Low-Bauschinger-effect low-strain-aging-effect steel tube and manufacturing method thereof

A Bauschinger effect and aging effect technology, which is applied to steel pipes with low Bauschinger effect and low strain aging effect and their manufacturing fields, can solve the problem of reduction of uniform deformation elongation, reduction of deformation capacity of steel pipes, and increase of yield strength ratio of steel pipes. Advanced problems, to achieve the effect of excellent strength and toughness, increased yield strength, and excellent deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical scheme of the present invention is described in further detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto:

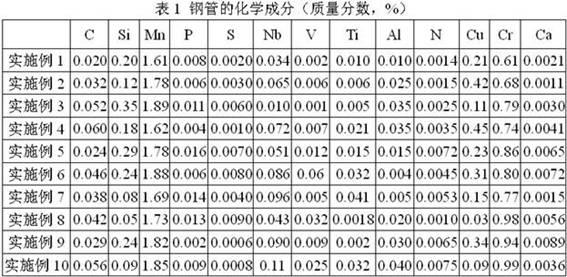

[0035] A steel pipe with low Bauschinger effect and low strain aging effect, the composition and mass percentage of the steel pipe are shown in Table 1.

[0036]

[0037] Manufacturing method:

[0038] The first method consists of the following steps:

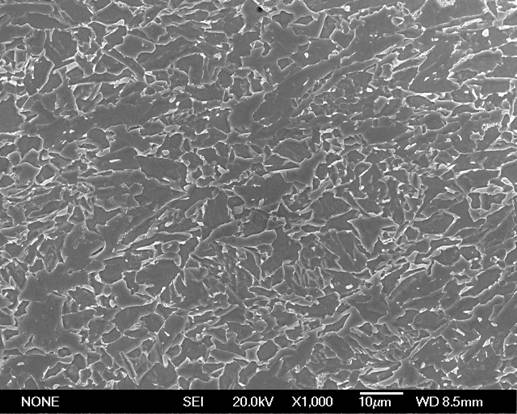

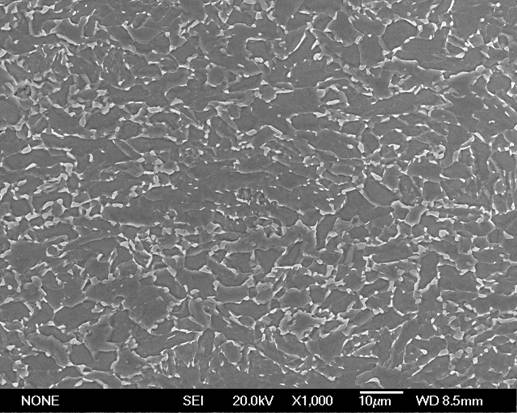

[0039] a) Prepare the steel plates of the various components and mass percentages through molten iron pretreatment, smelting, refining, continuous casting and thermomechanically controlled rolling controlled cooling process, and what obtains now is the acicular ferrite structure (the Acicular ferrite see figure 1 );

[0040] b) The steel plate is formed into a steel pipe by the JCO process;

[0041] c) Welding by straight seam submerged arc welding;

[0042] d) Only heat the pipe body other than the weld seam of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com