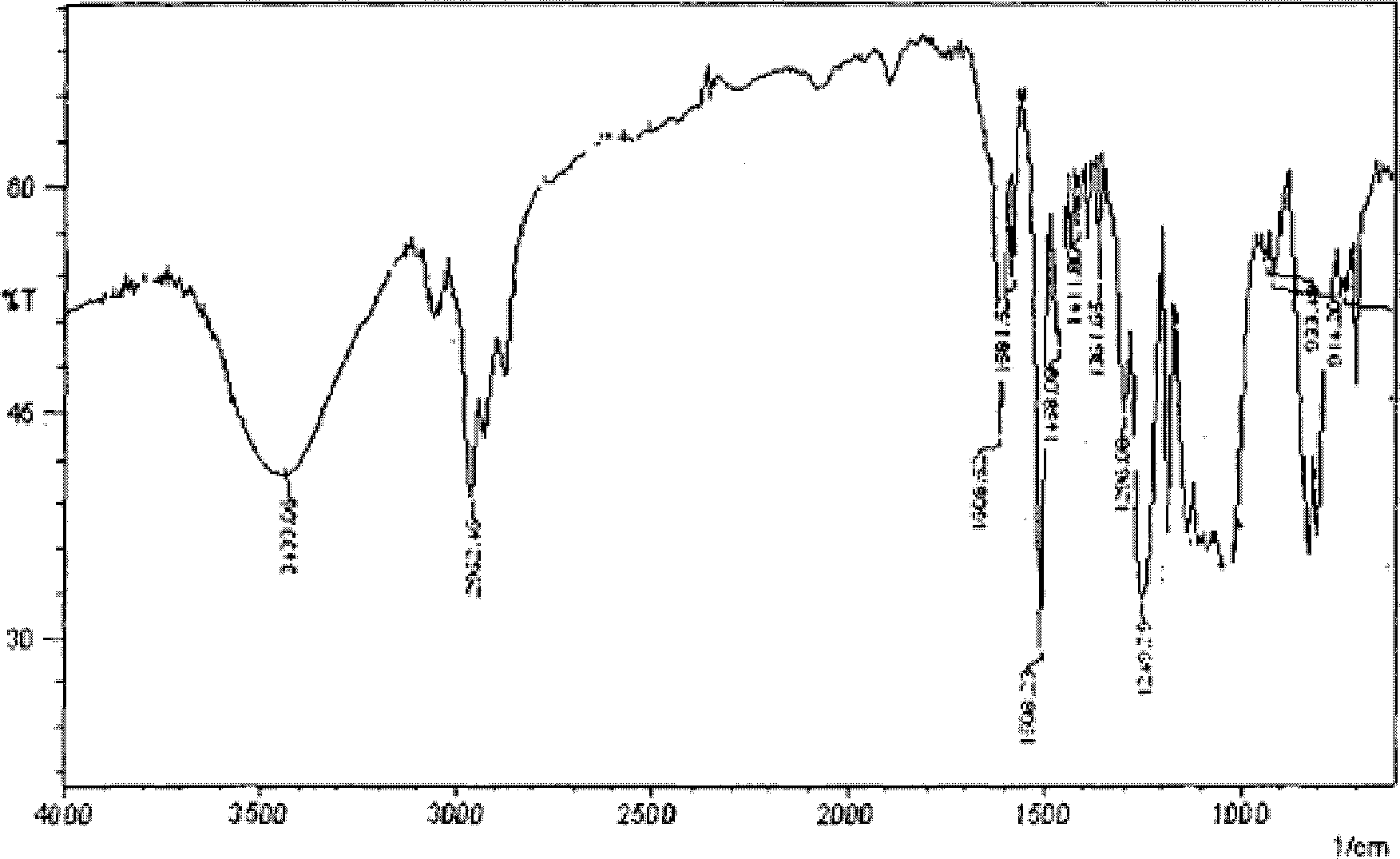

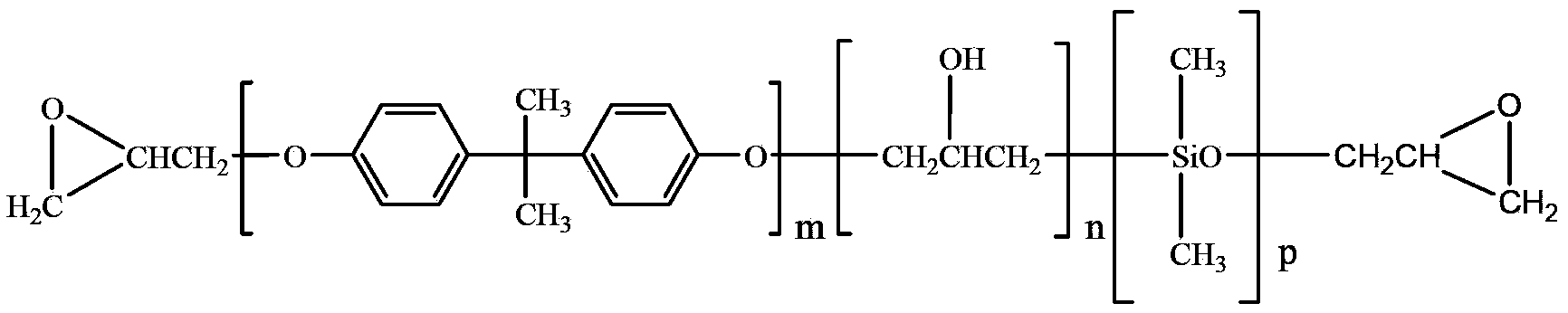

[0034] (1) Add 22.8g D4 (0.075mol), 68.5g (0.3mol) bisphenol A, 46.4g (0.5mol) epichlorohydrin to a 250ml clean three-necked bottle, mix well at 60°C, and then add 20g Sodium hydroxide, polymerize at 60°C for 3 hours, then add 150g of toluene, let the product dissolve completely under stirring, then let it stand for stratification, and reflux the upper layer product to remove water under stirring, continue to reflux for 1 hour after no bubbles appear, and let it stand , cooling, filtering, and desolventization under reduced pressure to obtain 115.8 g of colorless and transparent organosilicon-modified epoxy resin, whose viscosity is 12500 mPa·S, and its chemical formula after identification is CH 2 CHOCH 2 [OC 6 h 4 C(CH 3 ) 2 C 6 h 4 O] 3 [CH 2 CHOHCH 2 ] 3 [(CH 3 ) 2 SiO] 3 CH 2 CHCH 2O, its infrared spectrum is shown in figure 1 .

[0035] (2) Take 20g of the product obtained in (1), add 5g of epoxy diluent 2-cresyl glycidyl ether, 5.0g of nano-silicon diox...

Embodiment 2

[0038] (1) Add 22.8g of D3 (0.075mol), 45.7g (0.2mol) of bisphenol A, 37.2g (0.4mol) of epichlorohydrin into a 250ml clean three-necked bottle, mix well at 60°C, and then add 20g Potassium hydroxide, polymerize at 80°C for 2 hours, then add 150g of xylene, let the product dissolve completely under stirring, and then let it stand for stratification, and reflux the upper layer product to remove water under stirring, and continue to reflux for 2 hours after no bubbles appear, and let it stand place, cool, filter, and remove the solvent under reduced pressure to obtain 88.8 g of colorless and transparent organosilicon-modified epoxy resin with a viscosity of 8500 mPa·S, and its chemical formula is identified as CH 2 CHOCH 2 [OC 6 h 4 C(CH 3 ) 2 C 6 h 4 O] 2 [CH 2 CHOHCH 2 ] 2 [(CH 3 ) 2 SiO] 3 CH 2 CHCH 2 O.

[0039] (2) Take 25g of the product obtained in (1), add 5g of epoxy diluent 4-tert-butylphenyl glycidyl ether, 6.0g of nano-silica, mix well in a planetary m...

Embodiment 3

[0042] (1) Add 22.8g of D5 (0.075mol), 68.5g (0.3mol) of bisphenol A, 46.4g (0.5mol) of epichlorohydrin into a 250ml clean three-necked bottle, mix well at 60°C, and then add 20g Sodium hydroxide, polymerize at 60°C for 3 hours, then add a mixture of 75g toluene and 75g xylene, let the product dissolve completely under stirring, then let it stand for stratification, and reflux the upper layer product under stirring to remove water, until no bubbles appear Continue to reflux for 1h, let stand, cool, filter, and remove the solvent under reduced pressure to obtain 110g of colorless and transparent silicone modified epoxy resin, whose viscosity is 11000mPa·S, and its chemical formula is identified as CH 2 CHOCH 2 [OC 6 h 4 C(CH 3 ) 2 C 6 h 4 O] 3 [CH 2 CHOHCH 2 ] 3 [(CH 3 ) 2 SiO] 3 CH 2 CHCH 2 O.

[0043] (2) Take 20g of the product obtained in (1), add 5g of epoxy thinner neodecanoic acid oxirane methyl methyl ester, and 5.0g of nano silicon dioxide, and mix even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com