Preparation method of skutterudite preheated cement

A technology for cement preparation and skutterudite, applied in magnetic objects, electrical components, circuits, etc., can solve the problems of vertical mill vibration stop, poor removal of magnetic substances, damage to vertical mill roller surfaces and grinding discs, etc., to improve the safety factor , Improve stability, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

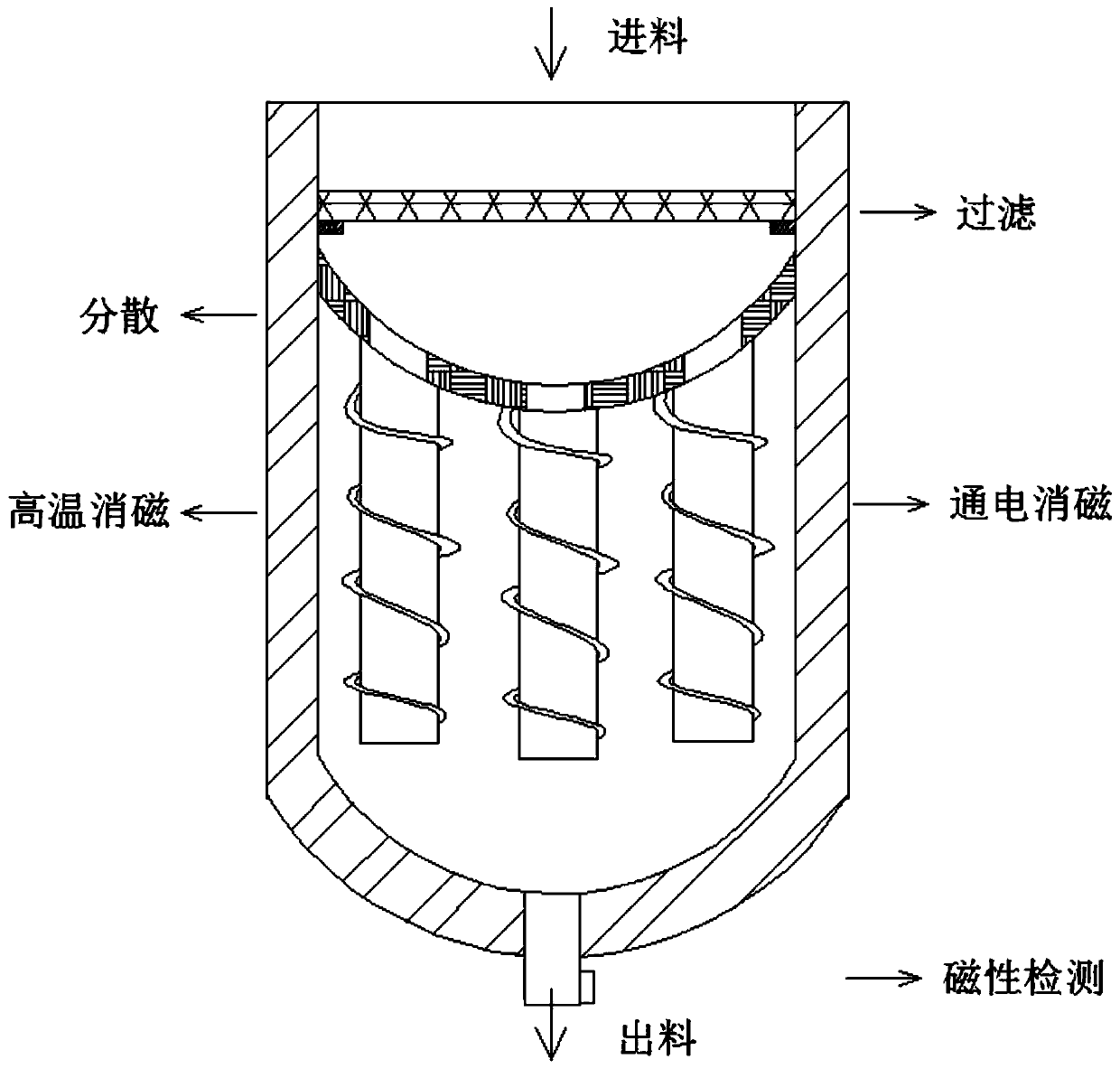

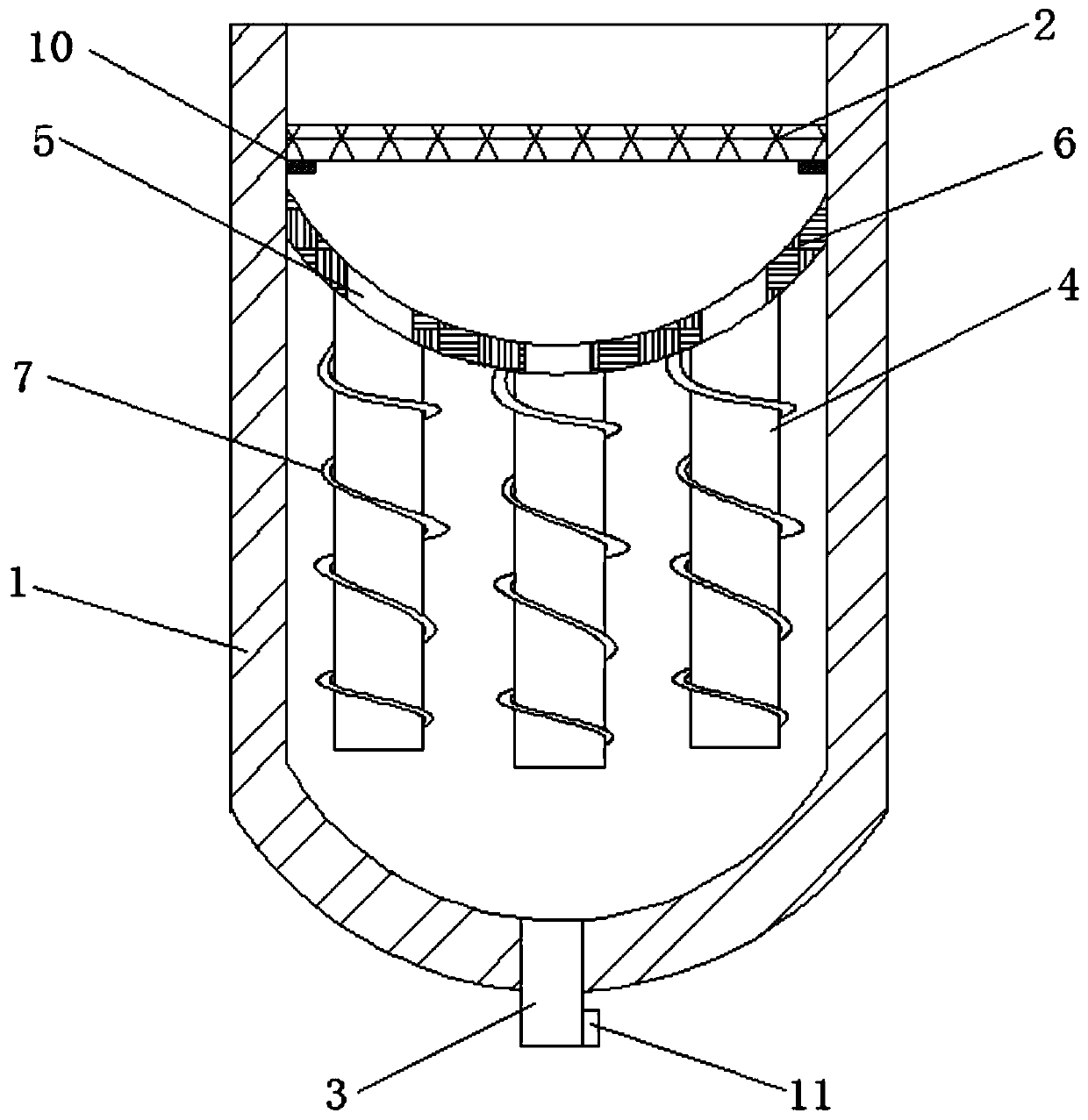

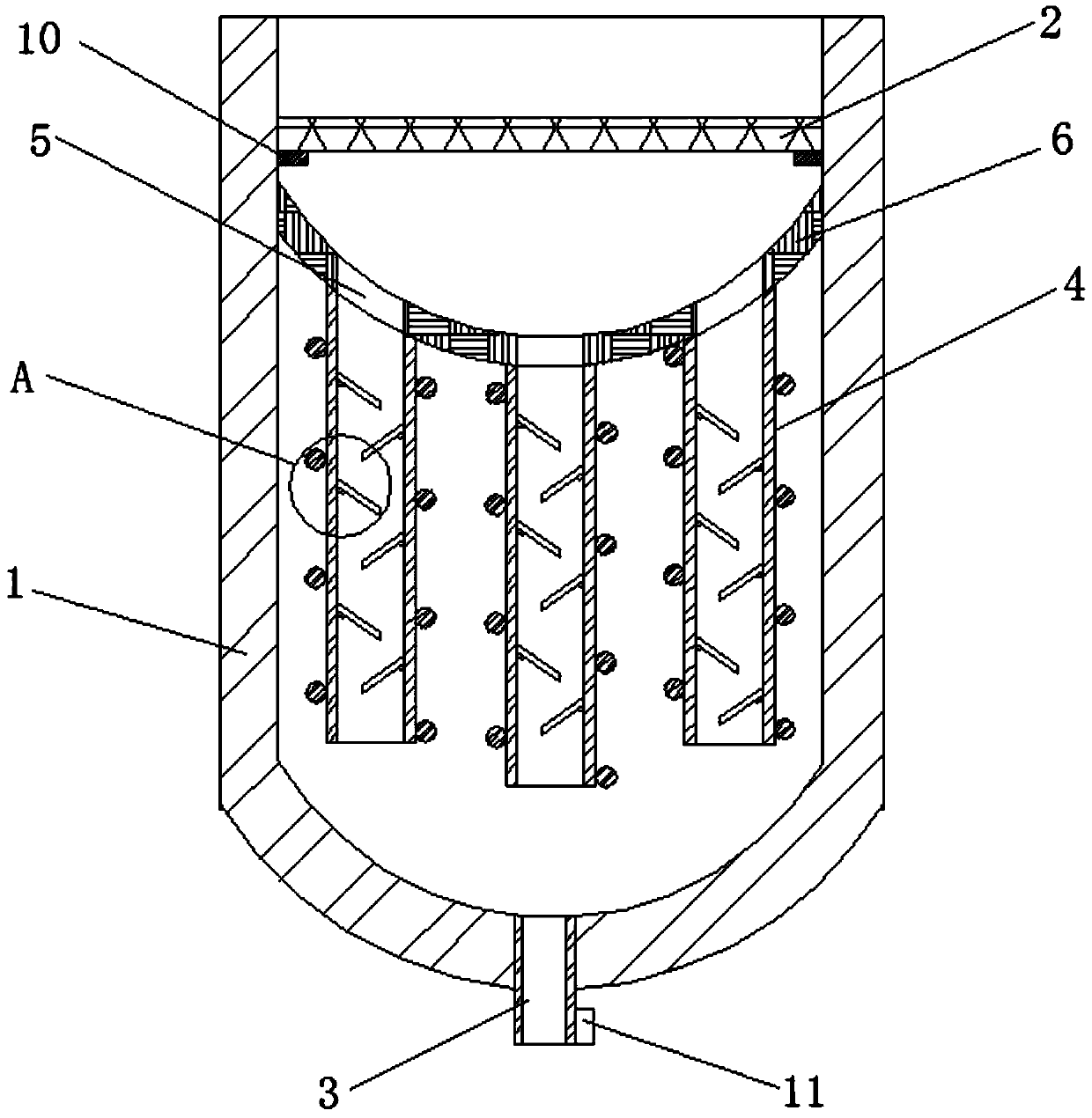

[0051] see figure 1 , a preparation method of skutterudite preheated cement, comprising the following steps:

[0052] S1. Feed materials, put the cement raw materials that have undergone the first demagnetization treatment into the powerful demagnetization cylinder;

[0053] S2, Filtration, the cement raw material is filtered through the upper part of the powerful degaussing cylinder;

[0054] S3, dispersion, automatic dispersion when the cement raw material falls;

[0055] S4. Preheating (high-temperature degaussing / power-on degaussing), the cement raw material is subjected to high temperature and "ionization" at the same time, and the magnetic substance inside it is degaussed;

[0056] S5. Magnetic detection, when the degaussed cement raw material falls to the lower end of the powerful degaussing cylinder, the content of magnetic substances inside it is detected;

[0057] S6, discharge, the cement raw material after testing leaks out of the powerful degaussing cylinder; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com