Semi-automatic carton opening machine

A kind of unpacking machine, semi-automatic technology, used in packaging, transportation and packaging, unsealing of objects, etc., can solve the problems of easily hazardous products, high manufacturing costs, high maintenance costs, achieve high cutting efficiency, reduce manufacturing costs and operating costs , the effect of good motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

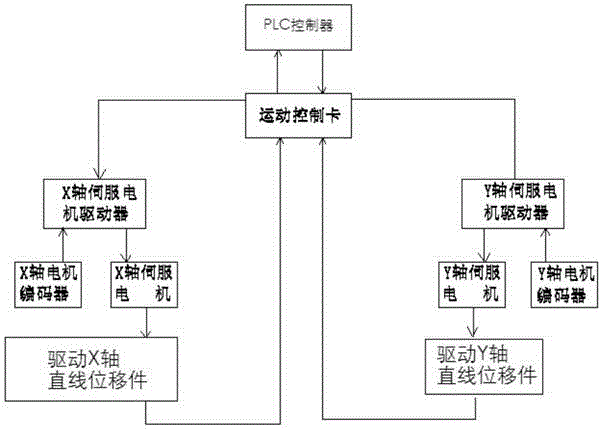

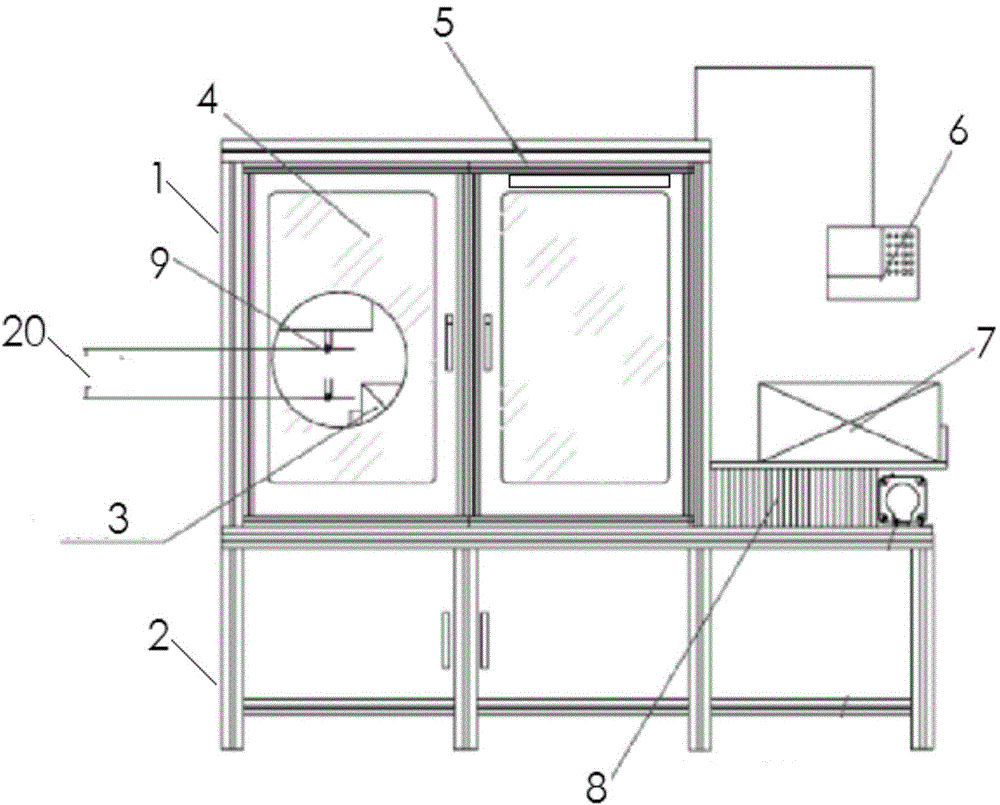

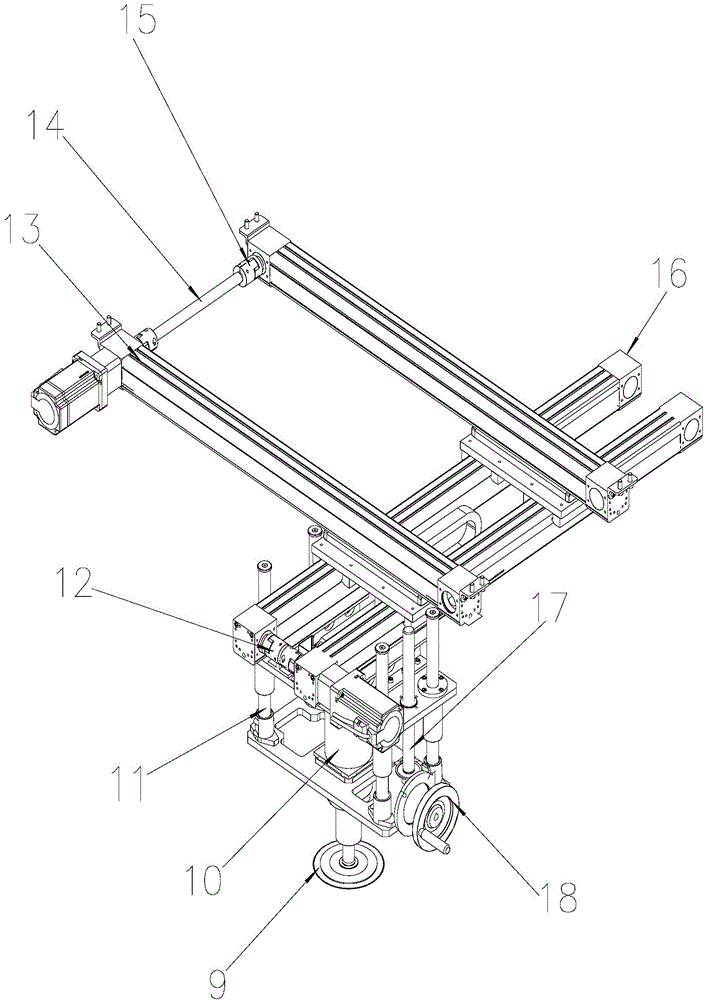

[0020] see figure 1 -4. A semi-automatic carton unpacking machine of the present invention, consisting of a PLC controller, a two-dimensional movement mechanism, a conveying roller, a pneumatic side pressure device, a front barrier, a sensor, a touch screen, a control cabinet, a control cabinet bracket, and an organ-type protective cover The control cabinet is supported by the control cabinet bracket, the PLC controller and the two-dimensional motion mechanism are located on the top of the control cabinet, the touch screen is located outside the control cabinet, and the organ type protective cover is located on the side of the control cabinet bracket side, the pick-and-place station is located on the side of the organ-type protective cover, the cutting station is located in the lower part of the control cabinet, the pick-and-place stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com