Steel wire rod having excellent cold heading quality and hydrogen delayed fracture resistance, method of manufacturing the same, and mehod of manufacturing bolt using the same

a technology of cold heading and cold heading, which is applied in the field of steel wire rods used for bolts, can solve the problems of increasing production costs, deteriorating cold heading quality, and reducing the life of cold headings, and achieve excellent cold heading quality, excellent hydrogen delayed fracture resistance, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Hereinafter, the invention is described in detail.

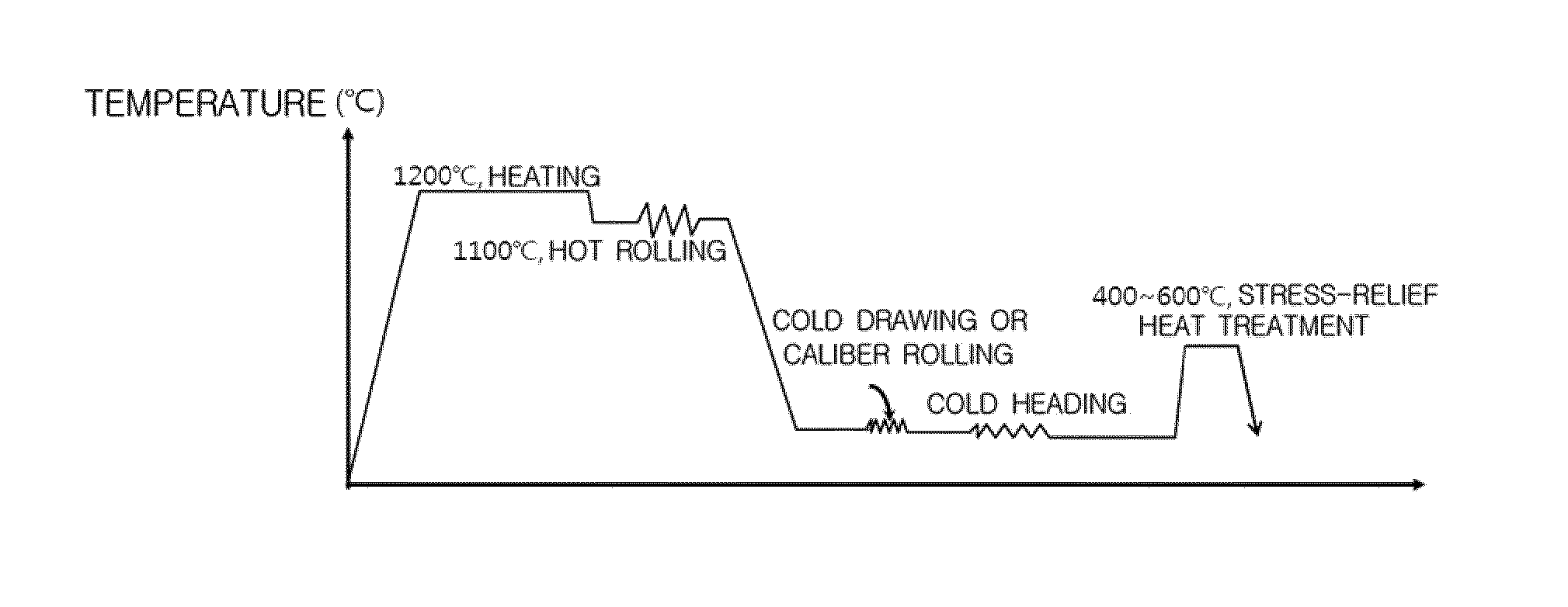

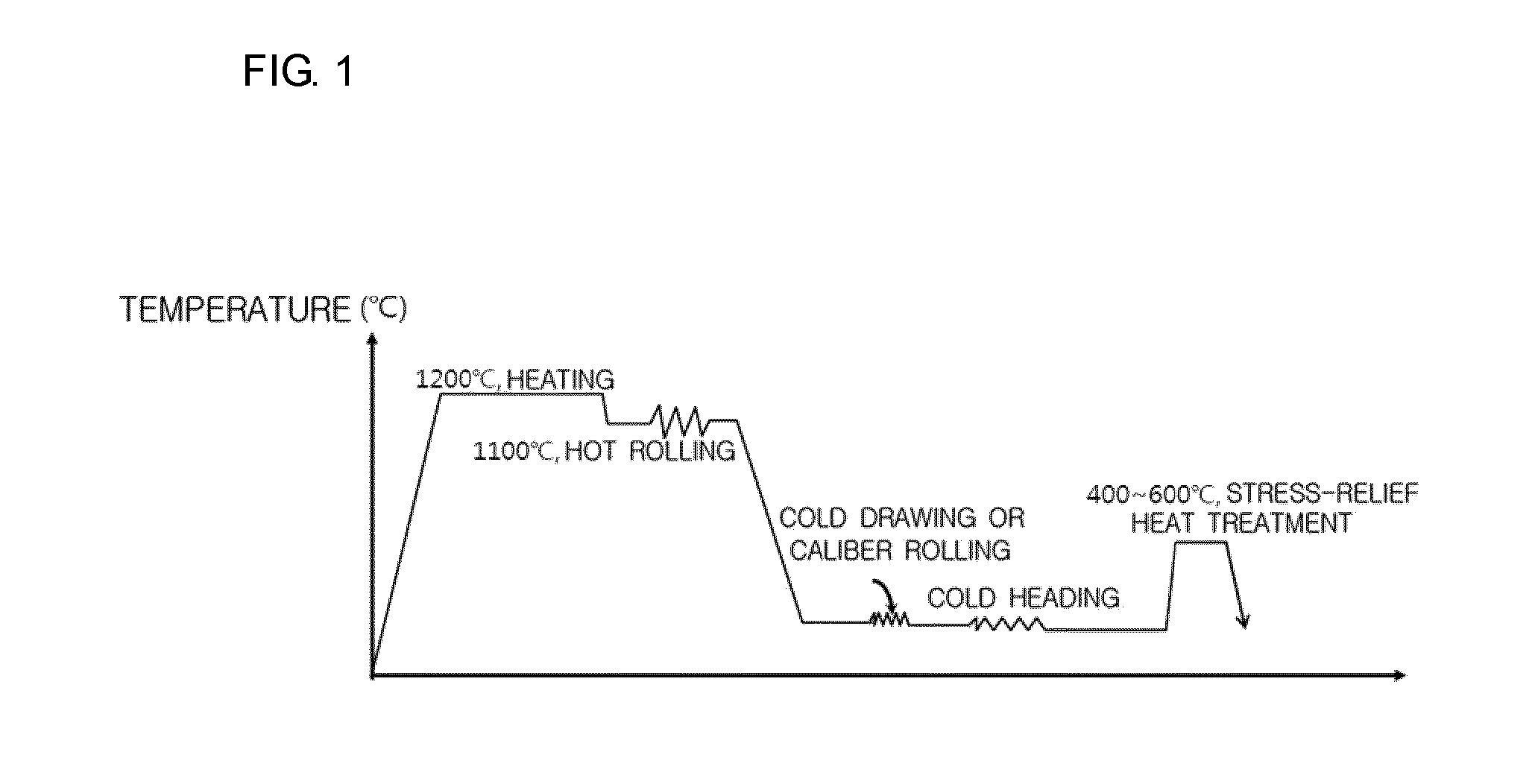

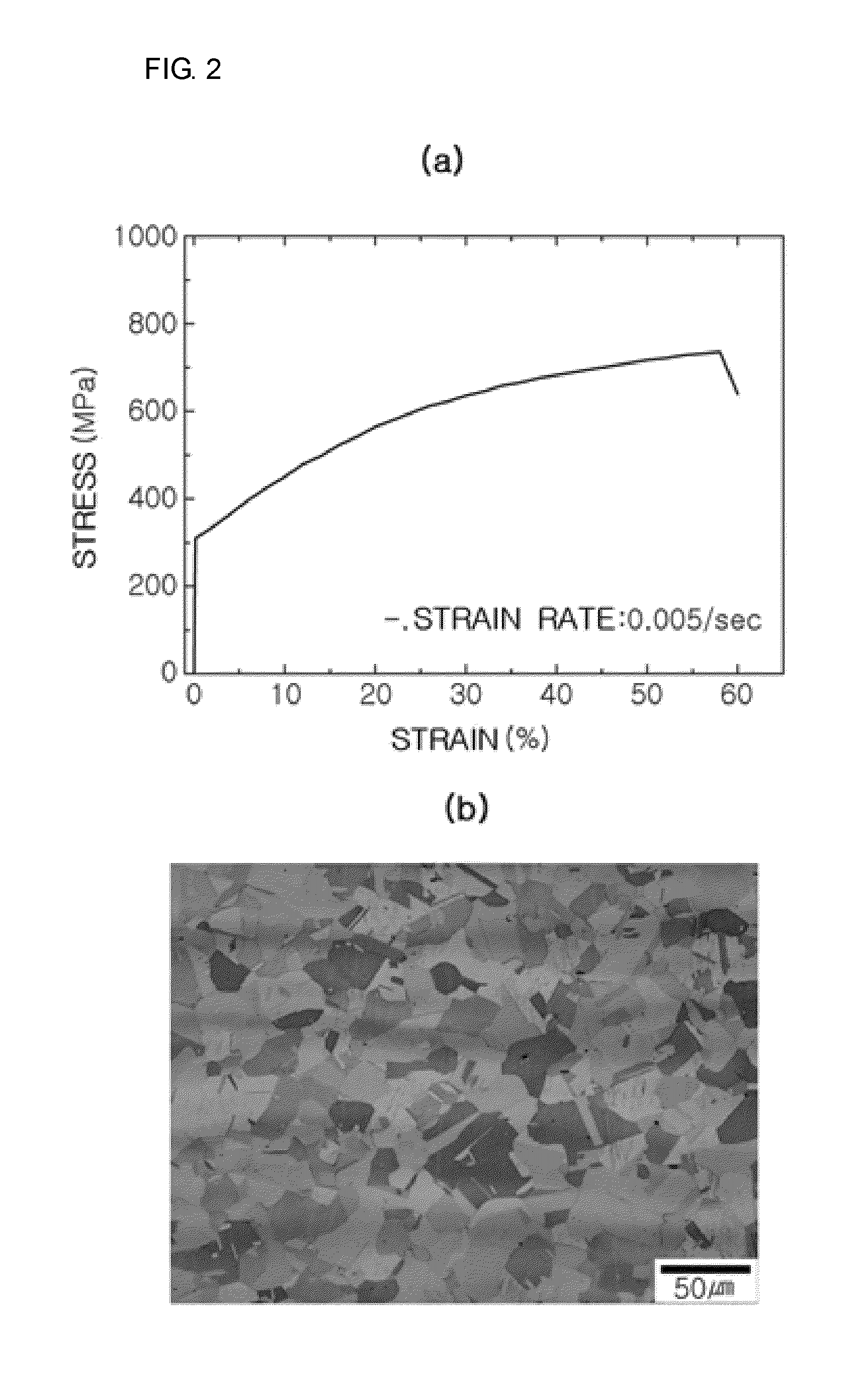

[0036]The present inventors developed a high-strength steel wire rod having excellent cold heading quality by using a dynamic strengthening deformation mechanism of twinning induced plasticity (TWIP) steel. The TWIP steel has excellent elongation and is enabled to omit heat treatments even though it is high-strength steel. It may be understood that the TWP steel had infinite strain without cracks according to the results of a compression test performed on 1800 MPa class high-strength steel, which had been pre-deformed by indirect multi-axial tension using caliber rolling.

[0037]The reason for this is that when compressive stress is exerted on a specimen under applied tensile stress, low yield strength is obtained according to the characteristics of the TWP steel having high back stress known as the Bauschinger effect, and continuous deformation and high strengthening are achieved by means of a twin mechanism.

[0038]Also, in a bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com