Rubber track plastics for engineering vehicle and preparation method thereof.

A technology for rubber tracks and engineering vehicles, which is applied to the field of rubber track plastics for engineering vehicles and its preparation, can solve the problems of products prone to early aging, poor ozone aging performance, frequent product replacement, etc., and achieves good process stability and improved durability. The effect of improving abrasion resistance and ozone aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of engineering vehicle supporting rubber crawler plastic, the mass percent of each component of described engineering vehicle supporting rubber crawler plastic comprises natural rubber 20%, styrene-butadiene rubber 30%, carbon black 40%, aromatic hydrocarbon oil 2%, anti-aging agent RD is 1 %, anti-aging agent 4010NA is 1%, anti-aging agent BLE is 1%, paraffin wax is 1%, vulcanizing agent and accelerator are 3%, and the rest are other additives, which include zinc oxide, stearic acid and silane coupling additives, etc., and other additives accounted for 1%. Here, other auxiliary agents are conventional raw materials in the field of rubber synthesis, and other auxiliary agents include zinc oxide, stearic acid and silane coupling agent, which are raw materials in conventional rubber processes.

[0024] The use of natural rubber and styrene-butadiene rubber in a ratio of 1:1 can improve wear resistance and reduce costs; in this technical solution, carbon black uses ...

Embodiment 2

[0033] The rest are the same as the above-mentioned embodiment, the difference is that a kind of engineering vehicle matching rubber crawler plastic, the mass percentage of each component of the engineering vehicle matching rubber crawler plastic includes natural rubber, 30%, styrene-butadiene rubber 20%, carbon black 30%, aromatic oil 10%, antioxidant RD 2%, antioxidant 4010NA 2%, antioxidant BLE 2%, paraffin 2%, vulcanizing agent and accelerator 1%, other additives 1%.

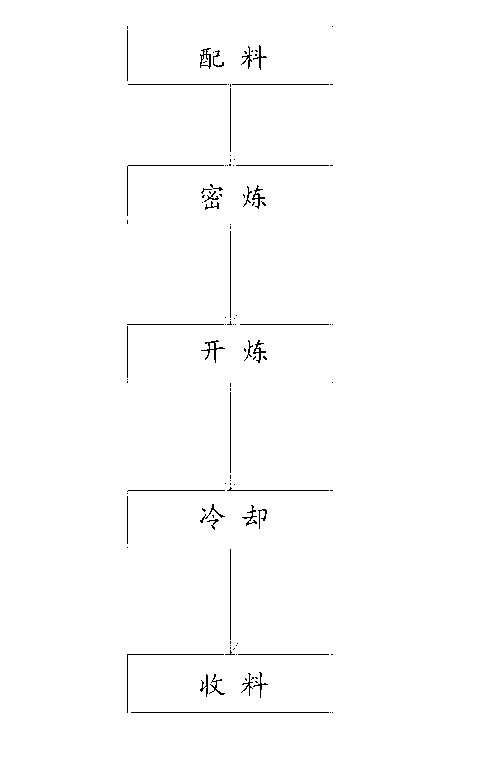

[0034] The method for preparing the above-mentioned engineering vehicle matching rubber crawler plastic, the specific steps include:

[0035] (1) Ingredients, according to claim 1, the matching rubber track plastics of the engineering vehicle are weighed and ingredients are weighed, and the anti-aging agent RD, anti-aging agent 4010NA, anti-aging agent BLE, paraffin, and other additives are weighed and prepared together, and then through the upper The auxiliary system automatically weighs the carbon black an...

Embodiment 3

[0041] The rest are the same as the above-mentioned embodiment, the difference is that the mass percent of each component of the rubber crawler plastic of the engineering vehicle includes 28% of natural rubber, 28% of styrene-butadiene rubber, 32% of carbon black, 4% of aromatic oil, anti-aging agent 1.2% of RD, 1.2% of anti-aging agent 4010NA, 1.2% of anti-aging agent BLE, 1.2% of paraffin, 1.5% of vulcanizing agent and accelerator, and 1.7% of other additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com