Patents

Literature

52 results about "Quadratic element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modeling method of plate rolling in online control model

InactiveCN101604144ACalculation speedEasy to controlRoll mill control devicesMetal rolling arrangementsModel methodEngineering

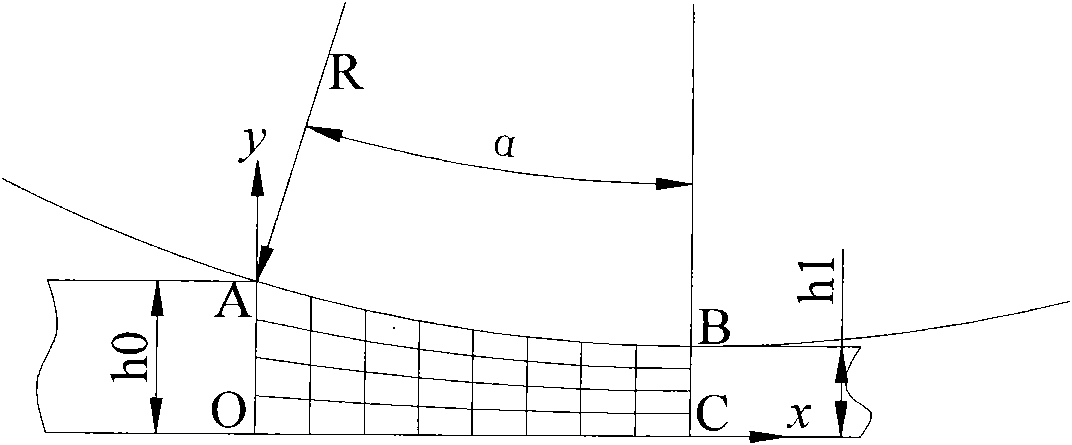

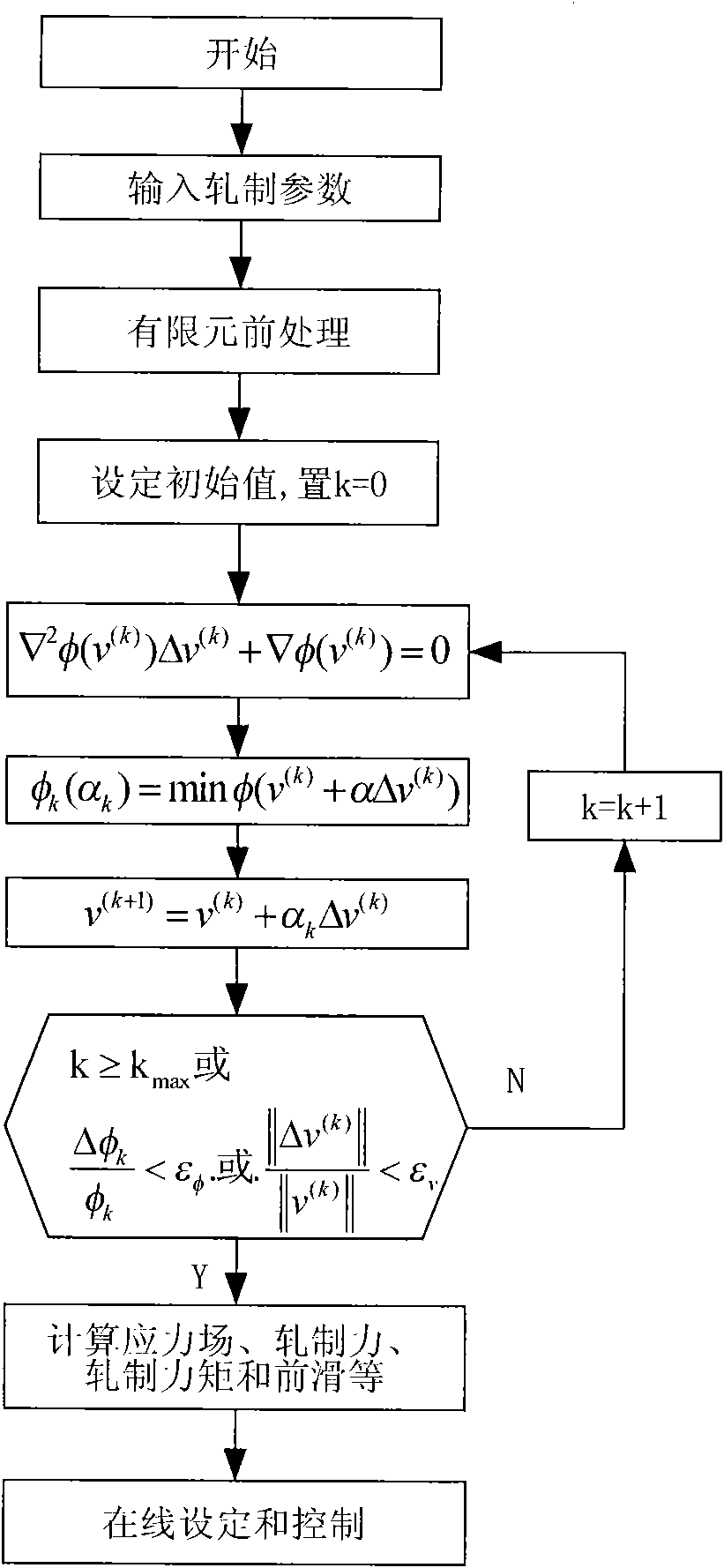

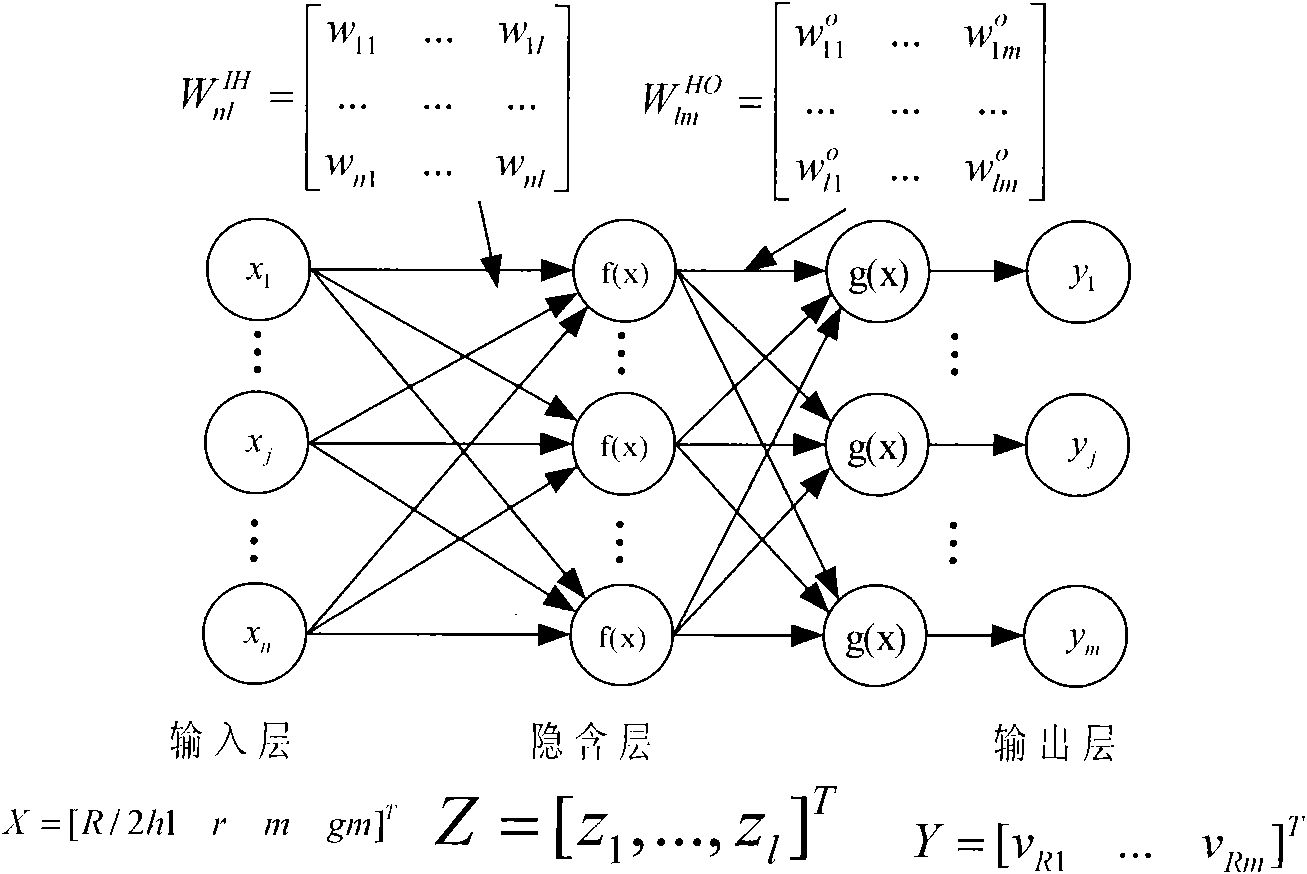

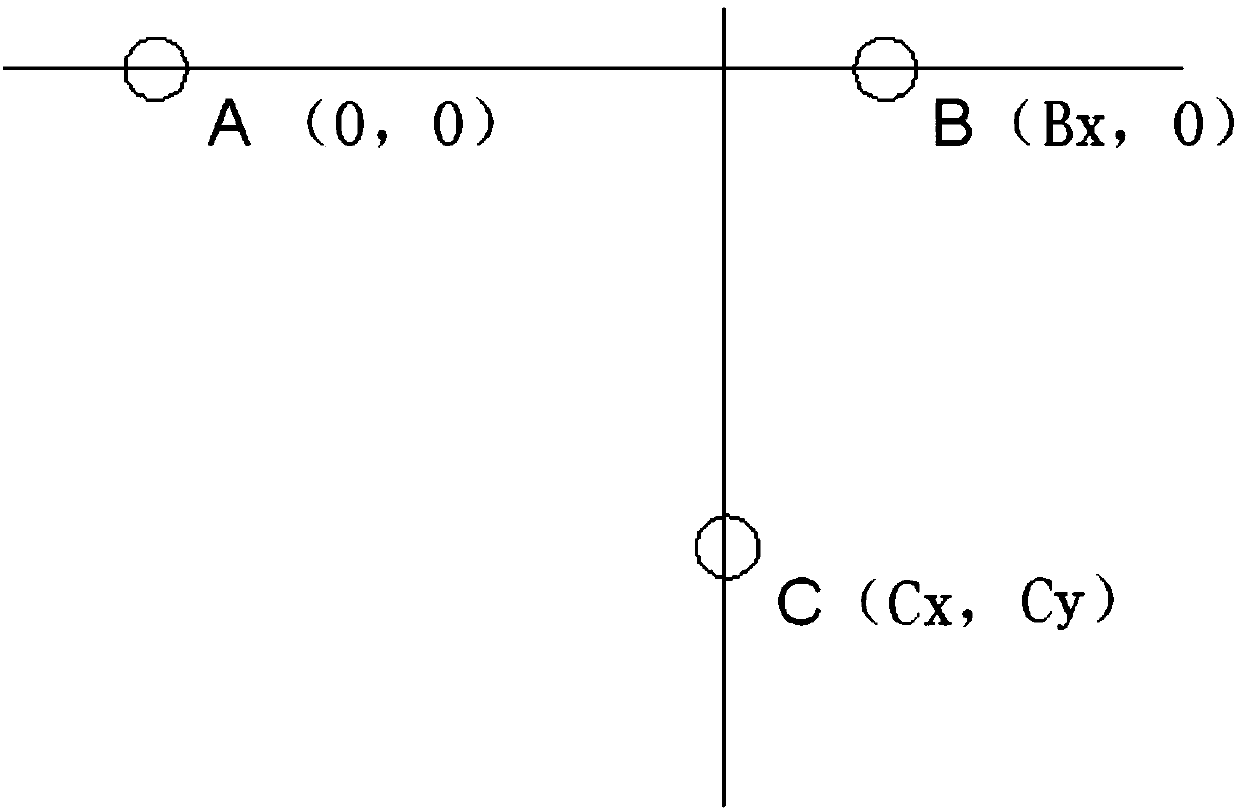

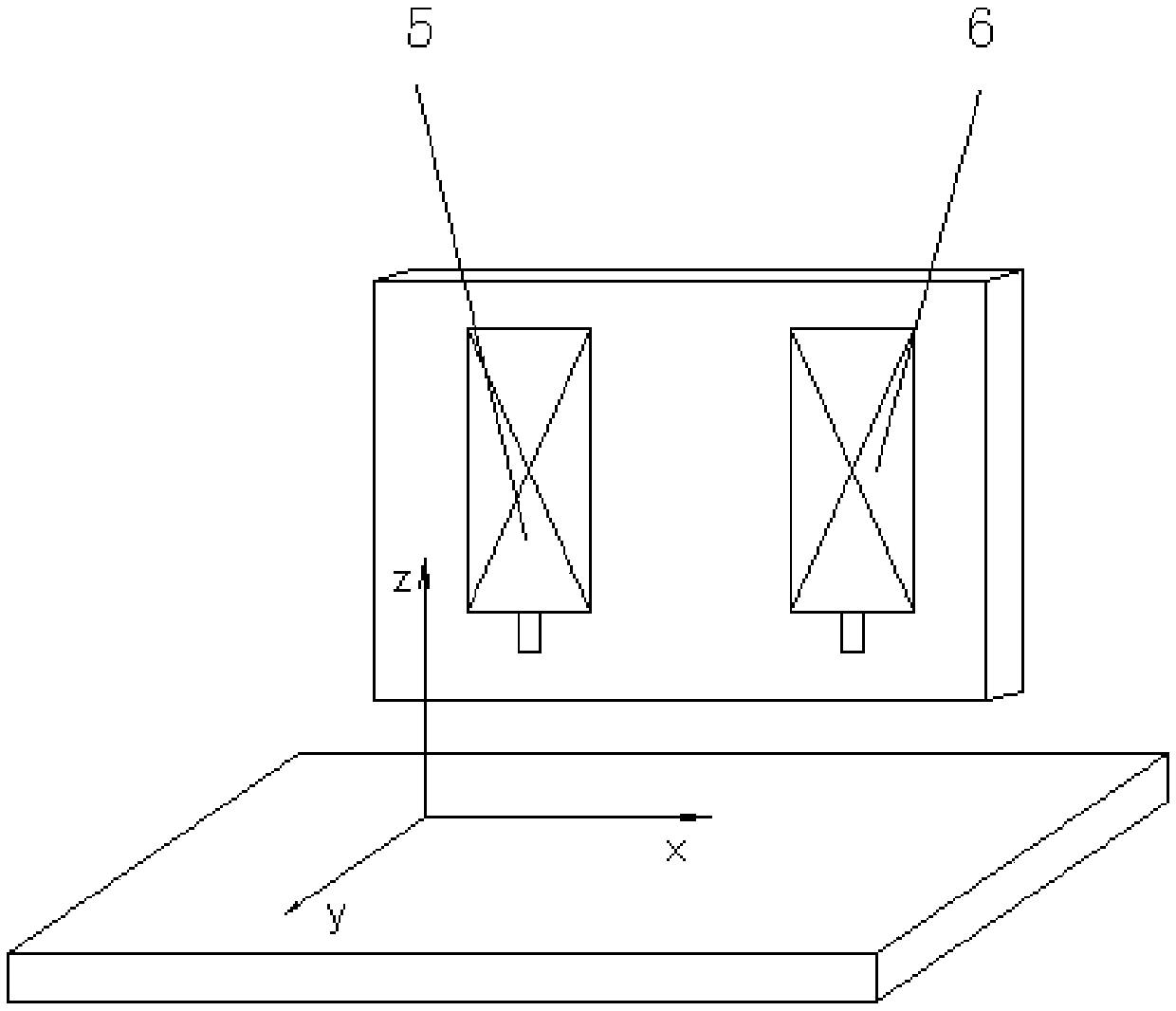

The invention relates to a modeling method of plate rolling in an online control model, which carries out the modeling by a rigid-plastic finite element method. The modeling method comprises the following steps: taking a central line of a plate as an x shaft and the thickness direction of the plate as a y shaft to build a two-dimension plane strain rolling model; inputting rolling conditions and parameters; dividing finite element grids in a rolling deformation region at the lower side of the rolling contact region by adopting a quadratic element and carrying out finite element pretreatment; setting the initial speed field of the finite element; building a rigid-plastic finite element energy functional by taking the initial speed field as an initial value, iterating and solving a minimum value point of the energy functional by adopting the damping Newton method, and obtaining the actual speed field; calculating the strain field and the strain field according to the actual speed field, further calculating online control parameters of the rolling force, the rolling torque and the forward slip value, and obtaining the plate rolling model. The invention improves the calculation speed of the finite element, realizes the online rapid calculation and control of the rigid-plastic finite element of the plate rolling and has strong antijamming capacity and good stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method of preparing aluminum base board short groove holes

ActiveCN103068170AThere is no problem of offset deformationIncrease productivityPrinted circuit manufactureEngineeringQuadratic element

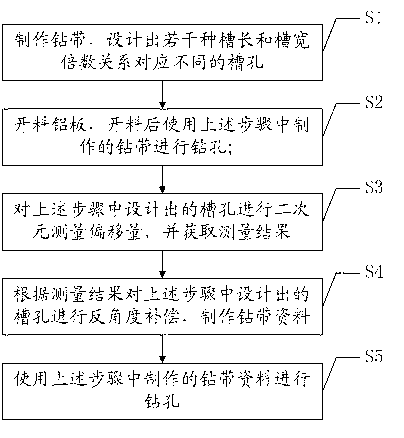

The invention discloses a method of preparing aluminum base board short groove holes. The method of preparing the aluminum base board short groove holes comprises the following steps: due to the fact that multiple relationship range between the length of the groove and the width of the groove is that 1.0 time the width of the groove is smaller than the length of the groove which is smaller than 2.0 times the width of the groove, a plurality of multiple relationships between the length of the groove and the width of the groove, corresponding to different groove holes, are designed. Machined groove holes, after cutting an aluminium sheet, served as a drilling belt to drill, and the offset of the drilling result is measured through quadratic element. According to an acquired measure result, the designed groove hole is compensated in reverse angle to make drilling belt data. Drilling is performed according to the drilling belt data. Targeted on procession drilling belt of the short groove hole, according to the proportional relationship between the length of the groove hole and the width of the groove hole, certain angle is compensated, and therefore the drilled groove hole is prevented from skewing and deforming. And guiding hole drilling hole is not needed, production efficiency and production quality is greatly improved, and production cost is reduced.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

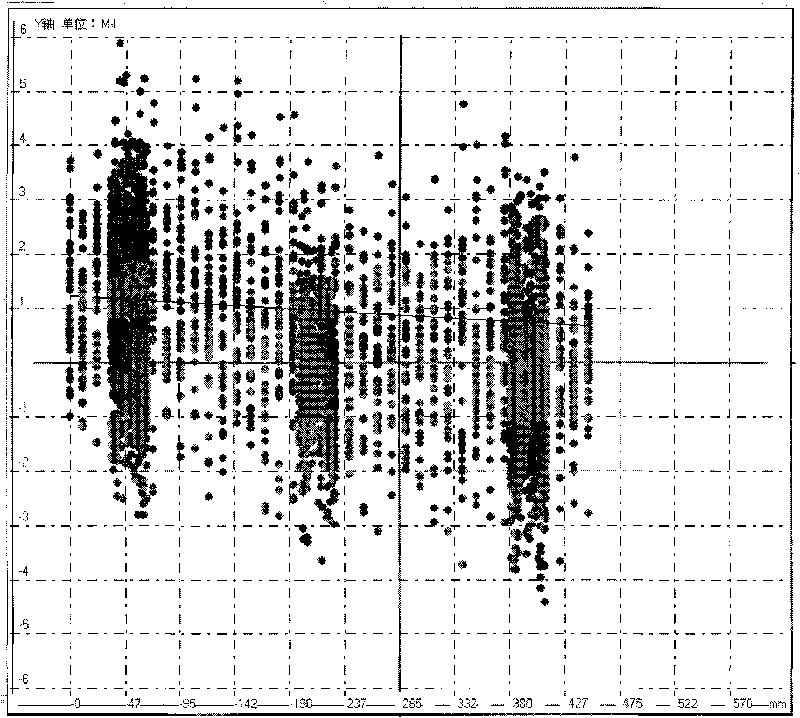

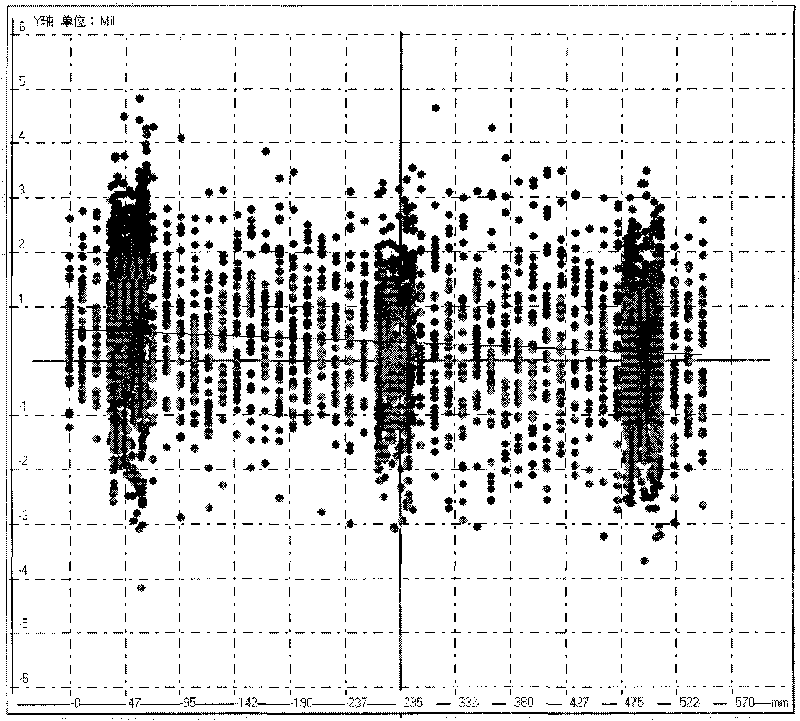

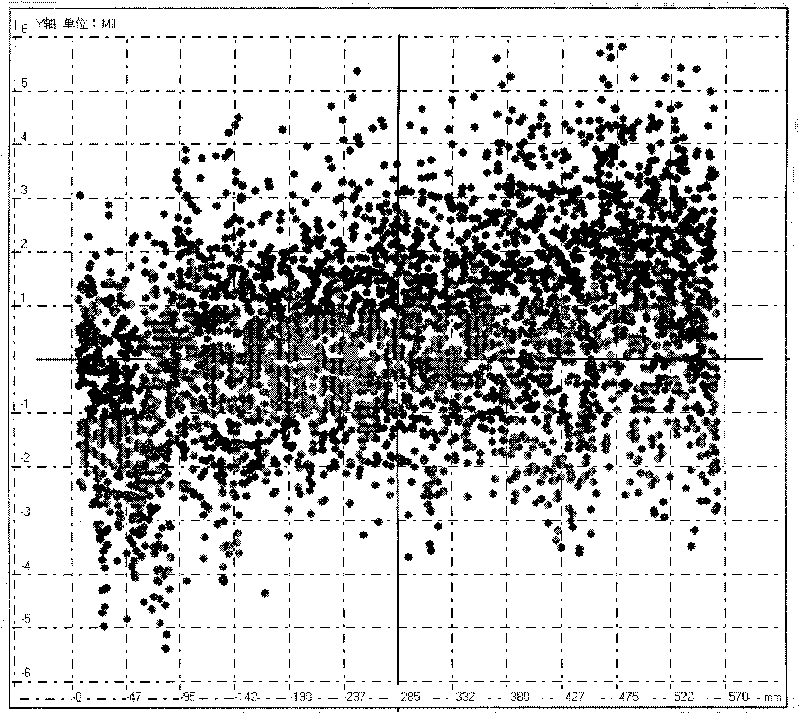

Method for analyzing borehole deviation of PCB drilling machine

ActiveCN101726245AHighlight substantive featuresEasy to analyzeUsing optical meansMeasuring instrumentAnalysis method

The invention relates to a method for analyzing the borehole deviation of a PCB drilling machine, comprising the following steps of: firstly, measuring the hole site of a borehole by using equipment to acquire corresponding hole site data; secondly, introducing the hole site data to analysis software; and finally, generating a scatter graph by using the hole site data, analyzing the deviation through the scatter graph, or generating a trend line through the scatter graph firstly and than analyzing the deviation through the trend line. The invention can most intuitively analyze through the hole site data acquired by a quadratic element measuring instrument; a target graph, a scatter graph and a trend graph can be simultaneously formed by using software; the whole analysis process is quite simple and convenient; and technicians can judge and draw a conclusion without accumulating plenty of practical experience or measuring the PCB drilling machine repeatedly to grope the root source of problems. The method not only can shorten the analysis time, but also can greatly improve the analysis precision.

Owner:SUZHOU VEGA TECH CO LTD

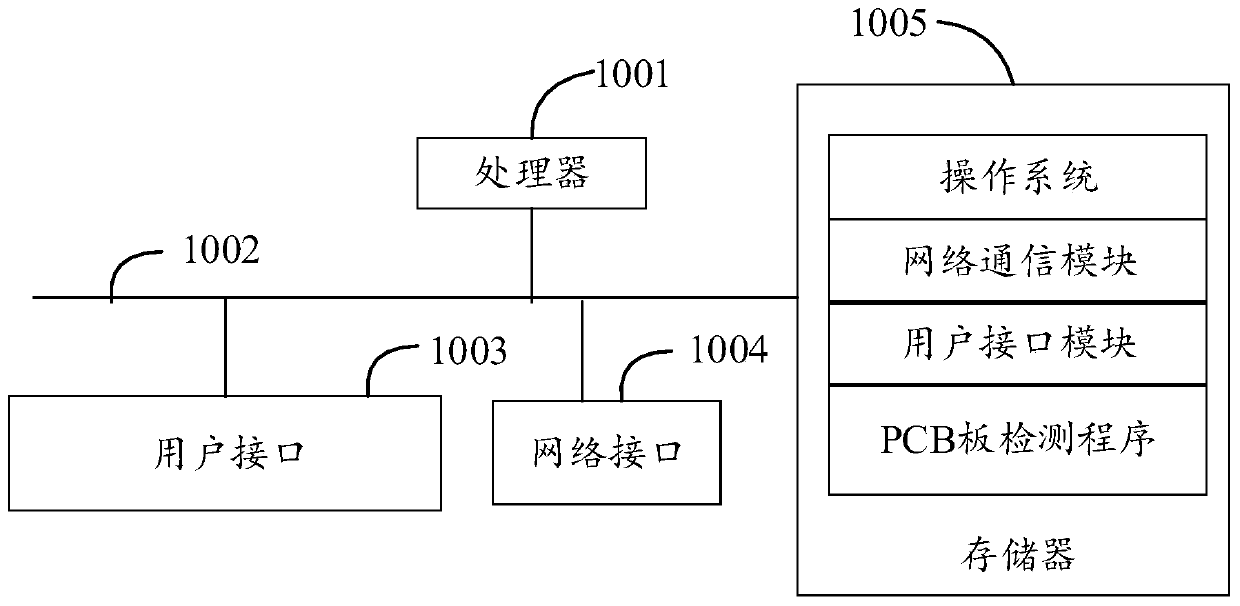

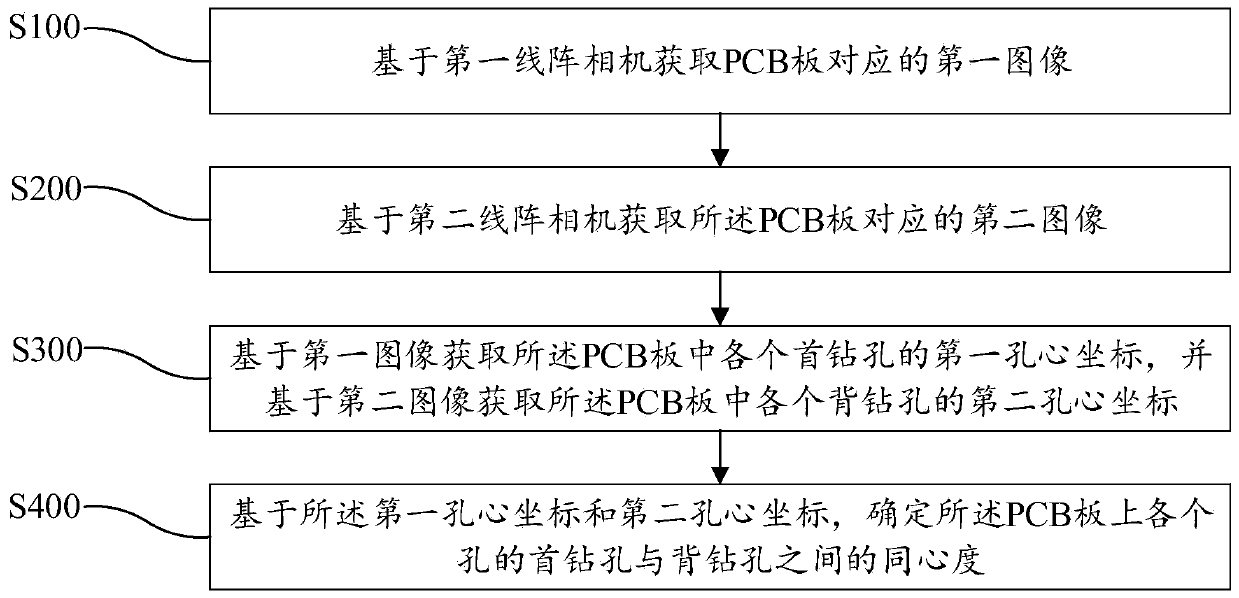

PCB detection method and device and computer readable storage medium

PendingCN109919919AImprove test efficiencyImprove test accuracyImage analysisOptically investigating flaws/contaminationQuadratic elementComputer science

The invention discloses a PCB detection method. The method comprises the steps of obtaining a first image corresponding to a PCB based on a first linear array camera; Acquiring a second image corresponding to the PCB based on a second linear array camera; Obtaining a first hole center coordinate of each first drill hole in the PCB based on the first image, and obtaining a second hole center coordinate of each back drill hole in the PCB based on a second image; And based on the first hole center coordinate and the second hole center coordinate, determining the concentricity between the first drill hole and the back drill hole of each hole in the PCB. The invention also discloses a PCB detection device and a computer readable storage medium. The concentricity of the PCB back drilled hole andthe first drilled hole is detected through image recognition, the concentricity of all the back drilled holes and the first drilled hole in the PCB can be detected at the same time through the firstimage and the second image, and the problem that manual quadratic element detection is low in efficiency is solved.

Owner:SHENZHEN EAGLE EYE ONLINE ELECTRONICS TECH

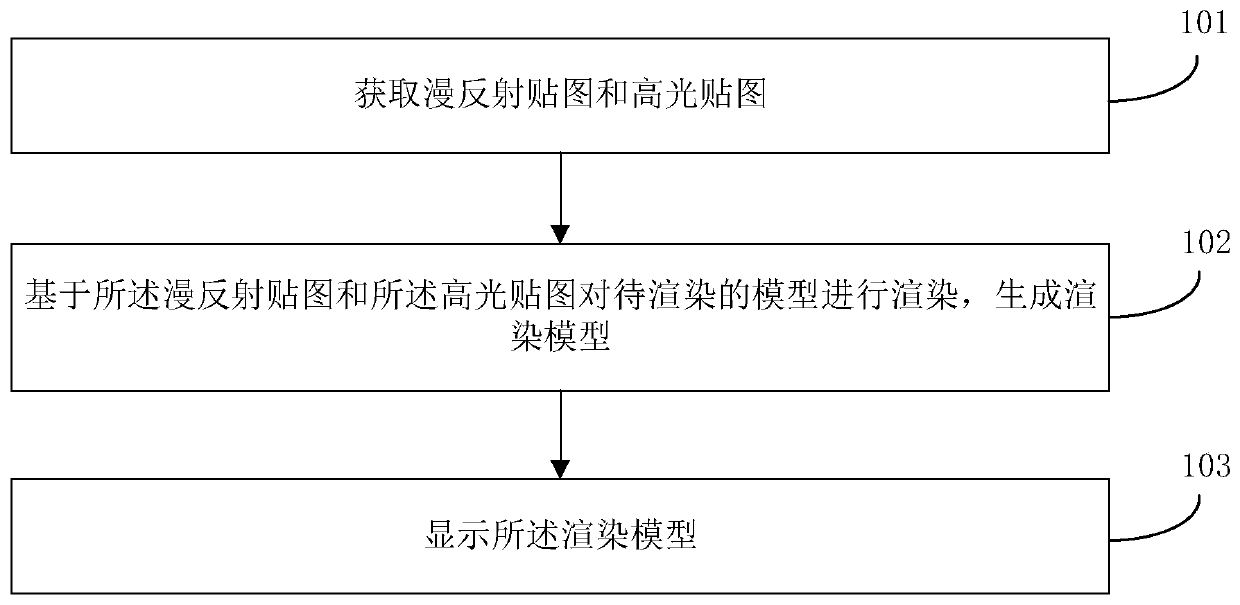

Model rendering method and device, storage medium and terminal

The embodiment of the invention discloses a model rendering method and device, a storage medium and a terminal. The method comprises the following steps that: acquiring a diffuse reflection map and ahighlight map; rendering a model to be rendered based on the diffuse reflection map and the highlight map to generate a rendered model; displaying the rendered model. By means of the technical schemes, the rendered model can dynamically show the specific diffuse reflection effect and highlight effect of quadratic elements, the rendering effect of the model is effectively improved, and the renderedmodel is more vivid and vivid.

Owner:SHANGHAI MIHOYO TIANMING TECH CO LTD

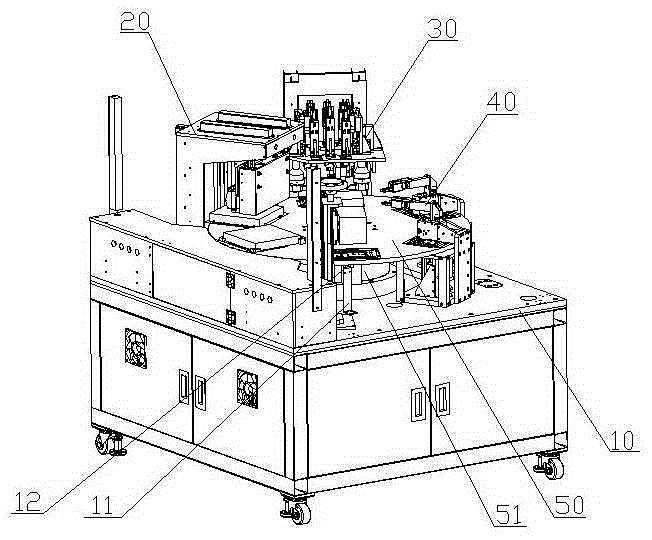

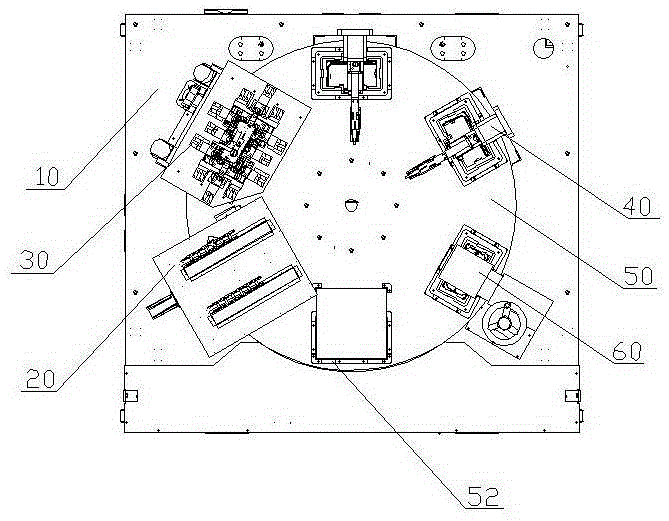

Tempered glass quality automatic detection device

The present invention belongs the glass quality detection field, especially relates to a tempered glass quality automatic detection device. The tempered glass quality automatic detection device comprises a workbench, a flatness and thickness detection mechanism, a quadratic element detection mechanism, a stress detection mechanism, a delivery mechanism and a control mechanism, wherein the flatness and thickness detection mechanism, the quadratic element detection mechanism, the stress detection mechanism, the delivery mechanism and the control mechanism are arranged on the workbench. The flatness and thickness detection mechanism, the quadratic element detection mechanism and the stress detection mechanism are uniformly distributed at the periphery of the delivery mechanism. The flatness and thickness detection mechanism, the quadratic element detection mechanism, the stress detection mechanism and the delivery mechanism are connected with the control mechanism. When the quality of glass is detected through the adoption of the tempered glass quality automatic detection device, workers only dispose the glass to be detected onto the delivery mechanism, the control mechanism is configured to control the transmission of the delivery mechanism, and the glass to be detected is delivered to each detection mechanism along with the delivery mechanism, therefore the quality detection of the glass is completed. According to the invention, the automatic detection is realized, the manual intervention time is decreased, and plenty of labors are saved.

Owner:SUZHOU PTC OPTICAL INSTR

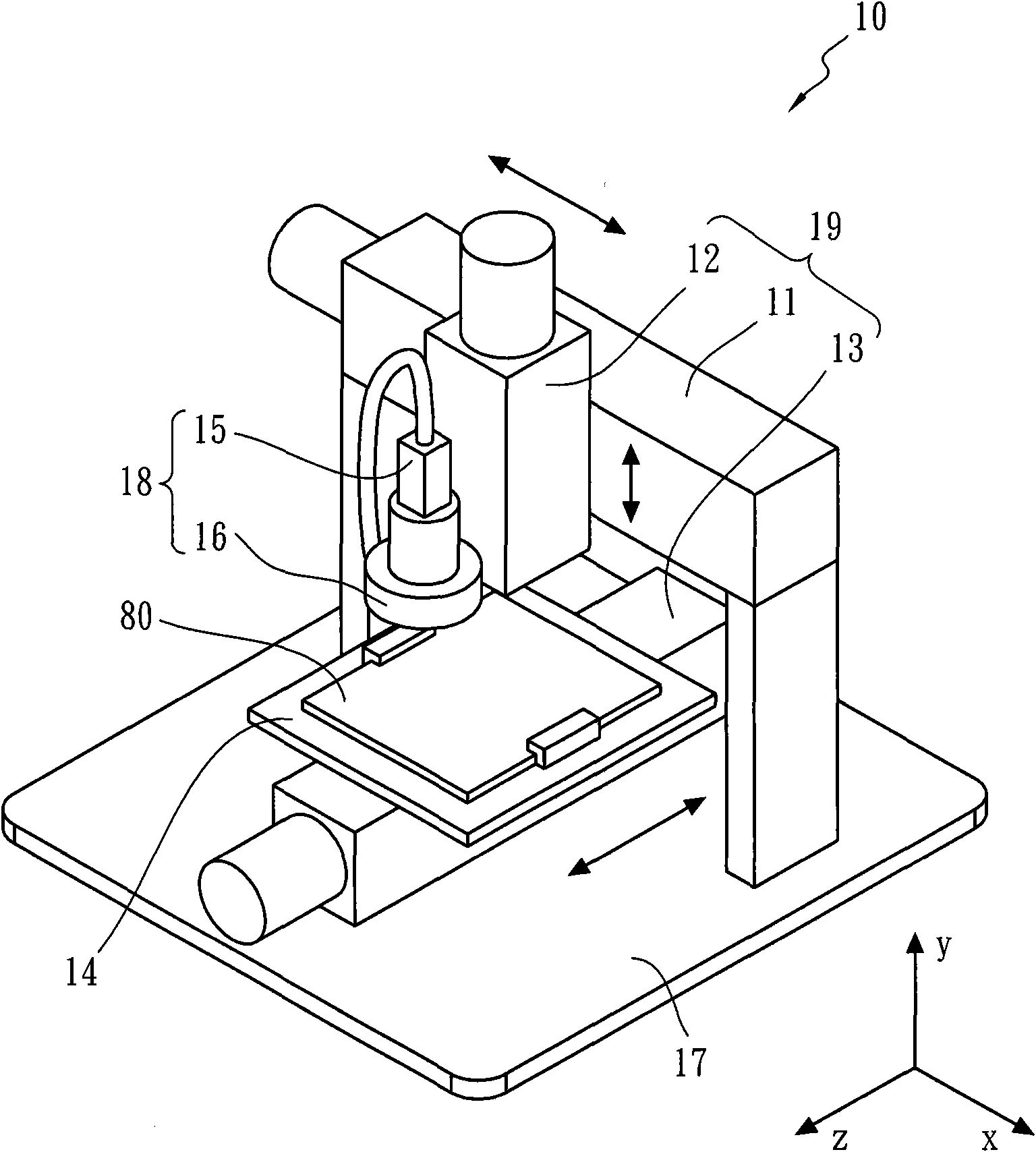

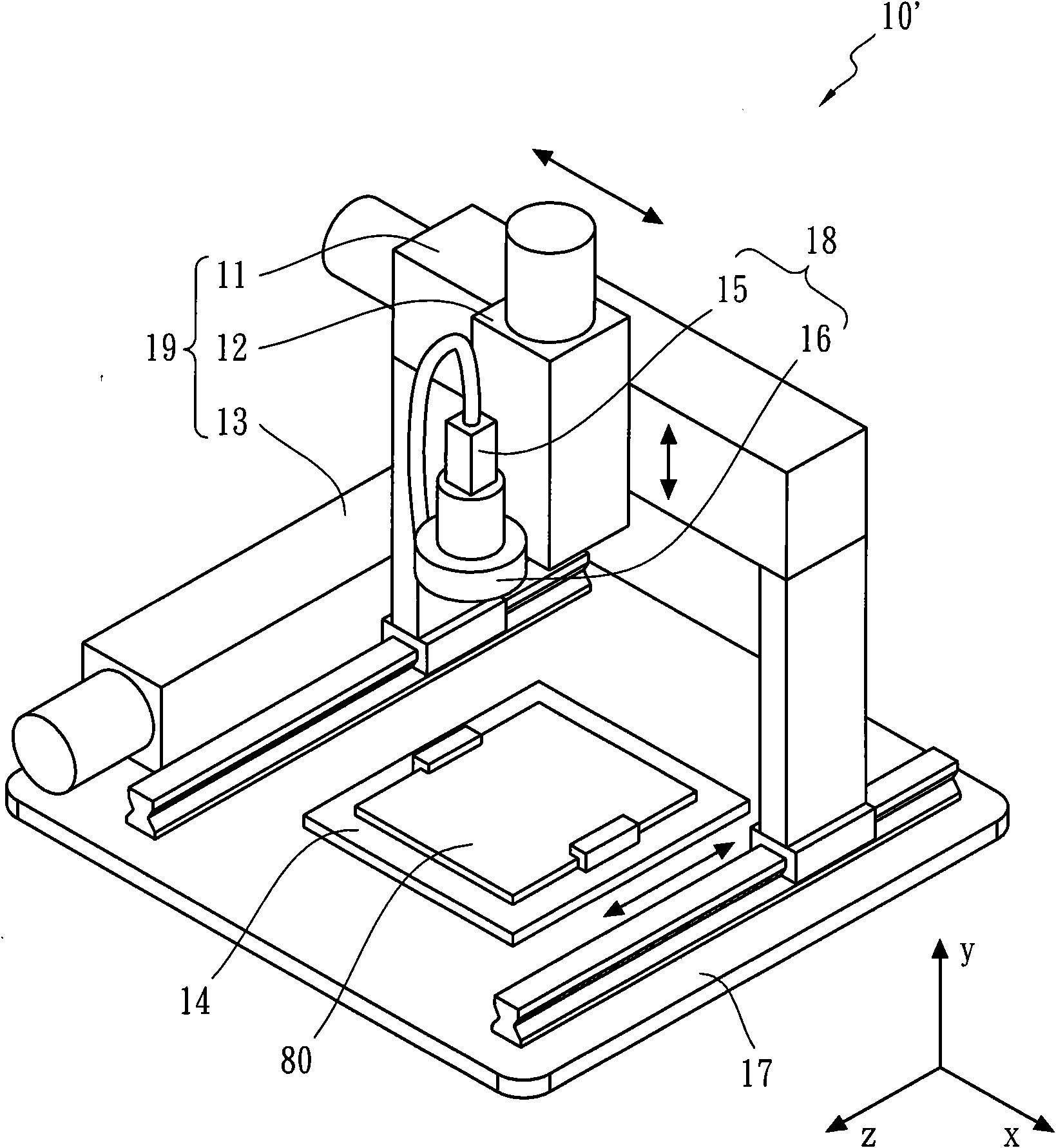

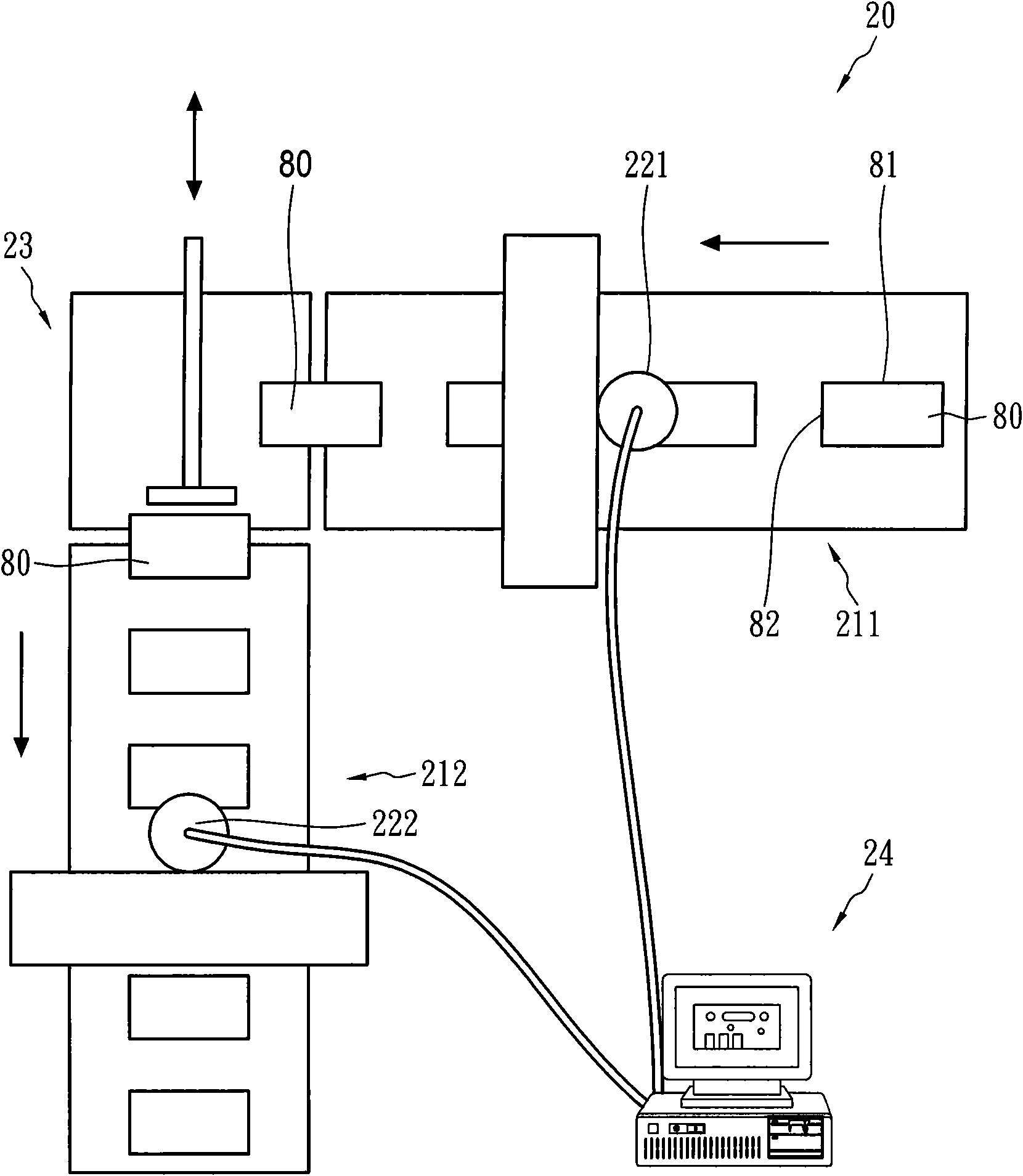

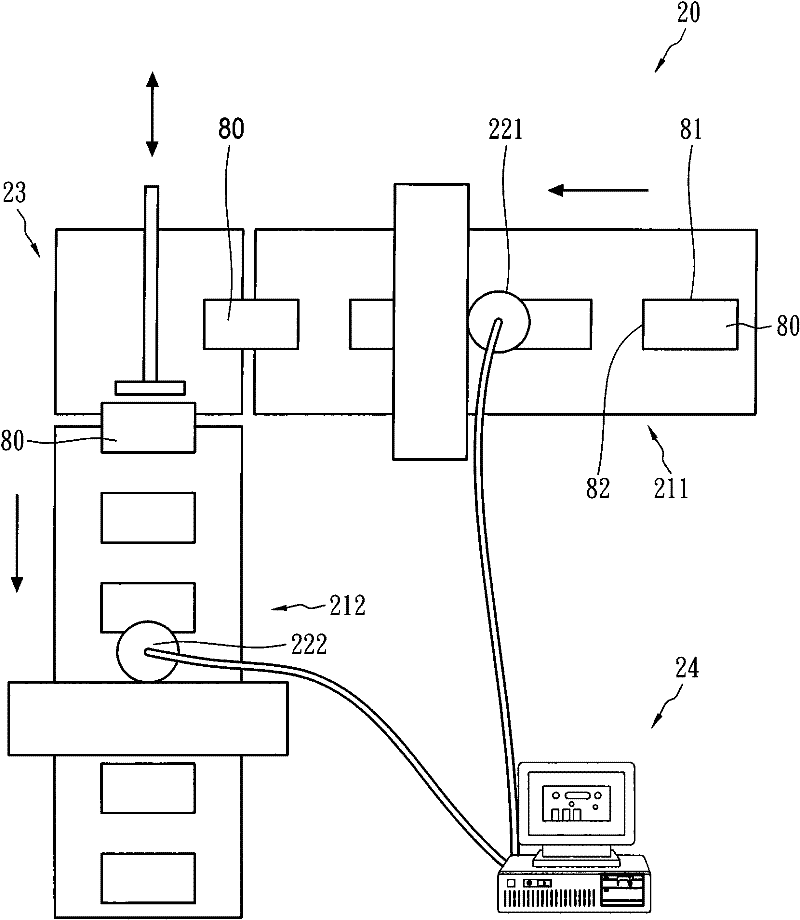

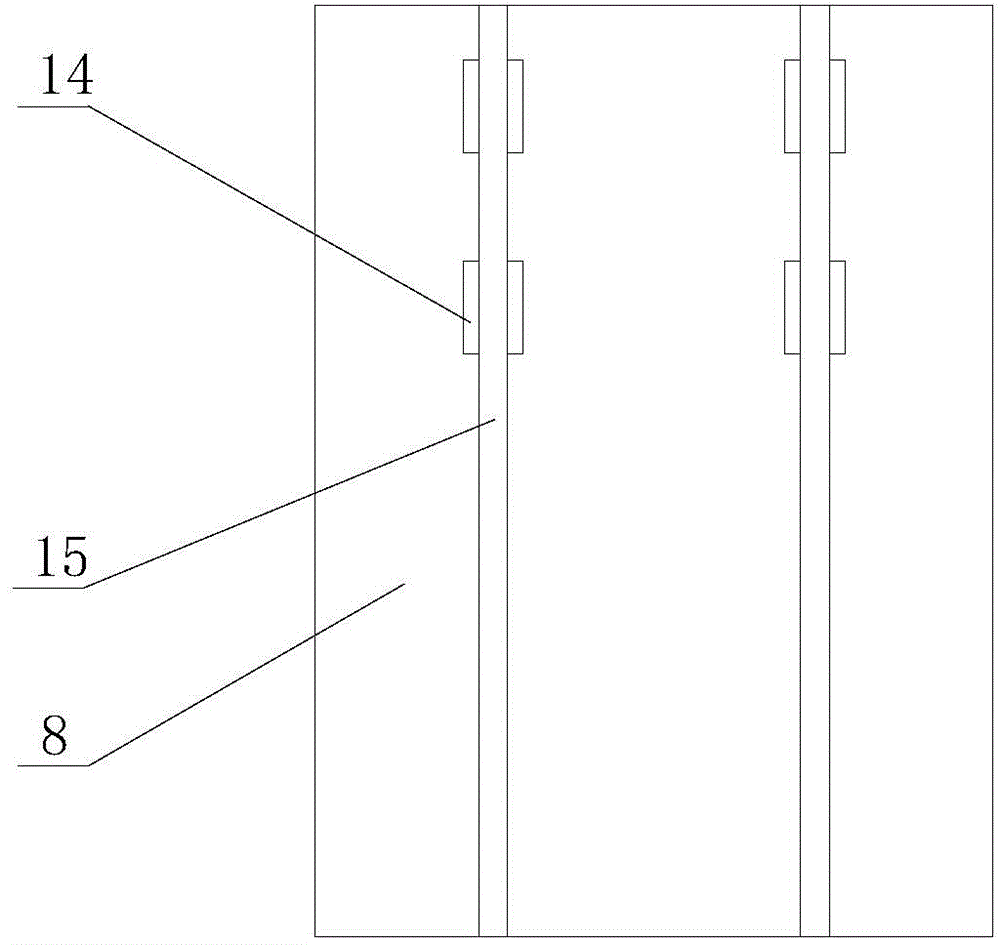

Quadratic element optical measuring device capable of continuously conveying objects to be measured

ActiveCN101929837ACorrectly synthesizedHigh precisionUsing optical meansContinuous measurementMeasurement device

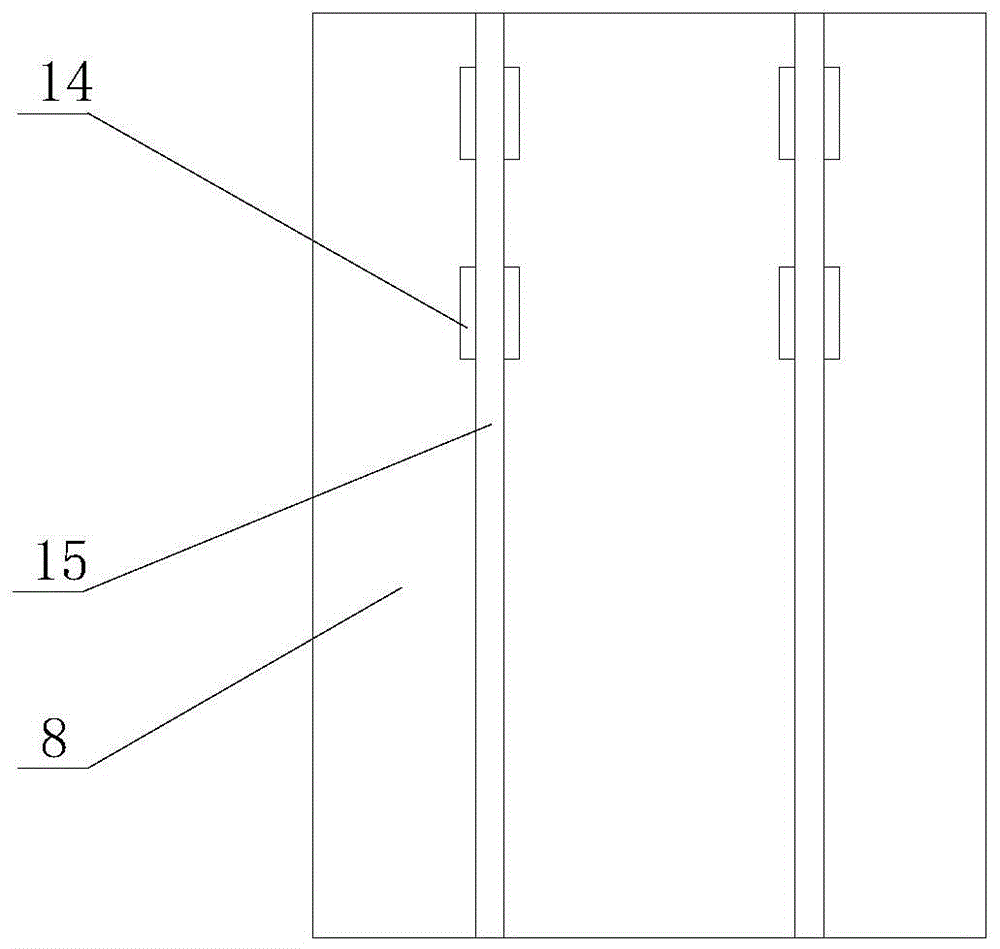

The invention discloses a quadratic element optical measuring device capable of continuously conveying objects to be measured, which can be used for continuously measuring a plurality of conveyed objects to be measured. The quadratic element optical measuring device comprises two image scanners, at least two conveyers, one steering transport mechanism and an image processor. The two image scanners are fixed at positions through which conveying belts of the at least two conveyors pass respectively, and retrieve images respectively along two approximately mutually vertical size directions on each object to be measured. The steering conveying transport mechanism steers the plurality of the objects to be measured respectively, and continuously conveys the objects to be measured between the at least two conveyers. The image processor receives image data of the two image scanners, and synthesizes the image data to obtain a two-dimensional image of each object to be measured so as to execute a geometric dimension measurement, thereby obtaining the effects of reduced cost, high unit time output and accurate measurement.

Owner:MACHVISION INC

Method for determining PCB (printed circuit board) inner layer film compensation coefficient

ActiveCN106852030AEnsure that the press fit is free of rivetingImprove Layer-to-Layer AlignmentMultilayer circuit manufactureX-rayEngineering

The invention provides a method for determining the PCB (printed circuit board) inner layer film compensation coefficient. The method comprises the following steps of (1) designing an inner layer film; (2) performing primary measurement on an expansion and shrinkage value in a measuring mode of performing quadratic element measurement on each layer of board of an etched PCB and then calculating the expansion and shrinkage extreme difference; (3) performing secondary measurement on the expansion and shrinkage value in a measuring mode of performing X-RAY measurement on each layer of board of the PCB subjected to board pressing and then calculating the expansion and shrinkage extreme difference; (4) determining the compensation coefficient of each inner layer film according to the obtained expansion and shrinkage extreme difference. The method has the advantages that the inner layer film compensation coefficient is obtained through comparing different expansion and shrinkage data; the PCB lamination expansion and shrinkage can be controlled; the influence on the PCB alignment precision is reduced; the method is practical; the operation is easy; the cost is low; the rejection rate of the multilayer board can be effectively reduced.

Owner:奥士康精密电路(惠州)有限公司

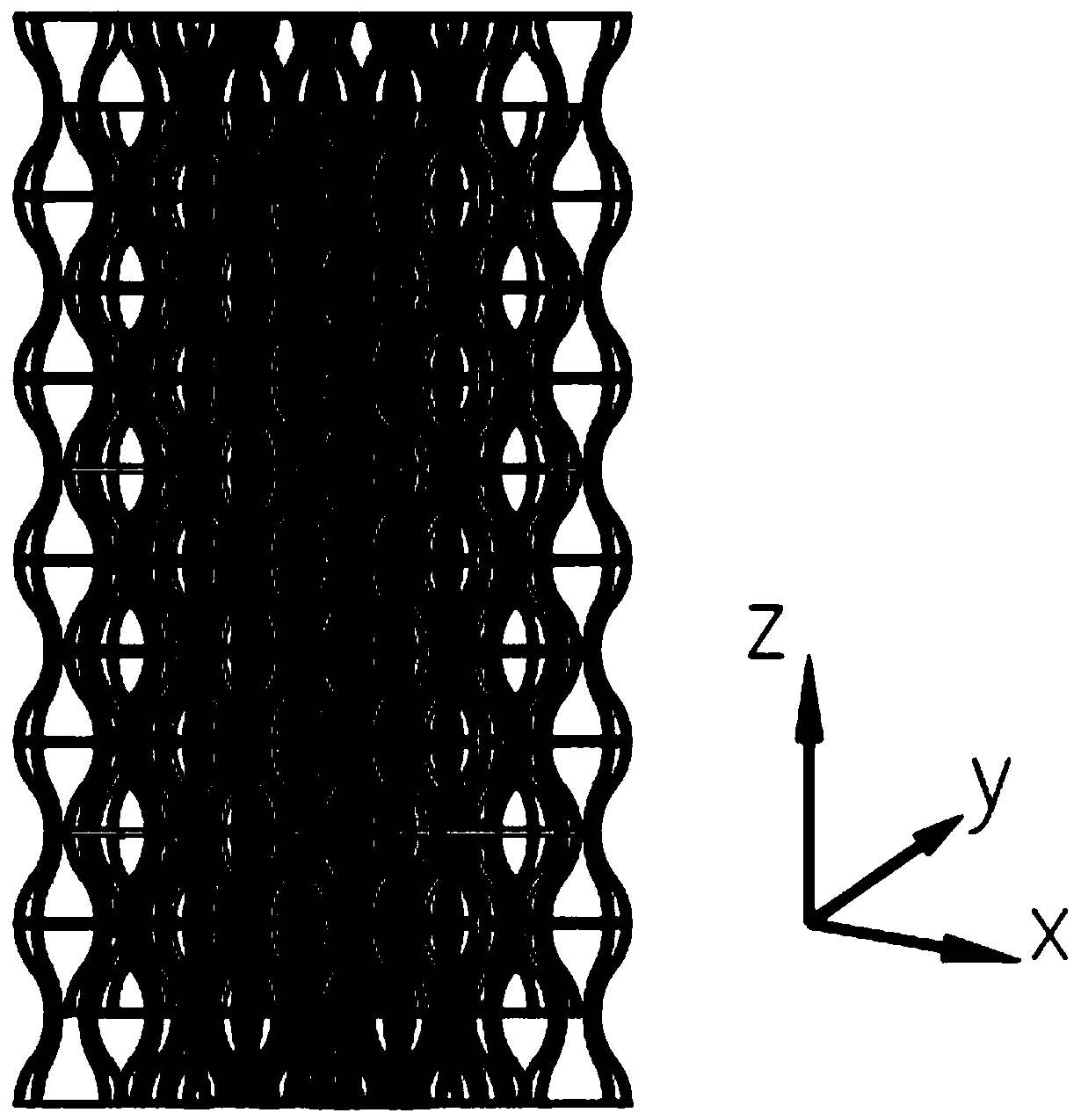

Three-dimensional impact-resisting material with negative poisson ratio characteristic

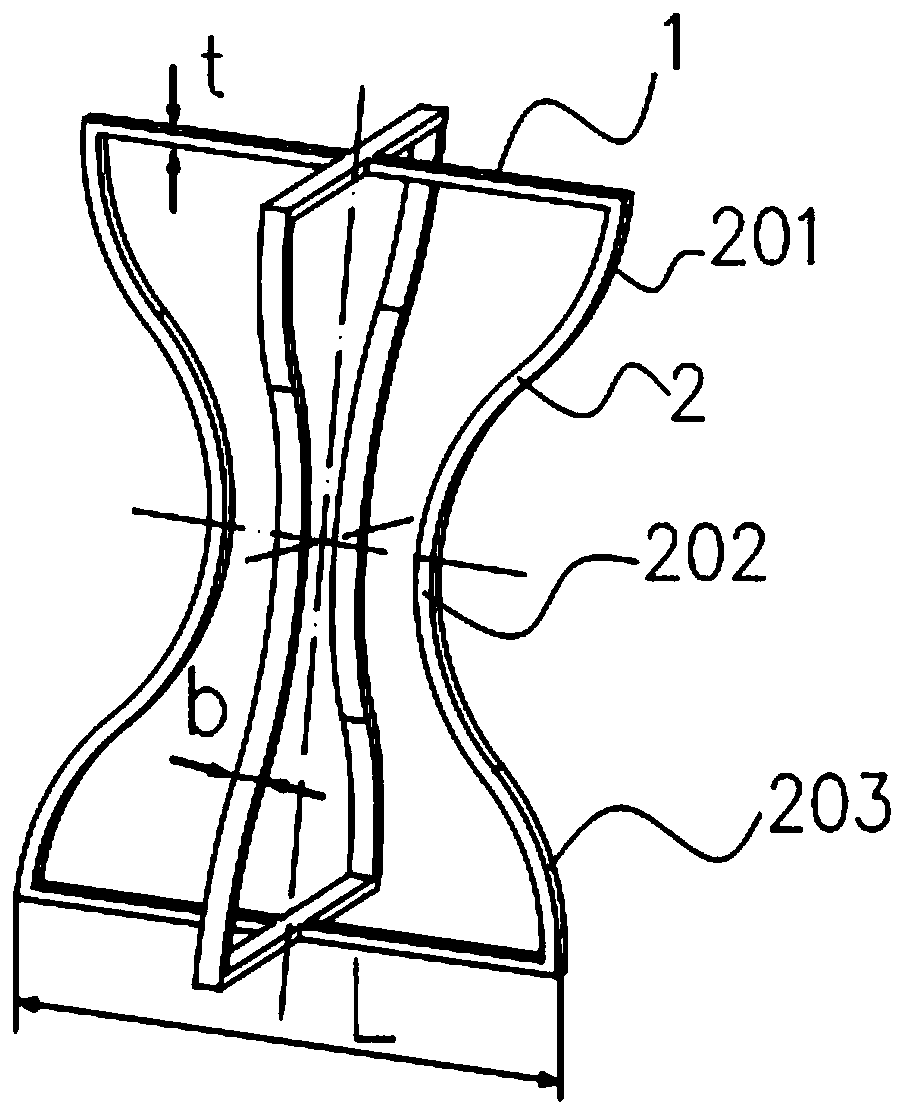

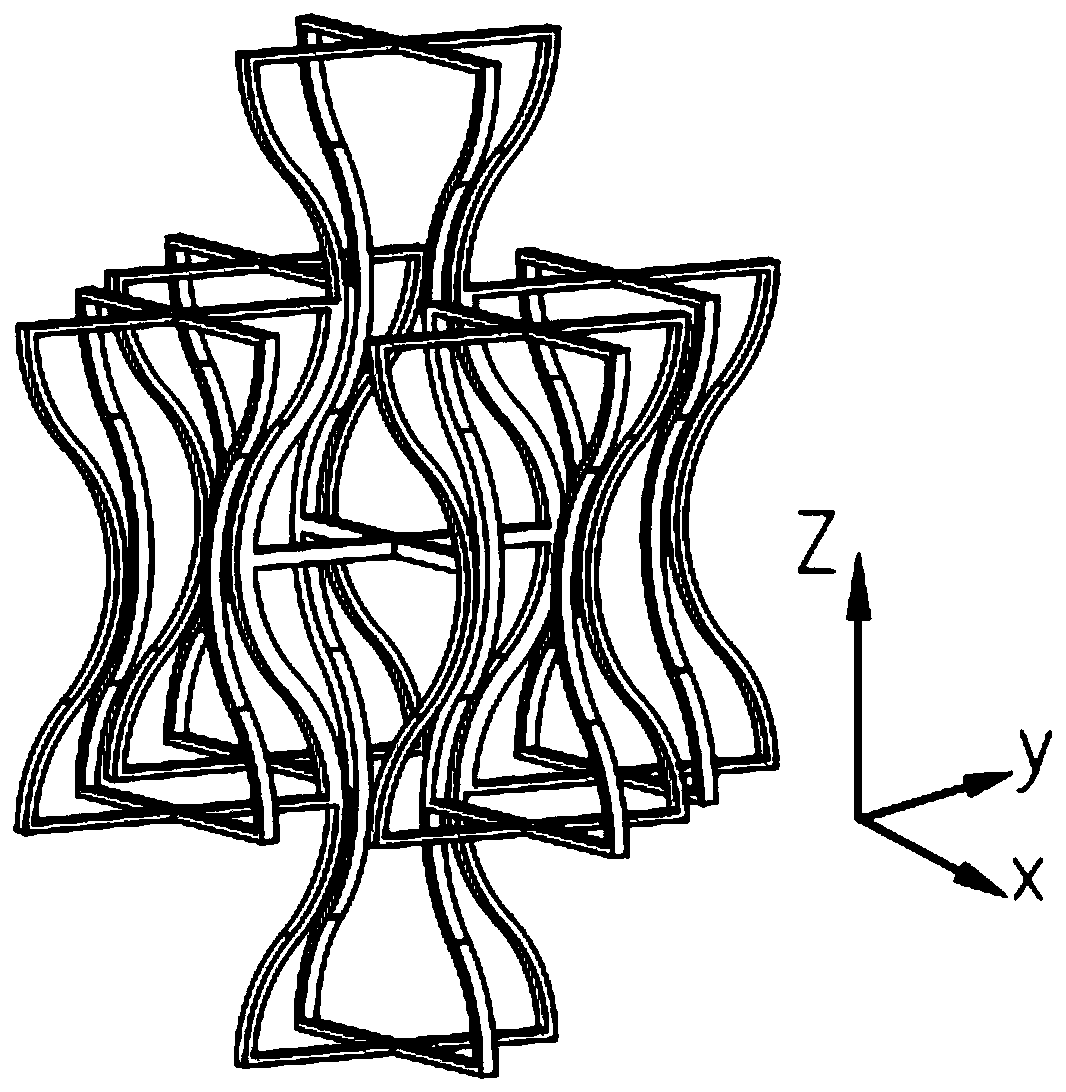

InactiveCN109869431AHas negative Poisson's ratio propertiesImprove impact toughnessElastic dampersThree-dimensional spaceEngineering

The invention discloses a three-dimensional impact-resisting material with a negative poisson ratio characteristic. The material is formed by periodically arranging single cell bodies in the three-dimensional space, wherein each single cell body is formed by connecting a pair of special-shaped quadratic element structures in a mutually orthogonal manner. The single cell bodies are tightly connected with the adjacent cell bodies in the Z direction in a mutually aligned manner through straight rib structures and tightly connected with the adjacent cell bodies through arc rib structures in a mutually parallel and aligned manner. The three-dimensional impact-resisting material with the negative poisson ratio characteristic expands in the X direction and the Y direction when being stretched inthe Z direction and contracts in the X direction and the Y direction when being compressed in the Z direction. The three-dimensional impact-resisting material with the negative poisson ratio characteristic can serve as a buffering material to be applied to structures such as automobile bodies and buffers, and the impact roughness and the anti-pressure capability are greatly improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

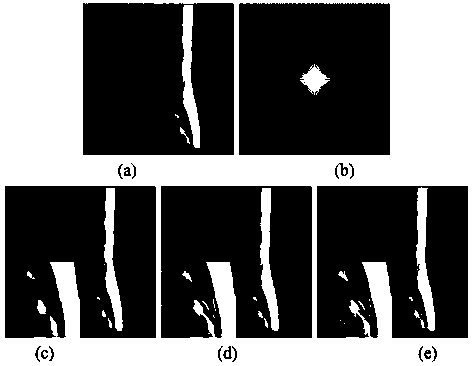

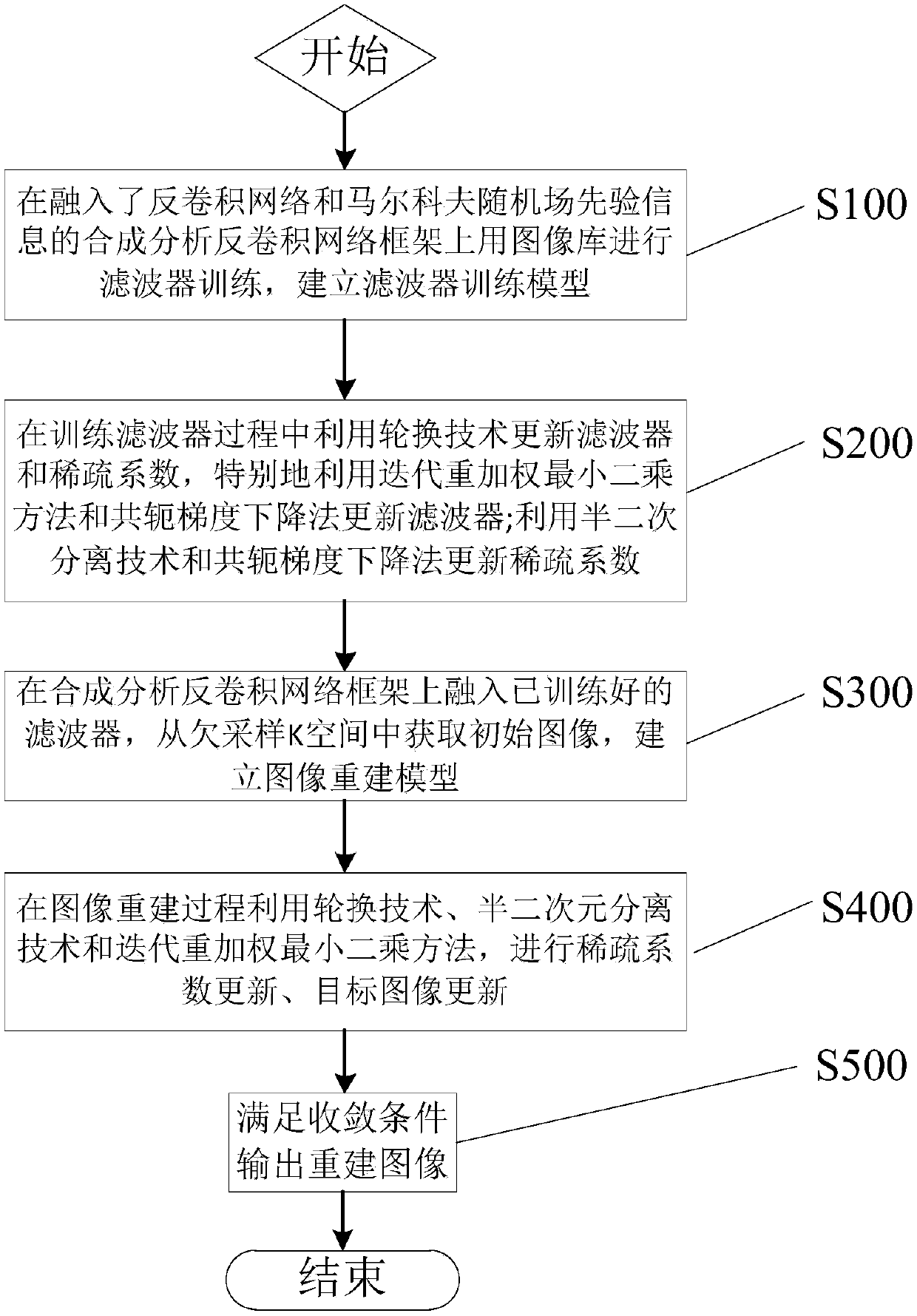

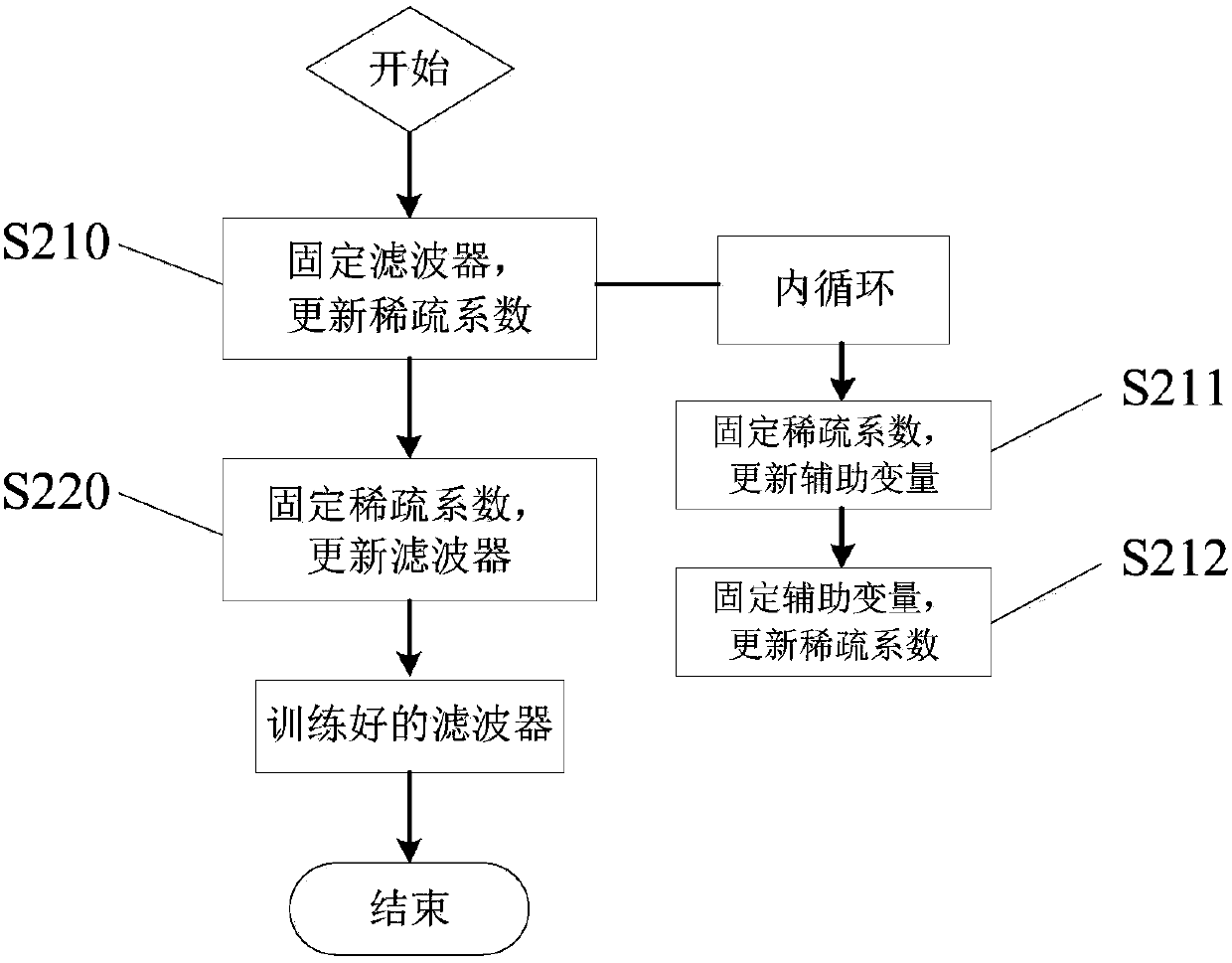

Fast imaging method and system based on synthetic analysis deconvolution network

ActiveCN106991651AAccurate reconstructionRecover image detailsImage enhancementImage analysisPrior informationComputer vision

A fast imaging method based on a synthetic analysis deconvolution network includes the steps of performing filter learning using an image library on the synthetic analysis deconvolution network integrated with DN and MRF prior information; in the process of filter training, updating the filter and sparse coefficients by the rotation technique, the semi-secondary separation technique and the iterative reweighted least squares method; on the basis of the trained filter, obtaining an initial image from an undersampled K space, and establishing an image reconstruction model; updating the sparse coefficient and a target image on the reconstruction model by using the rotation technique, the semi-quadratic-element separation technique and the iterative reweighted least squares method; and satisfying a convergence condition to obtain a reconstructed image. The invention improves the accuracy of image reconstruction to a certain extent, and also provides a fast imaging system based on a synthetic analysis deconvolution network using the fast imaging method of the synthetic analysis deconvolution network, which can obtain the reconstructed image with a high accuracy.

Owner:江西中科九峰智慧医疗科技有限公司

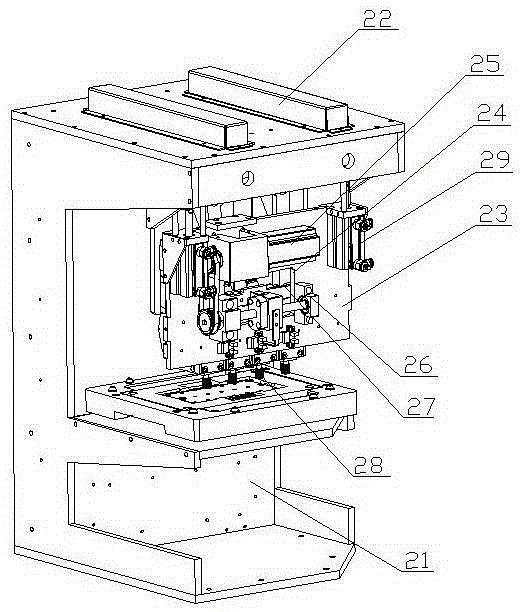

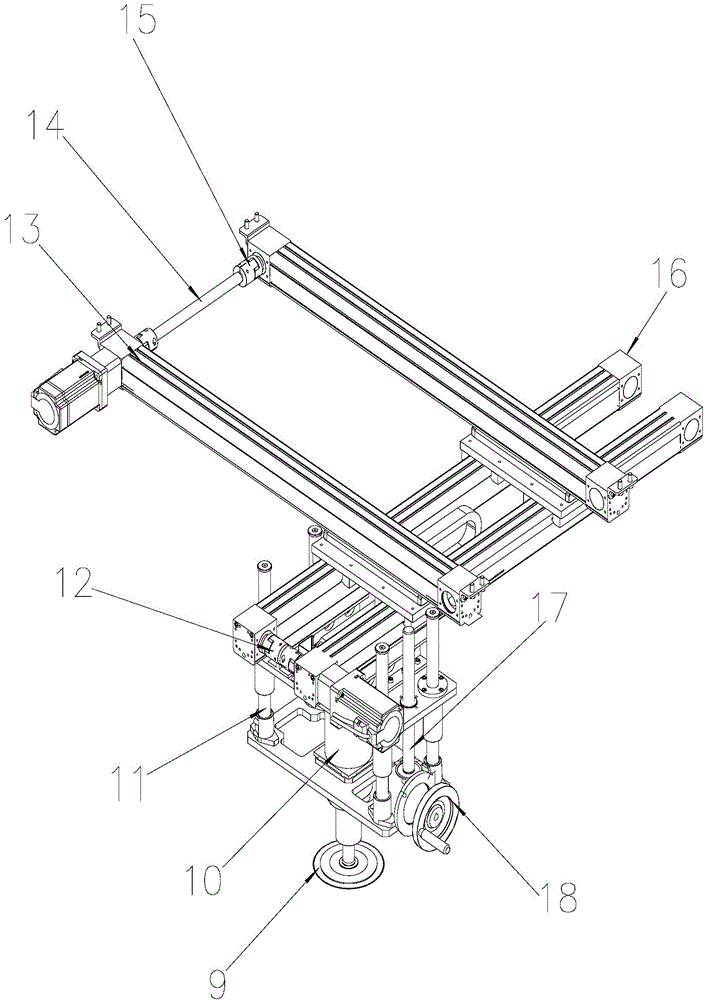

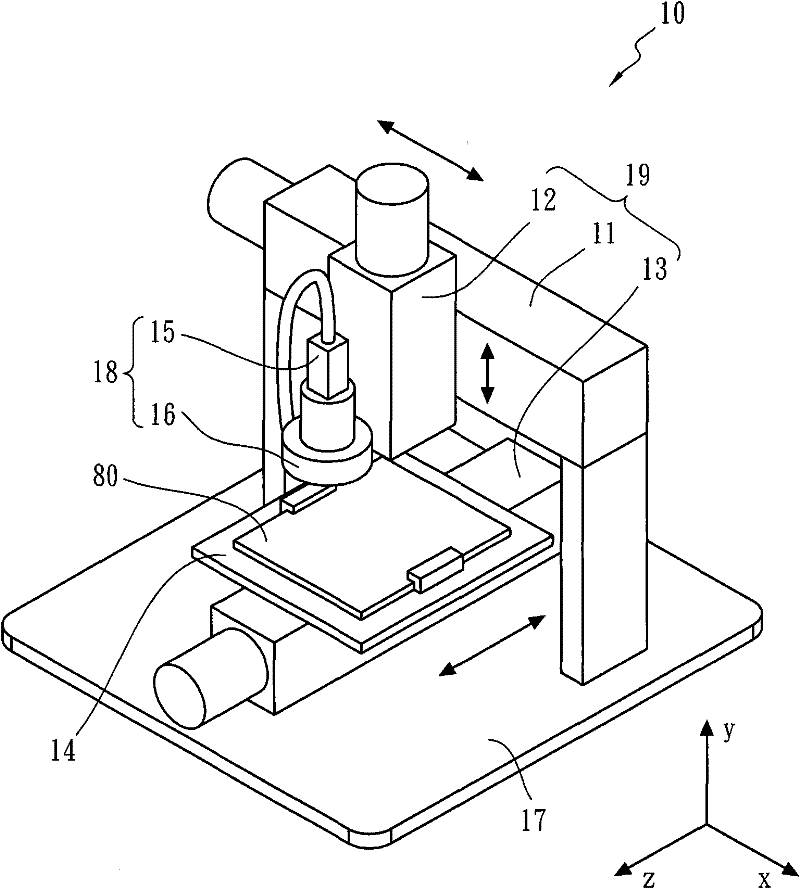

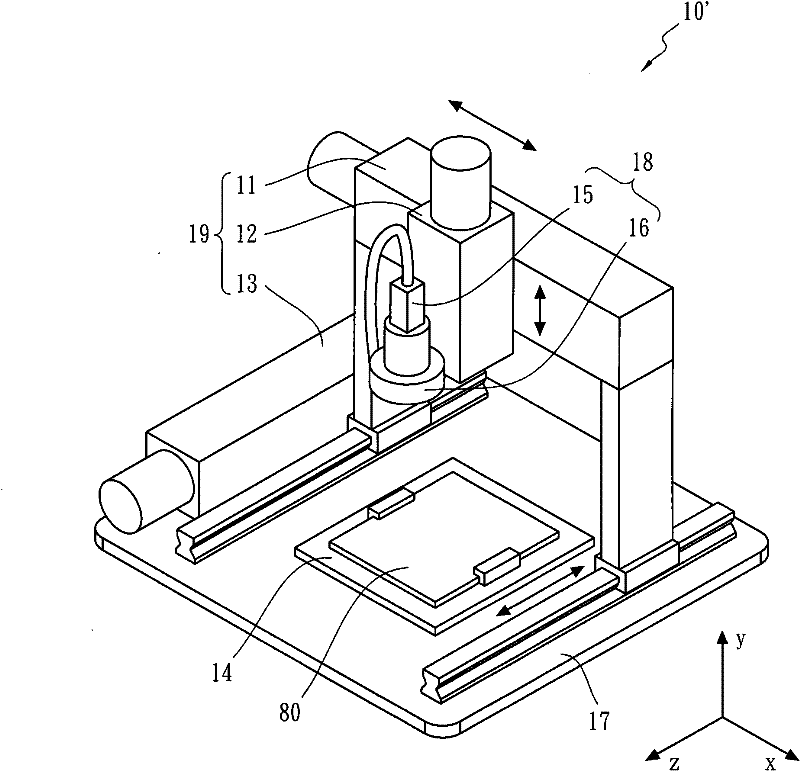

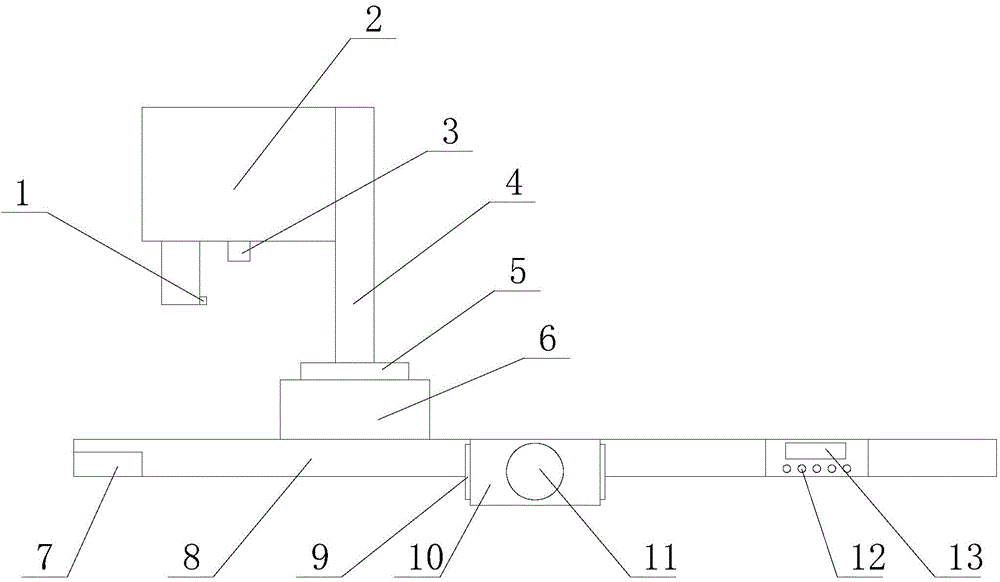

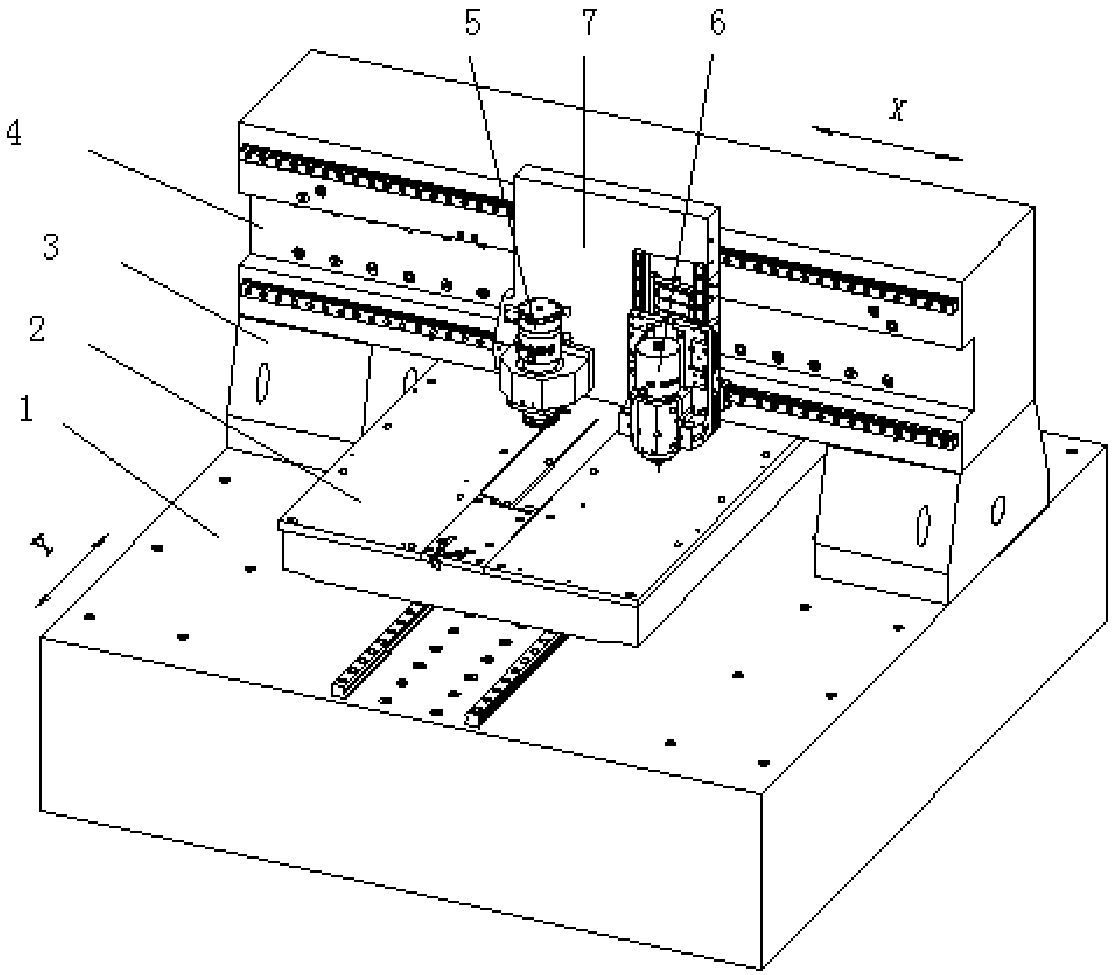

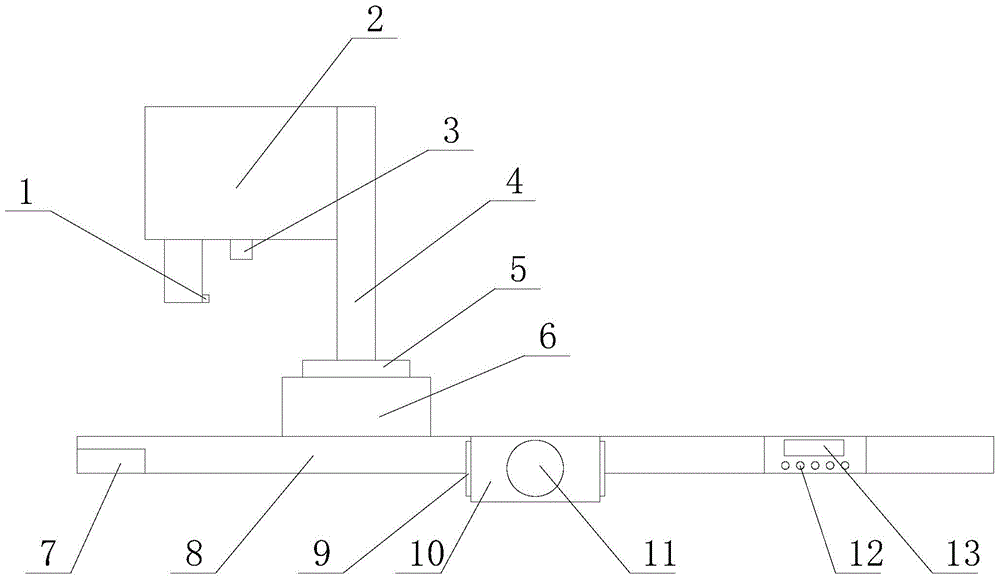

Multifunctional precision mapping measuring instrument practical training table

PendingCN109506588AImprove high-end precision measurement skillsCosmonautic condition simulationsUsing optical meansMeasuring instrumentQuadratic element

The invention discloses a multifunctional precision mapping measuring instrument practical training table. The practical training table comprises a practical training table body and numerical operation station. The practical training table comprises a base, a sliding block, a supporting seat, a deflection inspecting instrument, an X-axis sliding table, a Y-axis sliding table, a Z-axis sliding table, an imaging measuring instrument probe and a three-coordinate probe, the base is provided with a spare part kit, the Y-axis sliding table is fixedly installed on the base, the sliding block is slidably installed on Y-axis sliding table, the X-axis table is slidably installed on the sliding rail, the deflection inspecting instrument is fixedly installed at one end of the Y-axis sliding table, thesupporting seat is fixedly installed on the base, the Z-axis sliding table is slidably installed on the supporting seat, and the imaging measuring instrument probe and the three-coordinate probes arefixedly installed on the Z-axis sliding table. The practical training table has the advantages that by the arrangement of the spare kit, the deflection inspecting instrument, the imaging measuring instrument probe and the three-coordinate probe, measuring learning training can be completed with the help of quadratic elements and three-coordinate measuring software matching with a three-dimensional sliding table, the imaging measuring instrument probe and the three-coordinate probe.

Owner:卫国教育科技(河源)有限公司 +2

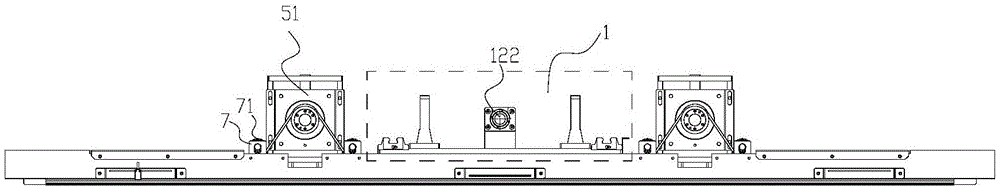

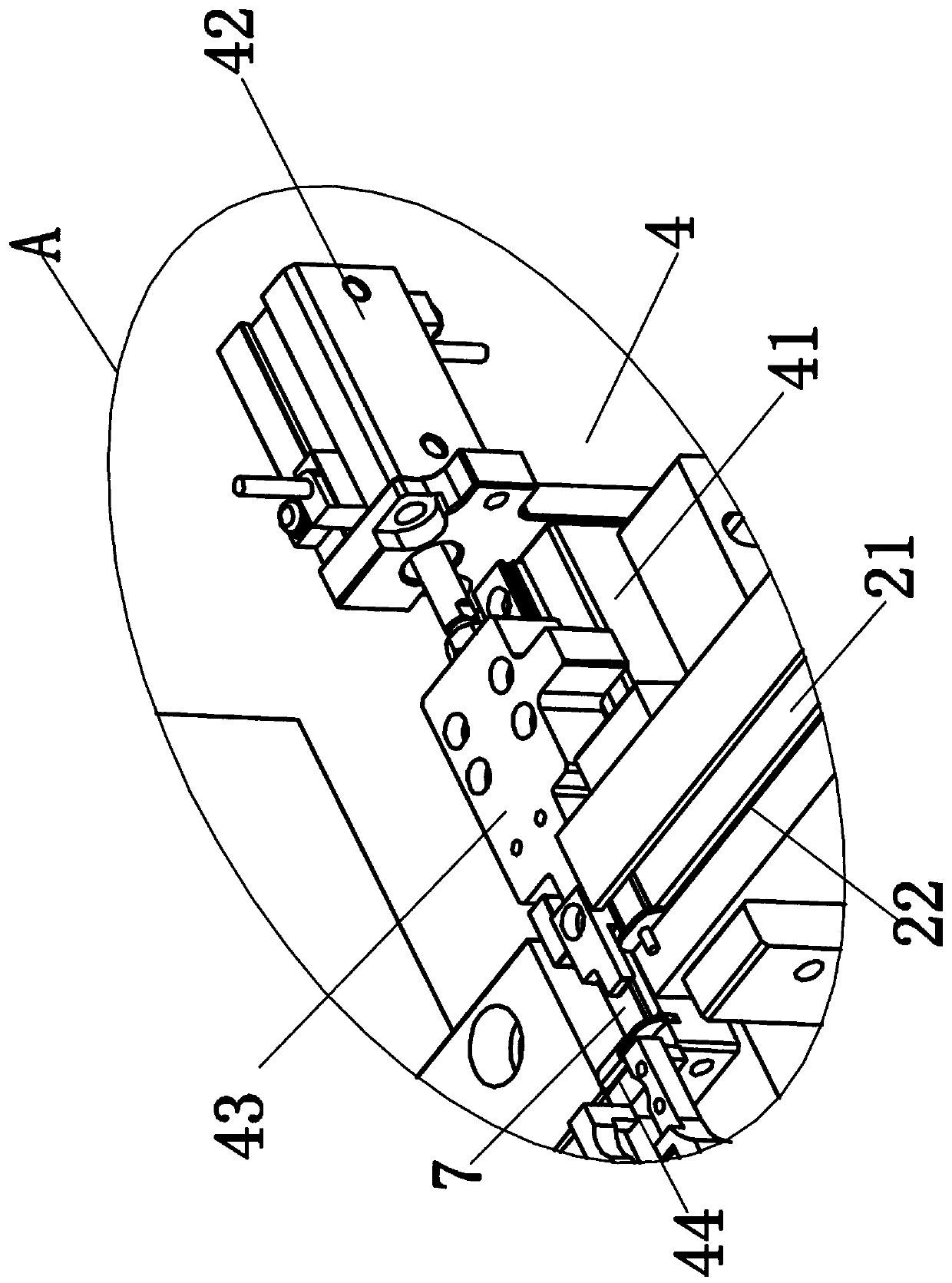

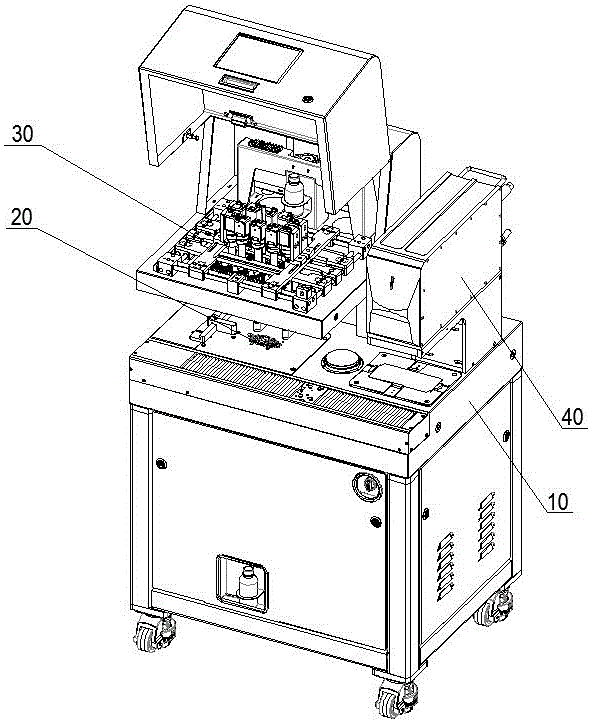

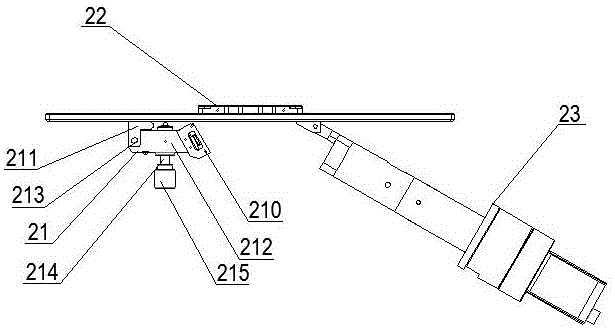

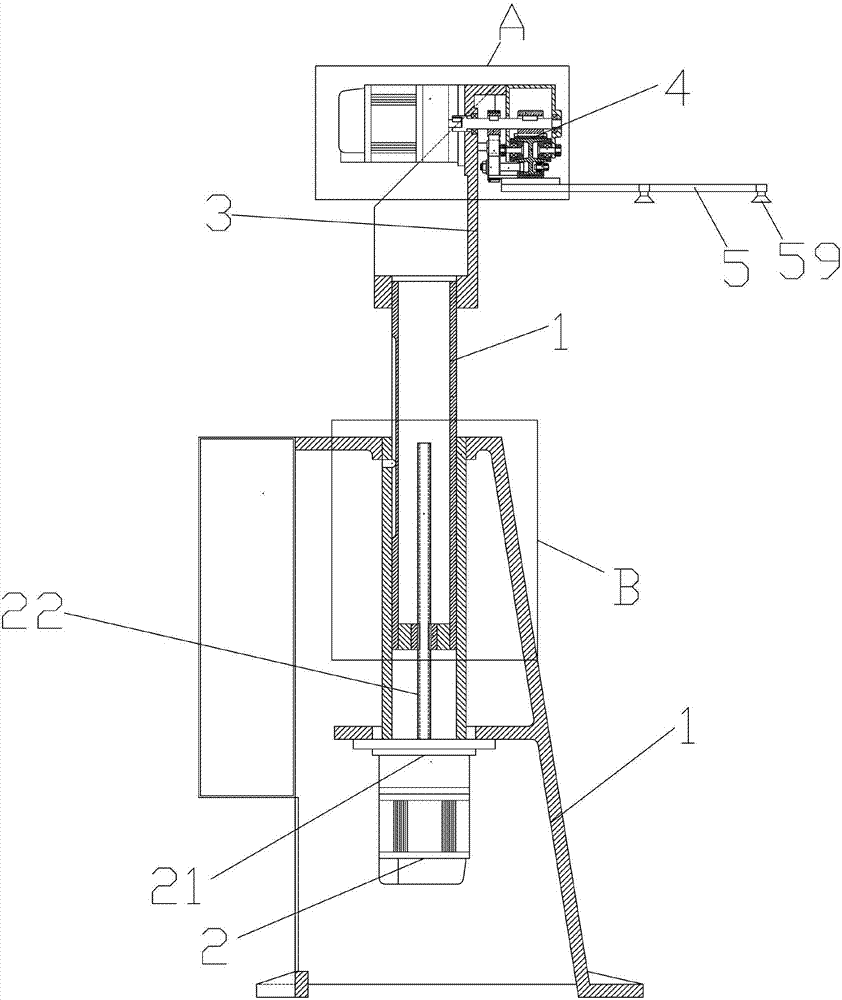

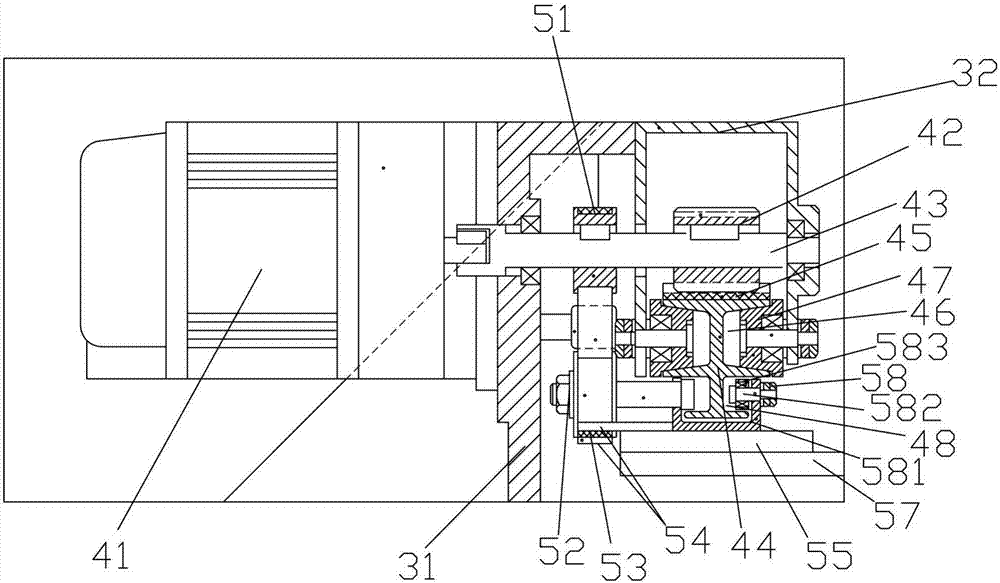

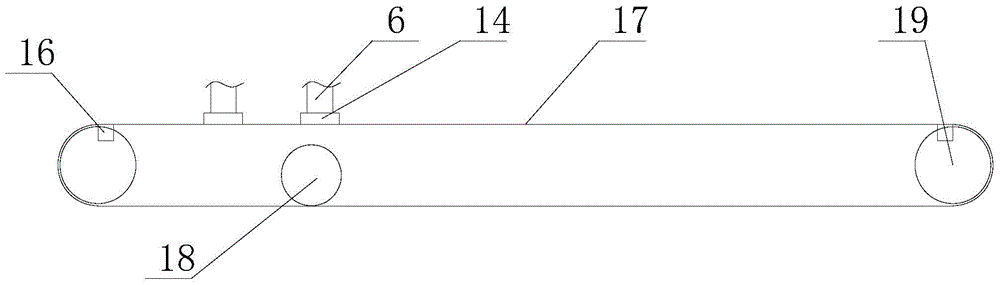

Double-dynamic quadratic-element internal robot

ActiveCN106335051AReduce distanceAvoid influenceProgramme-controlled manipulatorMetal-working feeding devicesEngineeringManipulator

The invention discloses a double-dynamic quadratic-element internal robot, which comprises a base, a mechanical arm connected with the movable base, a vertical driving assembly set on the base for driving vertical movement of the mechanical arm, the first horizontal driving assembly and the second horizontal driving assembly fixed to the mechanical arm, and the first manipulator and the second manipulator for sliding connection. The first horizontal driving assembly drives the horizontal movement of the first manipulator, and the second horizontal driving assembly drives the horizontal movement of the second manipulator. The invention relates to a mechanical arm which is provided with two manipulators which are controlled by different driving motors. The two manipulators can move independently and horizontally without interfering with each other, and the mechanical arm and the mechanical arm do not interfere with each other. In addition, the horizontal driving motor is arranged on both sides of the base, so that the structure of the double-dynamic quadratic-element internal robot is more compact and beautiful. At the same time, the tension wheel seat provided on both sides of the horizontal driving motor makes the timing belt to move closer to the main body of the transverse arm to avoid the influence of the timing belt on the base.

Owner:LEN SEIKI SHENZHEN

Semi-automatic carton opening machine

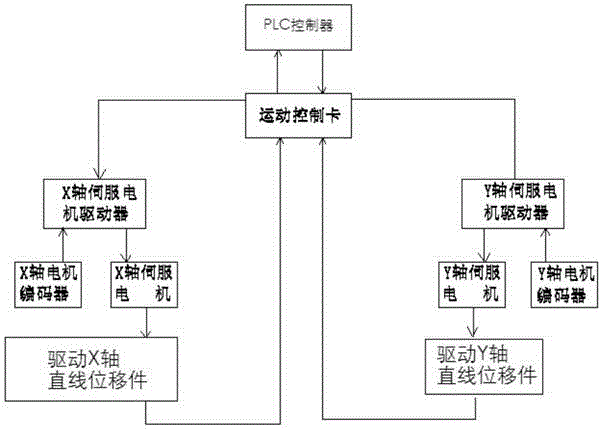

ActiveCN105564752ASimple structural designGood value for moneyArticle unpackingElectricityProgrammable logic controller

The invention relates to a semi-automatic carton opening machine which comprises a PLC (Programmable Logic Controller), a quadratic element movement mechanism, a conveying roller, a pneumatic side pressing device, a front block, a sensor, a touch screen, a control cabinet, a control cabinet support, an organ type protection cover, a part taking and placing station and a cutting station. The touch screen is located on the outer side of the control cabinet. The organ type protection cover is located on the side edge of the control cabinet support. The part taking and placing station is located on one side of the organ type protection cover. The cutting station is located at the lower portion in the control cabinet. The front block is located on one side of the conveying roller. The pneumatic side pressing device is located on one side of the cutting station. The sensor is arranged on the front block. The PLC is electrically connected with a servo motor system of the quadratic element movement mechanism, the sensor, the touch screen, a conveying roller motor, a front block starting switch and a starting switch for starting a pressure testing device. The semi-automatic carton opening machine is simple in structural design and high in performance cost ratio, the quadratic element movement mechanism is high in movement speed and good in movement precision, and extremely-high cutting efficiency can be provided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

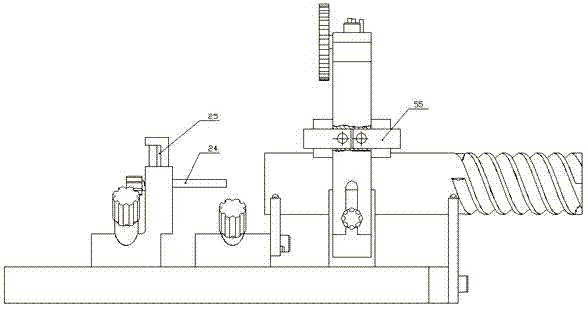

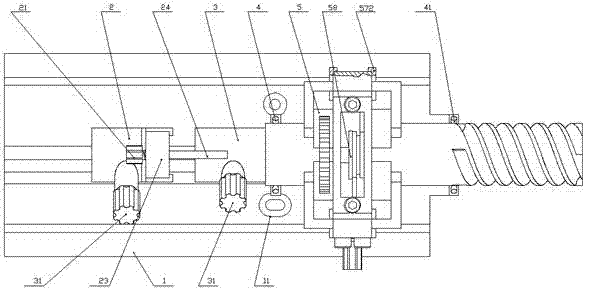

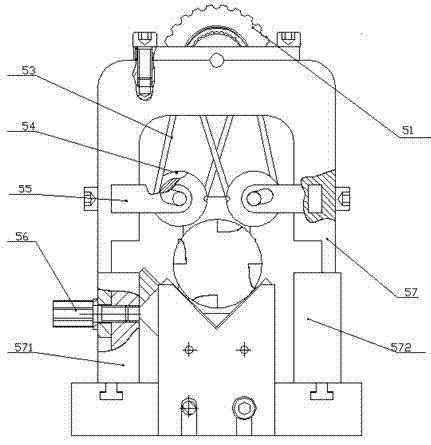

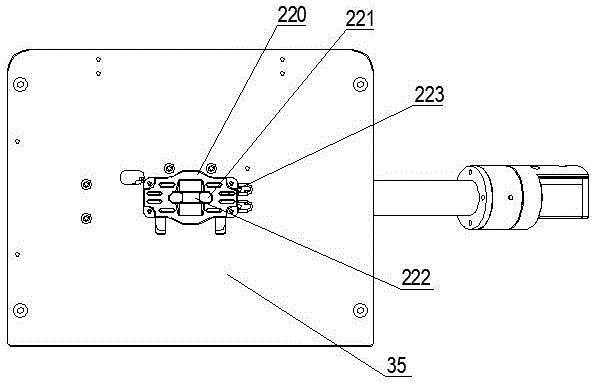

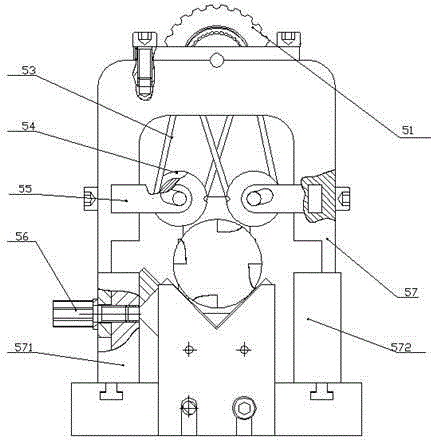

Parameter determination device for cutter of quadratic element image measurer

InactiveCN103206920AGuaranteed practicalityEasy to measureUsing optical meansLocking mechanismEngineering

The invention relates to a parameter determination device for a cutter of a quadratic element image measurer. The middle part of a fixture base is adjustably connected with a cutter axle center finding and axial positioning mechanism and a sliding block through a connecting groove. The right end of the fixture base is adjustably connected with a pressing stirring mechanism. The sliding block is positioned between the cutter axle center finding and axial positioning mechanism and the pressing stirring mechanism. A locking mechanism is arranged on each of the cutter axle center finding and axial positioning mechanism and the sliding block. A second V-shaped positioning plate is fixedly connected to the front end face of the sliding block, and a first V-shaped positioning plate is fixedly connected to the right end face of the fixture base. The cutter is positioned and centered by the axle center finding and axial positioning mechanism and the V-shaped positioning plates to facilitate the accurate clamping of a product, parameters such as circular runout of the cutter are conveniently measured by the pressing stirring mechanism, the whole tool is unlimited to the parameter measurement of the cutter in a certain specification, and the pressing stirring mechanism is adjusted upwards and downwards to ensure practicability for cutters in different specifications.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Multi-station quadratic element mechanical arm for hardware punching machining

PendingCN108543875ALess involved operationsReduce labor costsMetal-working feeding devicesPositioning devicesPunch pressElectric machine

The invention discloses a multi-station quadratic element mechanical arm for hardware punching machining. The multi-station quadratic element mechanical arm comprises a material suction air cylinder and an arm body. A plunger rod of the material suction air cylinder is connected with a vacuum suction cup. A material frame jacking oil cylinder is arranged under the vacuum suction cup. A to-be-machined material is placed on the material frame jacking oil cylinder. The arm body is arranged on left-right movement linear guide rails on the two sides. The left-right movement linear guide rails are arranged on a motor box. The left end of the arm body is located under the vacuum suction cup. The left-right movement linear guide rails are connected with a transmission mechanism through an openingand closing movement linear guide rail. The transmission mechanism is connected with an arm left-right movement servo motor. The two sides of the arm body are provided with a clamp A and a clamp B. According to the multi-station quadratic element mechanical arm for hardware punching machining, multi-procedure production can be finished through one-person operation production, the labor cost is reduced, a fault checking and knowing device is arranged, punch automation can be matched, running and producing are uninterrupted, and the production efficiency is greatly improved.

Owner:中山市新泰五金制品有限公司

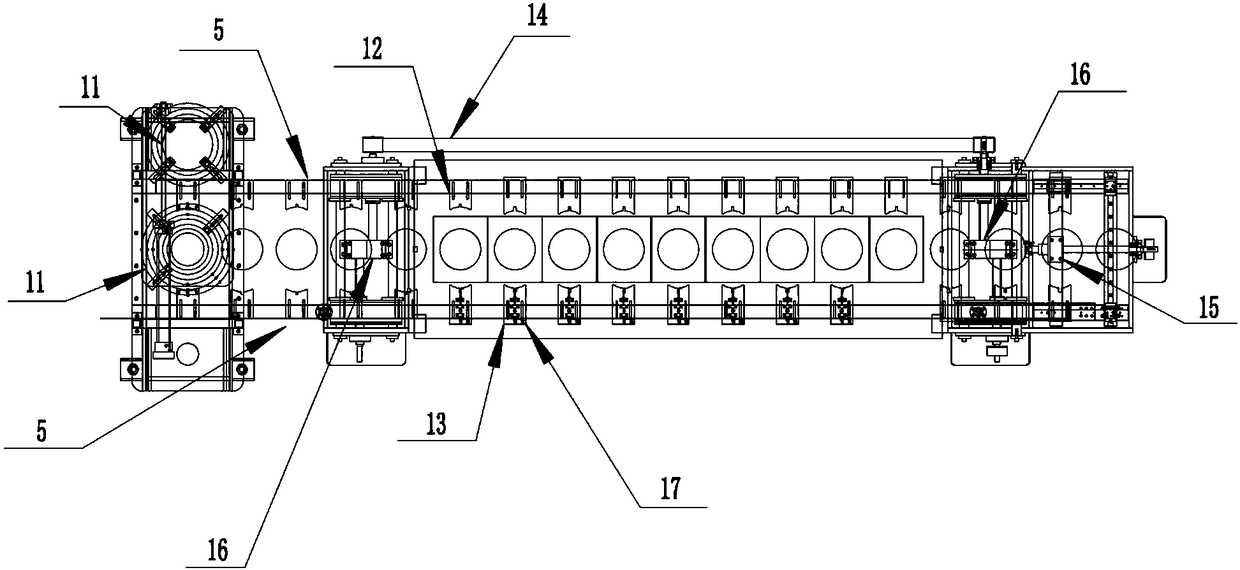

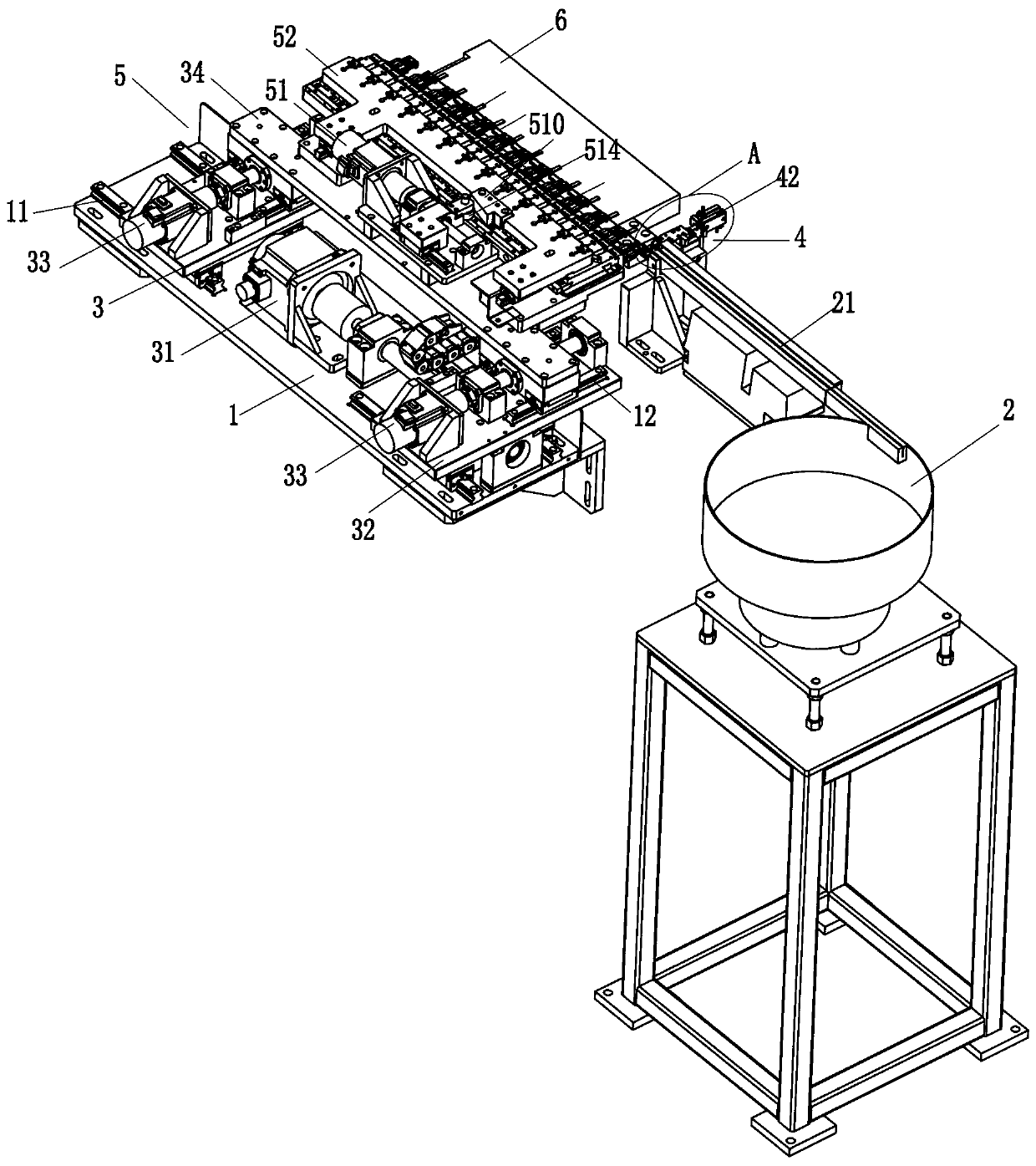

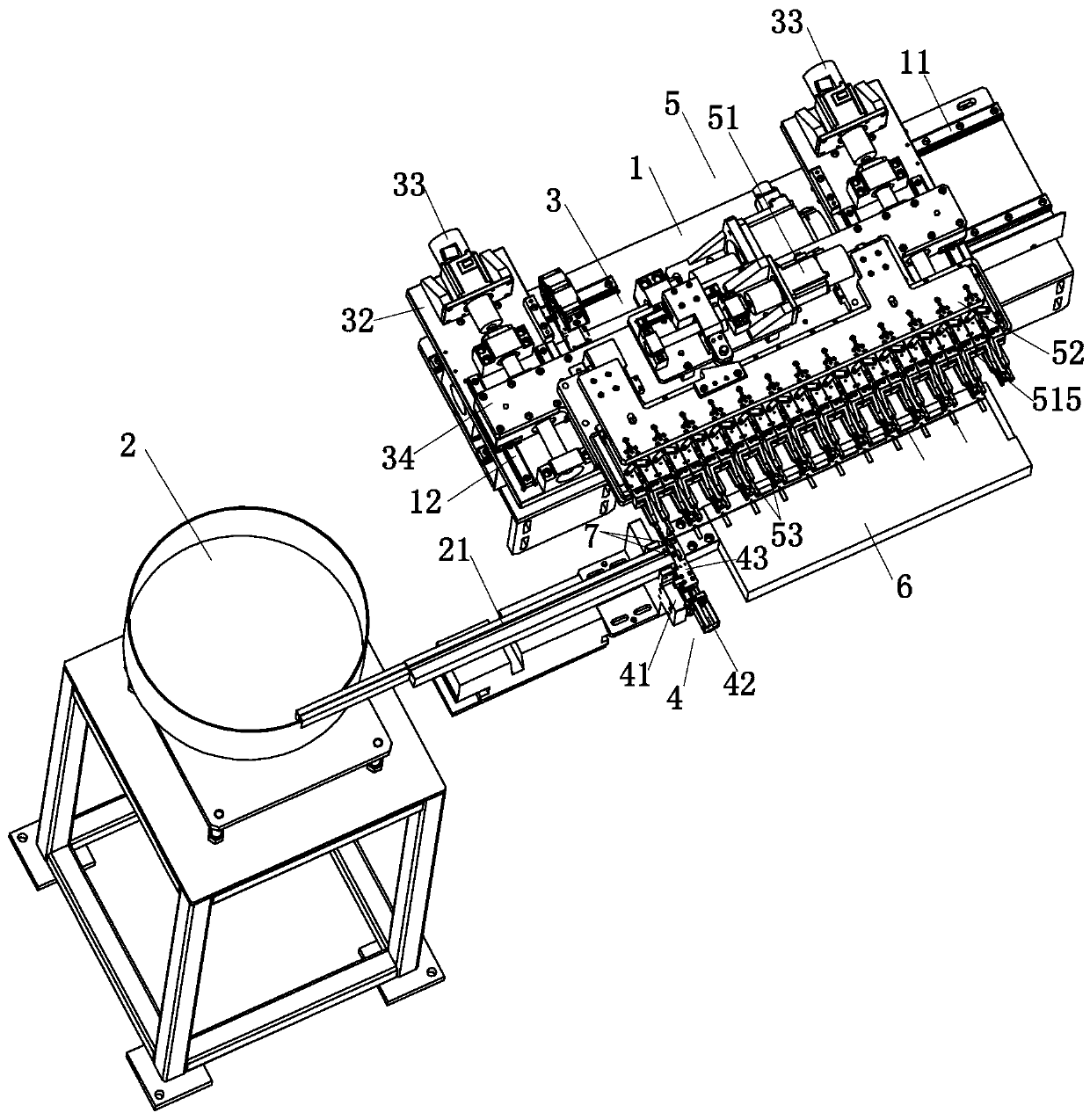

Quadratic element manipulator

PendingCN110523872AImprove transfer efficiencyIncrease productivityMetal-working feeding devicesGripping headsPunch pressManipulator

The invention relates to a quadratic element feeding manipulator. The manipulator comprises a vibration feeding disc, a material distributing mechanism, a horizontal sliding driving device and a feeding manipulator, the feeding manipulator comprises a clamping jaw opening driving device, a clamping jaw opening driving plate and a plurality of clamping jaws, a left clamping arm and a right clampingarm of each clamping jaw are arranged in the left-right direction of the horizontal sliding driving device in a sliding opening and closing mode, a plurality of clamping jaw opening driving blocks are arranged on the clamping jaw opening driving plate side by side, and the clamping jaw opening driving blocks are located between the left clamping arms and the right clamping arms. According to theinvention, the vibration feeding disc, the horizontal sliding driving device, the material distributing mechanism and the feeding manipulator are arranged, so a plurality of workpieces can be continuously conveyed; and the multiple clamping jaws of the feeding manipulator can convey the workpieces punched in the previous punching procedure of the punching machine to the next punching procedure forpunching at the same time, so that the punching machine can conduct continuous punching on the multiple workpieces at the same time, the workpiece conveying efficiency is high, the production efficiency is high, and full-automatic continuous high-speed production can be achieved.

Owner:FOSHAN SHUNDE KAISHUO PRECISION MOLD AUTOMATION TECH CO LTD

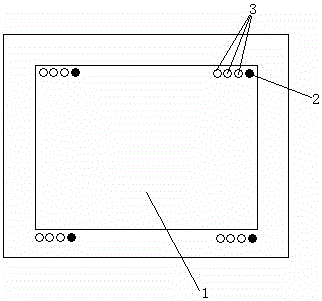

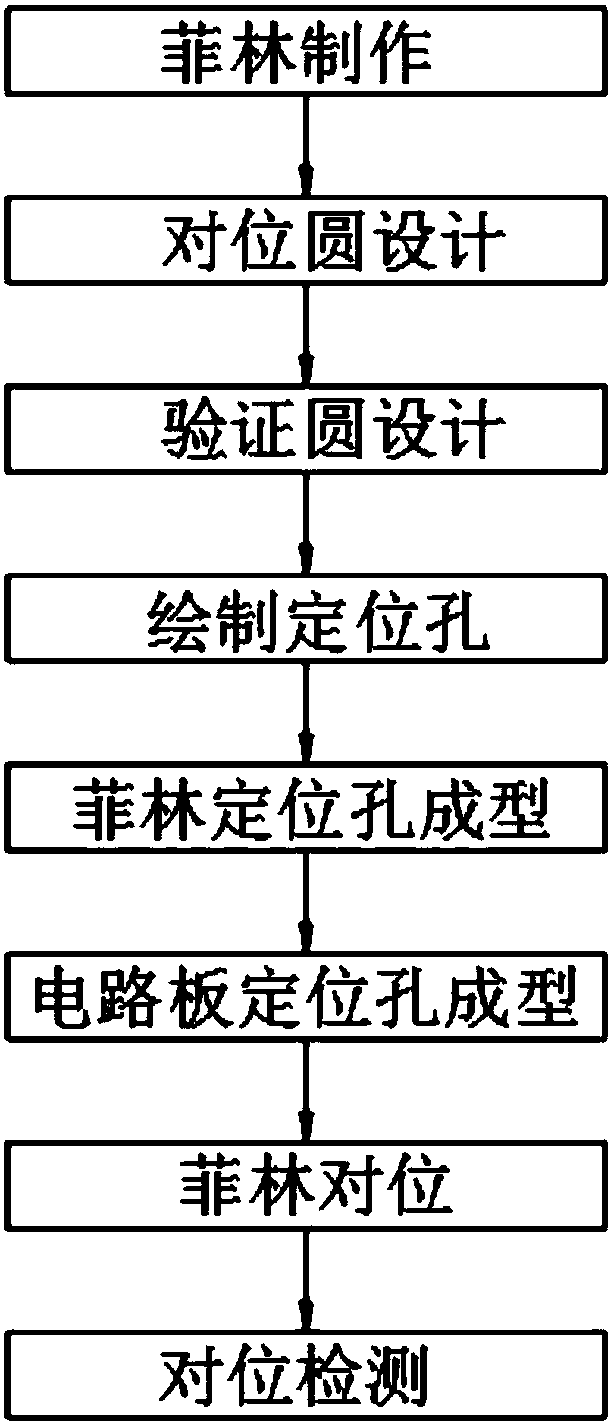

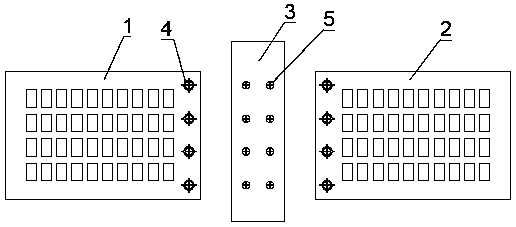

Alignment stability process for outer layer film design

InactiveCN107908085AImprove manufacturing speedImprove product qualityPhotomechanical treatmentEngineeringQuadratic element

The invention discloses an alignment stability process for outer layer film design. The alignment stability process comprises the following steps of performing film manufacturing, alignment circle designing, verification circle designing, positioning hole drawing, film positioning hole forming, circuit board positioning hole forming, and film alignment and alignment detecting, wherein in the step1), the obtained three-dimensional data needs to satisfy dimensional and surface precision condition needed in growth amplification; in growth amplification, a two-dimensional model is subjected to transition and fusion treatment based on partial similarity of three-dimensional lines on a sample; the alignment circles of an alignment circle arrangement structure and verification circles of a verification circle arrangement structure are both linearly arranged; the alignment circles of the alignment circle arrangement structure and verification circles of the verification circle arrangement structure are both positioned on the linear initial positions; and in the step 7), for ensuring film alignment precision, expansion and shrinkage needs to be measured accurately on quadratic element. Theprocess has a simple structure, convenience in manufacturing, and capability of effectively improving film alignment precision and alignment speed and improving use convenience.

Owner:KIN YIP TECHNOLDGY ELECTRONICS HUI ZHOUCO LTD

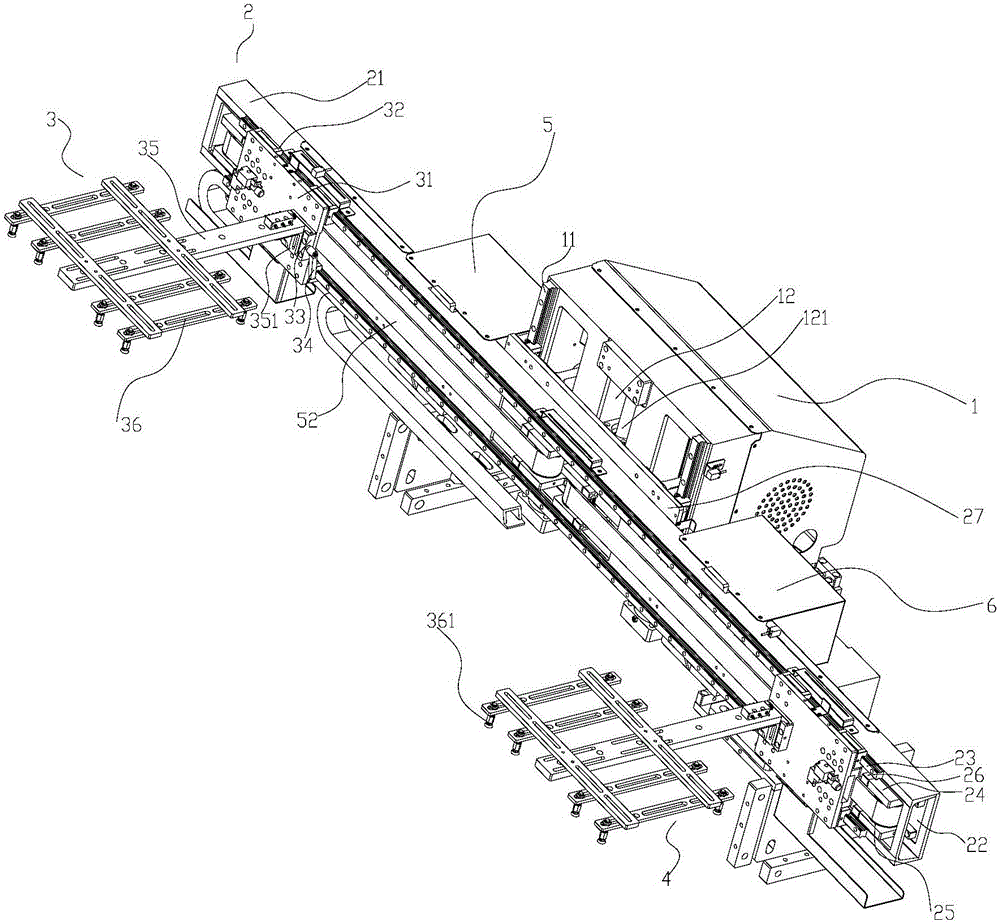

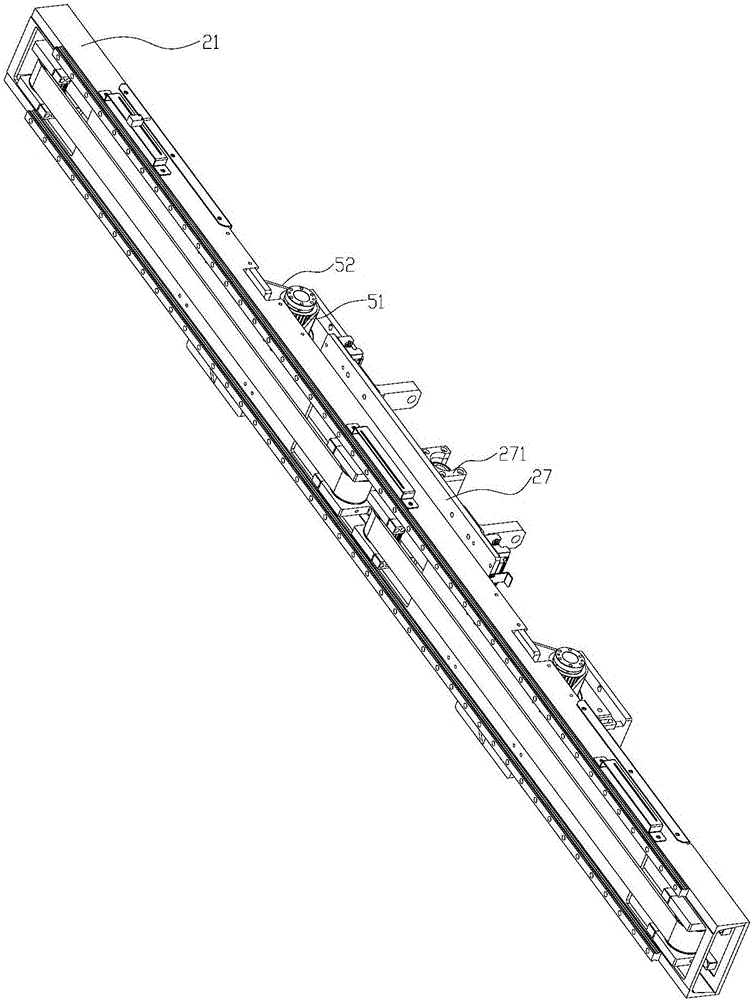

Quadratic element optical measuring device capable of continuously conveying objects to be measured

ActiveCN101929837BCorrectly synthesizedHigh precisionUsing optical meansMeasurement deviceDimension measurement

The invention discloses a quadratic element optical measuring device capable of continuously conveying objects to be measured, which can be used for continuously measuring a plurality of conveyed objects to be measured. The quadratic element optical measuring device comprises two image scanners, at least two conveyers, one steering transport mechanism and an image processor. The two image scanners are fixed at positions through which conveying belts of the at least two conveyors pass respectively, and retrieve images respectively along two approximately mutually vertical size directions on each object to be measured. The steering conveying transport mechanism steers the plurality of the objects to be measured respectively, and continuously conveys the objects to be measured between the atleast two conveyers. The image processor receives image data of the two image scanners, and synthesizes the image data to obtain a two-dimensional image of each object to be measured so as to executea geometric dimension measurement, thereby obtaining the effects of reduced cost, high unit time output and accurate measurement.

Owner:MACHVISION INC

Light painting film splicing method

The invention relates to the technical field of light painting film processing, in particular to a light painting film splicing method which comprises the following steps: preparing two splicing filmsnamely a first splicing film and a second splicing film, and then preparing a positioning film; brushing glue on the positioning film, utilizing the quadratic element to carry out precise positioningand adjust the relative position between the first splicing film and the positioning film; utilizing the quadratic element to carry out precise positioning and adjust the relative position between the second splicing film and the positioning film; after the inspection is approved, fixing and carrying out glue solution curing on the first splicing film, the second splicing film and the positioningfilm; cutting off the redundant positioning films at the two ends; and finally, utilizing a PET adhesive tape to fit the seam of the first splicing film and the second splicing film. According to thelight painting film splicing method, a reasonable splicing method is adopted to carry out high-precision splicing on the two light painting films, so that the spliced film size is increased, and theprecision can reach + / -60 microns.

Owner:嘉兴佳材科技有限公司

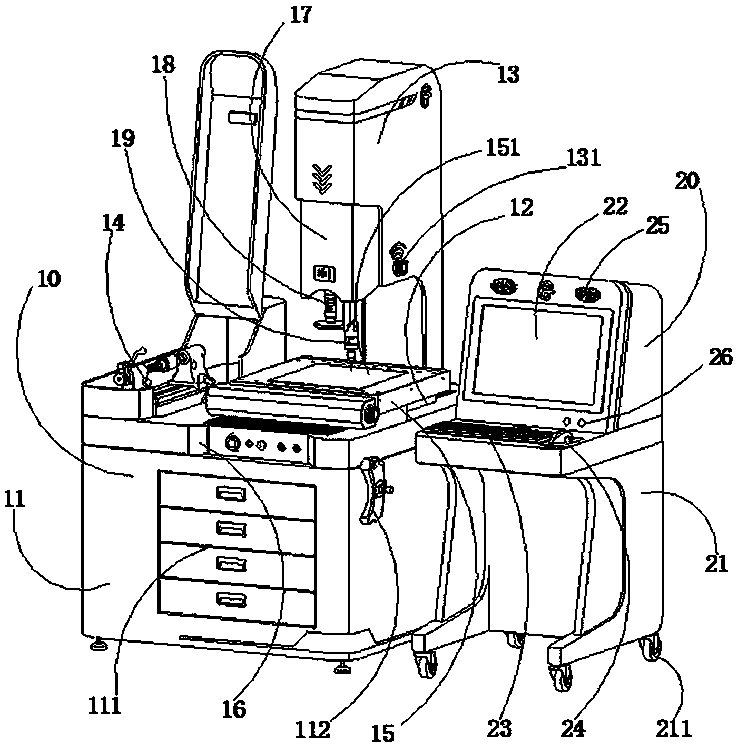

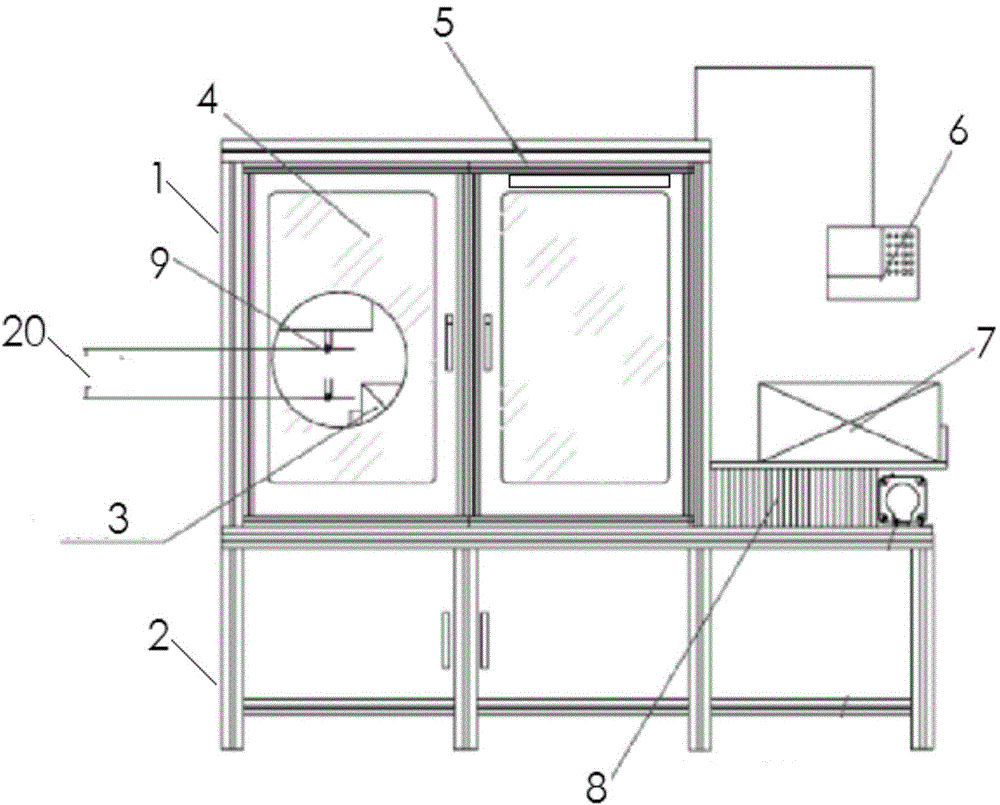

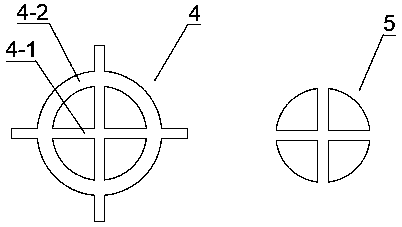

Stress quadratic element detecting integrated machine

PendingCN106839983AHighly integratedFlexible adjustmentForce measurement by measuring optical property variationUsing optical meansControl engineeringQuadratic element

The invention belongs to a field of optical detection and especially relates to a stress quadratic element detecting integrated machine capable of performing tempered glass stress detection and quadratic element information detection at the same time. The stress quadratic element detecting integrated machine includes a working table board. The working table board is provided with a stress detection mechanism and a quadratic element detection mechanism. The stress detection mechanism is arranged on the working table board and performs stress detection on a to-be-detected sample. The quadratic element detection mechanism is arranged across the stress detection mechanism and performs quadratic element detection on the to-be-detected sample. Therefore, by utilizing the stress quadratic element detecting integrated machine, stress detection and quadratic element information detection can be performed on the to-be-detected sample at the same time. The manufacture cost is reduced; the floor occupancy is saved; requirements to a detection field are lowered; only one detection worker is needed during a detection process, so that a large amount of man power is saved. Besides, the to-be-detected sample does not need to be moved again and again during the whole detection process, so that risks of damages to the to-be-detected sample are reduced and the detection efficiency is improved. The stress quadratic element detecting integrated machine has a broad market prospect.

Owner:SUZHOU PTC OPTICAL INSTR

Measuring device for tool parameters of a two-dimensional image measuring instrument

InactiveCN103206920BSame angleNo axial movementUsing optical meansLocking mechanismMeasuring instrument

The invention relates to a parameter determination device for a cutter of a quadratic element image measurer. The middle part of a fixture base is adjustably connected with a cutter axle center finding and axial positioning mechanism and a sliding block through a connecting groove. The right end of the fixture base is adjustably connected with a pressing stirring mechanism. The sliding block is positioned between the cutter axle center finding and axial positioning mechanism and the pressing stirring mechanism. A locking mechanism is arranged on each of the cutter axle center finding and axial positioning mechanism and the sliding block. A second V-shaped positioning plate is fixedly connected to the front end face of the sliding block, and a first V-shaped positioning plate is fixedly connected to the right end face of the fixture base. The cutter is positioned and centered by the axle center finding and axial positioning mechanism and the V-shaped positioning plates to facilitate the accurate clamping of a product, parameters such as circular runout of the cutter are conveniently measured by the pressing stirring mechanism, the whole tool is unlimited to the parameter measurement of the cutter in a certain specification, and the pressing stirring mechanism is adjusted upwards and downwards to ensure practicability for cutters in different specifications.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Quadratic element imager

ActiveCN104634247ARealize synchronous controlRealize transformationUsing optical meansCamera lensQuadratic element

The invention discloses a quadratic element imager, and belongs to the field of imager equipment. The quadratic element imager comprises a lens, wherein the lens is arranged on a connection frame; the connection frame is arranged on a stand column; the stand column is arranged on a rotary mechanism; the rotary mechanism is arranged on a bottom plate through a platform deck; a plurality of sliding chutes which are parallel with each other are formed in the bottom plate; moving mechanisms are arranged in the sliding chutes; the moving mechanisms are connected with a transmission mechanism. The quadratic element imager is reasonable in design, is easy to operate, can be moved and adjusted conveniently and rapidly, and has a higher industrial application value; the aims of accurately moving, adjusting and positioning are fulfilled.

Owner:东莞市乾丰电子科技有限公司

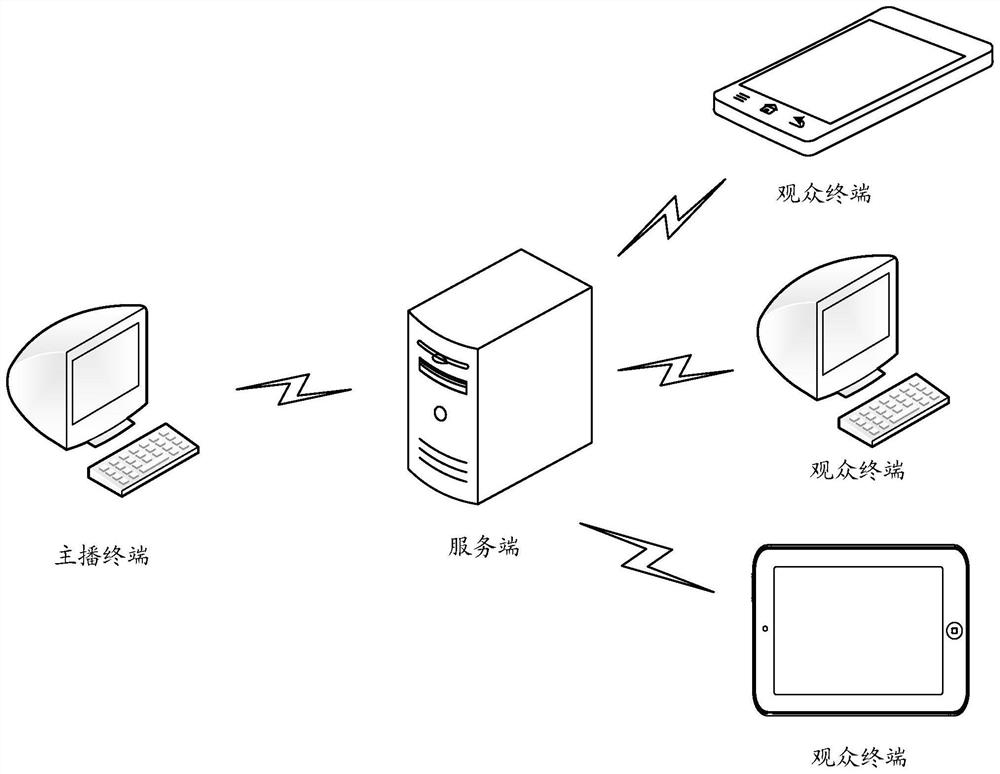

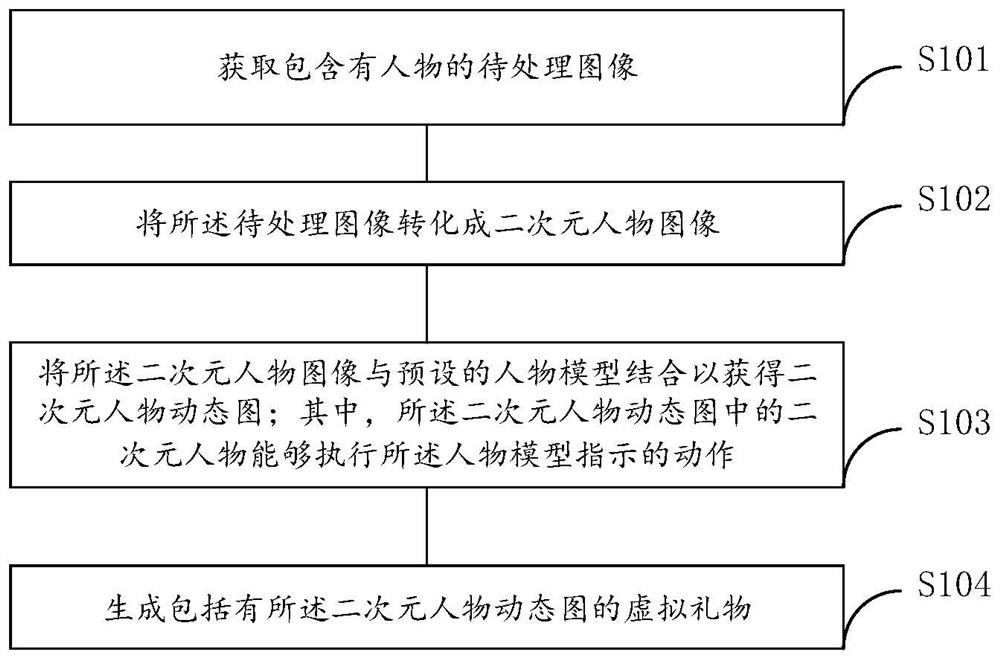

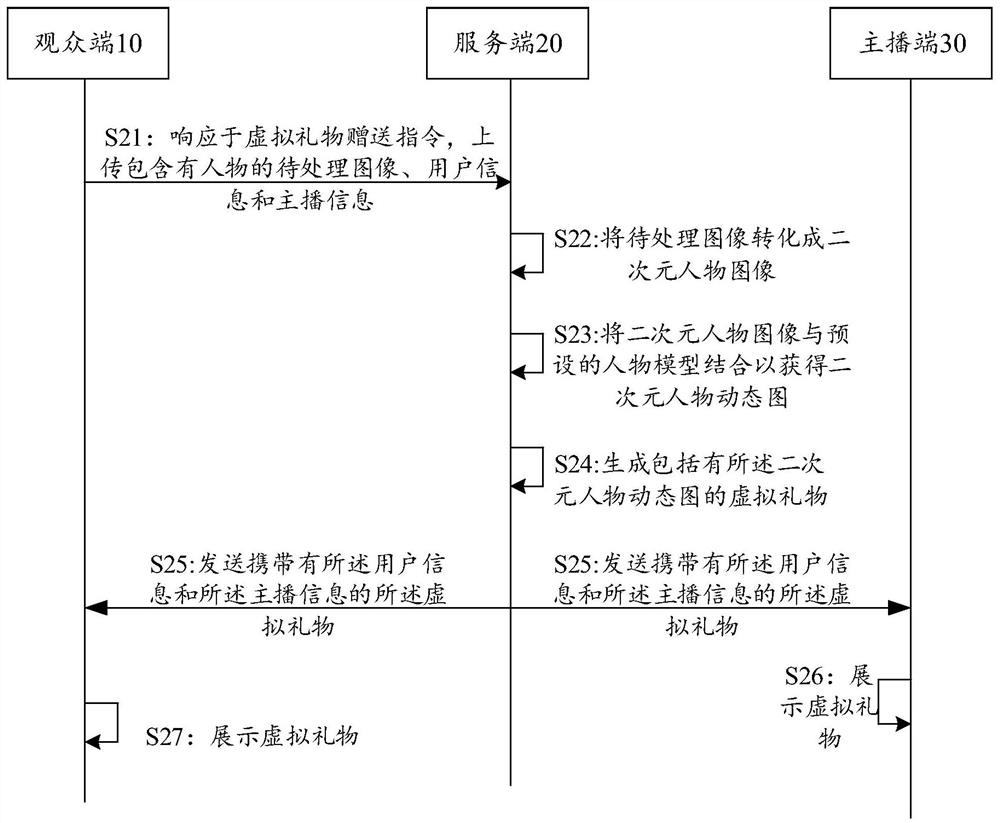

Quadratic element virtual gift generation method and device, electronic equipment and storage medium

PendingCN113992927ARealize personalized productionSelective content distributionPersonalizationAlgorithm

The invention relates to a quadratic element virtual gift generation method and device, electronic equipment and a storage medium. The method comprises the following steps: acquiring a to-be-processed image containing a figure; converting the to-be-processed image into a quadratic element figure image; combining the quadratic element character image with a preset character model to obtain a quadratic element character dynamic graph, wherein quadratic element characters in the quadratic element character dynamic graph can execute actions indicated by the character model; and generating a virtual gift comprising the quadratic element character dynamic graph. According to the embodiment, personalized production of the virtual gift is realized.

Owner:广州方硅信息技术有限公司

A method of calibrating the distance between axes

ActiveCN106736789BSolve the machining accuracyEasy to processDrilling/boring measurement devicesPositioning apparatusEngineeringThermal expansion

Owner:HANS CNC SCI & TECH

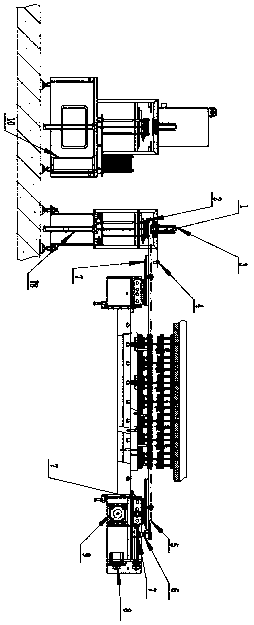

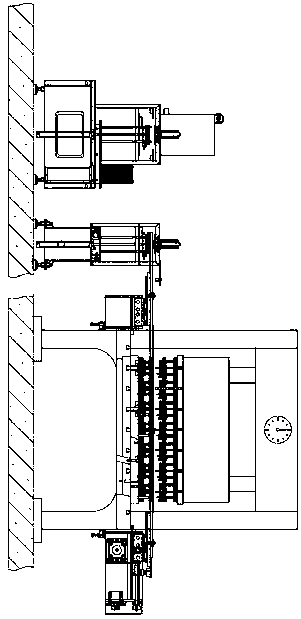

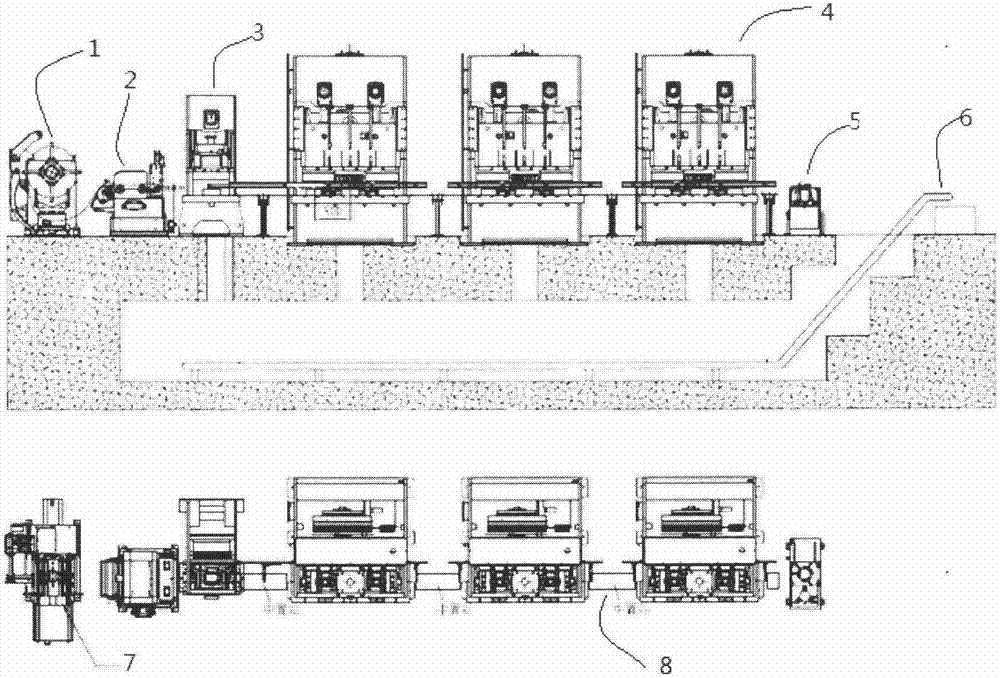

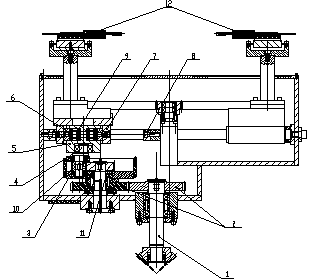

Multimachine and multi-engineering automated stamping production line

InactiveCN107398500ASmall footprintImprove work efficiencyMetal-working feeding devicesPositioning devicesProduction lineManipulator

The invention discloses a multi-machine and multi-engineering automatic stamping production line. Aiming at the technical problems that the casing parts of household appliances need multi-process forming, the labor intensity of workers is high, the safety factor is low, and the production efficiency is low, a multi-process production line that can adapt to the production process requirements is designed. Machine multi-engineering automated stamping production line. The production line includes a feeding assembly, a stamping assembly and a receiving assembly; it is characterized in that the stamping assembly includes 1 open single-point press (3), 3 open double-point presses (4), 1 set of nine engineering Mold, 3 sets of two-dimensional manipulators. Each set of two-dimensional manipulators is respectively arranged between two presses; the open single-point press (3) is connected to the feeding assembly, and one of the open double-point presses (4) is connected to the receiving assembly . The production line has the advantages of less labor, safe operation, high production efficiency and high processing precision, which fully reflects the modern production characteristics of automatic stamping equipment.

Owner:玉林市飞宇科技开发有限公司

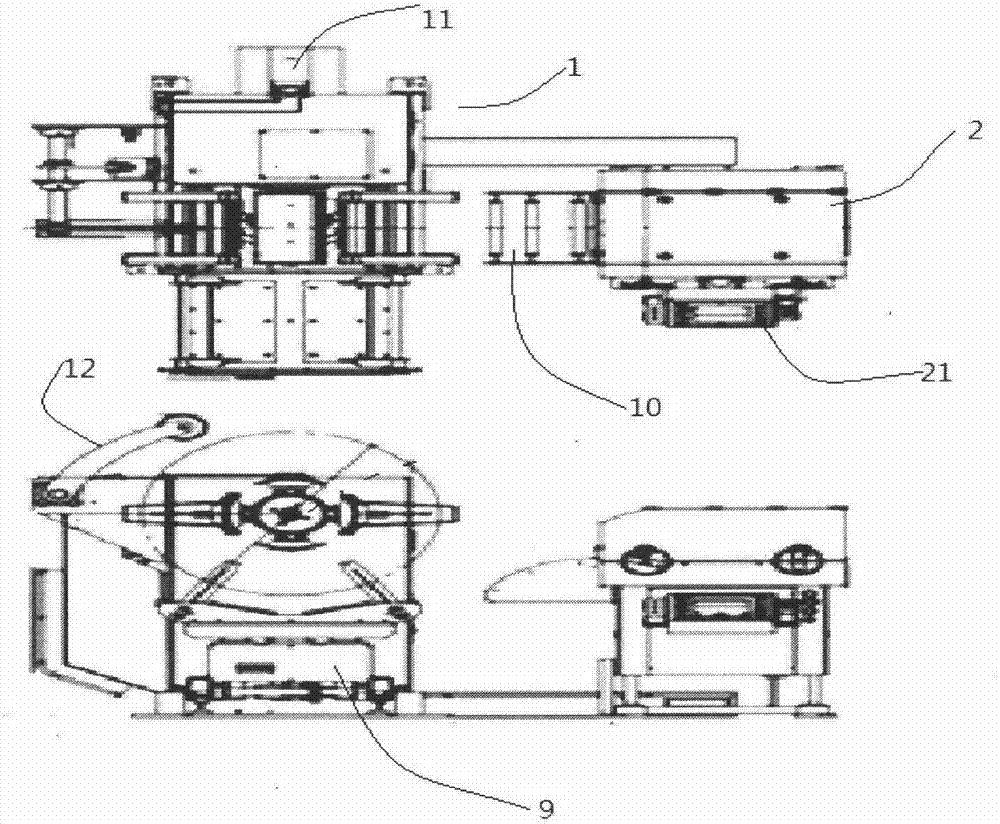

Quadratic-element manipulator with small machine table

The invention discloses a quadratic-element manipulator with a small machine table. The quadratic-element manipulator comprises a base, a lifting assembly arranged on the base, a moving cross arm fixing frame assembly arranged at the top end of the lifting assembly, a moving cross arm assembly arranged on the moving cross arm fixing frame assembly, and a grabbing jaw moving assembly arranged on the moving cross arm assembly, wherein the moving cross arm assembly comprises a moving cross arm drive device arranged on the moving cross arm fixing frame assembly and composed of a motor speed reducer, a cross arm drive wheel connected to the moving cross arm drive device through a transmission connection shaft, and a moving cross arm slidably arranged on the moving cross arm fixing frame; and a cross arm drive belt used cooperatively with the cross arm drive wheel is arranged on the moving cross arm. According to the quadratic-element manipulator disclosed by the invention, the movable distance of a grabbing jaw is greatly increased through the arrangement of the moving cross arm assembly and the grabbing jaw moving assembly which are used cooperatively; and a workpiece can be directly transferred between two stations, and a workpiece transfer link is reduced, so that production efficiency is increased.

Owner:SUZHOU SHENYUN ROBOT

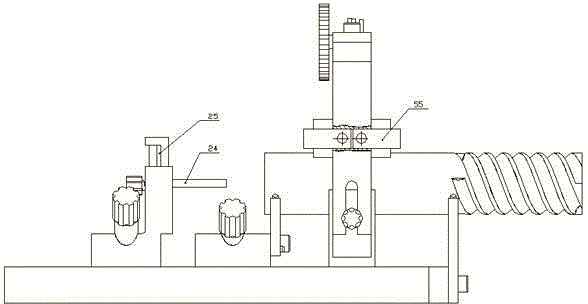

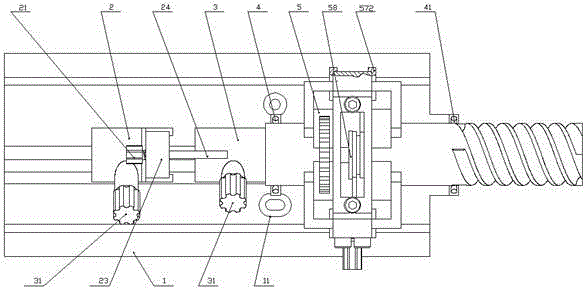

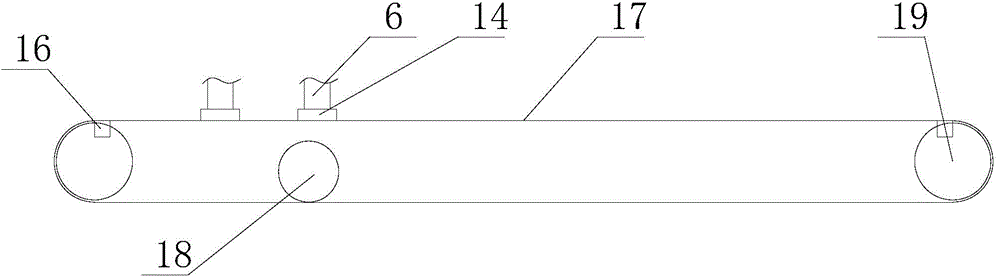

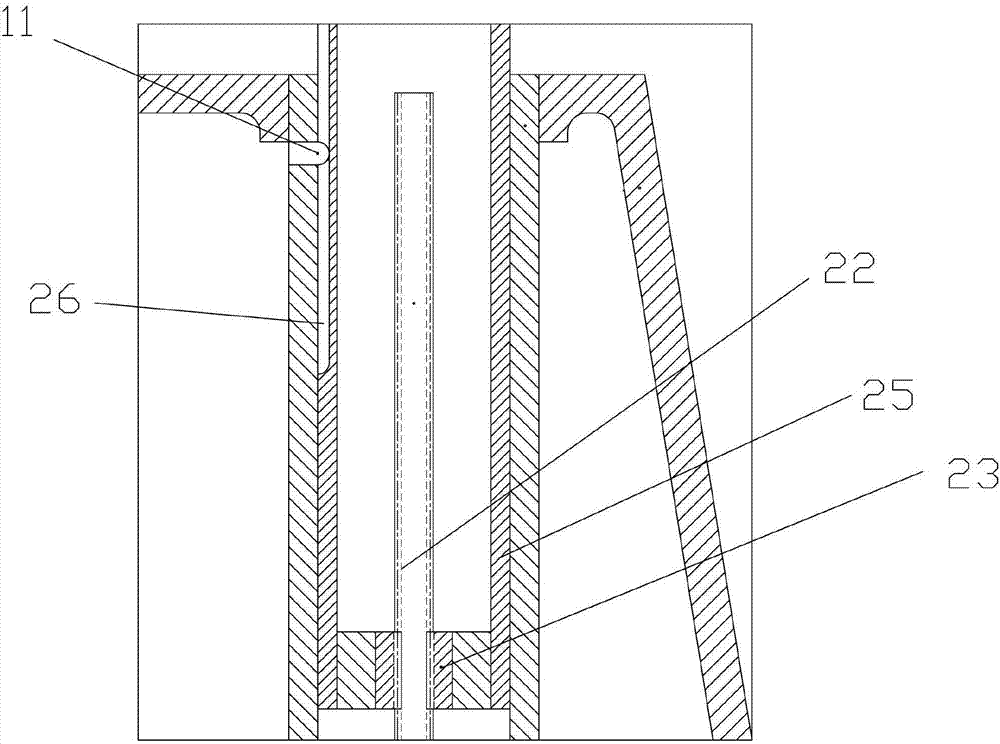

Quadratic element mechanical arm feeding-in-place buffer mechanism

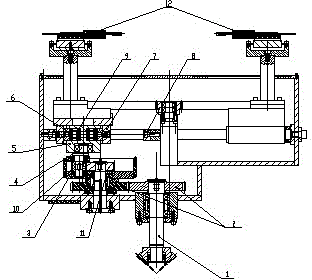

The invention relates to an invented feeding buffer device mechanism. The quadratic element mechanical arm feeding-in-place buffer mechanism comprises a transmission shaft (1), the transmission shaft (1) is connected with an eccentric shaft mechanism through a gear set (2), an eccentric shaft (4) of the eccentric shaft mechanism is connected with a clamping mechanism, the clamping mechanism comprises a base and clamps arranged on two sides of the base, a moving seat connected with the eccentric shaft (4) is arranged on one side of the base, and a fixed seat is arranged on the other side of the base. A stop block (7) is arranged at the front end of the moving seat, a limit block (8) corresponding to the stop block (7) is arranged at the front end of the fixed seat, and a clamped material travel distance is prearranged between the stop block (7) and the limit block (8). Through gear transmission and the arrangement of the eccentric mechanism, the moving seat and the fixed seat, a mechanical arm can achieve high-efficiency and high-precision feeding.

Owner:YANGZHOU FORGING MACHINE TOOL

Two-dimensional manipulator feeding in place buffer mechanism

The invention relates to an invented feeding buffer device mechanism. The quadratic element mechanical arm feeding-in-place buffer mechanism comprises a transmission shaft (1), the transmission shaft (1) is connected with an eccentric shaft mechanism through a gear set (2), an eccentric shaft (4) of the eccentric shaft mechanism is connected with a clamping mechanism, the clamping mechanism comprises a base and clamps arranged on two sides of the base, a moving seat connected with the eccentric shaft (4) is arranged on one side of the base, and a fixed seat is arranged on the other side of the base. A stop block (7) is arranged at the front end of the moving seat, a limit block (8) corresponding to the stop block (7) is arranged at the front end of the fixed seat, and a clamped material travel distance is prearranged between the stop block (7) and the limit block (8). Through gear transmission and the arrangement of the eccentric mechanism, the moving seat and the fixed seat, a mechanical arm can achieve high-efficiency and high-precision feeding.

Owner:YANGZHOU FORGING MACHINE TOOL

Two-dimensional imager

ActiveCN104634247BRealize synchronous controlRealize transformationUsing optical meansEngineeringQuadratic element

Owner:东莞市乾丰电子科技有限公司

Optical quadratic element based profile tolerance measurement method for spherical surface

InactiveCN110095084AHigh practicality and social valueUsing optical meansQuadratic elementComputer science

The invention discloses an optical quadratic element based profile tolerance measurement method for the spherical surface, and relates to the field of spherical surface contour degree detection of machine tooled parts. The method comprises that S1) all parts are arranged successively, and placed on a projector to project 2D surface contour degree lines successively; S2) an ideal 2D surface contourdegree zone of the parts s drafted, and a head model with a 2D surface contour degree tolerance zone of the parts is made; S3) the ideal 2D surface contour degree zone is overlapped with a measured practical 2D surface contour degree line, namely, the head model is overlapped in the head portion of a measured part; and S4) if the measured practical 2D surface contour degree line within the ideal2D surface contour degree zone is qualified, and otherwise, is unqualified. The method is simple, easy in measurement, and extremely high in practicality and social value.

Owner:苏州泰润达发动机零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com