Plate stamping springback control method and device

A control method and plate technology, applied in the direction of program control, computer control, general control system, etc., can solve problems such as poor precision of stamping springback control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

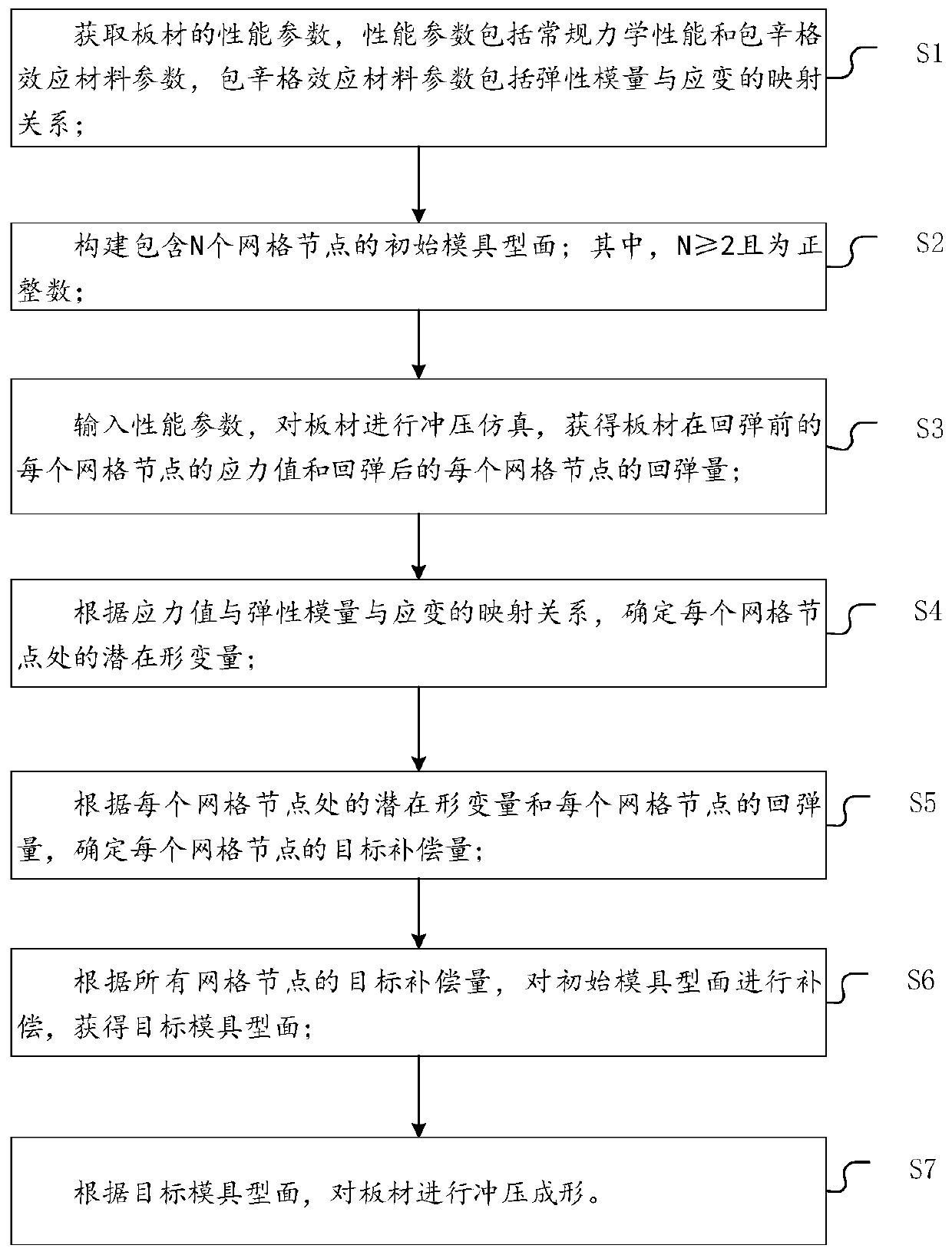

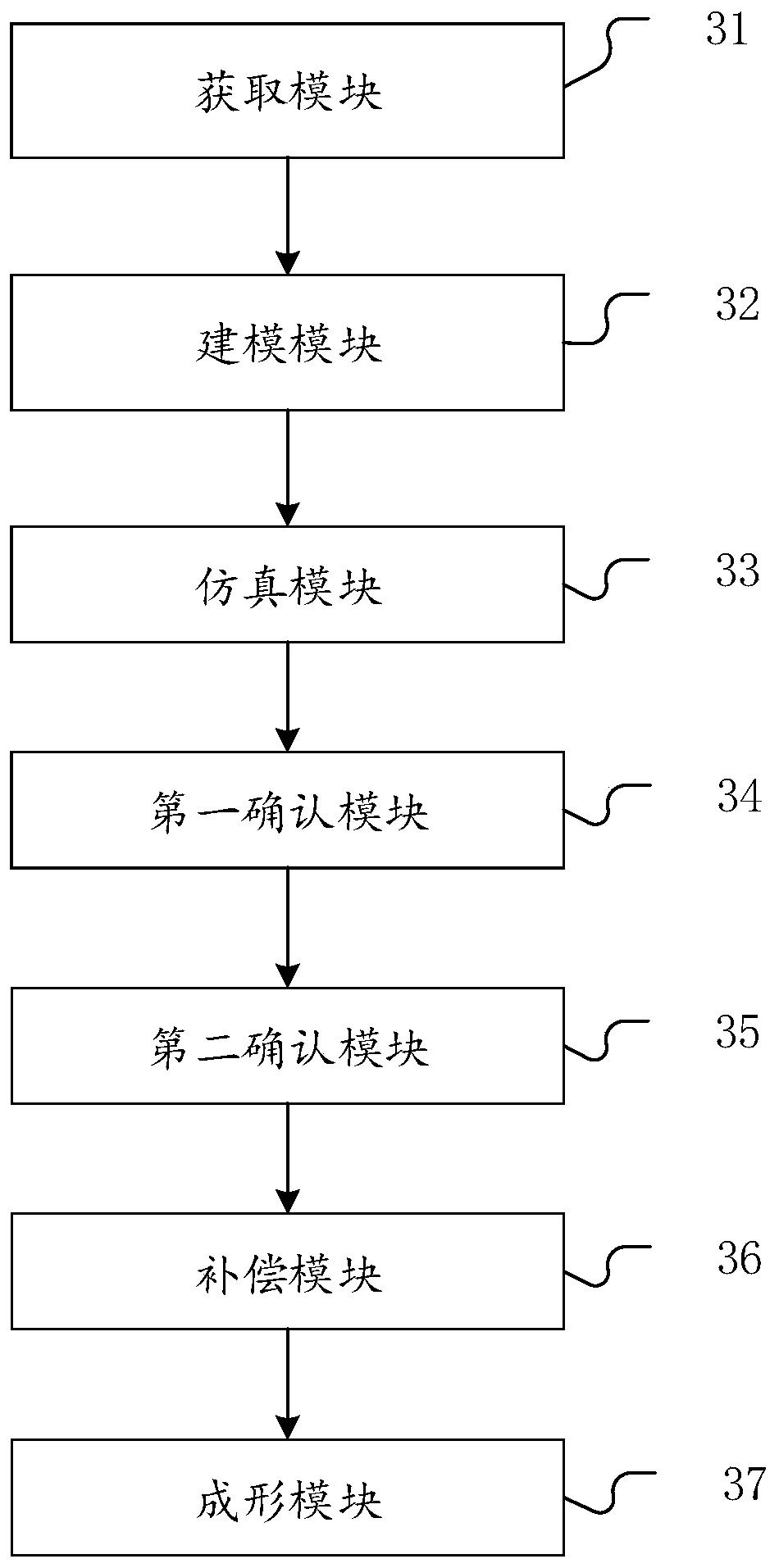

[0060] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

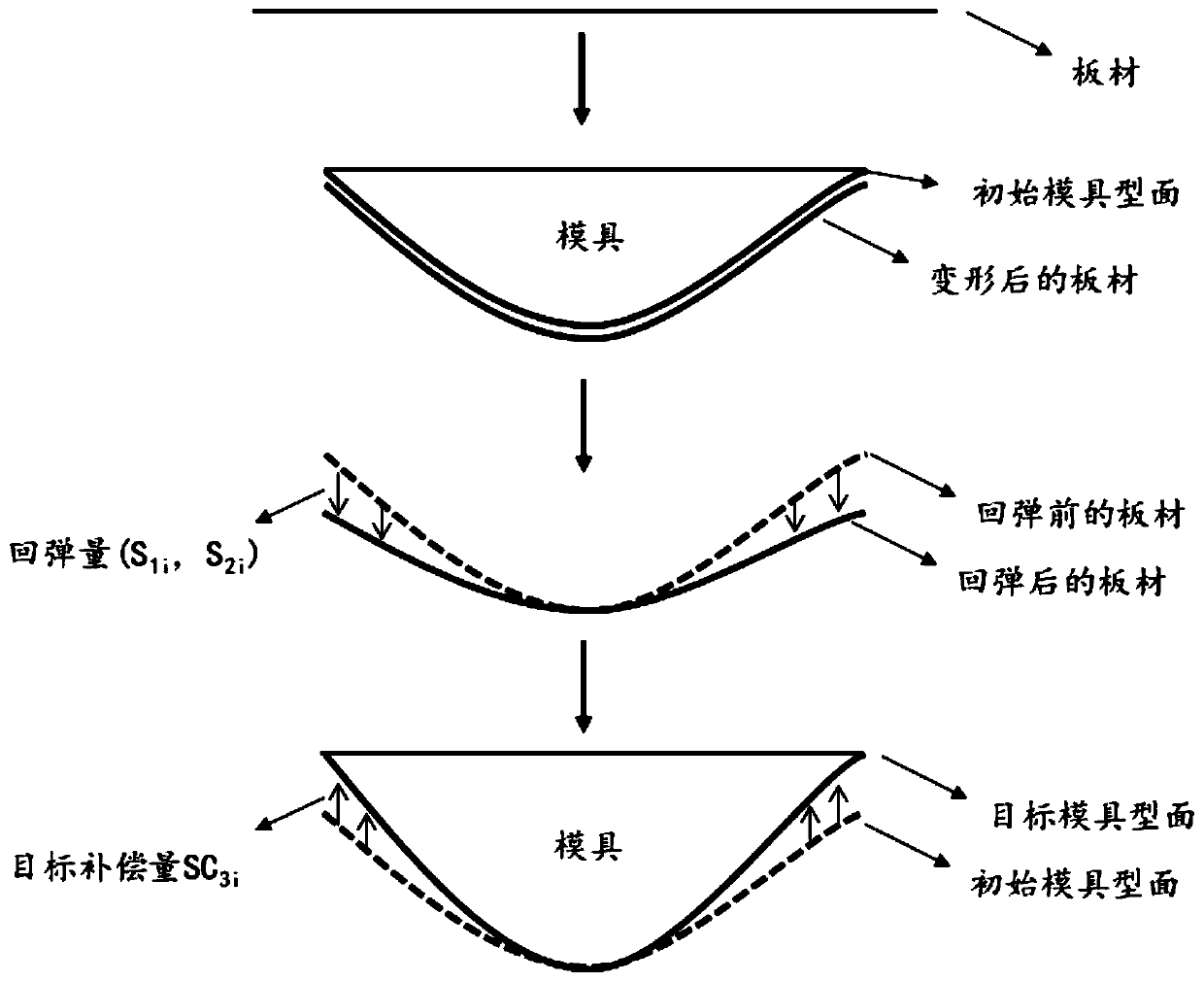

[0061] For the existing springback compensation control scheme, the inventor has obtained the following research findings through a large number of simulations and experiments: the existing springback compensation scheme does not take into account the amount of springback compensation for the mold surface during the stamping process. Stress concentration and stress variation in . In essence, springback is the result of elastic deformation caused by the stress redistribution of the sheet after the mold is unloaded. This stress includes both external stress and internal stress. In the stamping process, the sheet often has stress concentration and stress distribution values. At the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com