Patents

Literature

37 results about "Bauschinger effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

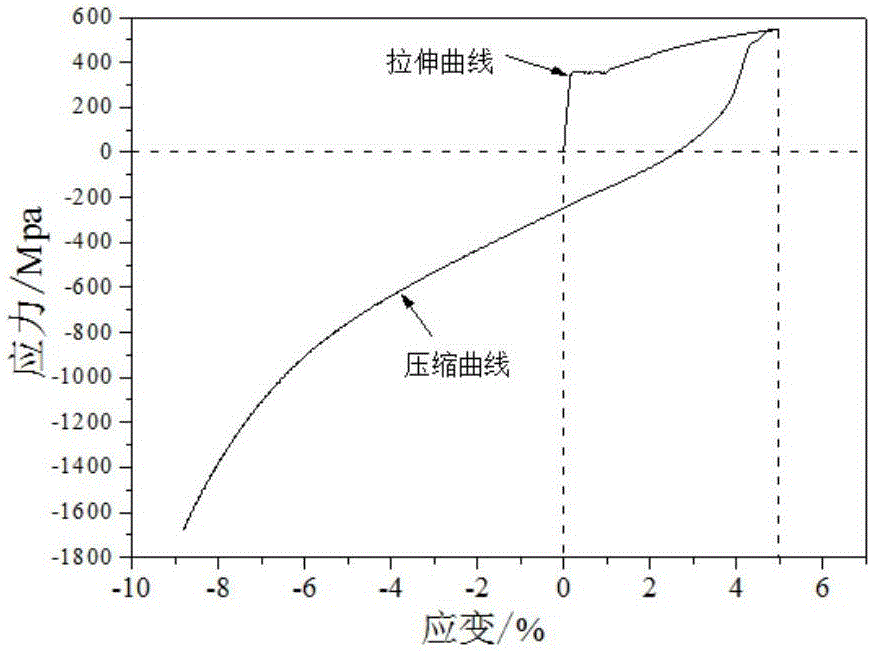

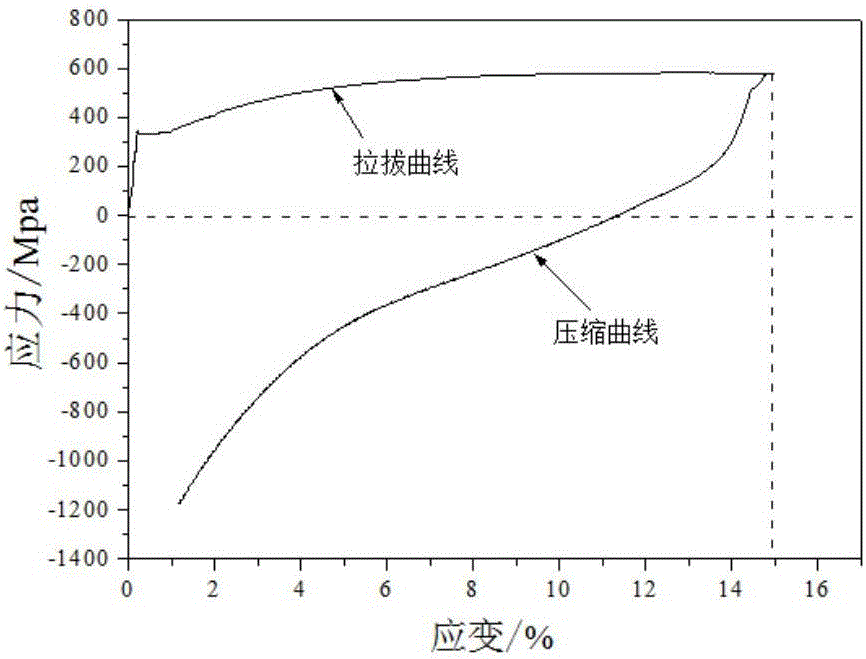

The Bauschinger effect refers to a property of materials where the material's stress/strain characteristics change as a result of the microscopic stress distribution of the material. For example, an increase in tensile yield strength occurs at the expense of compressive yield strength. The effect is named after German engineer Johann Bauschinger.

Welded steel pipe for linepipe with superior compressive strength and superior toughness, and process for producing same

InactiveCN102666899AHigh strengthHigh compressive strengthArc welding apparatusFurnace typesHeat-affected zoneSheet steel

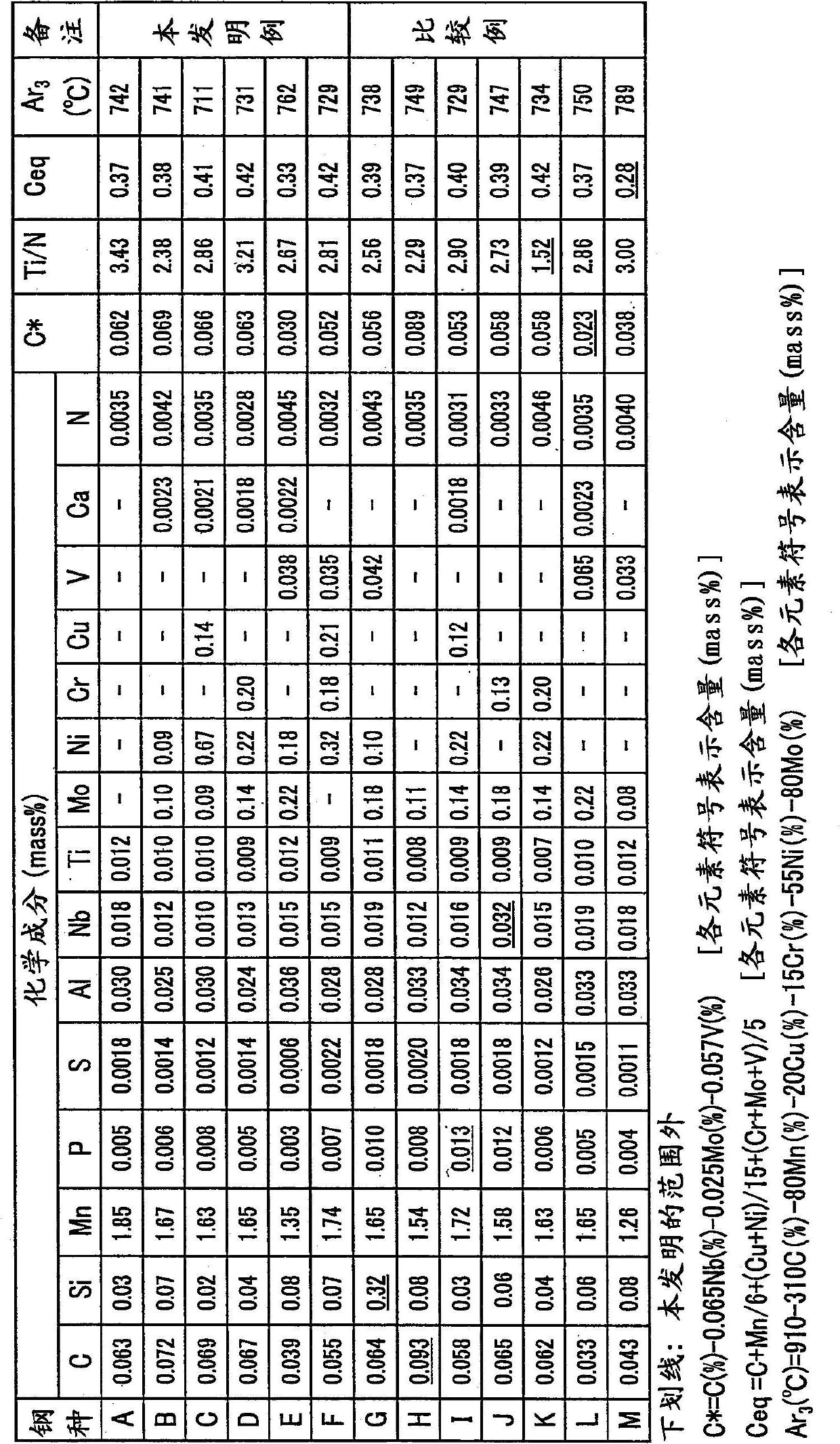

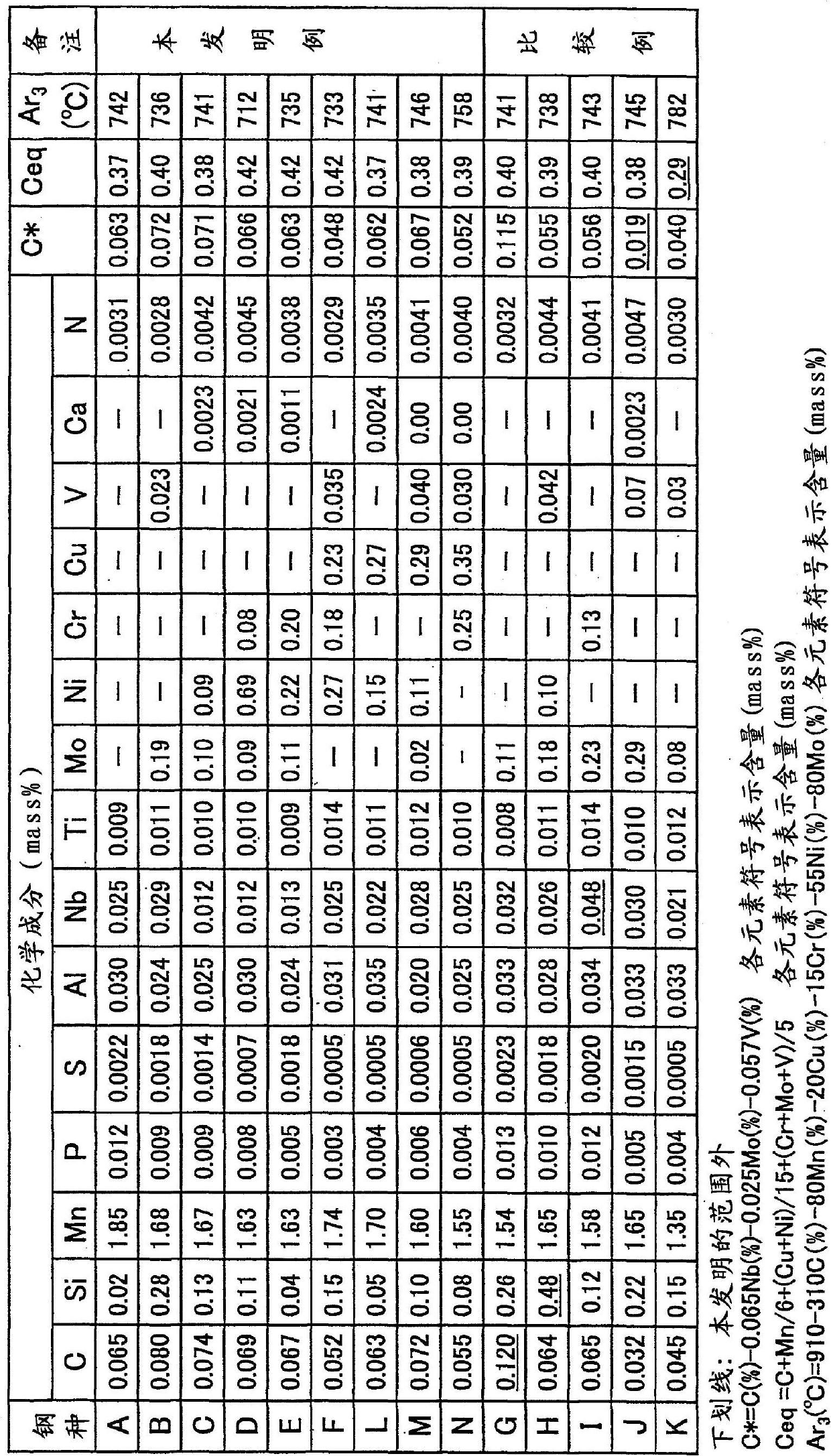

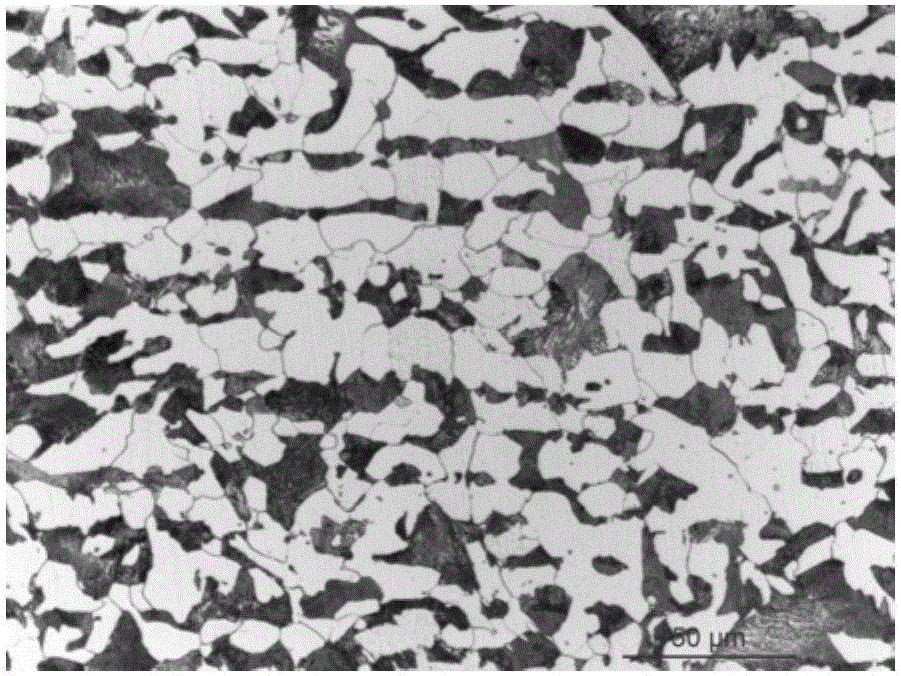

A thick-walled steel pipe for linepipes is provided in which the decrease in yield stress caused by the Bauschinger effect is inhibited by optimizing the metallographic structure of a steel plate and in which the base metal and the weld heat-affected zone have excellent toughness. The welded steel pipe for linepipes, which has superior compressive strength and superior toughness, contains, in terms of mass%, 0.03-0.08% C, up to 0.10% Si, 1.00-2.00% Mn, up to 0.010% P, up to 0.0030% S, up to 0.06% Al, 0.005-0.020% Nb, 0.005-0.025% Ti, and 0.0010-0.0060% N, Ti (%) / N (%) being 2-4, the value of Ceq being 0.30 or more, and the remainder comprising Fe and incidental impurities. The steel pipe is characterized in that the metallographic structure of the base metal has specific values of the contents of bainite, island martensite (MA), and cementite, etc. and that the weld heat-affected zone has a specific metallographic structure. Also provided is a process for producing the welded steel pipe.

Owner:JFE STEEL CORP

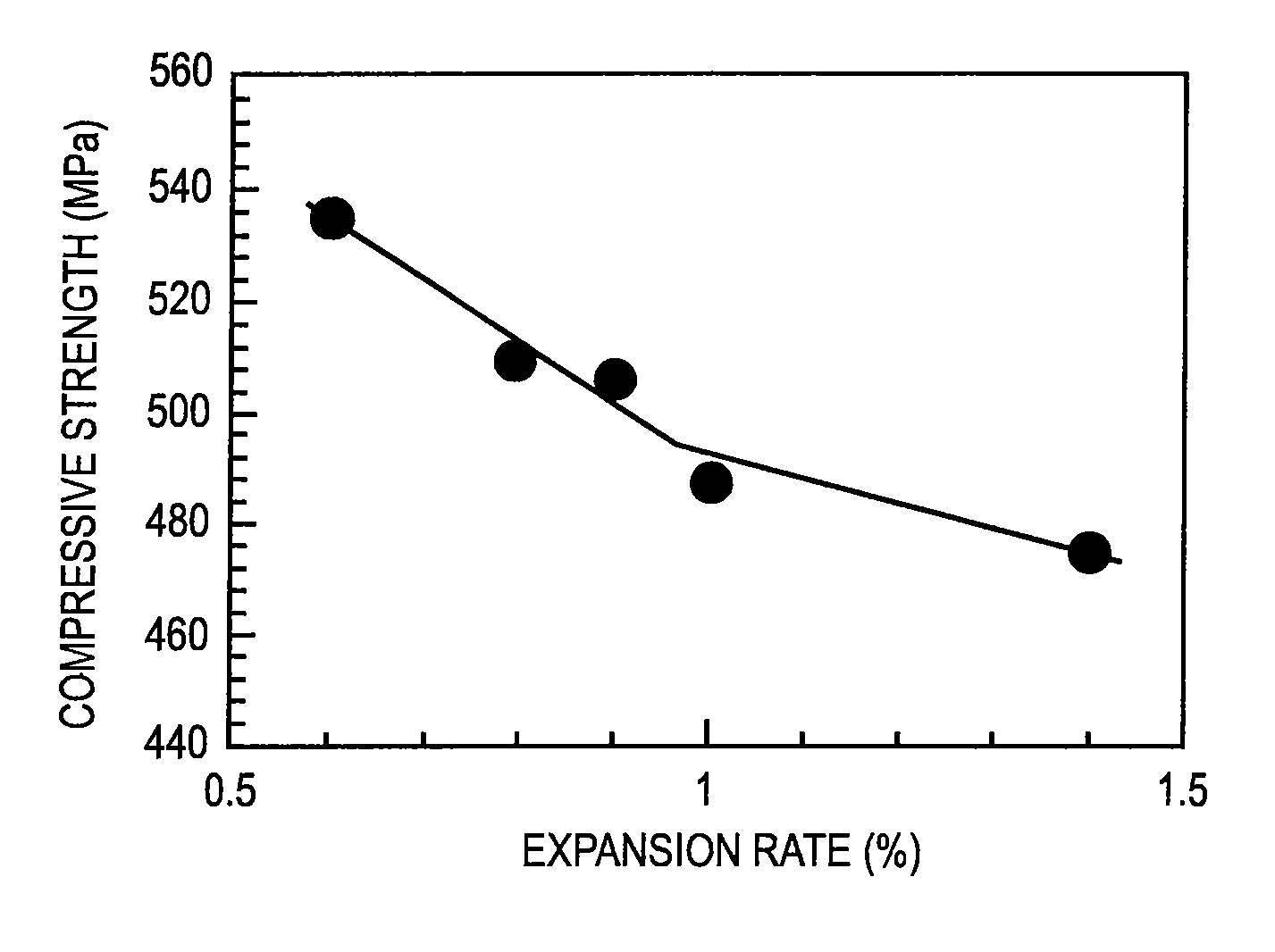

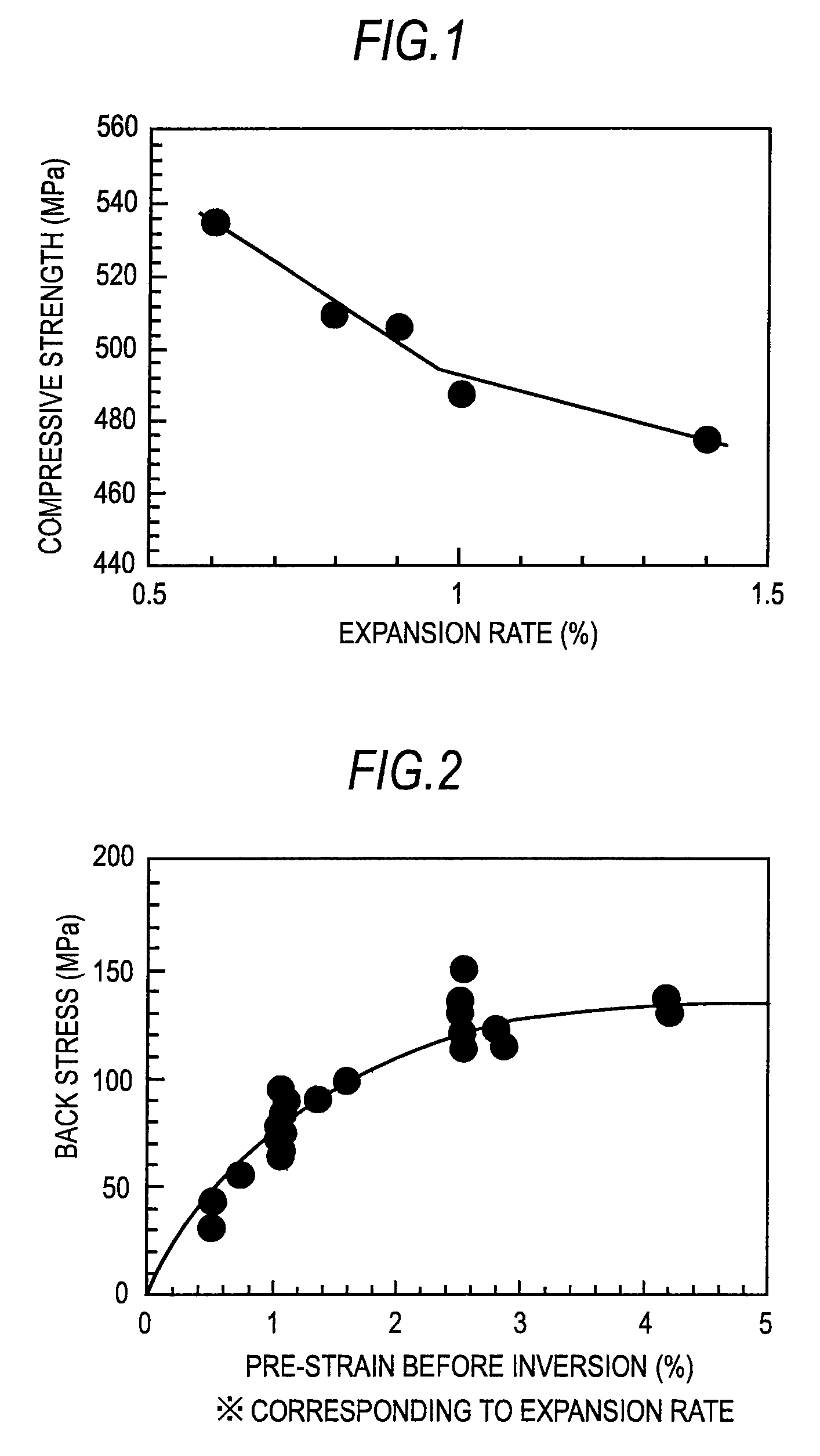

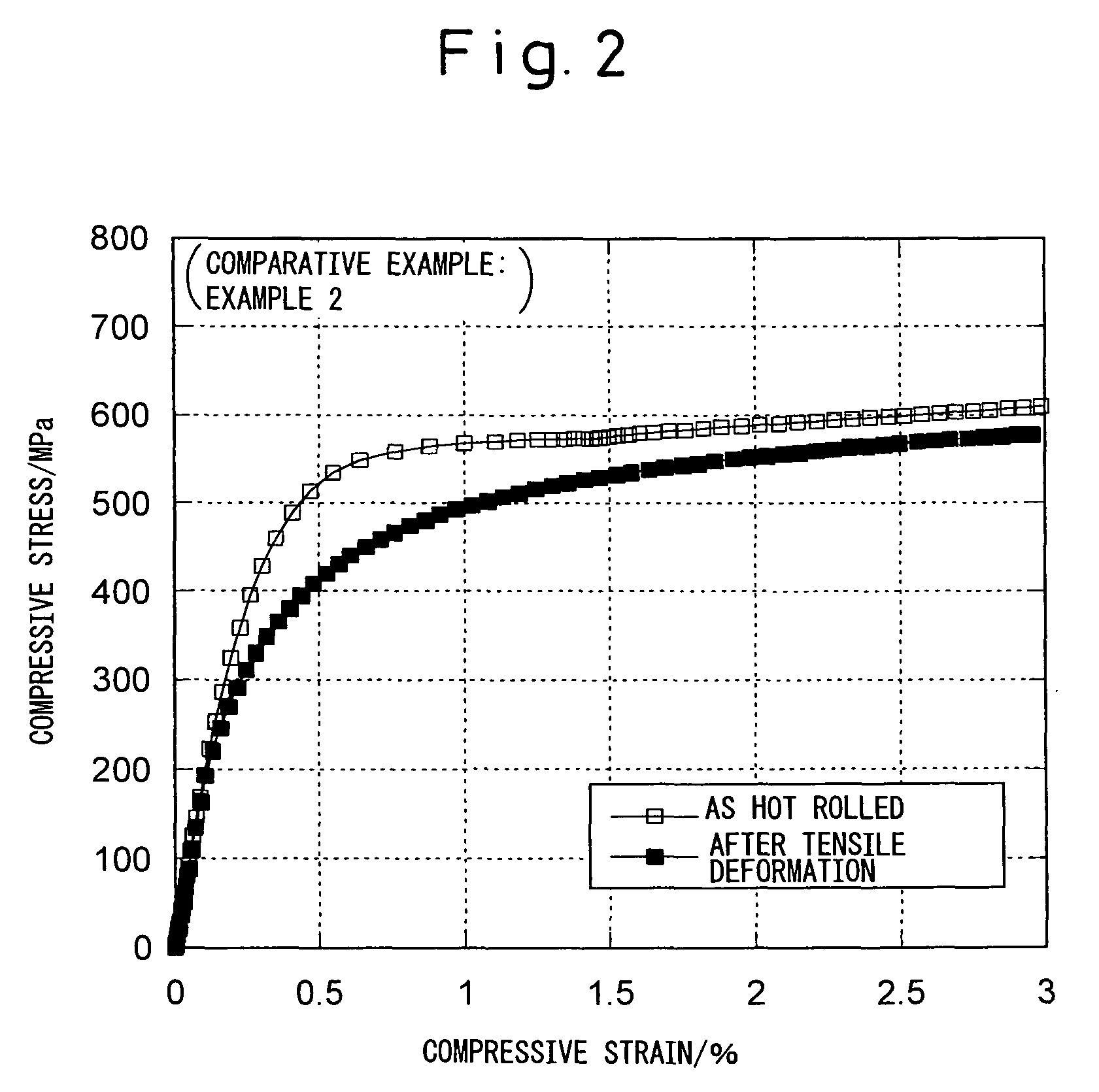

Steel Plate or Steel Pipe with Small Occurrence of Bauschinger Effect and Methods of Production of Same

InactiveUS20080286504A1Envelopes/bags making machineryLayered productsSheet steelCompressive strength

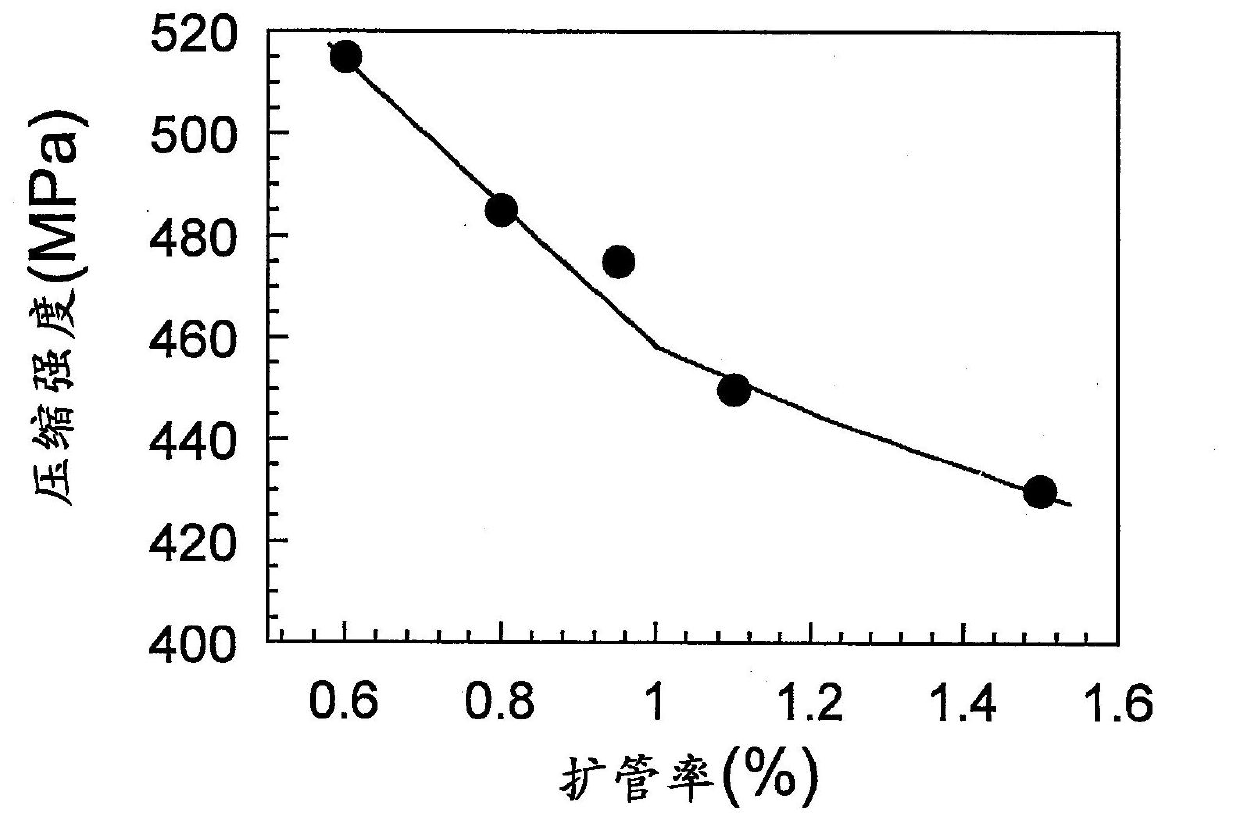

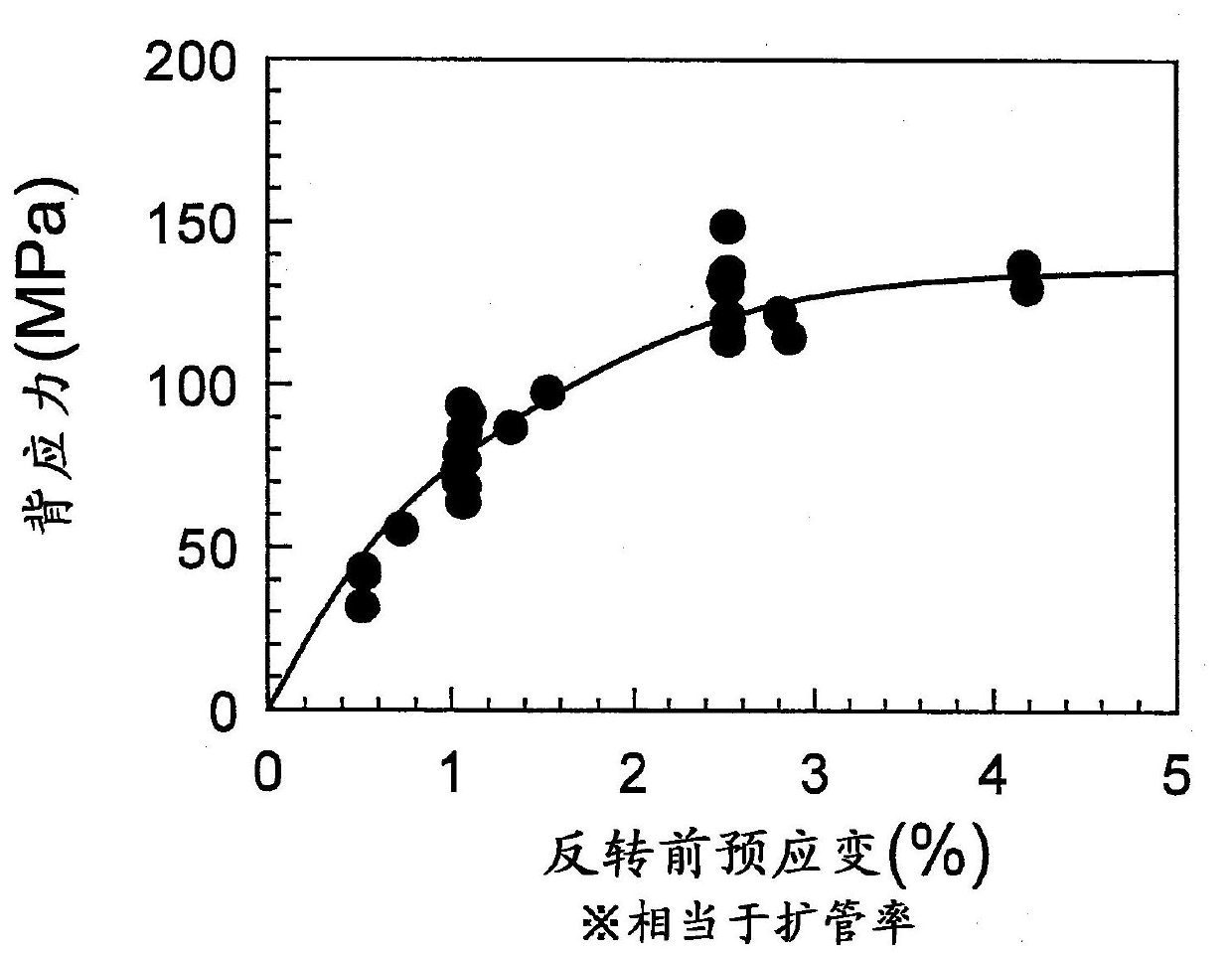

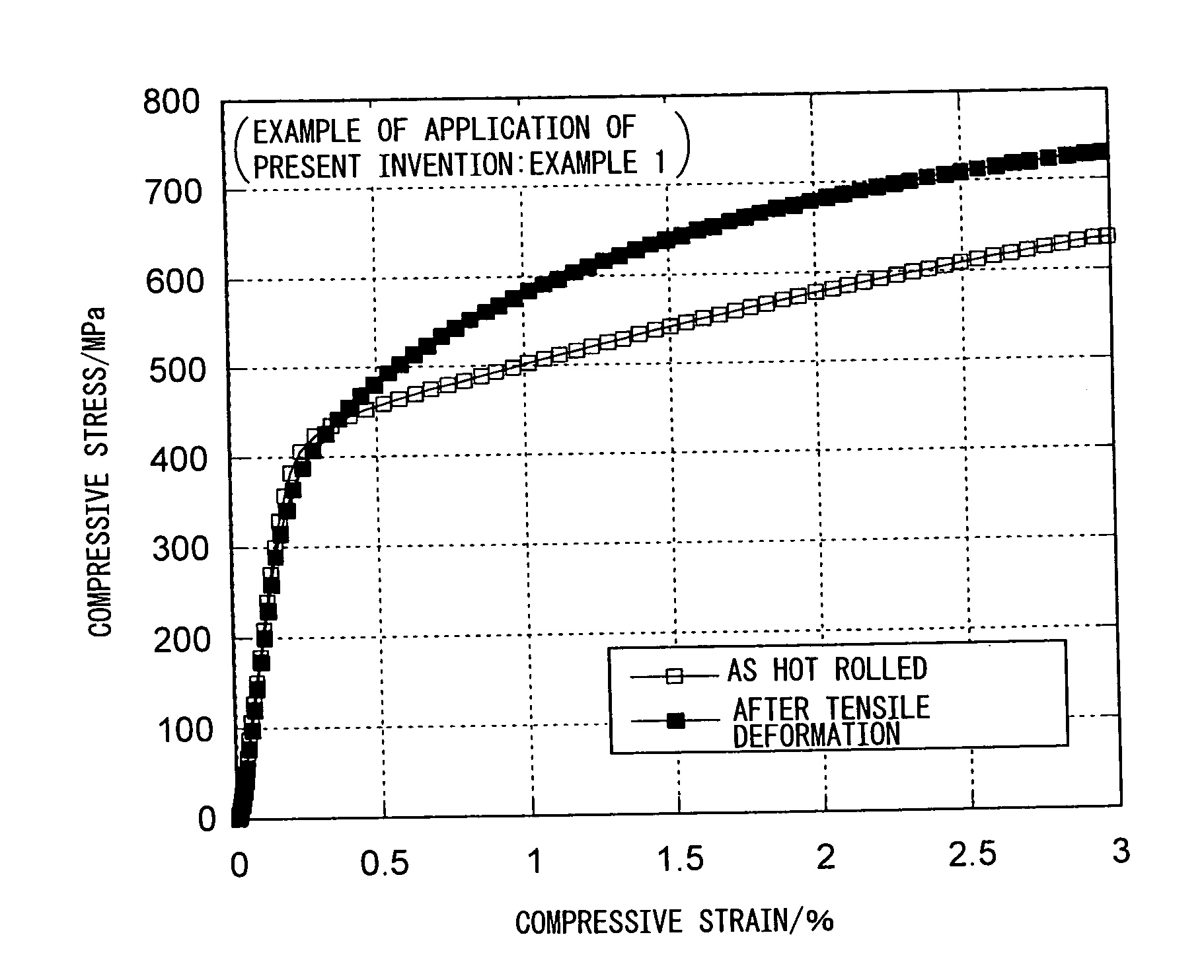

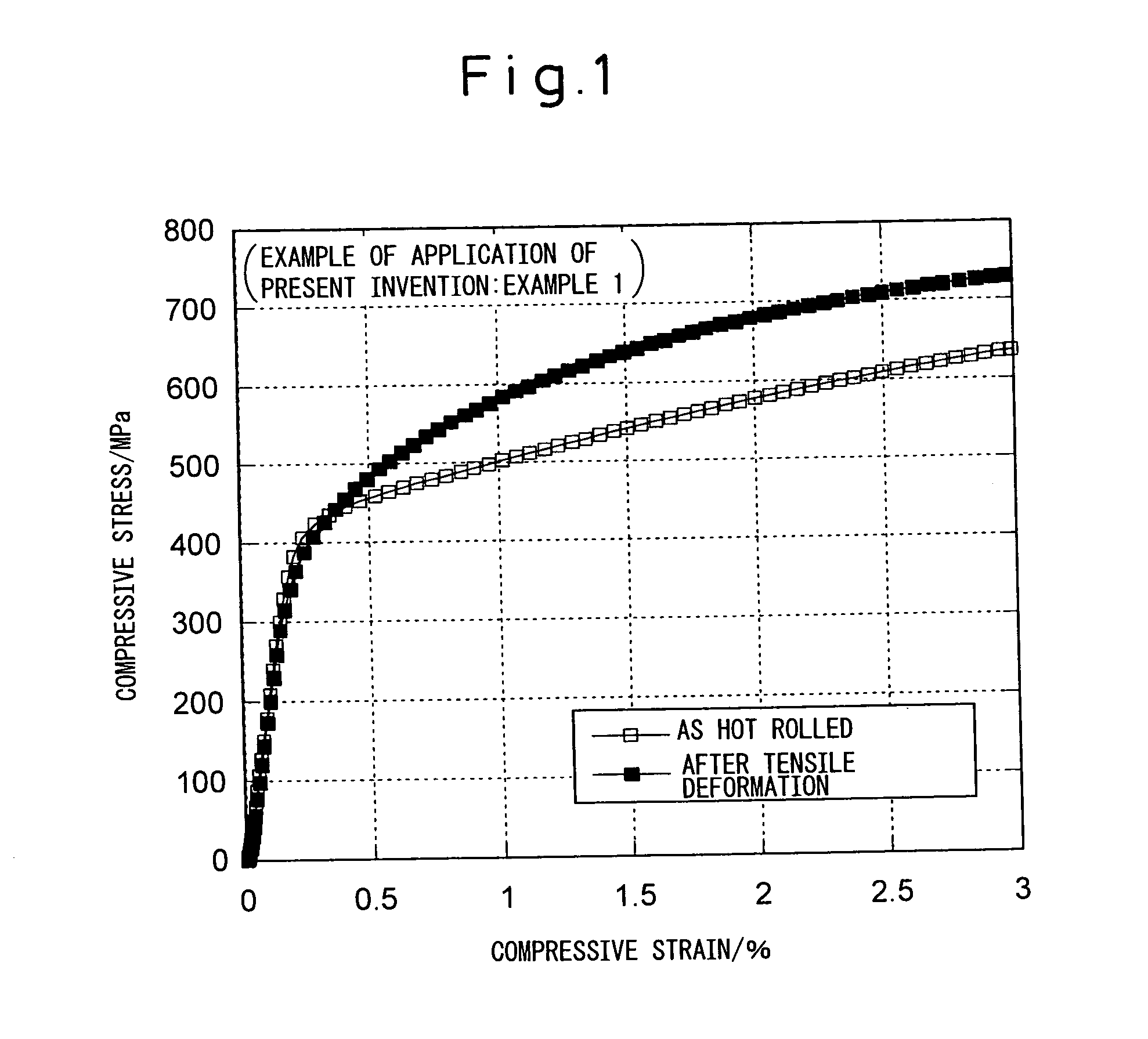

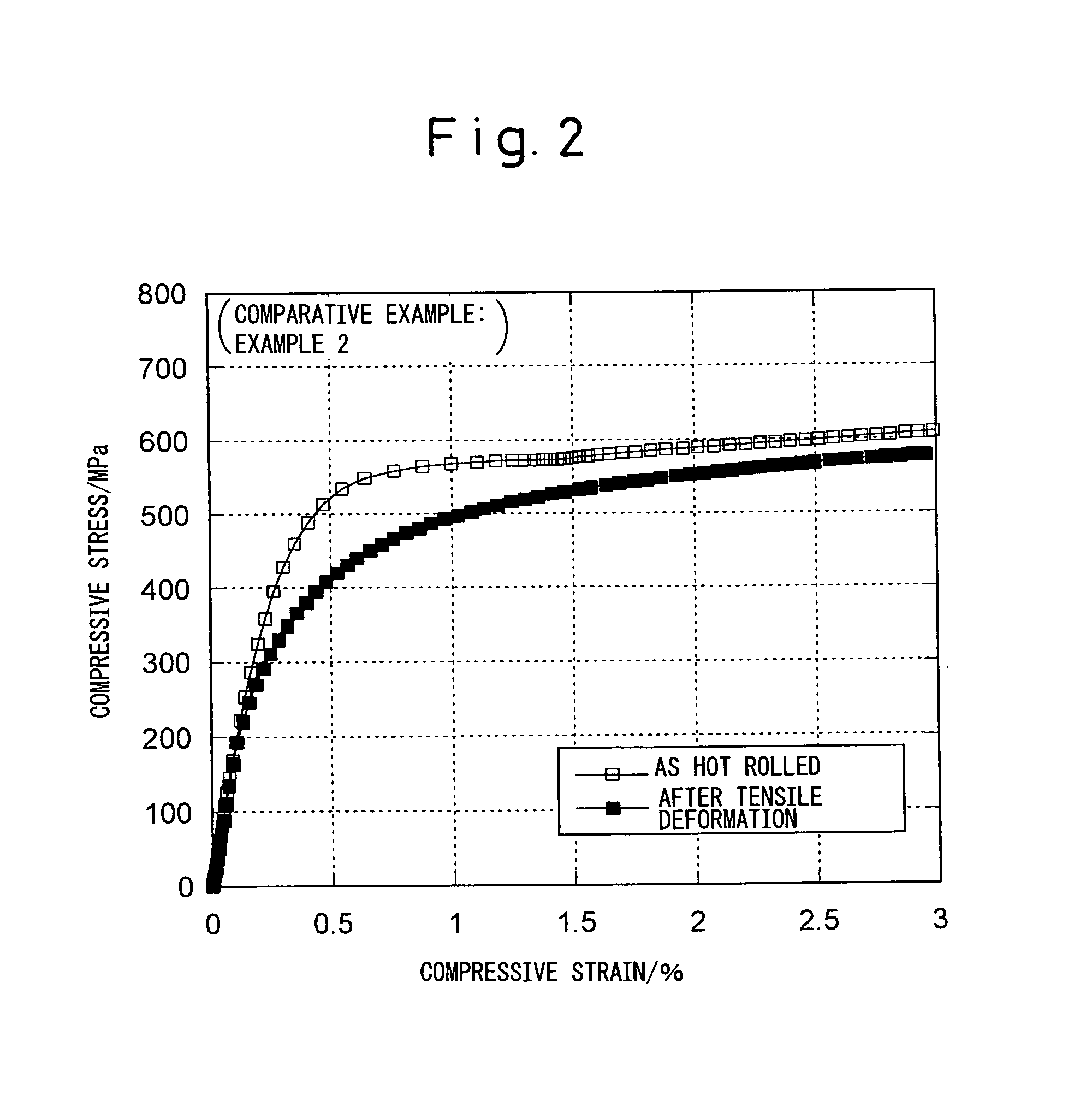

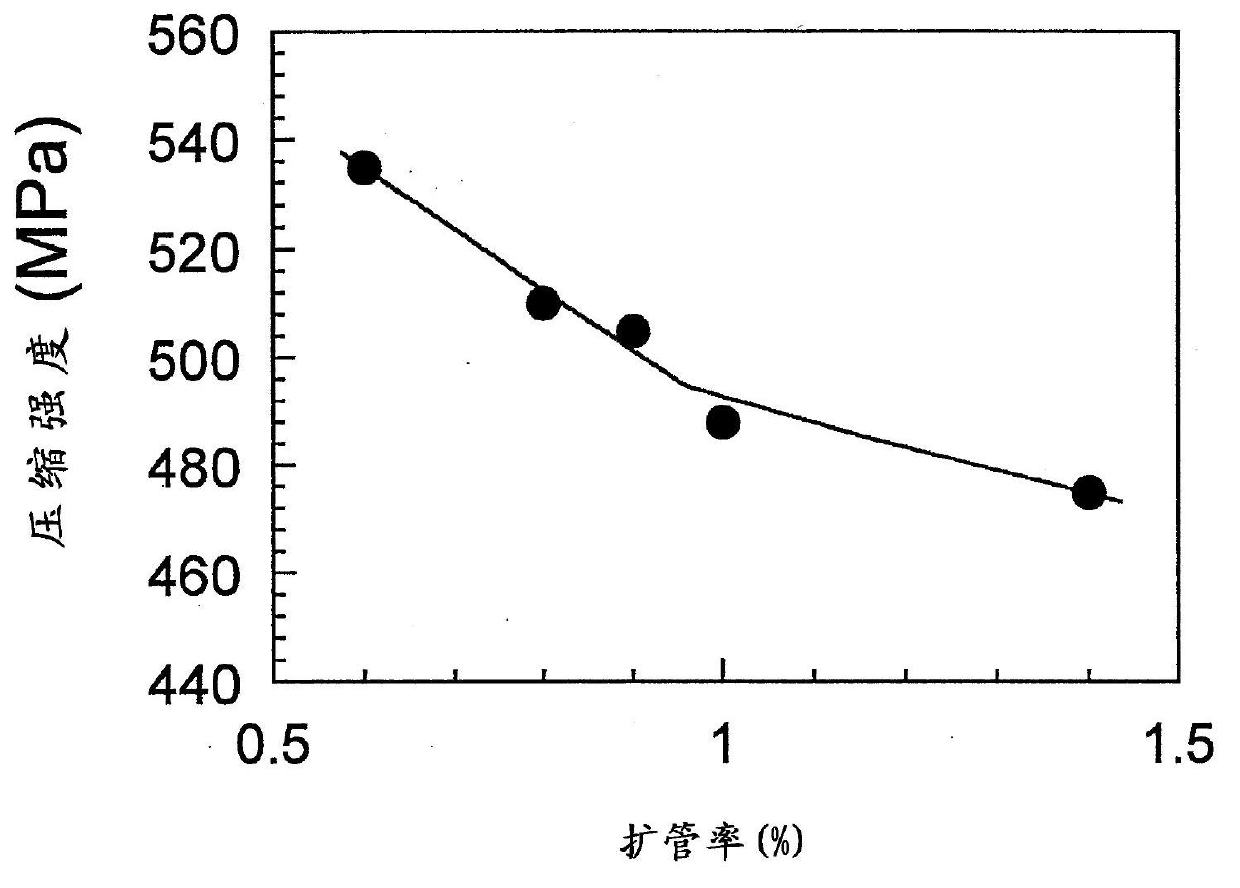

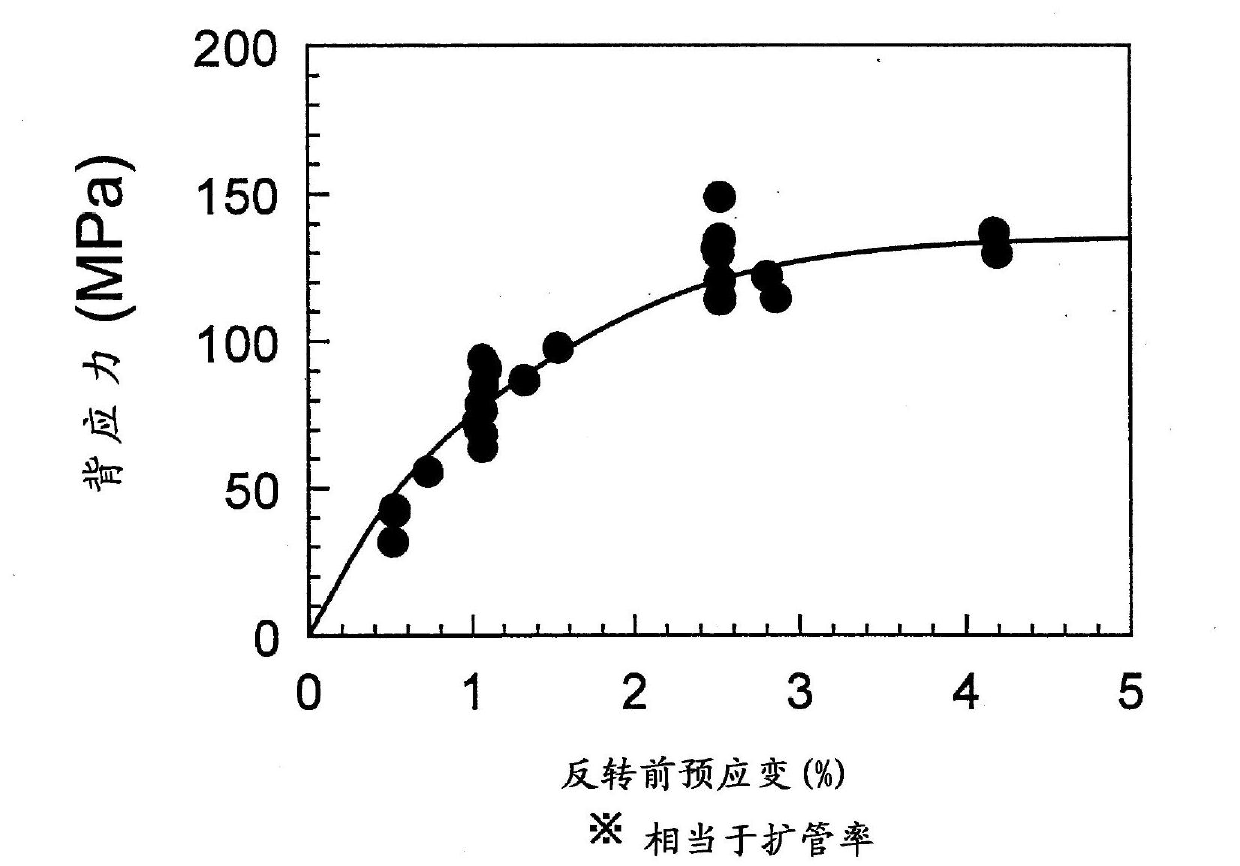

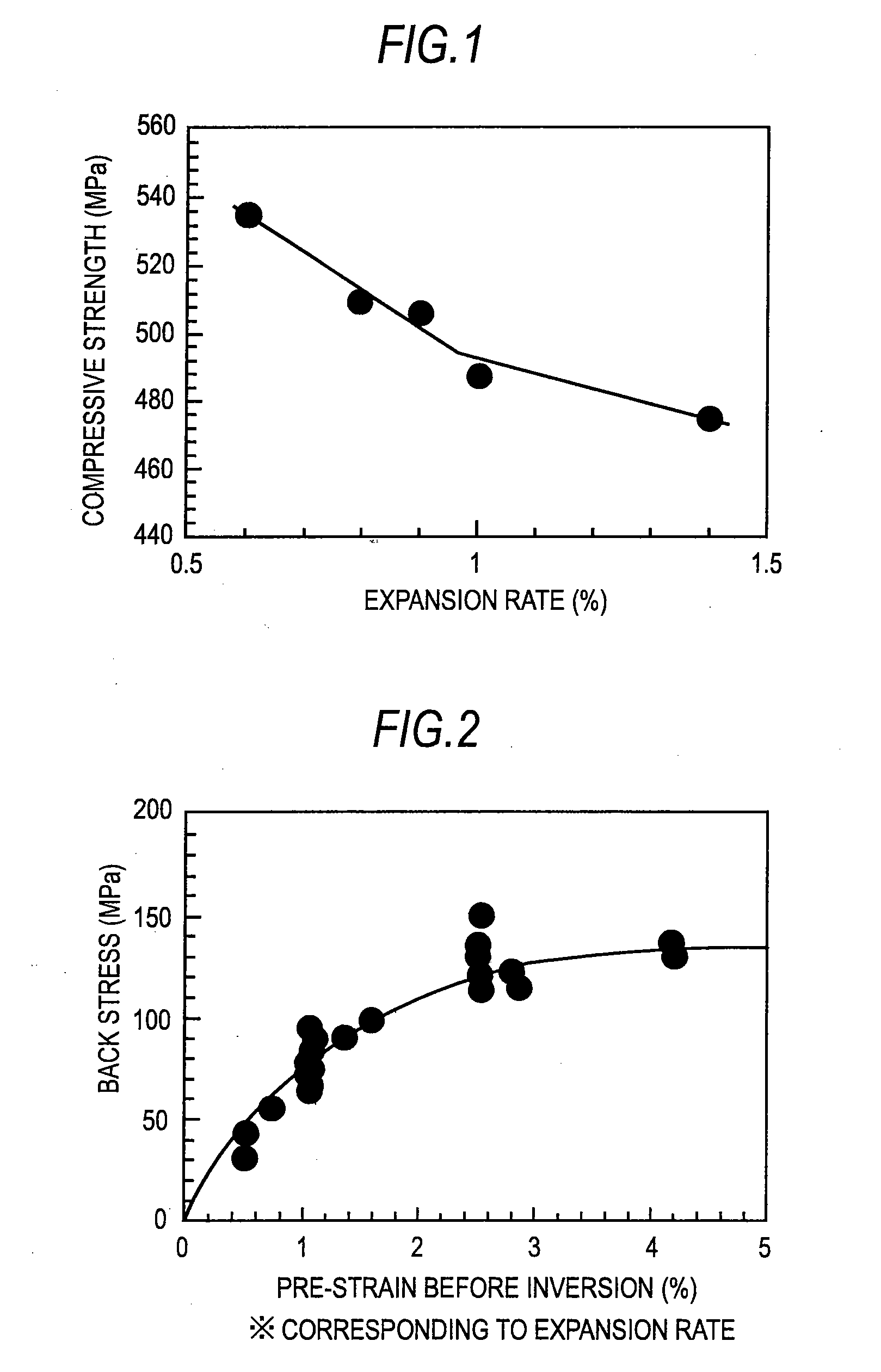

The present invention provides steel plate or steel pipe with small occurrence of the Bauschinger effect and methods of production of the same, particularly steel pipe used for steel pipe for oil wells or line pipe with a small drop in the compression strength in the circumferential direction due to the Bauschinger effect when expanded and methods of production of the same, that is steel plate or steel pipe with small occurrence of the Bauschinger effect characterized by having a dual-phase structure substantially comprising a ferrite structure and fine martensite which is dispersed in the ferrite structure. Further, this steel plate or steel pipe contains, by mass %, C: 0.03 to 0.30%, Si: 0.01 to 0.8%, Mn: 0.3 to 2.5%, P: 0.03% or less, S: 0.01% or less, Al: 0.001 to 0.01%, and N: 0.01% or less and a balance of iron and unavoidable impurities.

Owner:NIPPON STEEL CORP

Welded steel pipe for linepipe with superior compressive strength, and process for producing same

A thick-walled steel pipe for linepipes that has high compressive strength is provided in which the decrease in yield stress caused by the Bauschinger effect is inhibited by optimizing the metallographic structure of a steel plate without requiring special forming conditions for steel pipe formation or requiring any heat treatment after pipe production. The steel pipe for linepipes has superior compressive strength and excellent sour resistance and contains, in terms of mass%, 0.03-0.10% C, up to 0.30% Si, 1.00-2.00% Mn, up to 0.015% P, up to 0.003% S, up to 0.080% Al, 0.005-0.035% Nb, and 0.005-0.020% Ti, C (%)-0.065Nb (%) being 0.025 or more, the value of Ceq being 0.3 or more, and the remainder comprising Fe and incidental impurities. The steel pipe is characterized in that the metallographic structure has a bainite content of 60% or more, a processed-ferrite content of 5% or less, an island martensite (MA) content of 3% or less, an average MA grain diameter of 2 [Mu]m or smaller, and an MA aspect ratio of 5 or less. Also provided is a process for producing the steel pipe.

Owner:JFE STEEL CORP

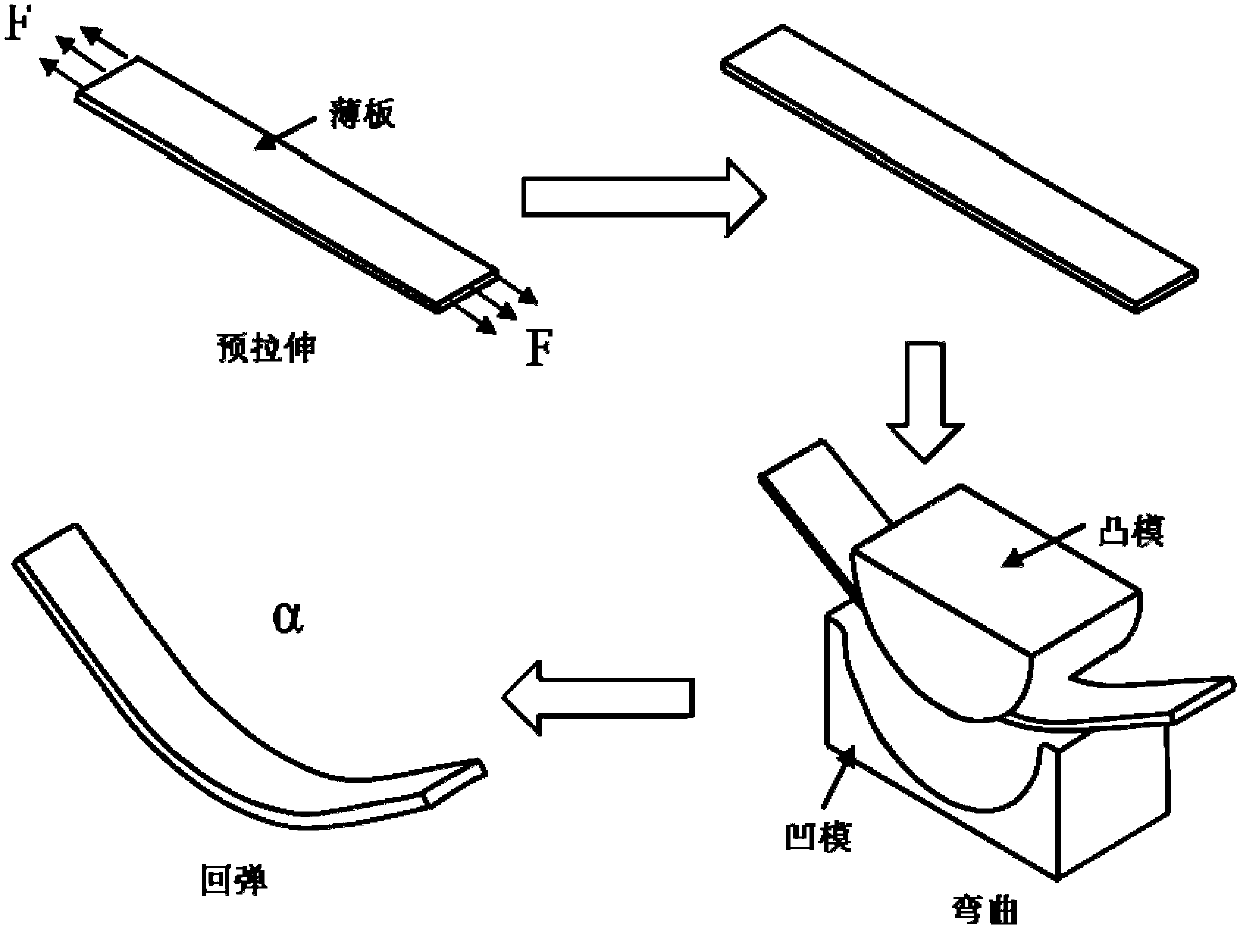

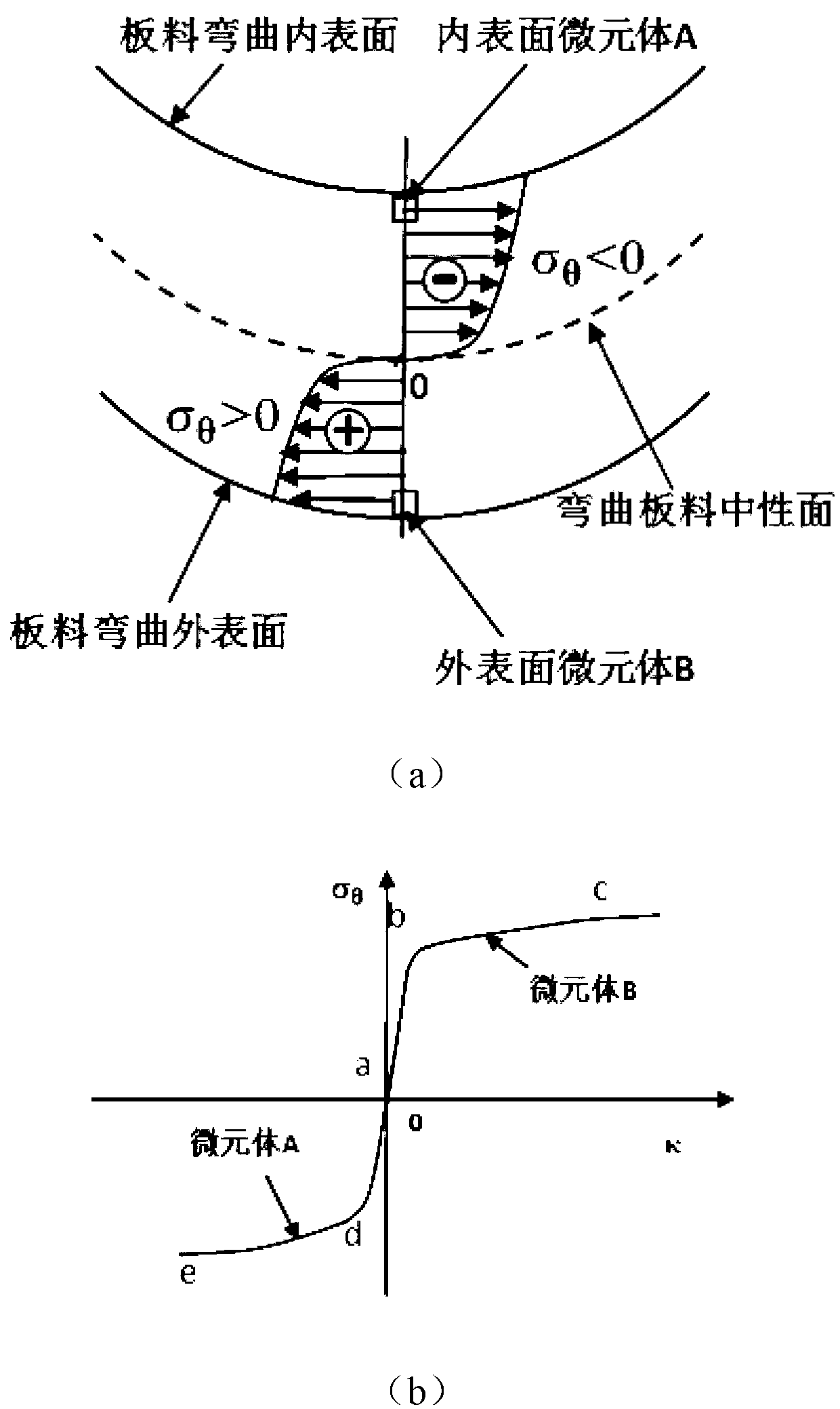

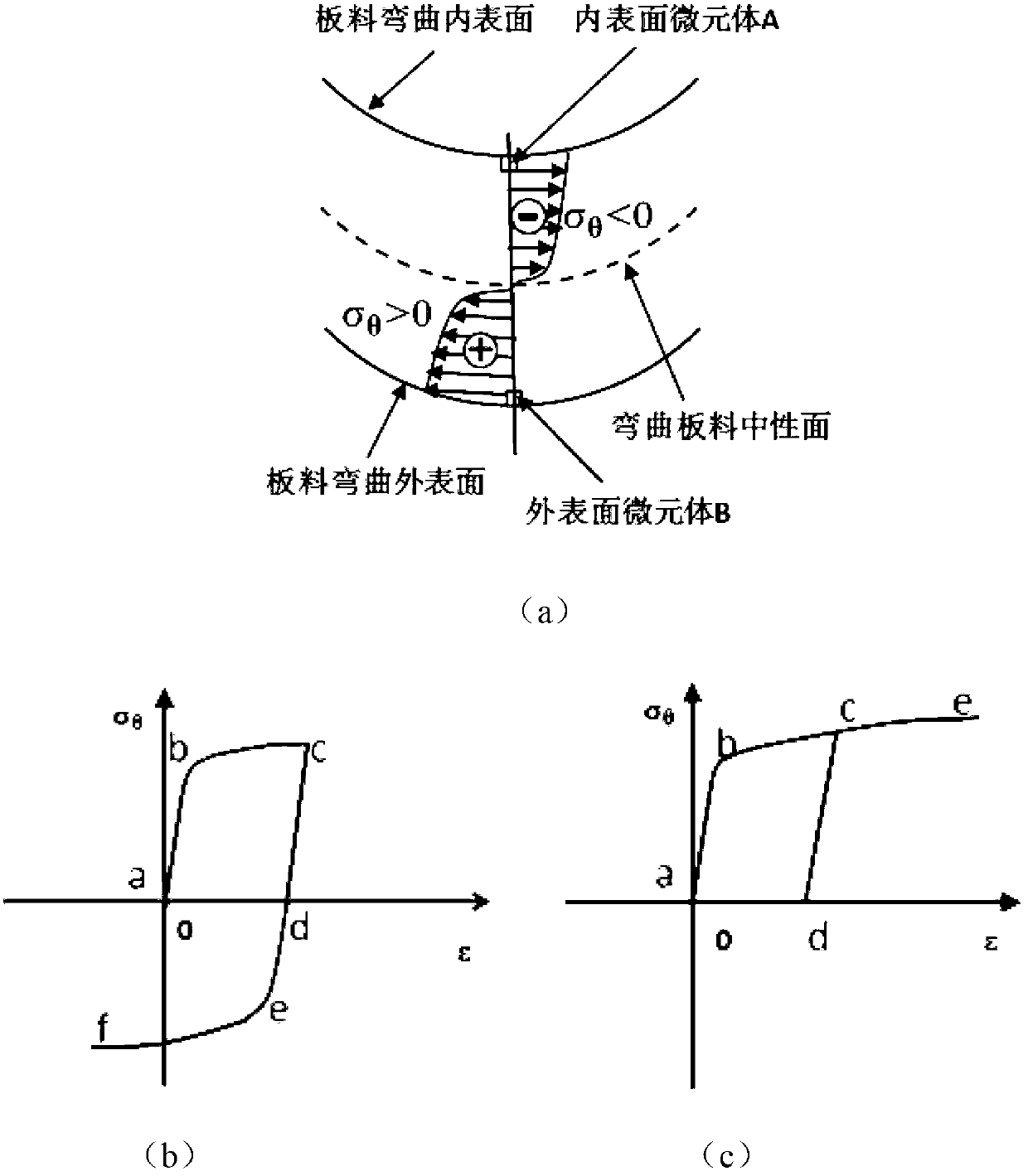

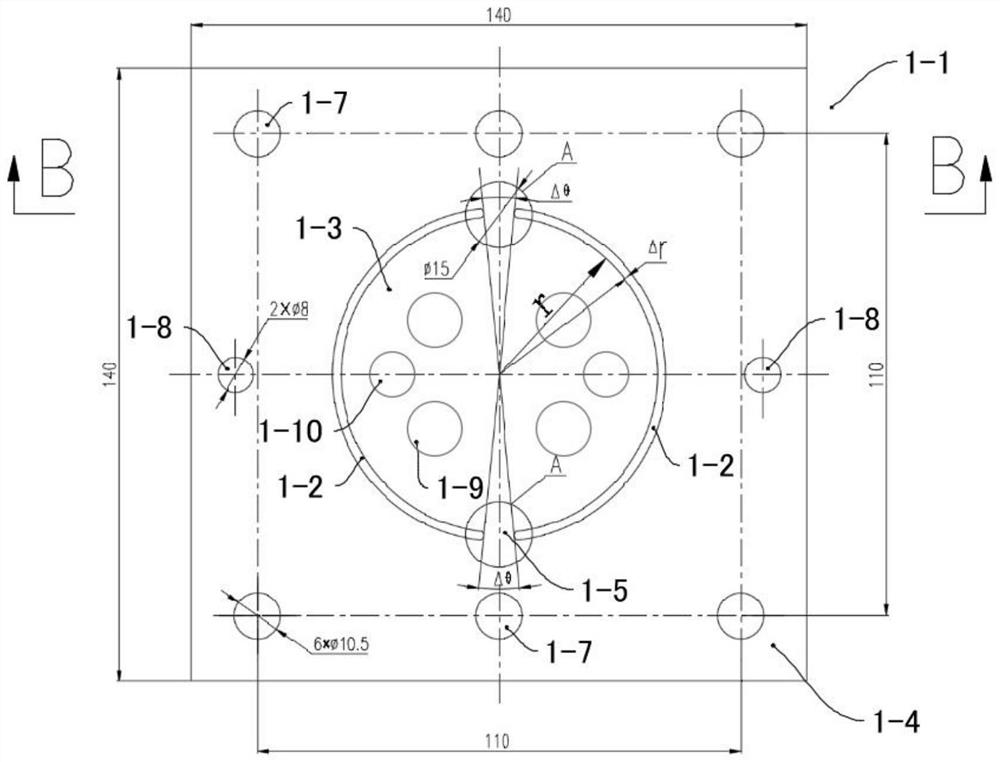

Method for determining thin plate reverse loading Bauschinger effect

Owner:XI AN JIAOTONG UNIV

Welded steel pipe for linepipe with high compressive strength and manufacturing method thereof

ActiveUS20120285576A1Suppress lowering of compressive strengthImprove fracture toughnessShaping toolsArc welding apparatusSheet steelCompressive strength

Provided are a steel pipe for a linepipe with high compressive strength and a heavy wall thickness, and a method of manufacturing the same. Lowering of yield stress caused by a Bauschinger effect can be suppressed by optimizing the metal microstructure of a steel plate without requiring particular forming conditions in forming the steel pipe, and without requiring heat treatment after pipe making. A steel pipe has the composition which contains by mass % 0.03 to 0.10% C, 0.30% or less Si, 1.00 to 2.00% Mn, 0.015% or less P, 0.003% or less S, 0.080% or less Al, 0.005 to 0.035% Nb, 0.005 to 0.020% Ti, and Fe and unavoidable impurities as a balance. The steel pipe has metal microstructure where a fraction of bainite is 60% or more, a fraction of rolled ferrite is 5% or less, and a fraction of M-A constituent (MA) is 3% or less.

Owner:JFE STEEL CORP

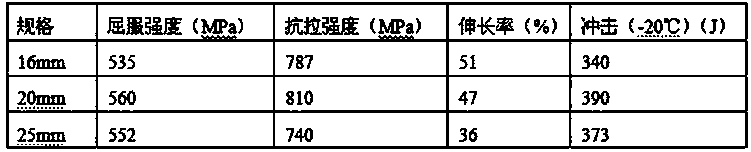

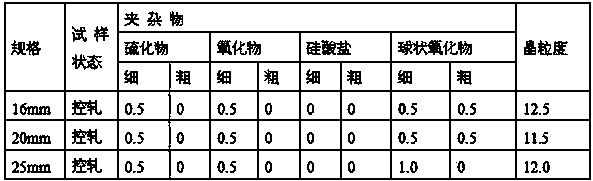

X 60 pipeline steel with thickness of 16-25 mm and production method of pipeline steel

The invention discloses X 60 pipeline steel with the thickness of 16-25 mm and a production method of the pipeline steel. The pipeline steel comprises chemical components as follows: 0.06 wt%-0.09 wt% of C, 0.25 wt%-0.35 wt% of Si, 1.55 wt%-1.69 wt% of Mn, 0.20 wt%-0.29 wt% of (Nb+Ti+V+Mo+Ni), no more than 0.010 wt% of P and no more than 0.003 wt% of S. The production method mainly comprises LF+VD, continuous casting and controlled rolling and controlled cooling. Obtained X 60 microstructure contains 42 %-46 % of lath-shaped ferrites, 32 %-38 % of acicular ferrites, 13 %-15 % of bainite, a small amount of M-A islands and fine dispersion precipitated phases; the phase interface bonding performance is good, the yield ratio is 0.66-0.76, and the grain size reaches 11.5-12.5 grades; and the welding performance is good, and the Bauschinger effect is low.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

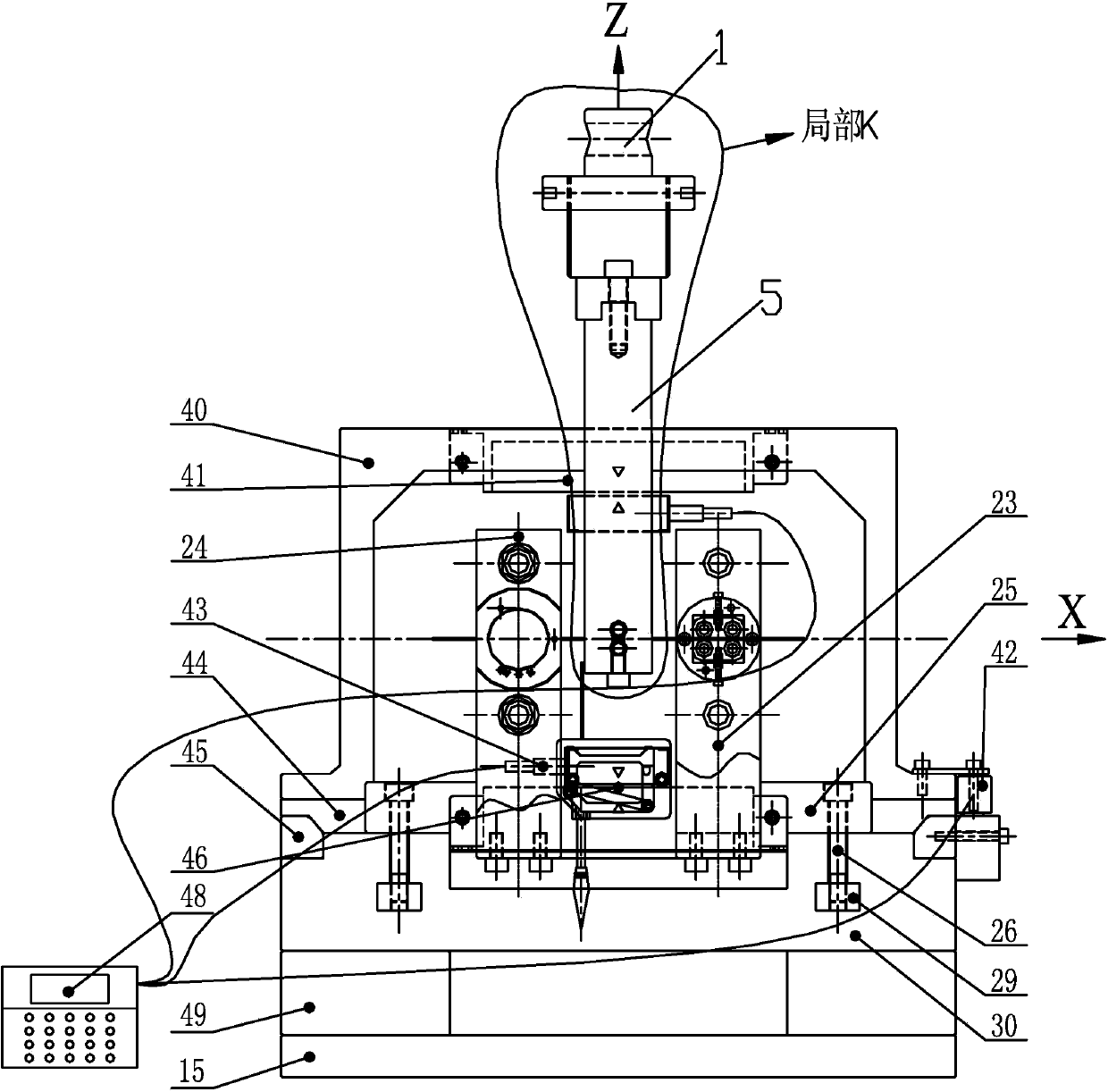

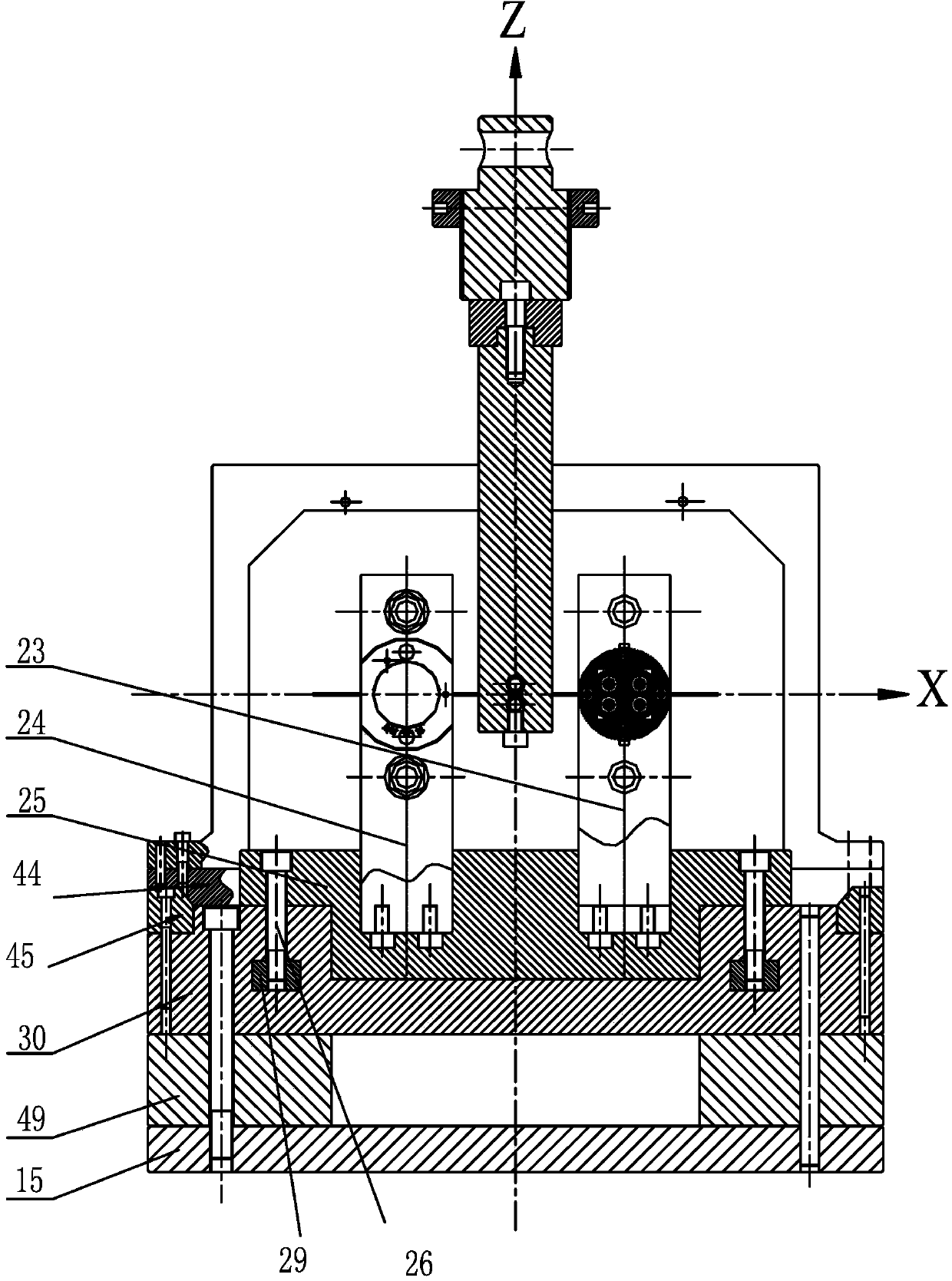

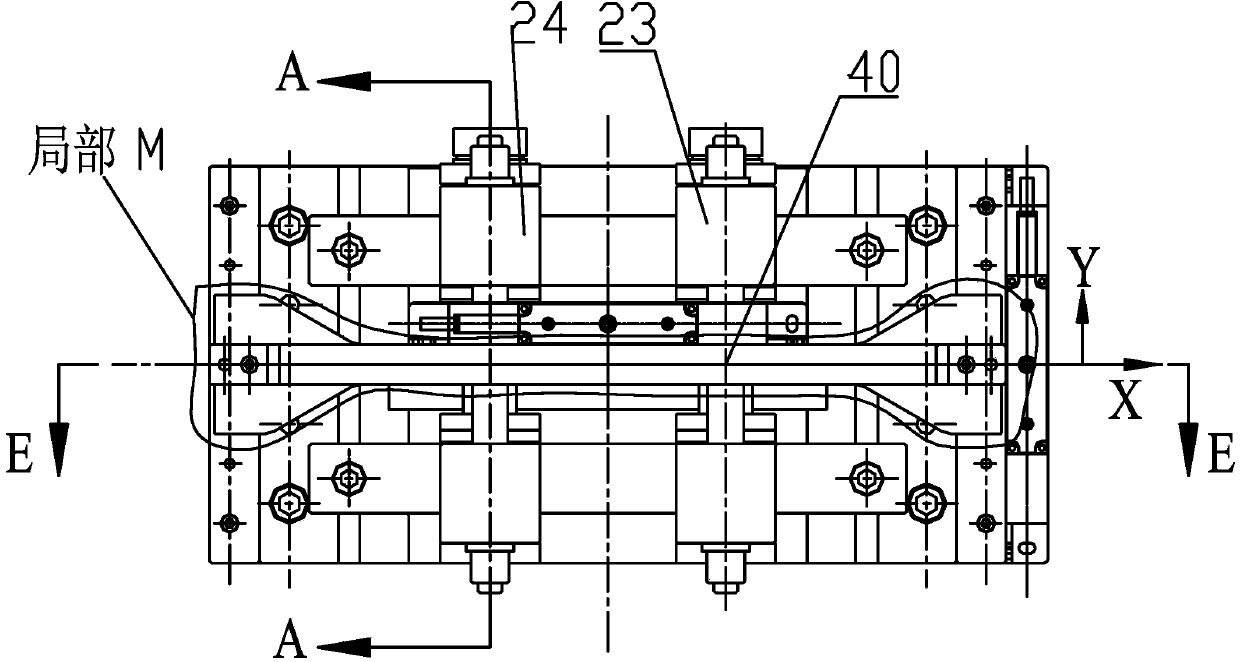

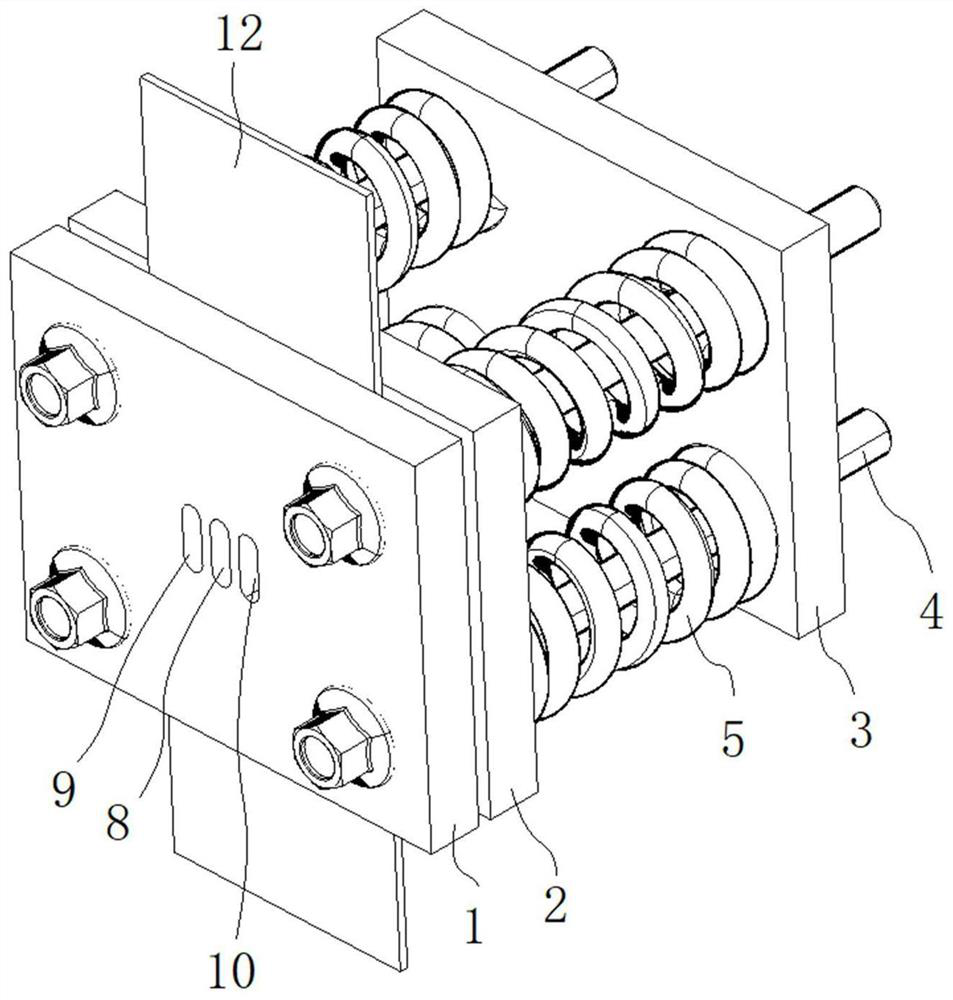

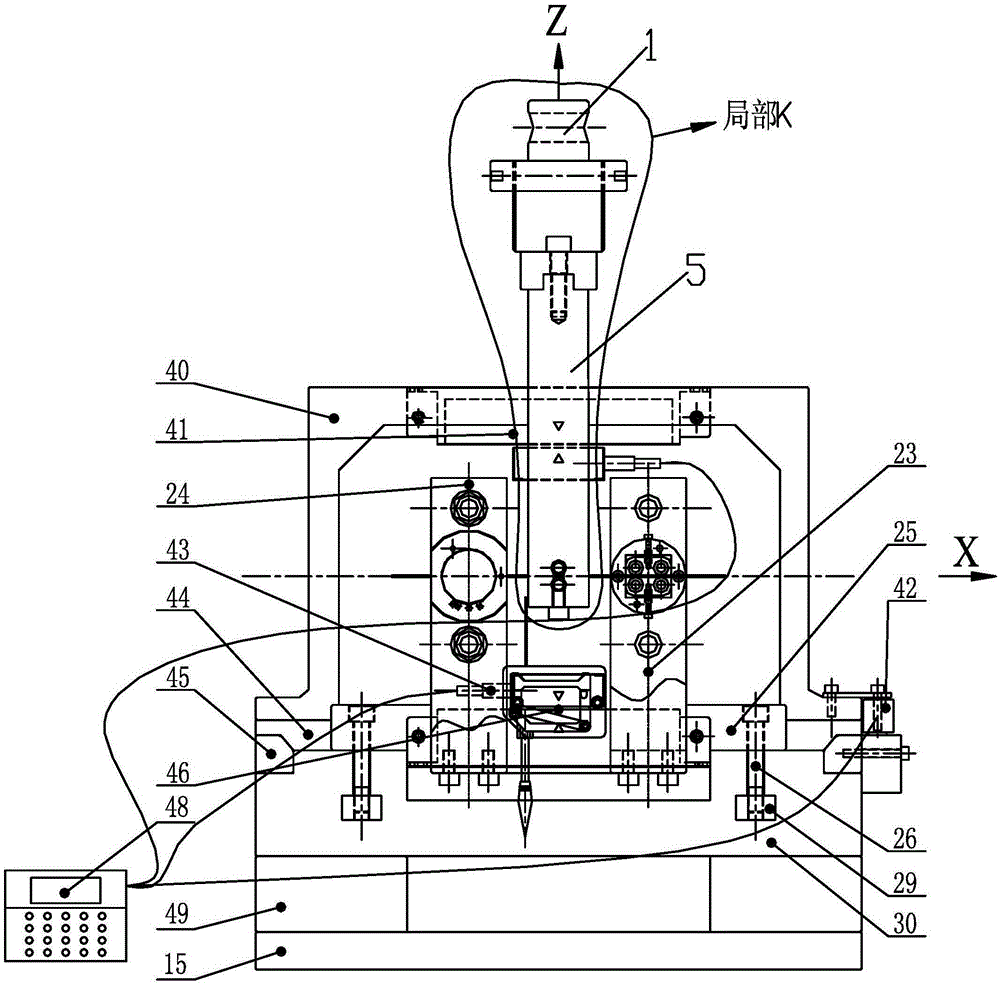

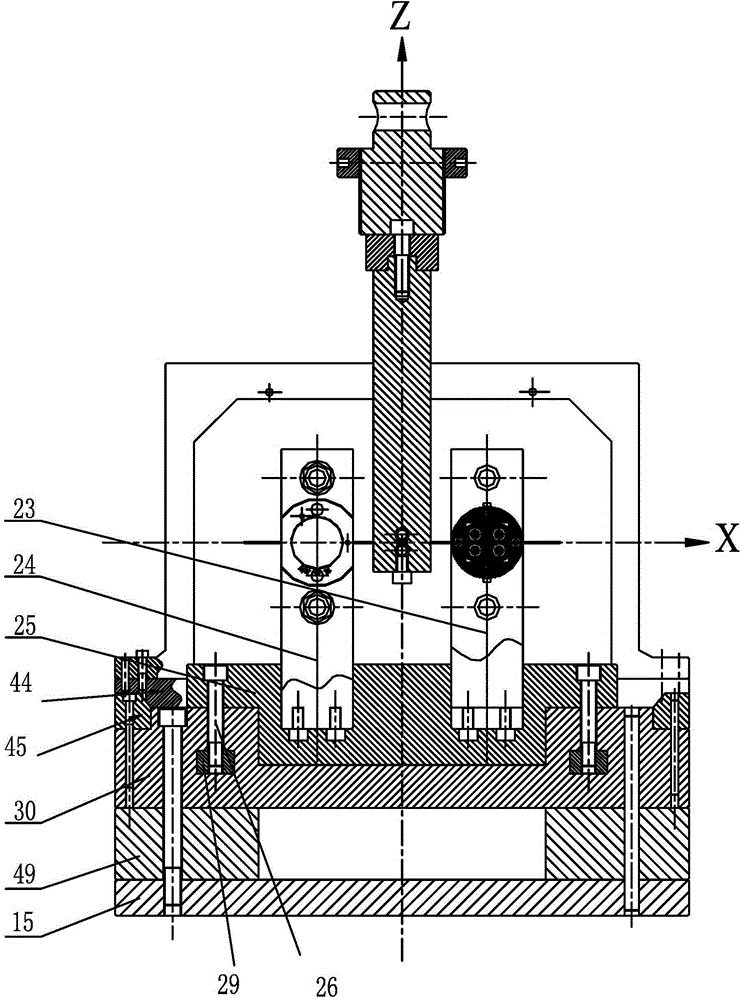

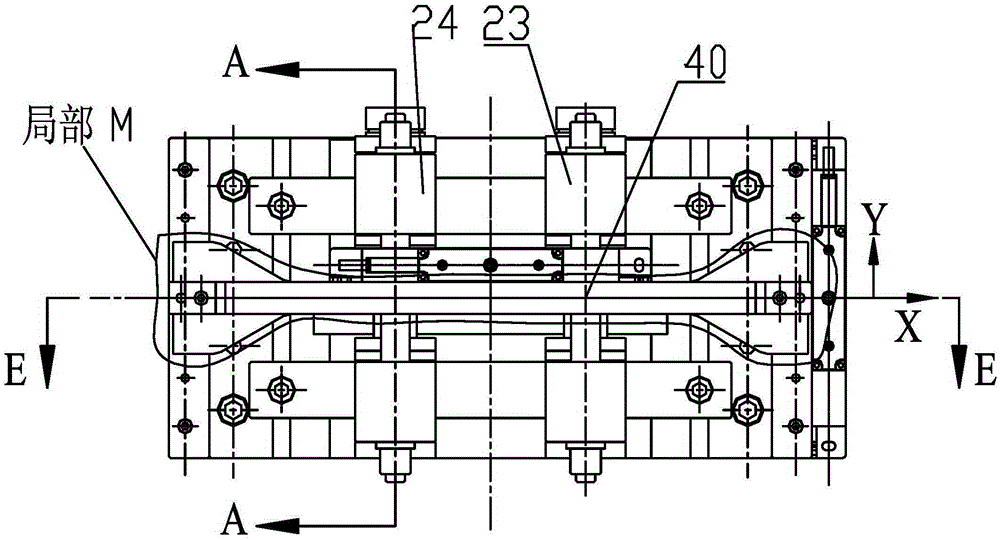

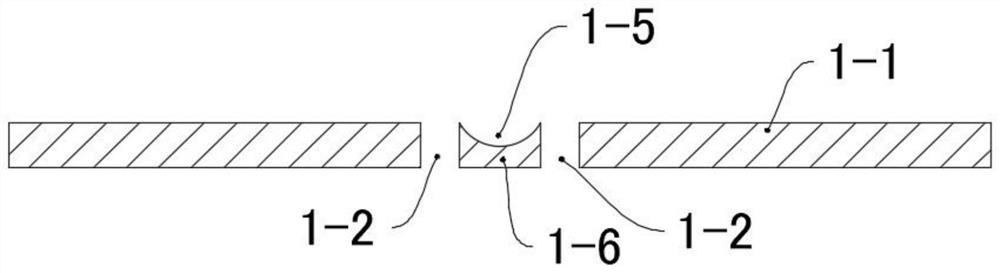

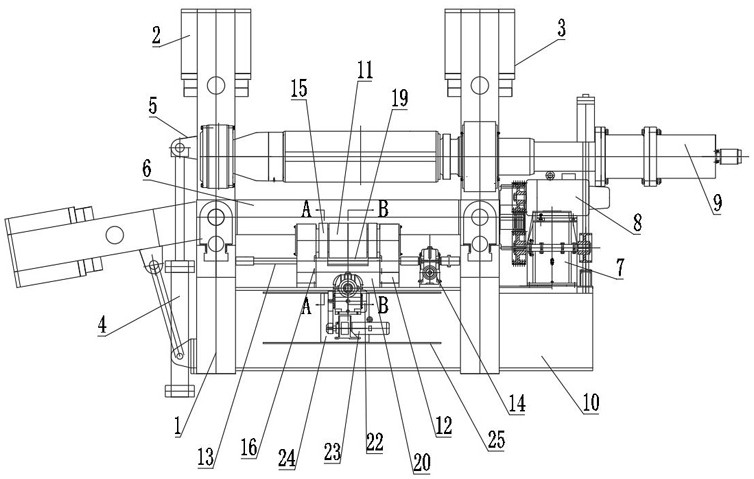

Apparatus and method for precisely detecting Bauschinger effect of repeated bending of metal plate

ActiveCN103592190ARequire flexibilitySimple structureMaterial strength using repeated/pulsating forcesEngineeringBauschinger effect

The invention relates to an apparatus and method for precisely detecting Bauschinger effect of repeated bending of a metal plate, the apparatus comprises a mechanics loading module and a plate clamping adjustable module fixed at the bottom of the mechanics loading module; the mechanics loading module is fixed and suspended through a testing machine and is vertically arranged, X-direction regulating blocks are symmetrically arranged at left side and right side along X-direction of the mechanics loading module, the front end and rear end of each X-direction regulating block are respectively fixed on the Y-direction regulating blocks, and is capable of respectively being driven by the Y-direction regulating blocks to horizontally slide on a pedestal along the Y-direction back and forth; the operation is easy and has automation function, force and displacement during a loading process can be measured, the coordinate figure, curvature radius and strain value at random point on both surface of the plate during the loading process can be measured, the error of test data is less, and the flexibility requirement of the Bauschinger effect for the plate can be satisfied, so that accurate calibration basis for determining material parameter of Bauschinger effect for the plate can be provided.

Owner:WUHAN UNIV OF TECH

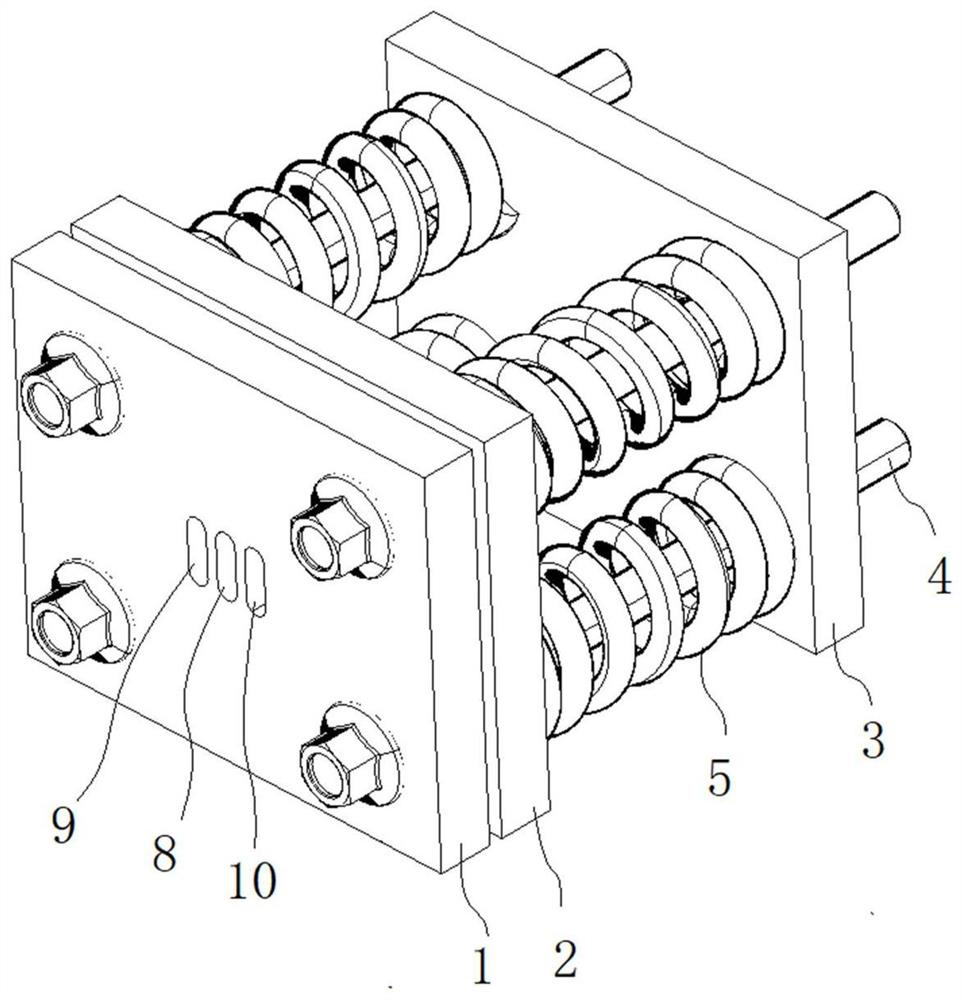

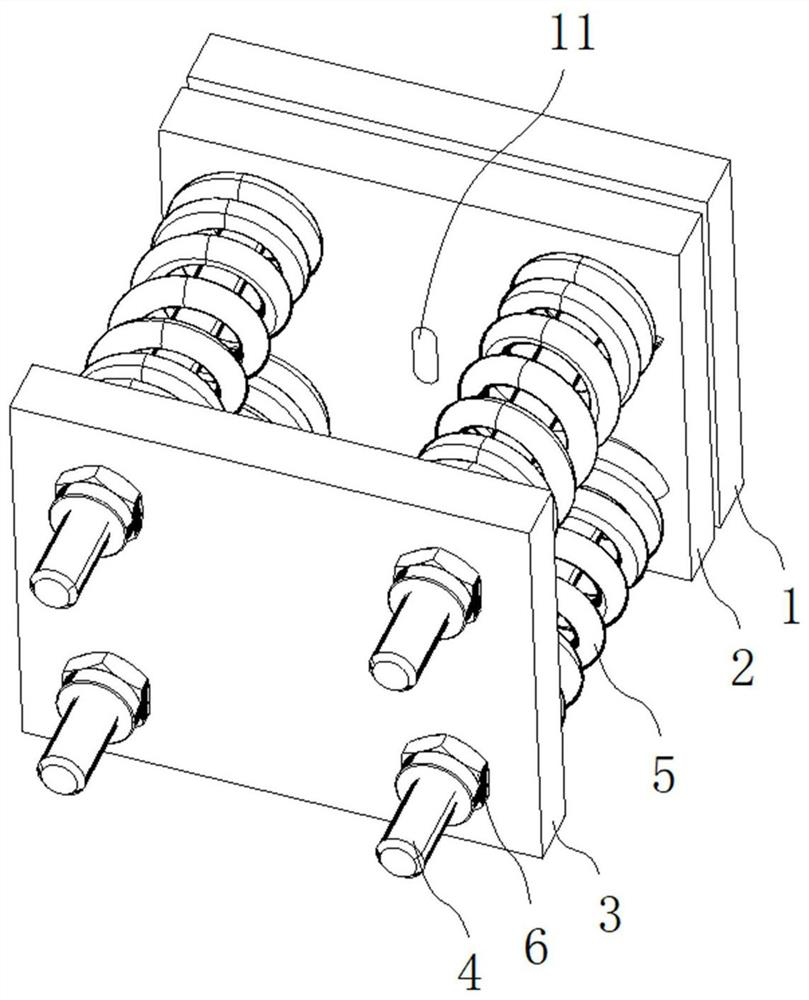

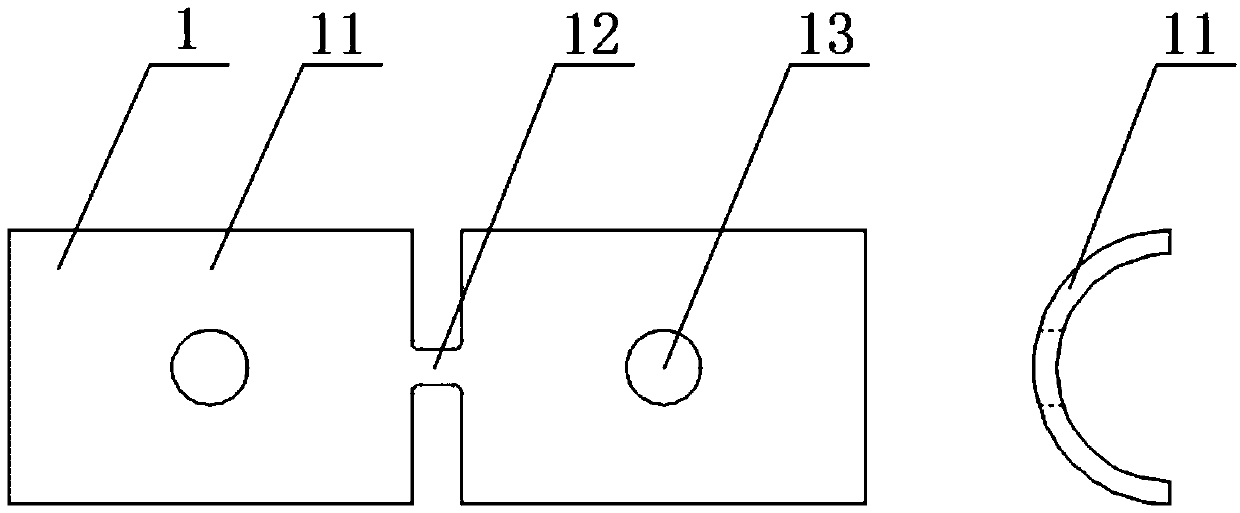

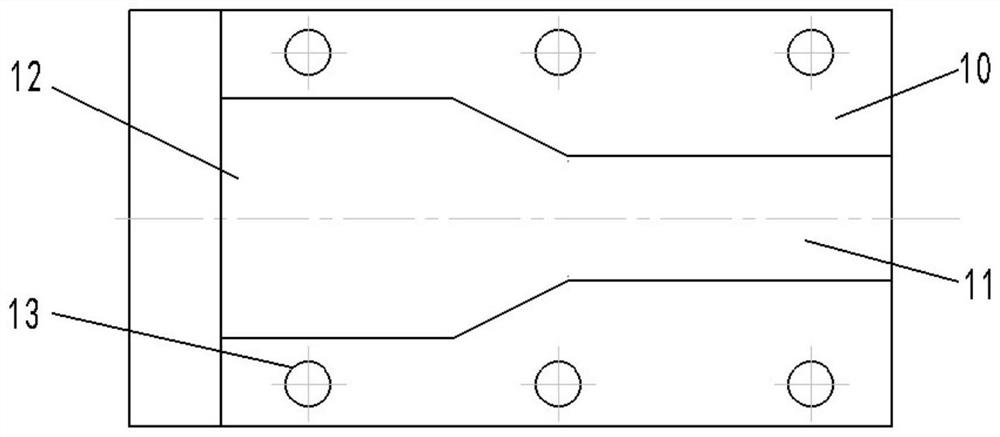

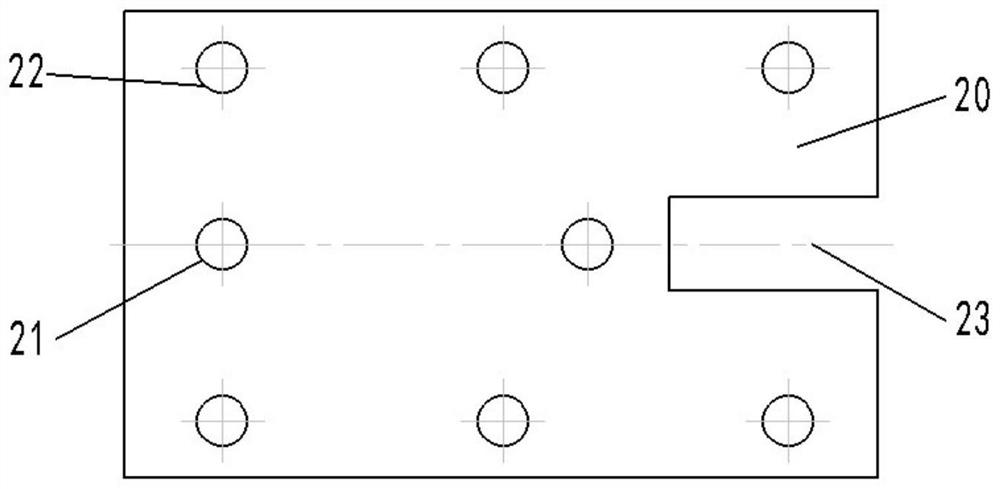

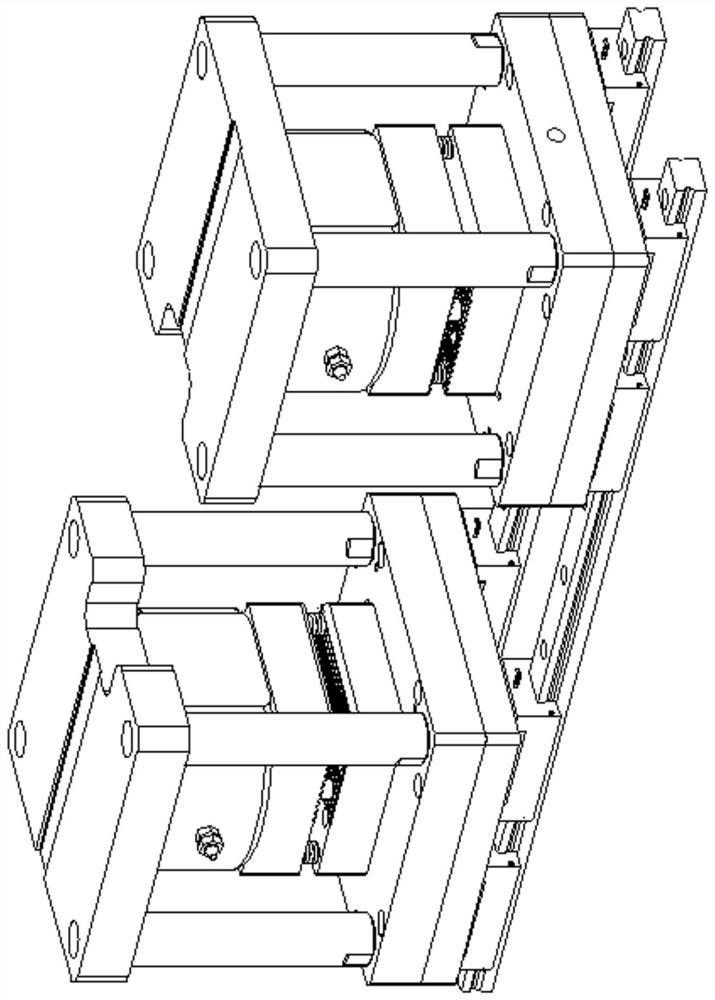

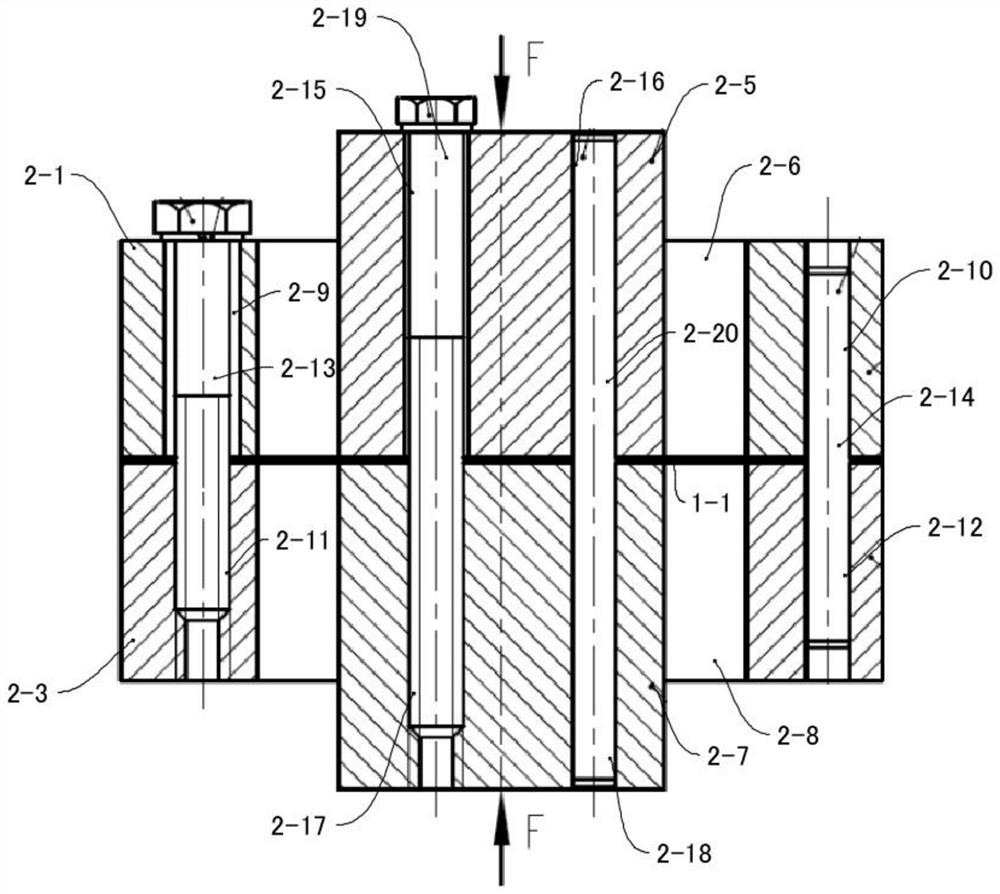

Anti-buckling clamping device, sample and assembling method thereof

PendingCN111781060AMake sure it's compressedBreak through limitationsMaterial strength using tensile/compressive forcesUniaxial compressionFriction effect

The invention discloses an anti-buckling clamping device. The device comprises an outer clamping plate, an inner clamping plate, a spring pressing plate, a spiral spring, a bolt and a nut, an outer state concave part, a left observation concave part and a right observation concave part are arranged on the outer clamping plate, and an outer state concave part is disposed on the inner clamping plate. Meanwhile, the invention further discloses an assembly method of the anti-buckling clamping device, a sample matched with the anti-buckling clamping device is designed, and the invention further discloses a method for eliminating the friction effect of the anti-buckling clamping device. Through the anti-buckling clamping device, the sample and the assembly method of the anti-buckling clamping device, the deformation measurement range of uniaxial compression test can be expanded, the test cost can be reduced, the device is simple and easy to operate, and meanwhile, the test data obtained by the method subverts the traditional cognition of the Bauschinger effect and expands the depth of scientific research on the material, therefore the anti-buckling clamping device has important theoretical and engineering practice significance.

Owner:武汉上善仿真科技有限责任公司

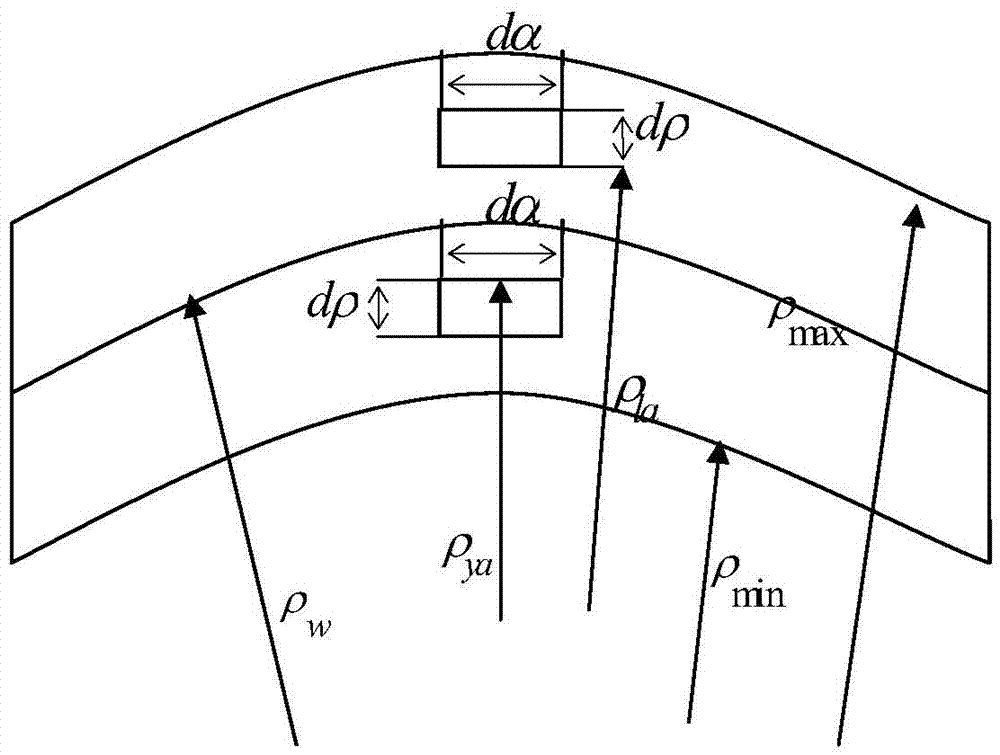

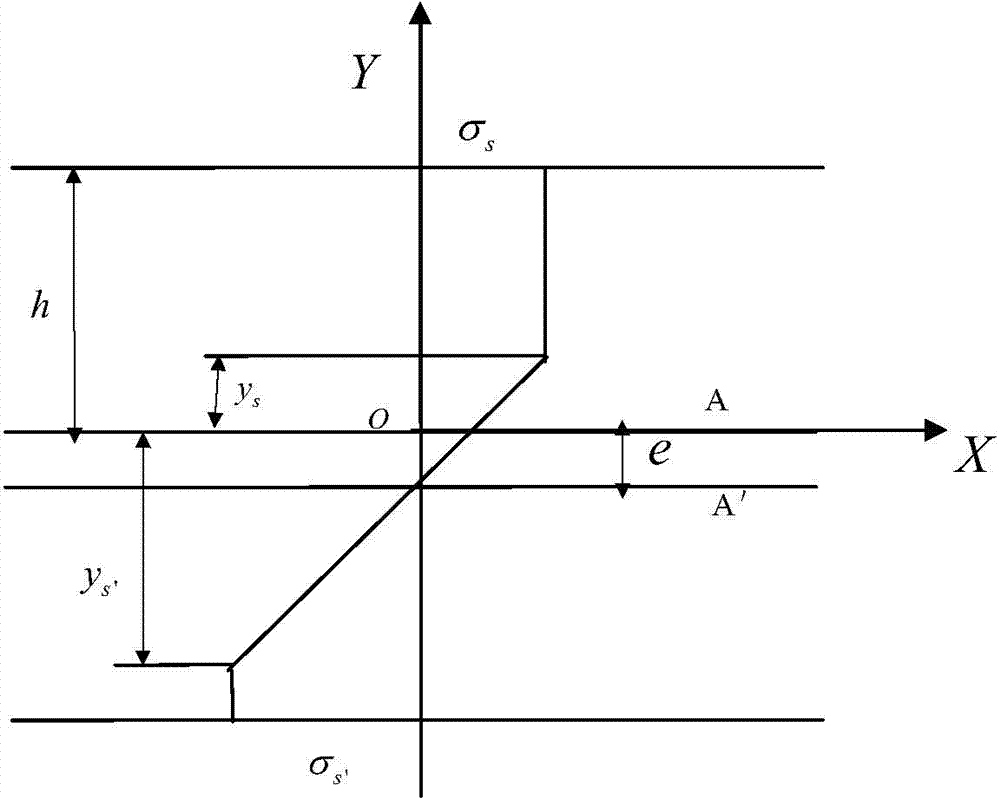

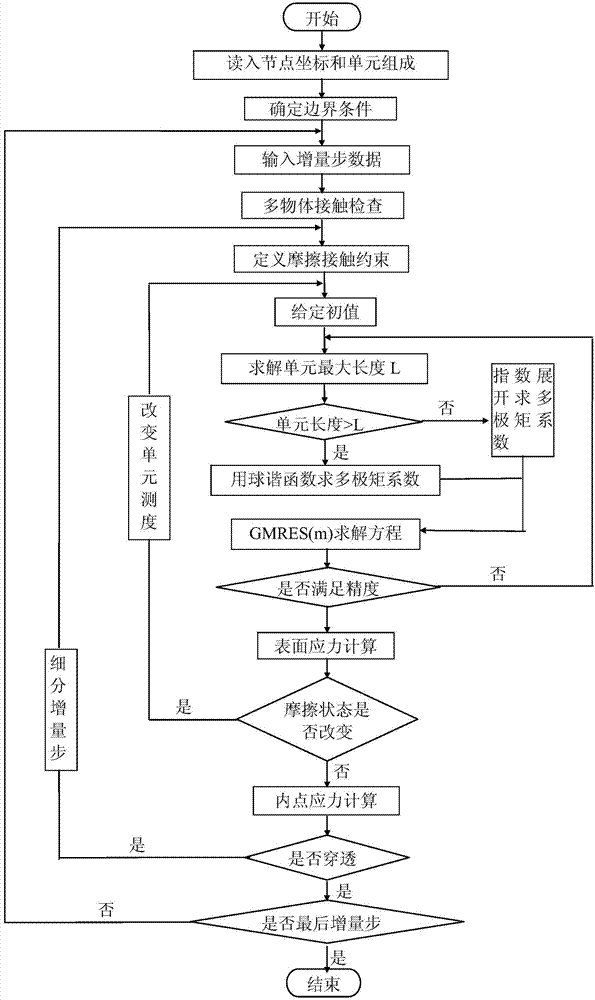

Method for calculating straightening force of roller type straightening machine through multi-pole boundary element method

InactiveCN103678932AHigh precisionImprove straightening efficiencySpecial data processing applicationsEngineeringElastic plastic

The invention provides a method for calculating straightening force of a roller type straightening machine through a multi-pole boundary element method, and belongs to the technical field of roller type straightening. The method is characterized in that the method includes the steps of firstly, calculating and considering straightening force of deviation of a neutral layer, secondly, calculating and considering straightening force of the bauschinger effect, thirdly, using an independently developed three-dimensional elastic-plastic multi-object contact multi-pole boundary element method program package for calculating straightening force, finally, giving comprehensive consideration to the three factors, and utilizing weight, occupied in straightening force, of each factor to obtain the size of straightening force in the roller type straightening process at last. The method has the advantages that a more accurate straightening force calculating formula is obtained, theoretical support is provided for design of the straightening machine, straightening force calculation is more accurate, the straightening effect is improved effectively, and accordingly the product quality is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

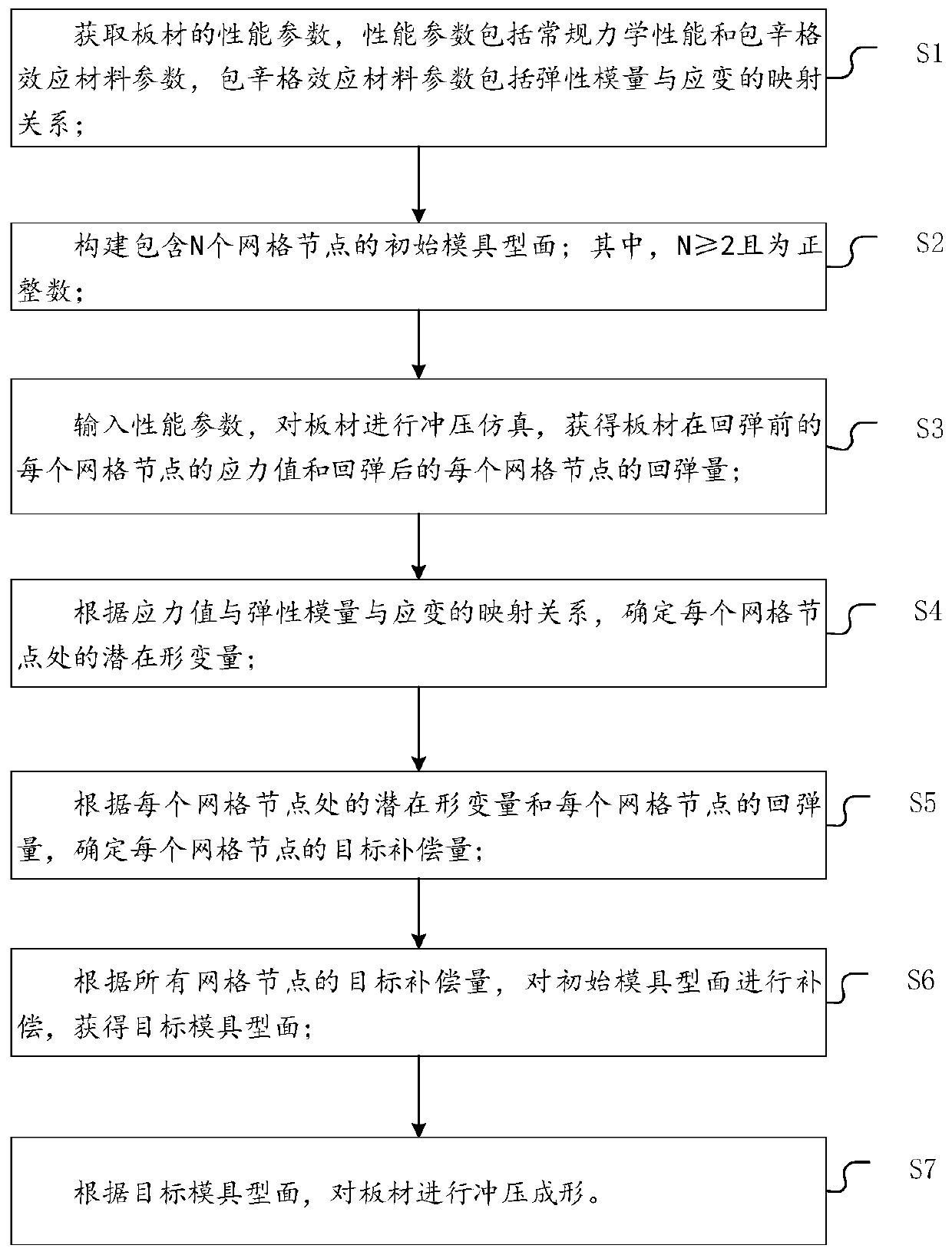

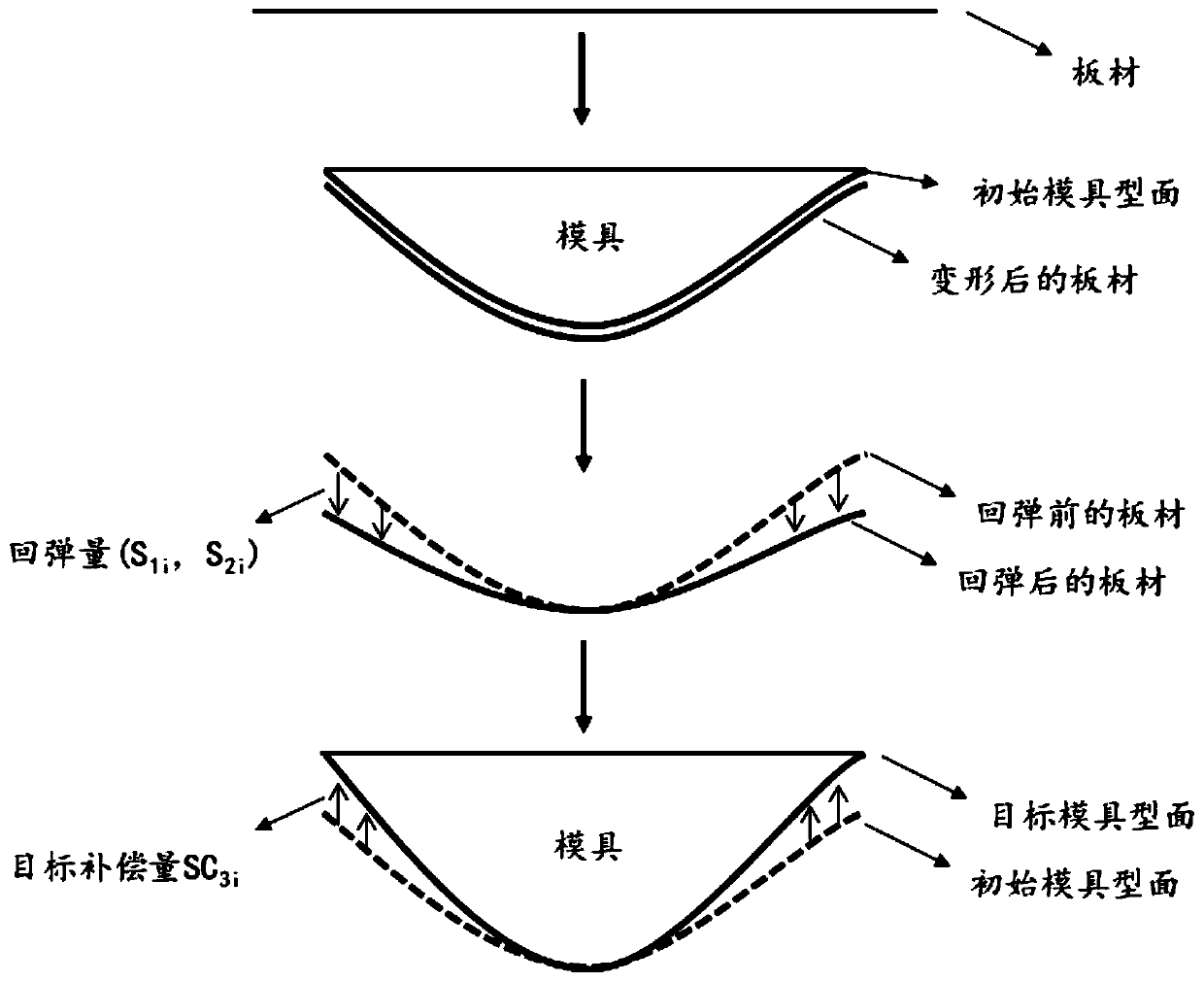

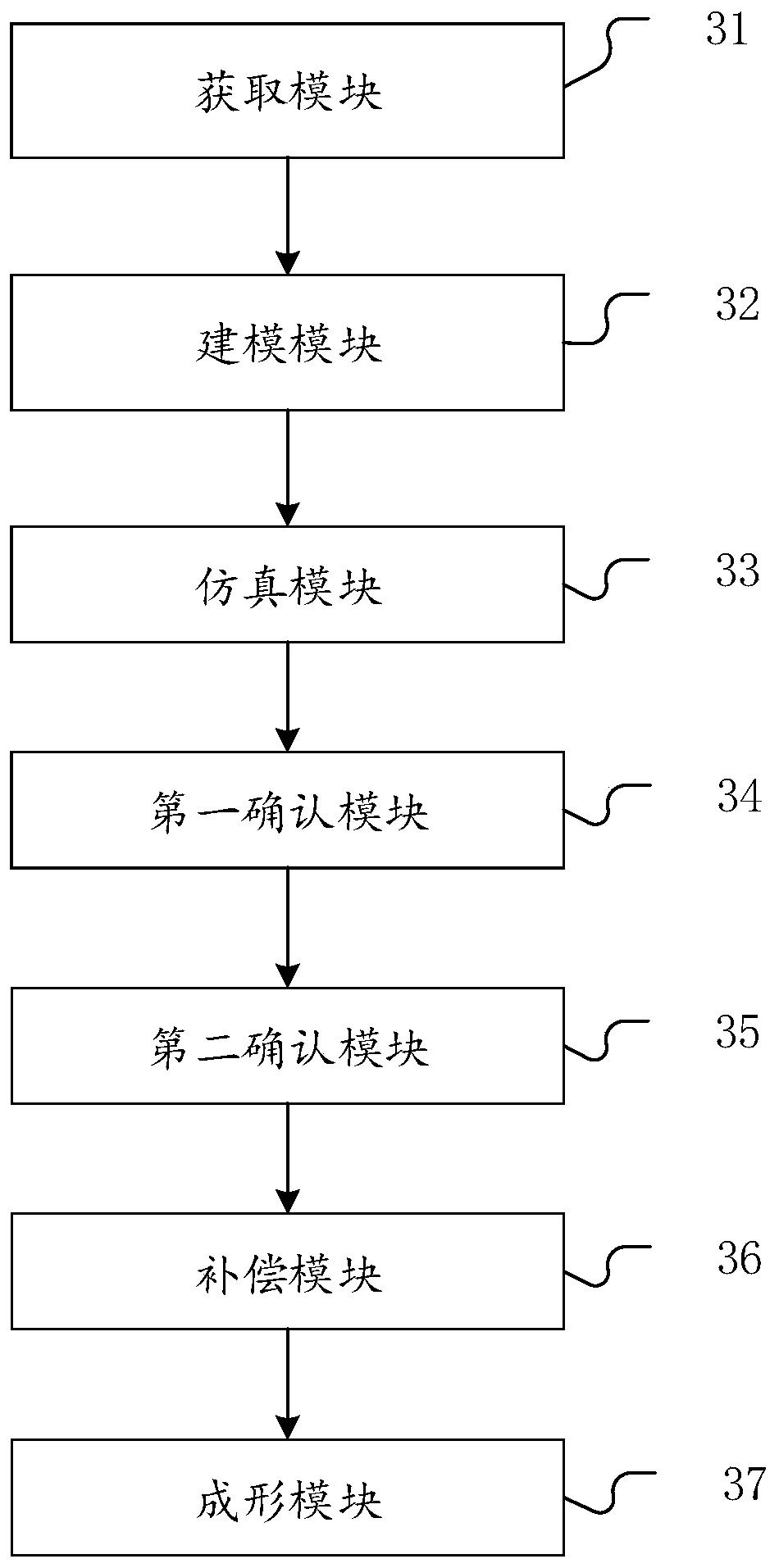

Plate stamping springback control method and device

ActiveCN111399442AReduce the number of iterationsIn line with the actual deformationProgramme controlComputer controlClassical mechanicsStructural engineering

The invention discloses a plate stamping springback control method which comprises the steps: obtaining performance parameters, including a Bauschinger effect material parameter, of a plate; constructing an initial mold profile comprising N grid nodes; inputting performance parameters, carrying out stamping simulation conducted on the plate, and obtaining the stress value of each grid node of theplate before springback and the springback amount of each grid node after springback; determining a potential deformation quantity at each grid node according to the stress value and the Bauschinger effect material parameter; determining a target compensation amount of each grid node according to the potential deformation amount and the springback amount, and compensating the initial mold profileto obtain a target mold profile; and according to the target mold profile, stamping and forming the plate. By means of the control method, the target mold profile meeting stamping springback precisioncontrol can be obtained more quickly and accurately, and the stamping simulation and design efficiency is improved.

Owner:SHOUGANG CORPORATION

DIC-based Bauschinger effect test sample, fixture and method

InactiveCN109540659ASmall deformation areaObjective compressive strainStrength propertiesBlack spotTest sample

The invention discloses a DIC-based Bauschinger effect test sample, fixture and method. First, a tube blank is processed into a small gauge-length sample by wire cutting according to the size; a layerof white paint is uniformly sprayed at a sample gauge-length section; after the paint is dried, uneven black spotted paint is sprayed, a speckle sample is manufactured, and the sample is clamped on the test fixture; an electronic universal test machine and a digital speckle system are opened to set focal length to a focal plane where the sample is located, the aperture size is adjusted to obtaina clear speckle picture, then, a calibration plate is used to calibrate the digital speckle system under the condition; a tensile test under different pre-compressed strain conditions is carried out;and the test data is analyzed to obtain a Bauschinger effect of the material. The small gauge-length sample used in the invention has small deformation area and uniform deformation, and can realize tensile compression stress reverse loading. The test method can efficiently and accurately determine the Bauschinger effect of the thin wall plate / tube material.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for controlling non-quenched and tempered high-intensity screw bolt steel high Bauschinger effect

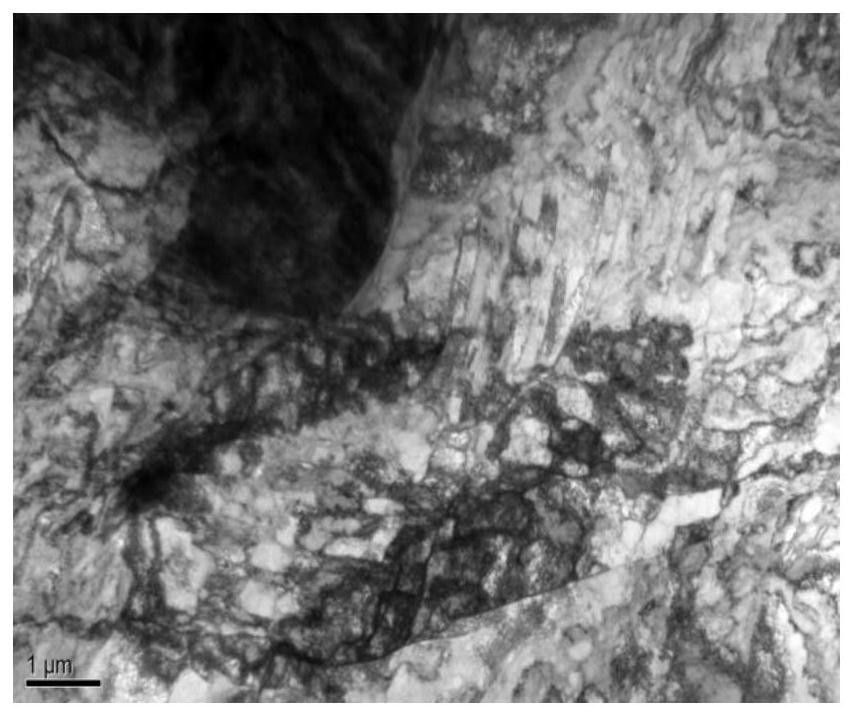

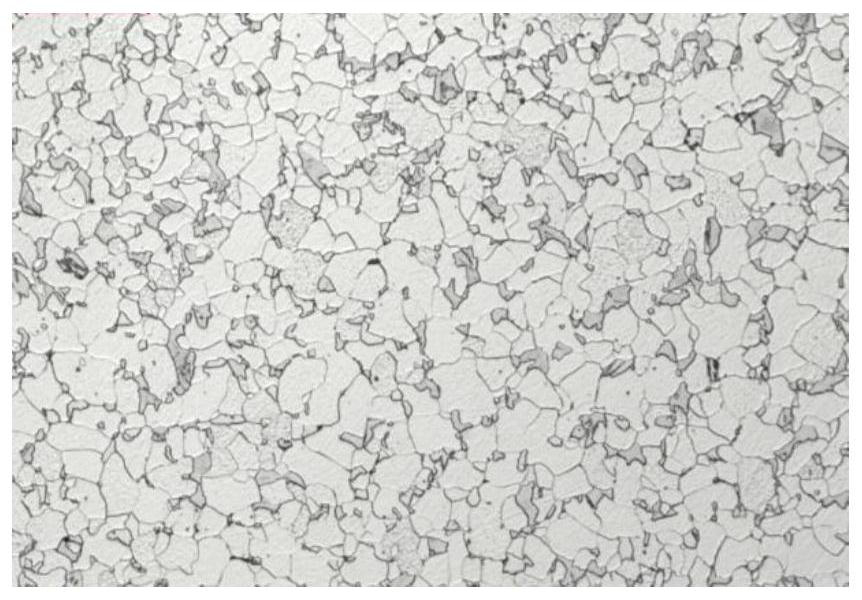

InactiveCN106834639AHigh Bauschinger effect valueOptimum forward dislocation densityHigh intensityDislocation

The invention relates to a method for controlling the non-quenched and tempered high-intensity screw bolt steel high Bauschinger effect, and belongs to the field of control of a deep processing drawing technology. The method comprises the following process steps and control technical parameters that the Stelmor air cooling control is used; a heat insulation cover is used for covering; the cooling speed after the cooling is controlled to be 1 to 3 DEG C / s; the obtained ferrite content is 45 to 55 percent; a ferrite-pearlite type hot rolling material is subjected to deep processing drawing treatment to realize instant cooling and reinforcement; the drawing area reducing rate is controlled to be 20 to 25 percent. The method has the advantages that the cold drawing area reducing rate and the steel ferrite ratio of the ferrite-pearlite type non-quenched and tempered high-intensity screw bolt are controlled to obtain the optimal positive dislocation density inside tissues; the high Bauschinger effect value is obtained.

Owner:SHOUGANG CORPORATION

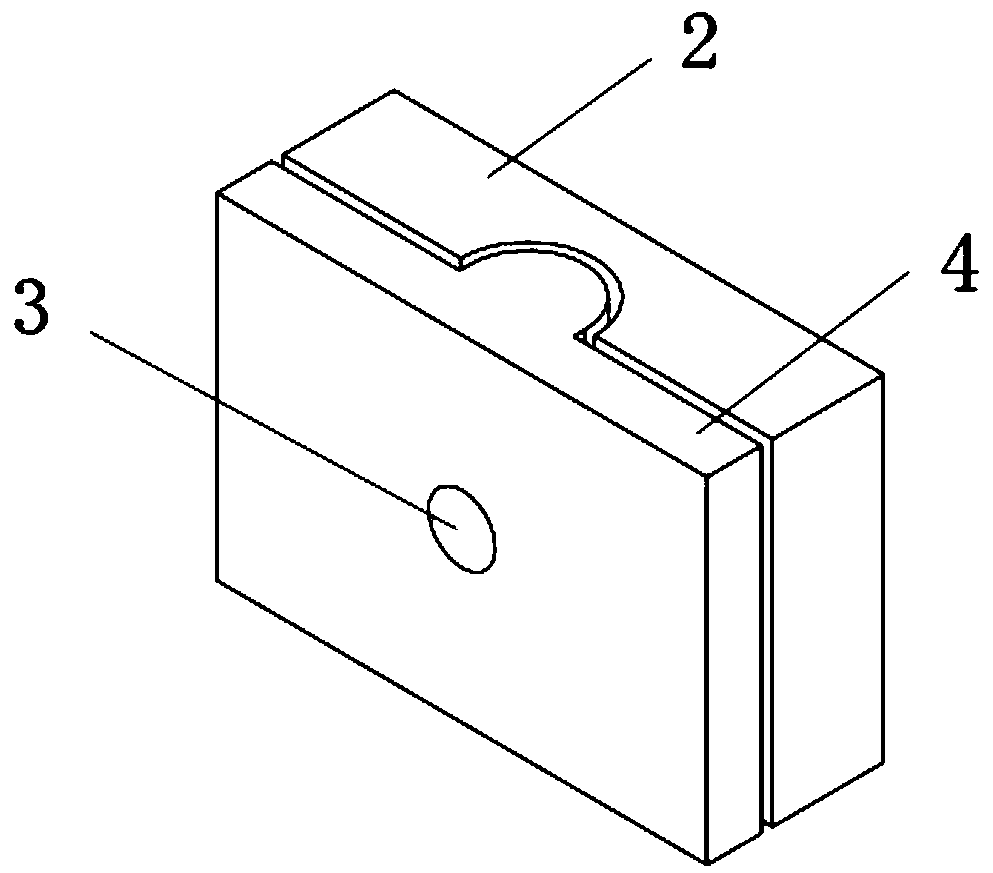

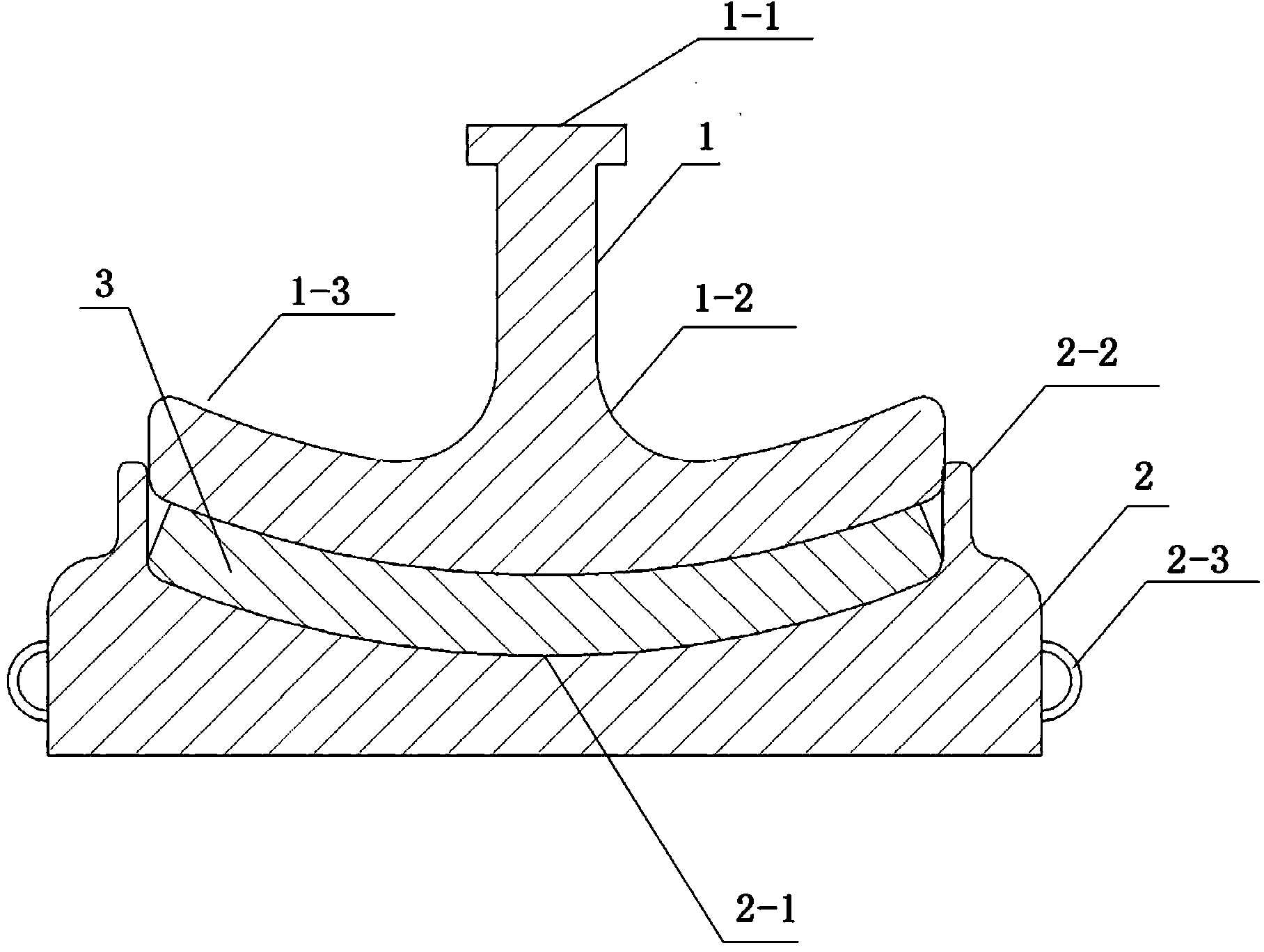

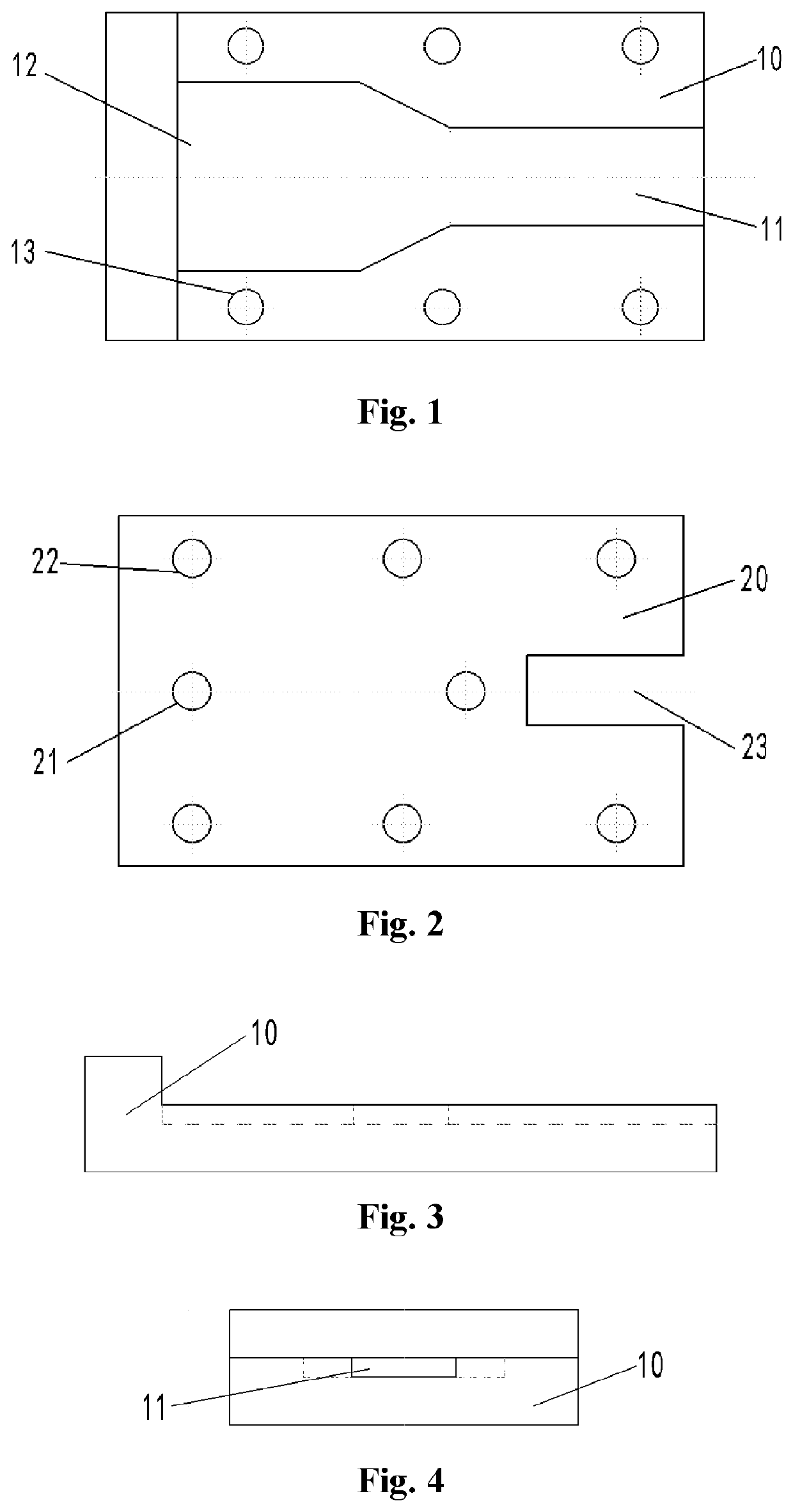

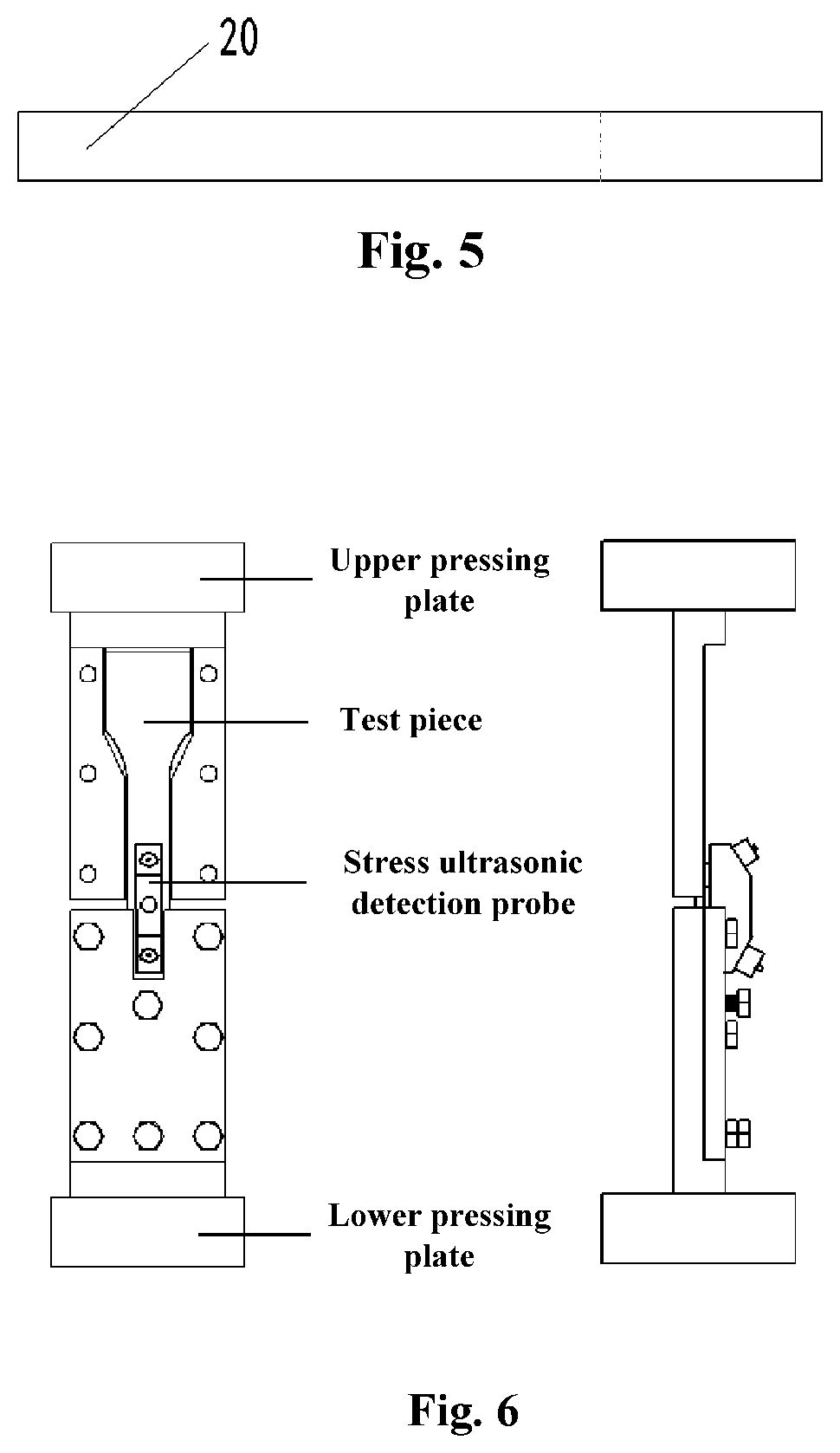

Bauschinger effect test fixture

ActiveCN112033798ASolve the bendSolve instabilityMaterial strength using tensile/compressive forcesEngineeringUltrasonic testing

The invention provides a Bauschinger effect test fixture which is matched with a tension and compression material test machine for use to perform a Bauschinger effect test on a test piece. The test piece is of a symmetrical strip-shaped structure with two wide ends and a narrow middle, and comprises two identical split bodies. The split body comprises a base and a gland, wherein a limiting groovecorresponding to the half profile of the test piece is longitudinally formed from the middle part to one end of the base, and a plurality of threaded through holes are symmetrically formed in two sides of the limiting groove; and the gland is provided with two threaded through holes along the central axis, the test piece is pressed by a bolt, a plurality of through holes are symmetrically formed in the two sides of the gland, and the gland is connected with the plurality of threaded through holes of the base through bolts, a through groove is formed in one end, corresponding to the opening ofthe limiting groove, of the gland and is used for placing a stress ultrasonic detection probe on the test piece. The problem that the existing tension and compression material test machine cannot complete a Bauschinger effect test can be solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Welded steel pipe for linepipe with high compressive strength and manufacturing method thereof

ActiveUS9089919B2Suppress lowering of compressive strengthImprove fracture toughnessShaping toolsArc welding apparatusSheet steelCompressive strength

Provided are a steel pipe for a linepipe with high compressive strength and a heavy wall thickness, and a method of manufacturing the same. Lowering of yield stress caused by a Bauschinger effect can be suppressed by optimizing the metal microstructure of a steel plate without requiring particular forming conditions in forming the steel pipe, and without requiring heat treatment after pipe making. A steel pipe has the composition which contains by mass % 0.03 to 0.10% C, 0.30% or less Si, 1.00 to 2.00% Mn, 0.015% or less P, 0.003% or less S, 0.080% or less Al, 0.005 to 0.035% Nb, 0.005 to 0.020% Ti, and Fe and unavoidable impurities as a balance. The steel pipe has metal microstructure where a fraction of bainite is 60% or more, a fraction of rolled ferrite is 5% or less, and a fraction of M-A constituent (MA) is 3% or less.

Owner:JFE STEEL CORP

Method and device for quickly detecting bauschinger effect value of pipeline steel in steel plate production field

InactiveCN103528881AEasy to operateThe detection process is fastStrength propertiesMetallurgyBauschinger effect

The invention relates to the field of performance detection of pipeline steel and in particular relates to a method for quickly detecting the bauschinger effect value and the surface crack sensitivity of the pipeline steel in a steel plate production field as well as a multifunctional mould. The method comprises the following steps: processing a tensile sample and a crack sample by the multifunctional mould, detecting the yield strength value Rp0.2 of the tensile sample, and digitally processing to obtain the bauschinger effect value; detecting the surface crack sensitivity of the crack sample by naked eyes and a magnifier. The multifunctional mould comprises an upper mould and a lower mould, wherein the diameter of an outer arc of a punch head of the upper mould, the diameter of a circular arc of a groove of the lower mould and the diameter of a steel pipe after steel plates are made into the steel pipe are the same. The method has the beneficial effects that the operation is simple and feasible, the detection speed is high, and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

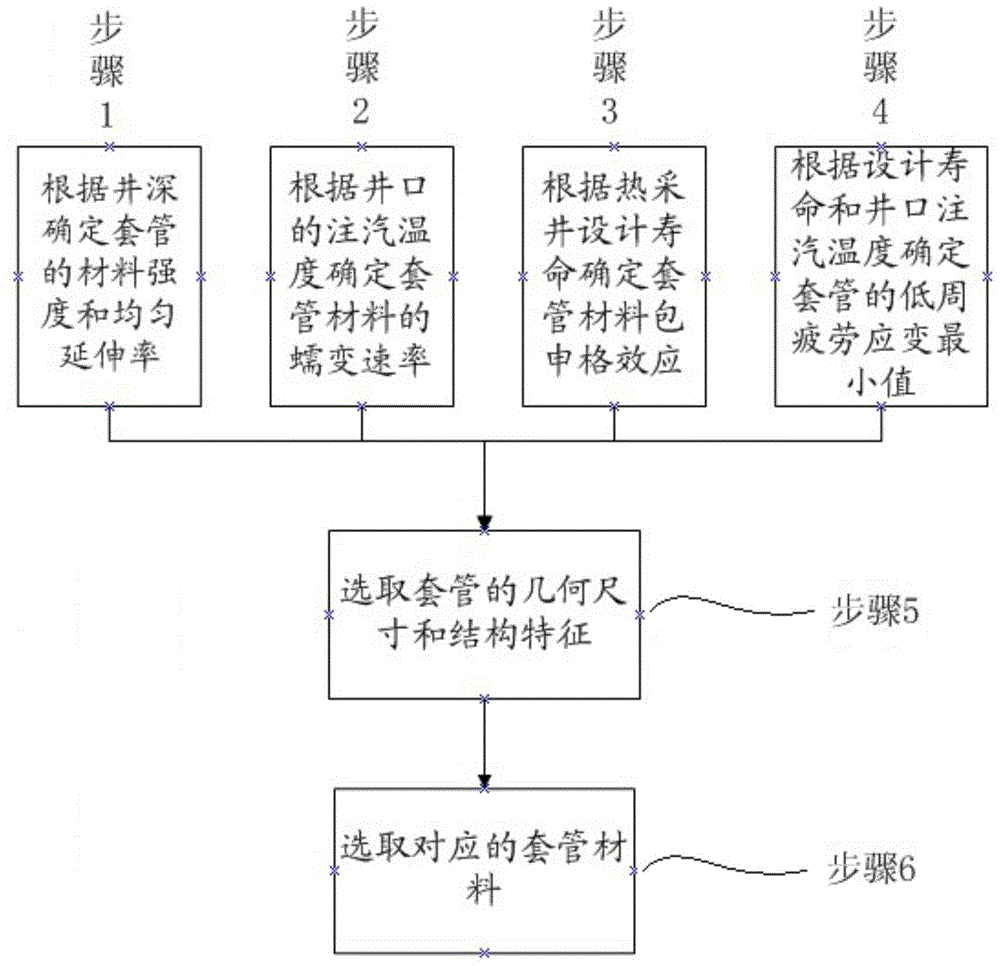

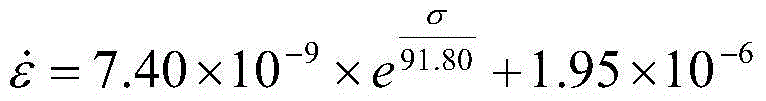

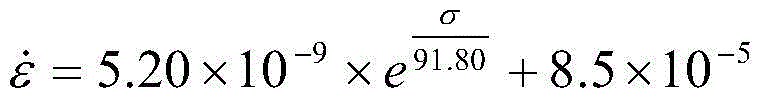

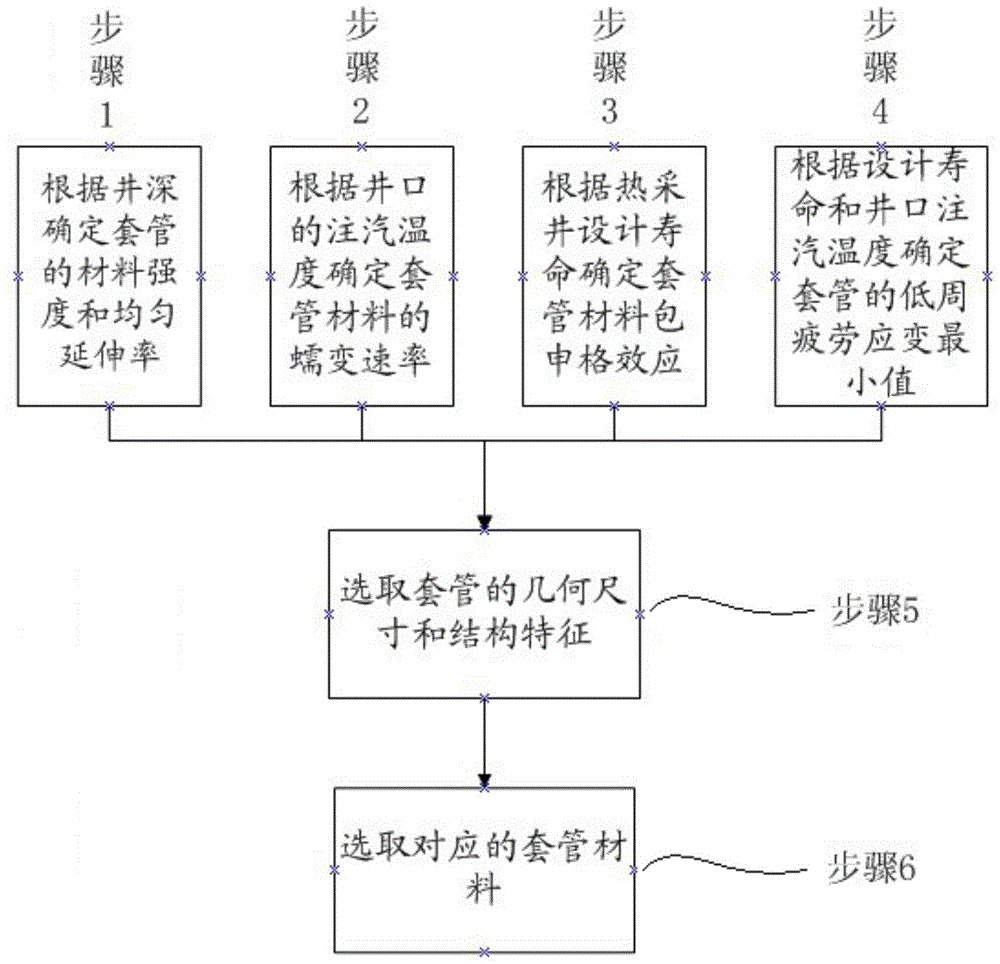

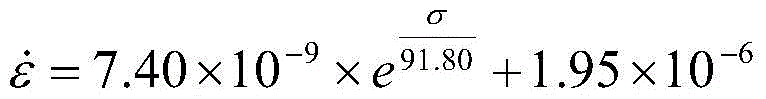

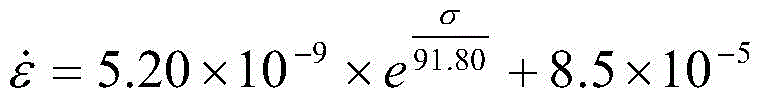

Thermal recovery well casing material selection method

ActiveCN104632093AAvoid failureGuarantee the safety of useDrilling rodsDrilling casingsPerformance indexEngineering

The invention discloses a thermal recovery well casing material selection method. The casing material selection method comprises the steps of determining the material strength properties and the uniform elongation of a casing material according to the depth of a thermal recovery well; determining the creep rate performance of the casing material according to the steam injection temperature of a wellhead; determining the Bauschinger effect performance of the casing material according to the design life of the thermal recovery well; determining the least low-cycle fatigue strain value of a casing according to the design life of the thermal recovery well and the steam injection temperature of the wellhead; selecting the geometry size and structure characteristics of the casing according to the existing oil industry standards; and selecting the corresponding casing according to the performance indexes, geometry size and structure characteristics of the casing. Multiple performance indexes of the casing material are determined through the well depth, the steam injection temperature of the wellhead, and the design life of the thermal recovery well, and therefore the performance of the casing can be more comprehensively assessed; the casing can meet the production safety requirement on the steam huff and puff working condition; failure caused by plastic deformation of the casing can be effectively avoided; and the normal production of the thermal recovery well is guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

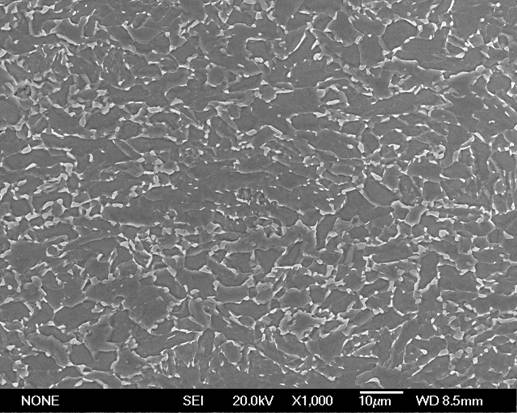

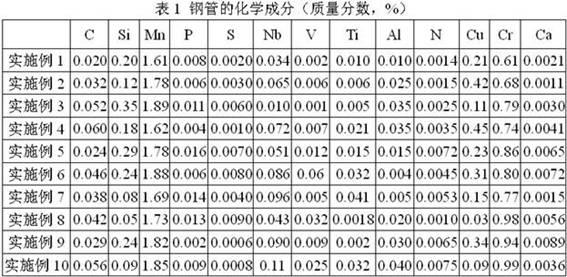

Low-Bauschinger-effect low-strain-aging-effect steel tube and manufacturing method thereof

The invention belongs to the field of steel materials and manufacturing thereof, and discloses a low-Bauschinger-effect low-strain-aging-effect steel tube and a manufacturing method thereof. The steel tube comprises the following components in percentage by mass: 0.02-0.06% of C, 0.05-0.42% of Si, 1.61-1.99% of Mn, at most 0.020% of P, at most 0.010% of S, at most 0.11% of Nb, at most 0.06% of V, at most 0.05% of Ti, 0.0010-0.0080% of N, at most 0.50% of Cu, 0.60-1.00% of Cr, at most 0.0105 of Ca and the balance of Fe and inevitable impurities. The formula and the manufacturing method are reasonably designed; and the steel tube has low Bauschinger effect and low strain aging effect, and remains well matching of excellent deformability and excellent toughness.

Owner:ZHENGZHOU UNIV +1

Novel device capable of being used for thin strip tension bending experiment

PendingCN112393988AIntelligent tension controlAchieve bendingMaterial strength using steady bending forcesEngineeringMetal sheet

The invention discloses a novel device capable of being used for a thin strip tension bending experiment, and belongs to the technical field of metal thin plate shape straightening. The novel device comprises tension mechanisms, clamping mechanisms and a bending mechanism. Each tension mechanism comprises a tension linear servo motor part and a tension sensor. Each clamping mechanism comprises a clamping rack, a clamp, a hydraulic mechanism, a sliding block and a guide rail. A bending linear servo motor part and the bending mechanism comprise a bending rack, a bending force sensor, a forward and reverse bending pressure head, a simply supported beam bending module and a three-point bending module. The device has the advantages that: 1, a thin strip, particularly an ultra-thin strip, can besubjected to no-damage pressure-stabilizing clamping; tension control is more intelligent, multiple bending roller sets are arranged, multiple forms of tension bending are achieved, and experimentalconditions are provided for research in the tension bending field; and 3, an alternate bending experiment of a material is carried out to test the Bauschinger effect of the material, and the device has great significance for researching the stretch bending and straightening process of the ultra-thin strip.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

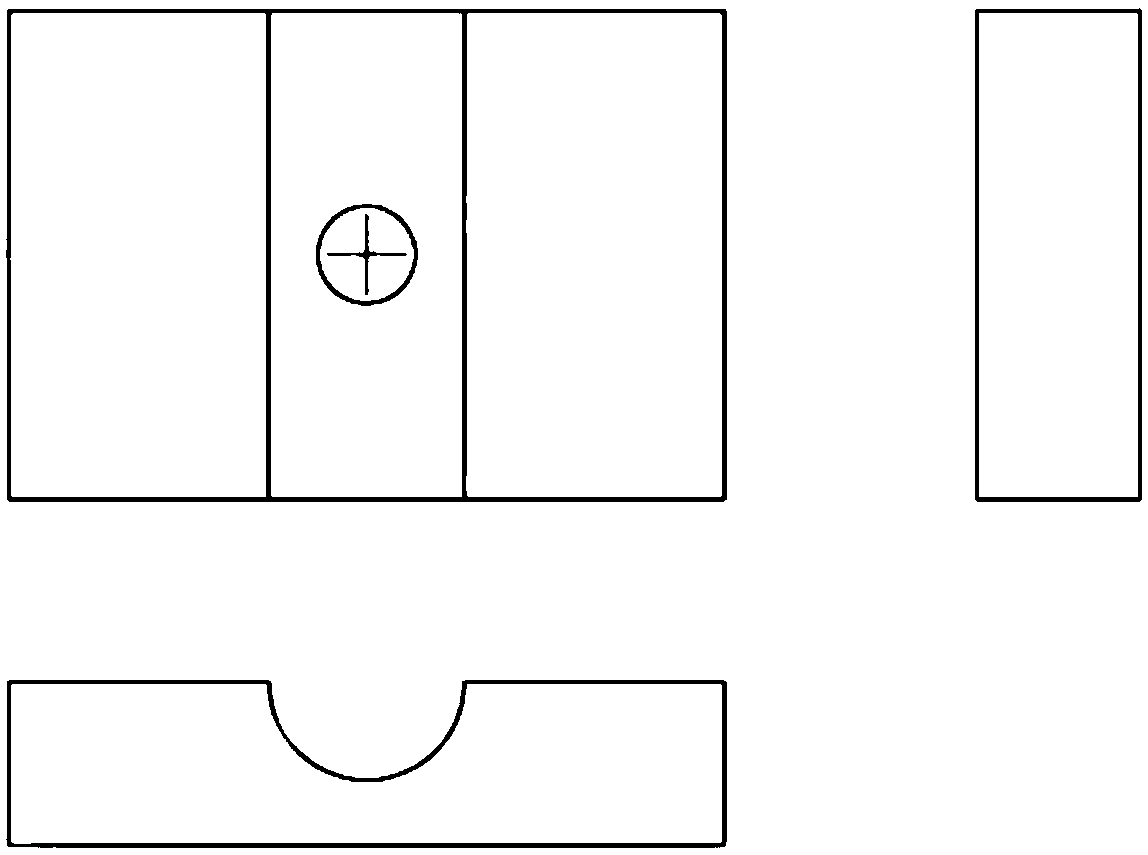

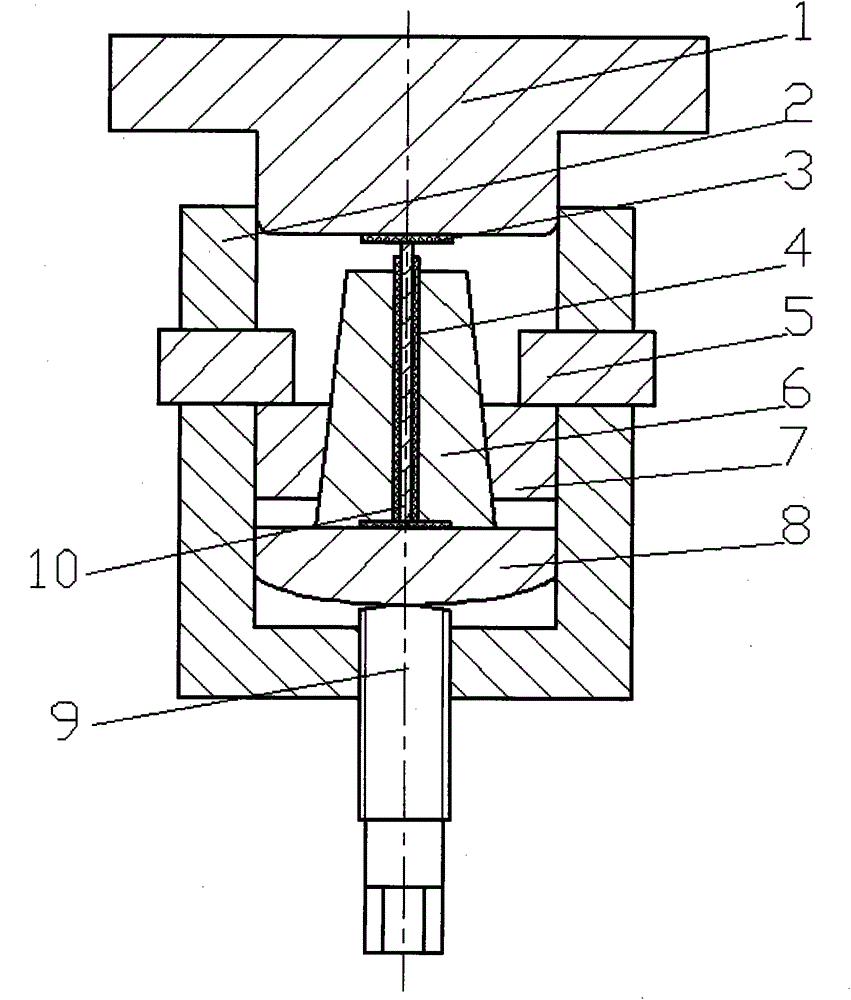

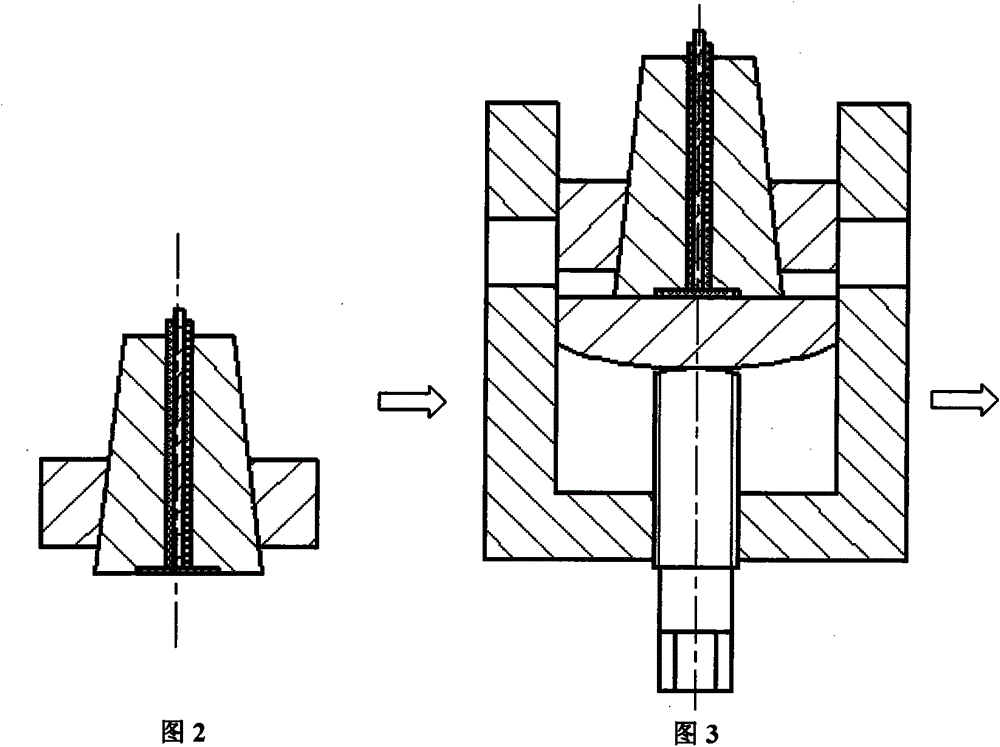

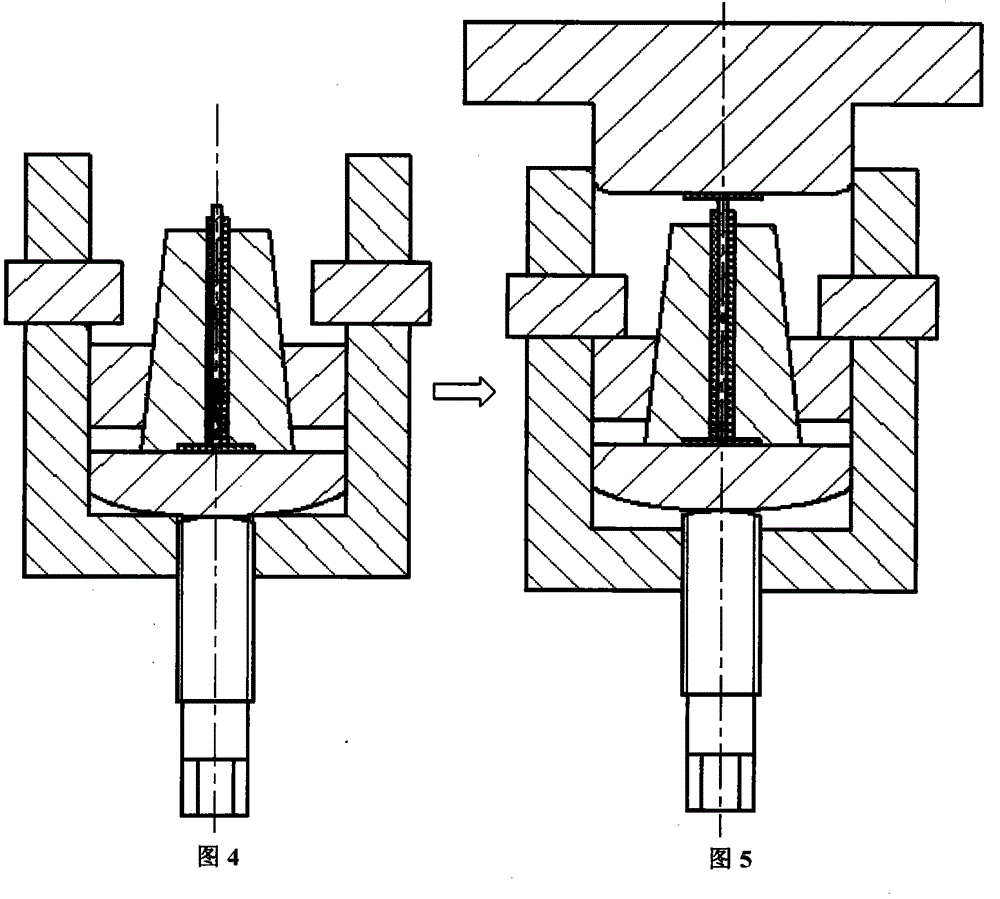

Experimental device for steel plate Bauschinger effect coefficient measurement

InactiveCN103913376ALimit bucklingReduces the effects of compression setMaterial strength using tensile/compressive forcesAxial compressionUltimate tensile strength

The invention relates to an experimental device for steel plate Bauschinger effect coefficient measurement and belongs to the technical field of a material performance test. According to the test, an average value of ratios of compressive yield strength values of a material to corresponding tensile yield strength values is used as a Bauschinger effect coefficient of the materials. In compressive yield strength measurement, when a common sample clamping device is used, a sample can produce untimely unstable buckling in compression and influence caused by factors such as friction can be produced because a metal clamp head directly press tightly sides of the sample. Aiming at solving the above problem, the invention designs the novel experimental device for steel plate Bauschinger effect coefficient measurement. Two sides of a sample 10 are pasted with plastic side pads, then the sample 10 is tightly clamped by tapered pressing blocks 6 acting on two sides of the sample 10 so that unstable buckling of the sample under the pressure is effectively limited, and the plastic side pads have good lubricity so that the influence produced by a frictional force on sample compression deformation is substantially reduced; a tapered ring 7 and the tapered pressing blocks 6 can tightly and reliably clamp the sample by tapered surfaces; and upper and lower surfaces of a pressing block 1 have a high parallel degree and the pressing block 1 and a main cylinder 2 have a high guide precision so that sample axial-compression can be ensured. The experimental device improves the accuracy of compressive yield strength measurement.

Owner:JILIN UNIV

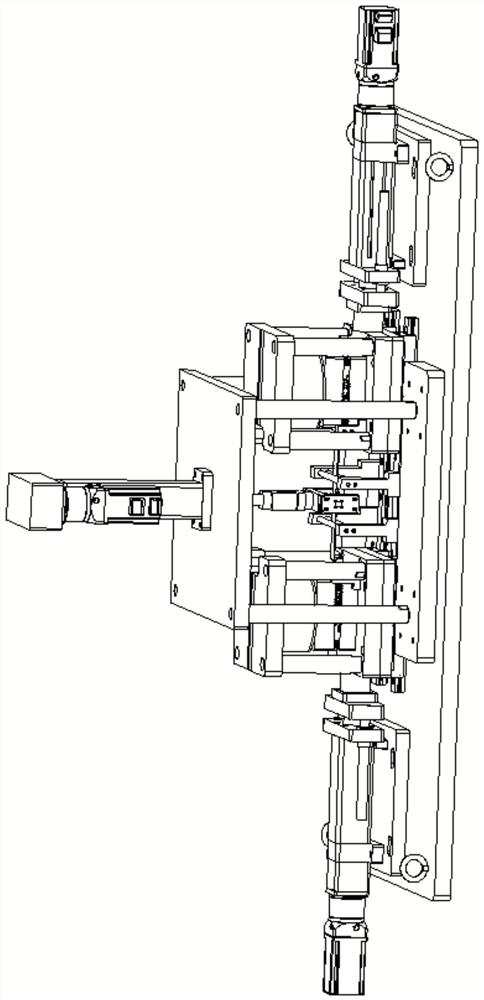

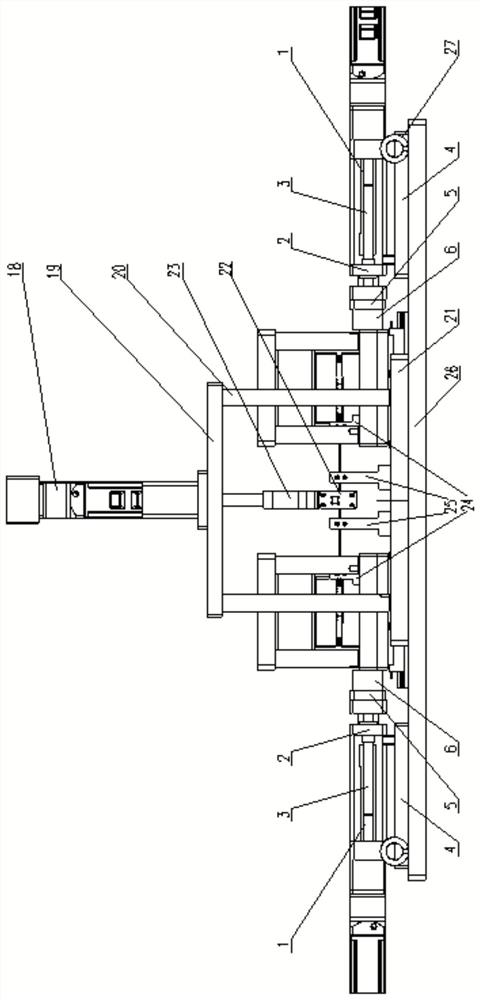

Device and method for precise detection of Bauschinger effect in repeated bending of sheet metal

ActiveCN103592190BRequire flexibilitySimple structureMaterial strength using repeated/pulsating forcesComputer moduleEngineering

The invention relates to an apparatus and method for precisely detecting Bauschinger effect of repeated bending of a metal plate, the apparatus comprises a mechanics loading module and a plate clamping adjustable module fixed at the bottom of the mechanics loading module; the mechanics loading module is fixed and suspended through a testing machine and is vertically arranged, X-direction regulating blocks are symmetrically arranged at left side and right side along X-direction of the mechanics loading module, the front end and rear end of each X-direction regulating block are respectively fixed on the Y-direction regulating blocks, and is capable of respectively being driven by the Y-direction regulating blocks to horizontally slide on a pedestal along the Y-direction back and forth; the operation is easy and has automation function, force and displacement during a loading process can be measured, the coordinate figure, curvature radius and strain value at random point on both surface of the plate during the loading process can be measured, the error of test data is less, and the flexibility requirement of the Bauschinger effect for the plate can be satisfied, so that accurate calibration basis for determining material parameter of Bauschinger effect for the plate can be provided.

Owner:WUHAN UNIV OF TECH

Production method of hot rolled steel strip Q355B for economical welded pipe

ActiveCN113913674AHigh elongation after breakImprove mechanical propertiesTemperature control deviceProcess efficiency improvementManganeseAlloy

The invention discloses a production method of a hot rolled steel strip Q355B for an economical welded pipe. The production method comprises the following steps of precise alloy content design, converter smelting, continuous casting, hot rolling and coiling, wherein the precise alloy content design step is conducted according to the following processes of a, determining the content of a carbon element; b, determining the content of a manganese element, specifically, determining a minimum value of the manganese content according to a manganese-carbon ratio and a manganese-sulfur ratio; and c, determining the content of a titanium element, specifically, calculating the content of the titanium element in steel according to a desired value of the yield strength of a product and a relational expression between the content of the carbon, manganese and titanium elements and the yield strength. According to the method disclosed by the invention, the elongation after fracture of the steel strip is improved and the Bauschinger effect is reduced by means of accurately determining the content of the elements such as carbon, manganese and titanium, controlling the chemical components in a narrow range, controlling the oxygen content in the steel, canceling an LF refining furnace process, increasing the temperature of a heating furnace, reducing the coiling temperature and the like. By adopting the method, the production cost is reduced by about 5.21 yuan / t under the same content of the carbon element, and the mechanical property of the steel strip is superior to that of the prior art.

Owner:德龙钢铁有限公司

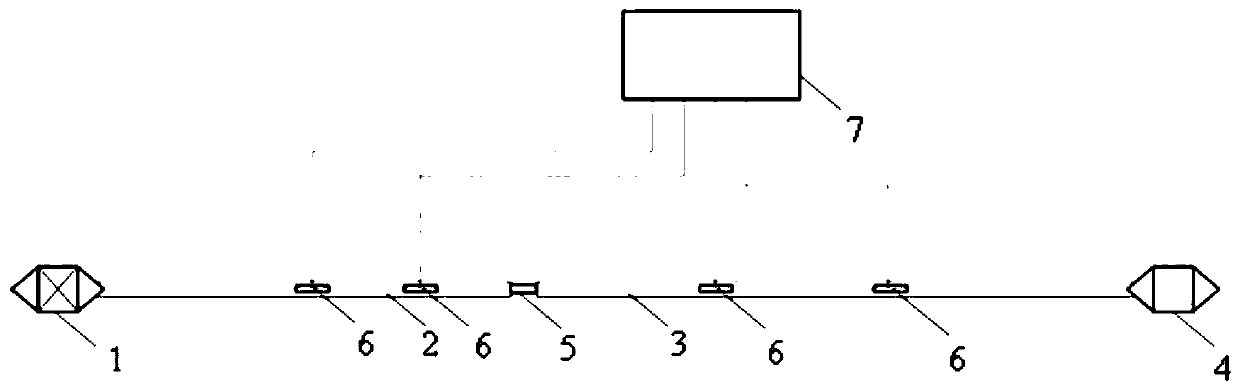

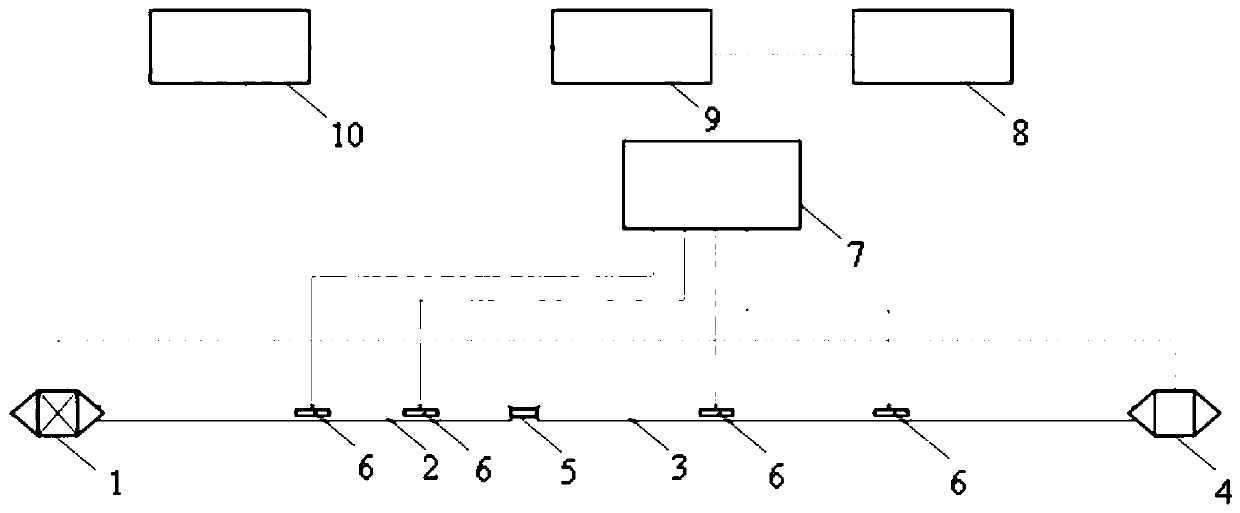

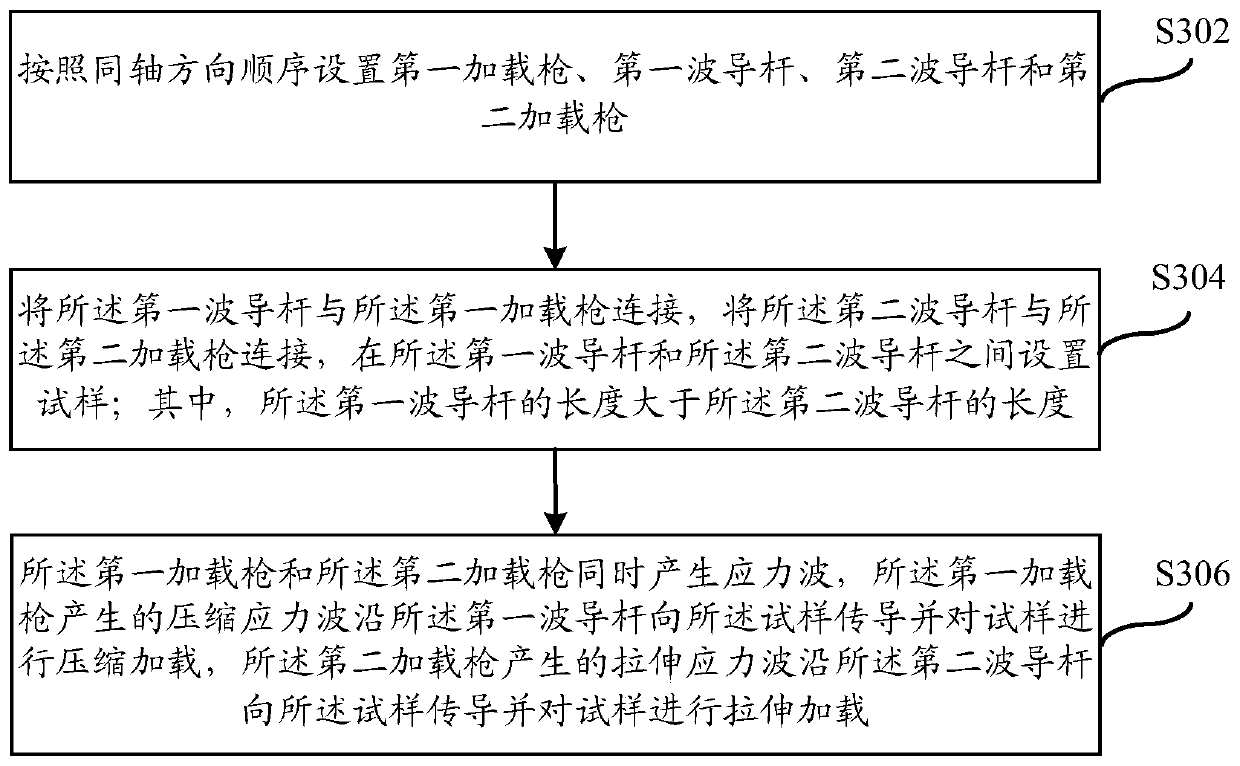

Dynamic uniaxial bidirectional asynchronous loading device and method thereof

ActiveCN111398072ARealize single-axis bidirectional asynchronous loadingStrength propertiesEngineeringWaveguide

The invention discloses a dynamic uniaxial bidirectional asynchronous loading device and a method thereof. The device comprises a first loading gun, a first waveguide rod, a second waveguide rod and asecond loading gun which are coaxially arranged in sequence. The first loading gun is used for emitting a compressive stress wave; the second loading gun is used for emitting a tensile stress wave; the first waveguide rod is connected with the first loading gun, the second waveguide rod is connected with the second loading gun, and a sample is arranged between the first waveguide rod and the second waveguide rod; the length of the first waveguide rod is greater than that of the second waveguide rod; the first loading gun and the second loading gun generate stress waves at the same time, the compression stress waves generated by the first loading gun are conducted to the sample along the first waveguide rod and conduct compression loading on the sample, and the tensile stress waves generated by the second loading gun are conducted to the sample along the second waveguide rod and conduct tensile loading on the sample. According to the invention, the Bauschinger effect of the material under dynamic loading can be obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

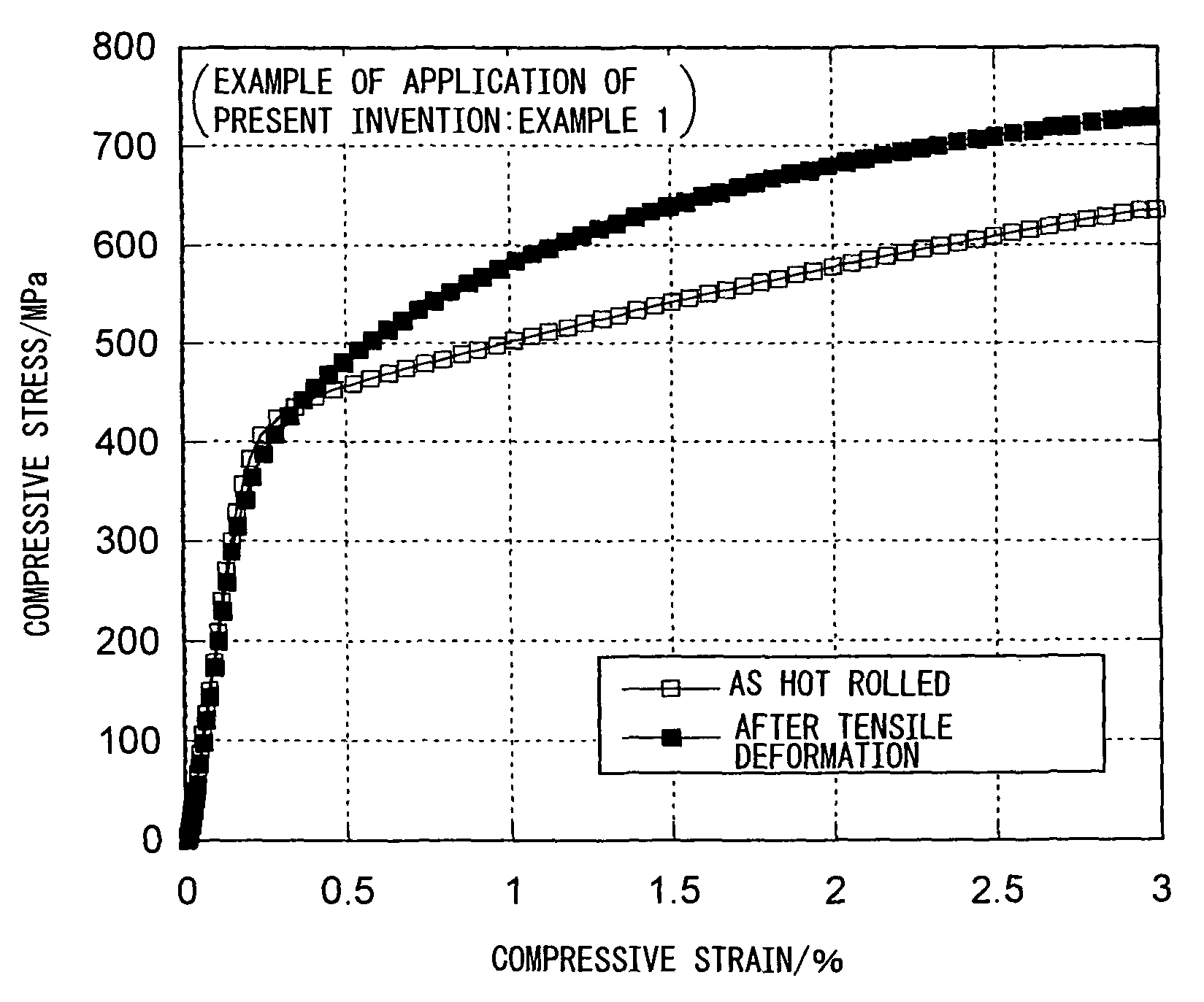

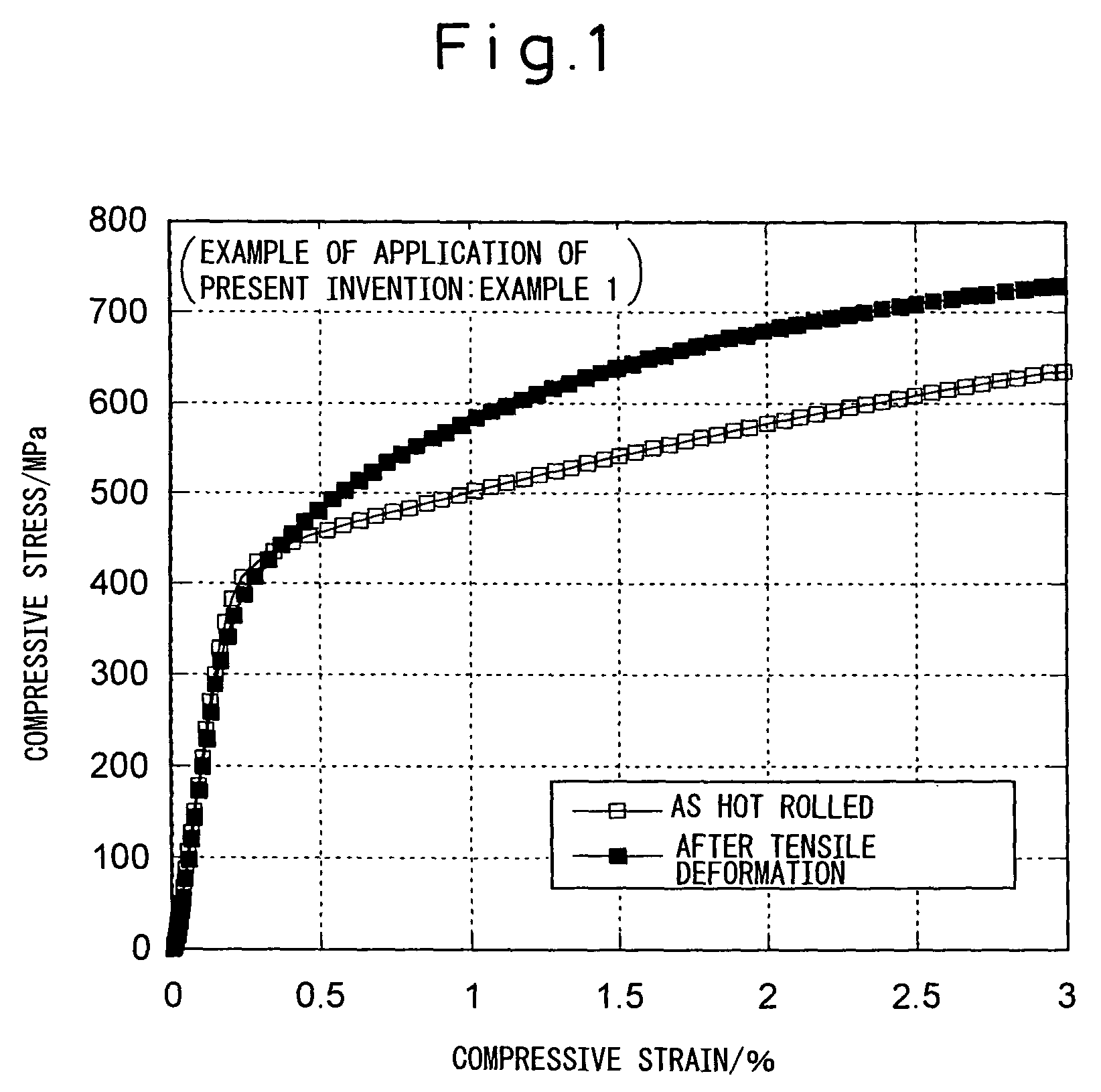

Steel plate or steel pipe with small occurrence of Bauschinger effect and methods of production of same

The present invention provides steel plate or steel pipe with small occurrence of the Bauschinger effect and methods of production of the same, particularly steel pipe used for steel pipe for oil wells or line pipe with a small drop in the compression strength in the circumferential direction due to the Bauschinger effect when expanded and methods of production of the same, that is steel plate or steel pipe with small occurrence of the Bauschinger effect characterized by having a dual-phase structure substantially comprising a ferrite structure and fine martensite which is dispersed in the ferrite structure. Further, this steel plate or steel pipe contains, by mass %, C: 0.03 to 0.30%, Si: 0.01 to 0.8%, Mn: 0.3 to 2.5%, P: 0.03% or less, S: 0.01% or less, Al: 0.001 to 0.01%, and N: 0.01% or less and a balance of iron and unavoidable impurities.

Owner:NIPPON STEEL CORP

A method for selecting casing materials for thermal recovery wells

ActiveCN104632093BAvoid failureGuarantee the safety of useDrilling rodsDrilling casingsPerformance indexEngineering

The invention discloses a thermal recovery well casing material selection method. The casing material selection method comprises the steps of determining the material strength properties and the uniform elongation of a casing material according to the depth of a thermal recovery well; determining the creep rate performance of the casing material according to the steam injection temperature of a wellhead; determining the Bauschinger effect performance of the casing material according to the design life of the thermal recovery well; determining the least low-cycle fatigue strain value of a casing according to the design life of the thermal recovery well and the steam injection temperature of the wellhead; selecting the geometry size and structure characteristics of the casing according to the existing oil industry standards; and selecting the corresponding casing according to the performance indexes, geometry size and structure characteristics of the casing. Multiple performance indexes of the casing material are determined through the well depth, the steam injection temperature of the wellhead, and the design life of the thermal recovery well, and therefore the performance of the casing can be more comprehensively assessed; the casing can meet the production safety requirement on the steam huff and puff working condition; failure caused by plastic deformation of the casing can be effectively avoided; and the normal production of the thermal recovery well is guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A method to improve the Singer effect of non-quenched and tempered bolt ladle

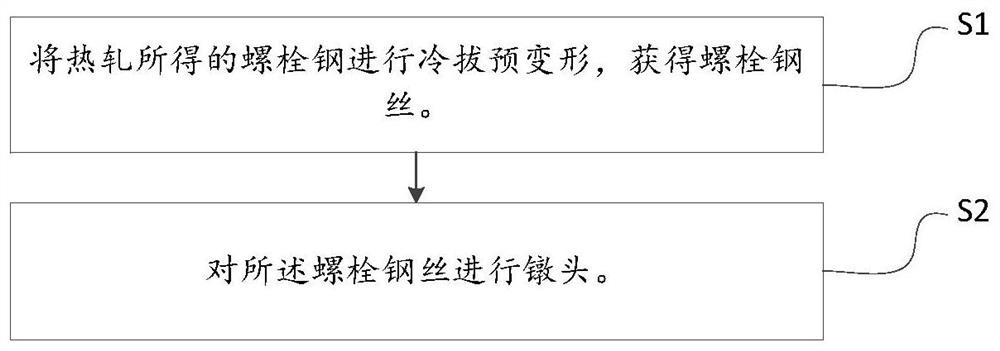

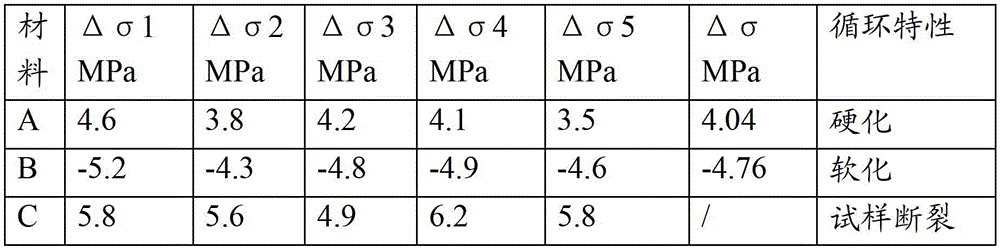

The invention discloses a method for improving the Singer effect of a non-quenched and tempered bolt ladle. The method includes: performing cold drawing pre-deformation on the hot-rolled bolt steel; the amount of cold-drawing pre-deformation is γ 1 ; The steel wire after the cold drawing is carried out heading; The deformation of the heading is γ 2 ; the gamma 1 with gamma 2 Satisfy the relational expression: where δ is the volume percentage of MA components in the metallographic structure of the bolt steel. Adopting a method for improving the Singer effect of the non-quenched and tempered bolt steel ladle provided by the present invention can maximize the Bauschinger effect of the bolt steel, reduce the deformation strength of the heading head after cold drawing of the material, and solve the mold loss in the heading process Big and easy to crack the heading head.

Owner:SHOUGANG CORPORATION

Bauschinger Effect Evaluation Method for Casing in Heavy Oil Steam Huff and Puff Thermal Recovery Wells

ActiveCN104111203BMaterial strength using repeated/pulsating forcesMaterial under testUltimate tensile strength

The invention discloses a method for evaluating the Bauschinger effect of casings used in heavy oil steam huff and puff thermal recovery wells, belonging to the field of oil and gas exploitation, including: S1, measuring the initial yield strength σ of casing materials to be evaluated 0 and tensile strength σ t ; S2, take the casing sample, conduct multiple tension-compression symmetric cycle tests, and measure the yield strength σ of each tension stage 1 , σ 2 , σ 3 , ...; S3, calculate the increment Δσ of the yield strength after each cycle of tension-compression 1 , Δσ 2 , Δσ 3 , ..., define the average value of each yield strength increment as Δσ; S4, according to the formula Δσ T =A×B×ΔσPredict the total increment of yield strength Δσ within the service life of the casing T ; S5, if Δσ is positive, and the formula Δσ T ≤σ t -σ 0 If it is established, the tested casing material is qualified, otherwise it is unqualified; if Δσ is a negative value, and the formula σ 0 +Δσ T ≥σ c If it is established, the tested casing material is qualified, otherwise it is unqualified. By measuring and calculating the average value Δσ of the yield strength increment, the invention visually judges whether the casing material under evaluation belongs to cyclic softening or cyclic hardening, and further judges whether the casing material under test is qualified.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Test sample for measuring plate Bauschinger effect, test fixture and test method

ActiveCN113820206ASimple structureThe testing process is simpleMaterial strength using steady torsional forcesDesign optimisation/simulationTest sampleClassical mechanics

The invention discloses a test sample for measuring the Bauschinger effect of a plate. The test sample specifically comprises the plate, two semi-annular grooves and two grooves, wherein the two semi-annular grooves are located in the plate, the two semi-annular grooves are symmetrically arranged, a clamping area is formed between the two semi-annular grooves, and an acting area is formed outside the two semi-annular grooves; the two grooves are located at the joint of the two semi-annular grooves, and the two semi-annular grooves are located at the joint of the two semi-annular grooves; meanwhile, the invention further discloses a testing clamp and a testing method which are matched with the testing sample and used for measuring the plate Bauschinger effect. The test sample and the test fixture disclosed by the invention are simple in structure, and by combining with the test method, the Bauschinger effect test of the plate is simple, efficient, accurate and easy to use.

Owner:JILIN UNIV

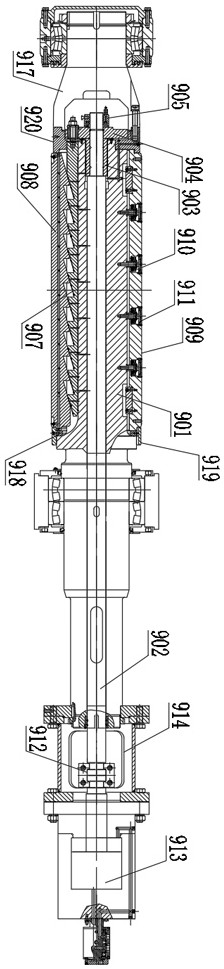

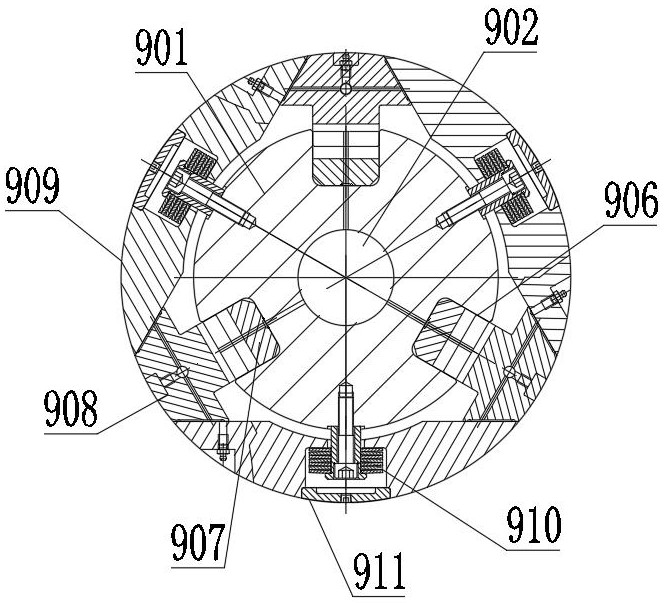

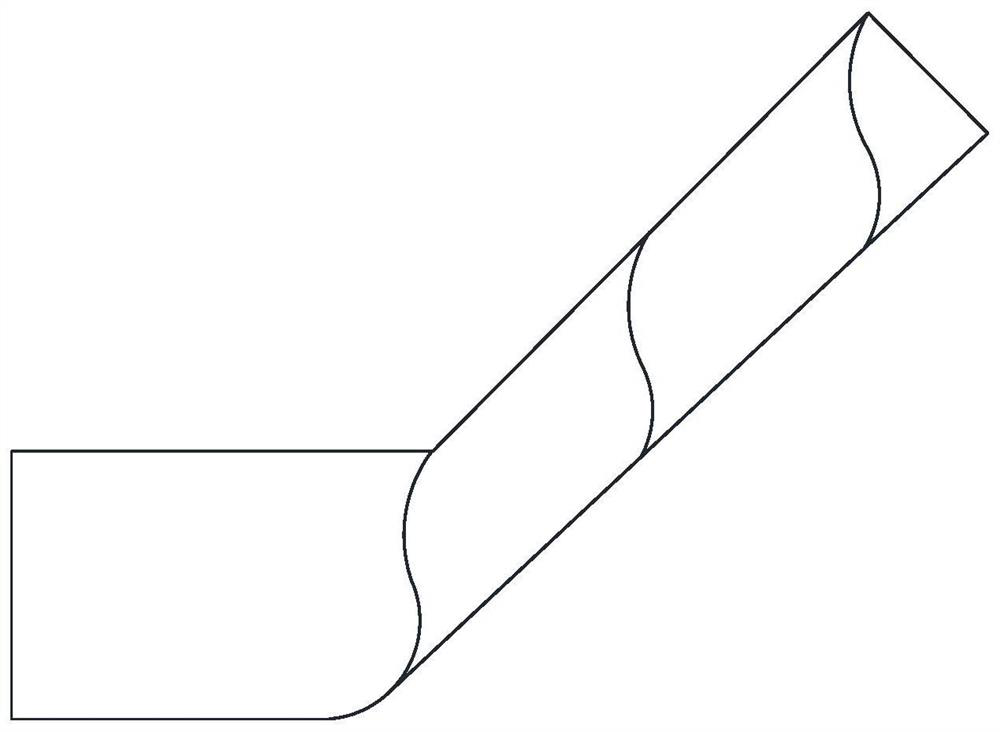

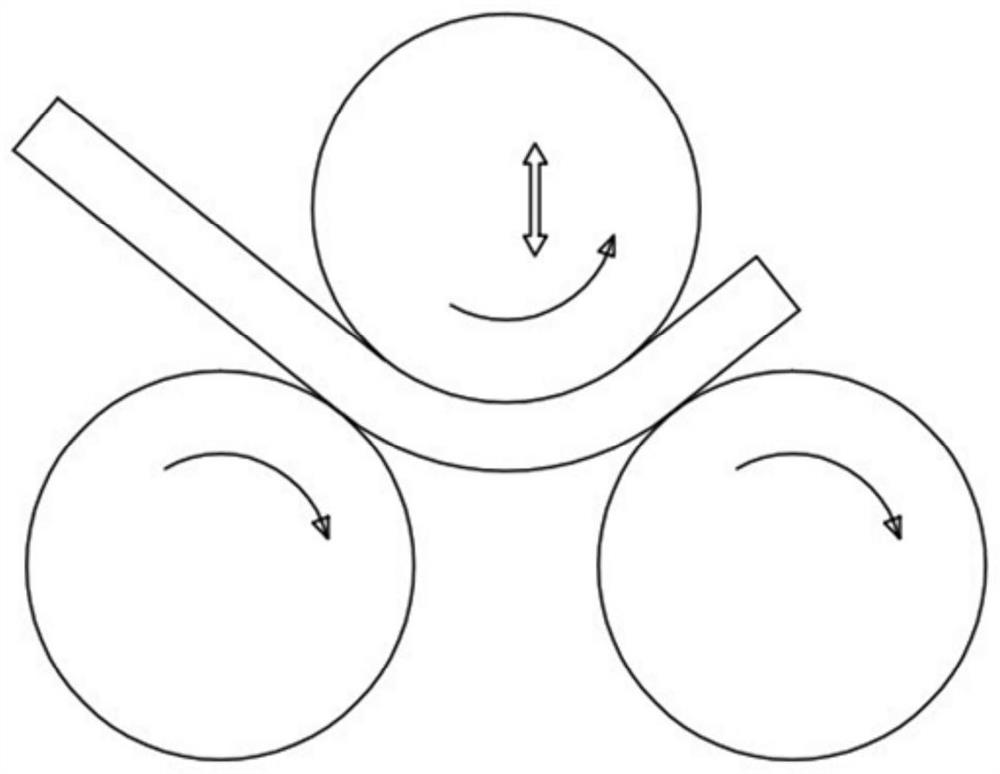

Continuous progressive diameter expansion and rounding device and method for thick-walled metal straight seam welded pipe

ActiveCN113751606BEliminate internal and external stress differencesReduce the Bauschinger effectWork rollStructural engineering

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

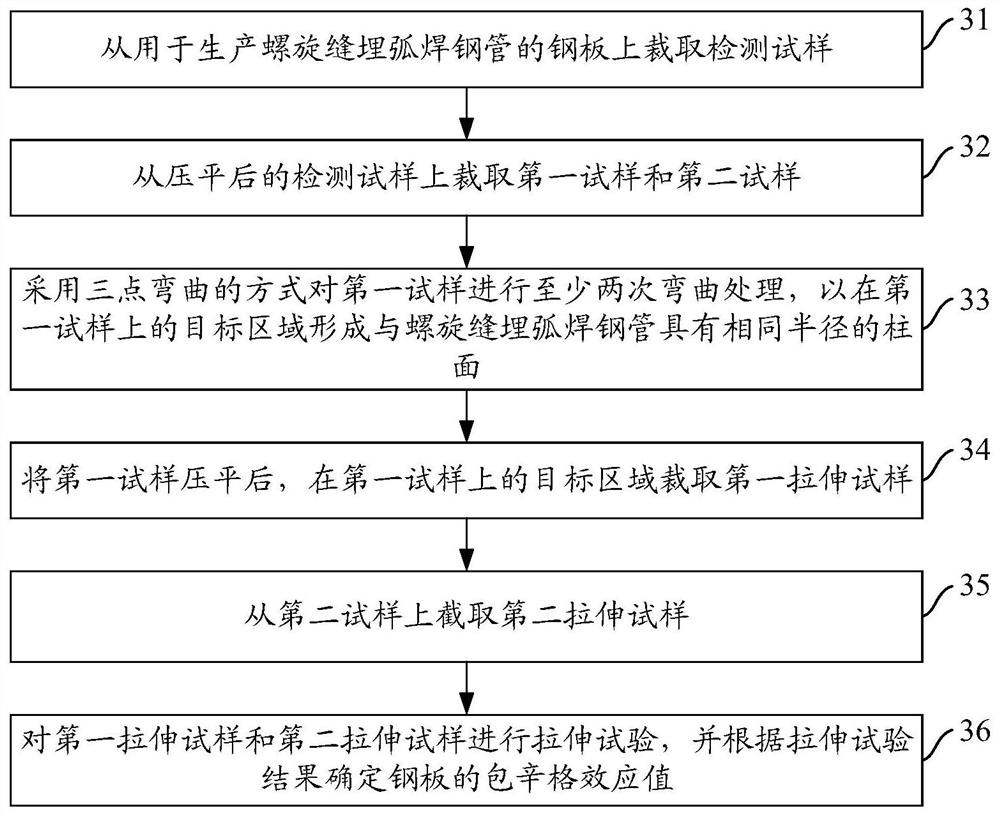

Method for detecting Bauschinger effect value of steel plate for welded pipe

PendingCN114509335AReduce wasteLow costPreparing sample for investigationMaterial strength using tensile/compressive forcesPipeMechanical engineering

The invention provides a method for detecting a Bauschinger effect value of a steel plate for a welded pipe, and belongs to the technical field of steel performance detection. The method comprises the following steps: cutting a detection sample from a steel plate for producing the spiral seam submerged arc welding steel pipe; cutting a first sample and a second sample from the flattened detection sample; the first sample is bent at least twice in a three-point bending mode, so that a cylindrical surface with the same radius as the spiral seam submerged arc welding steel pipe is formed in a target area on the first sample; after the first sample is flattened, a first tensile sample is cut from the target area on the first sample; cutting a second tensile sample from the second sample; and performing a tensile test on the first tensile sample and the second tensile sample, and determining the Bauschinger effect value of the steel plate according to a tensile test result. According to the scheme, the cost for detecting the Bauschinger effect value can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Bauschinger effect test fixture

ActiveUS20220065763A1Solve the real problemMaterial strength using tensile/compressive forcesUltrasonic testingTest fixture

A Bauschinger effect test fixture that cooperates with a test machine for stretching and compressing materials to perform a Bauschinger effect test on a test piece having a symmetrical configuration with two wide ends and a narrow middle part. The fixture includes two identical split bodies, where each split body has a base provided, longitudinally from a central part to one end of the base, with a limiting groove corresponding to a half of the profile of the test piece. Two sides of the groove are arranged symmetrically with a plurality of threaded through holes and a cover is provided along its central axis with two threaded through holes with which the test piece is pressed tightly by bolts. An end of the cover corresponding to a notch of the limiting groove is provided with a through groove configured for placing a stress ultrasonic detection probe on the test piece.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com