Modeling method of plate rolling in online control model

A technology of control model and modeling method, which is applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of long calculation time of finite element method, achieve online fast calculation and control, reduce the number of iterations, Guarantee the effect of convergence speed and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the plate rolling process, since the deformation in the plate width direction relative to the rolling direction is very small and negligible, it can be treated as a plane strain problem. According to above characteristics, the inventive method realizes through the following steps:

[0045] 1. Establish a two-dimensional plane strain rolling model.

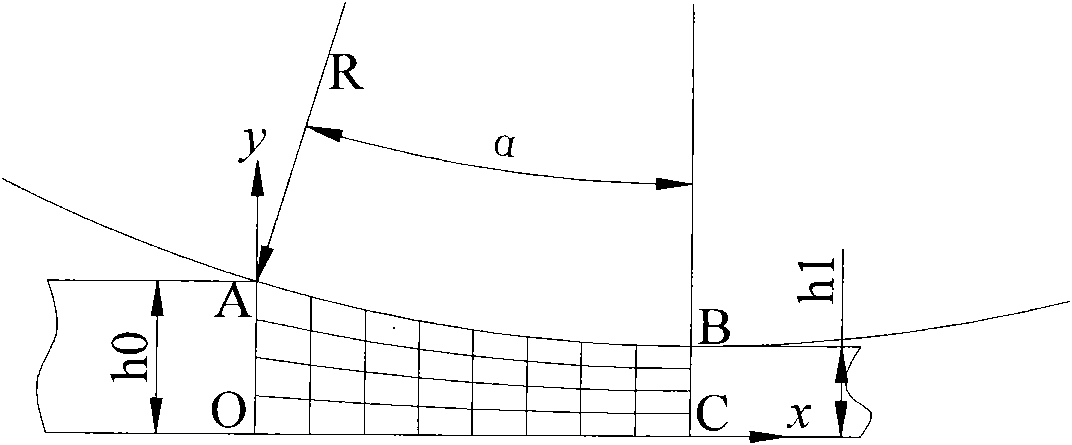

[0046] According to the symmetry of the plate rolling process, the upper half of the plate rolling is taken as the research object. The established finite element model of the plate rolling process is shown in figure 1 shown. In the figure, R is the radius of the roll, h0 is the half-thickness at the entrance of the rolled piece, h1 is the half-thickness at the exit of the rolled piece, α is the rolling bite angle, OC is the center line of the plate as the x-axis, OA is the thickness direction of the plate as the y-axis, β is the contact angle.

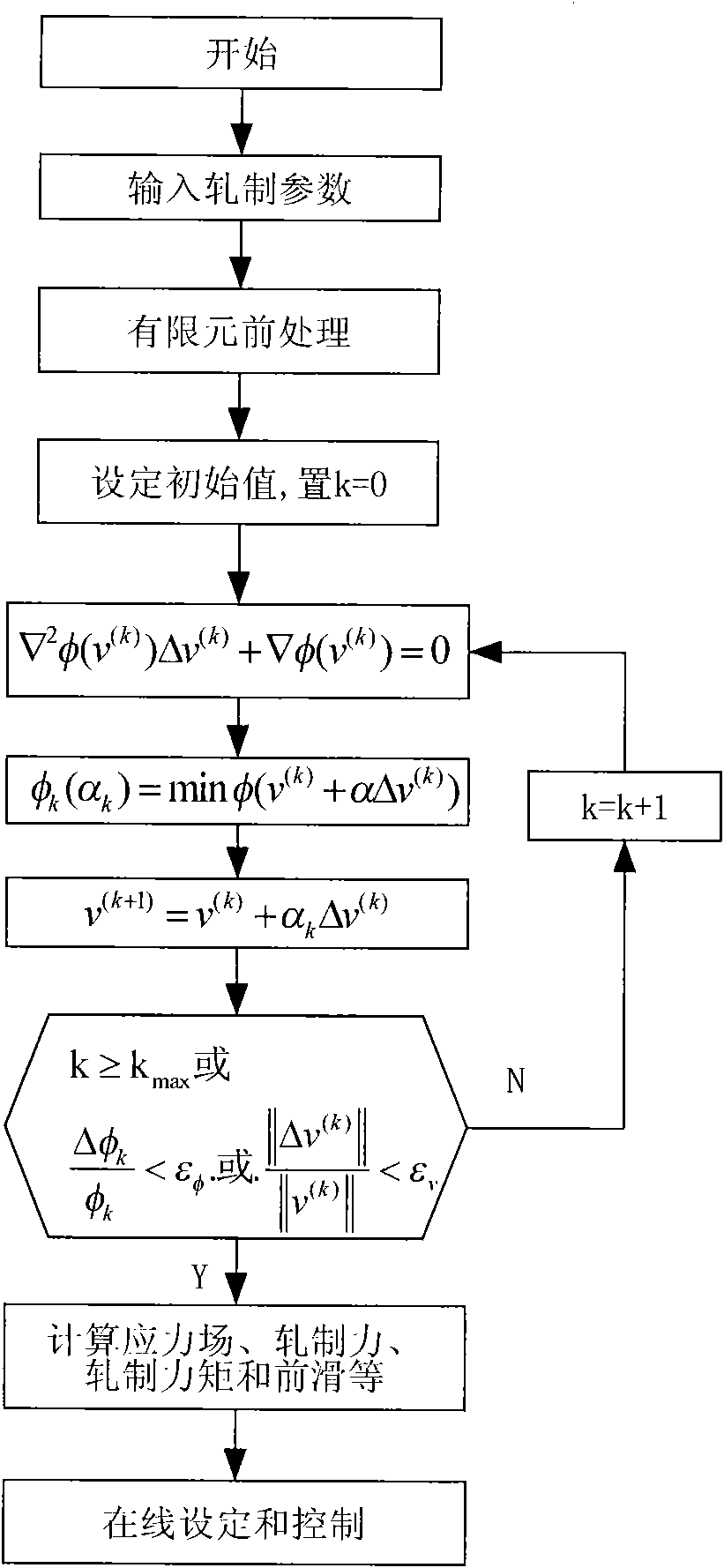

[0047] The next steps are as follows figure 2 As shown, it is a fast c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com