Patents

Literature

53results about How to "Good motion precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

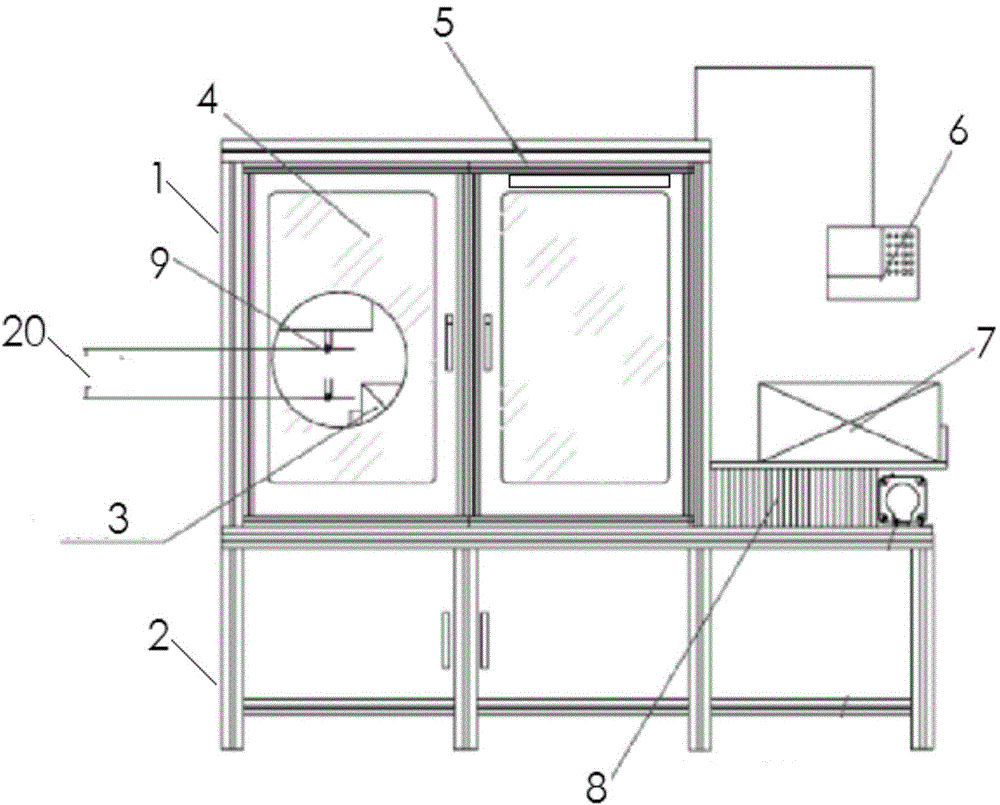

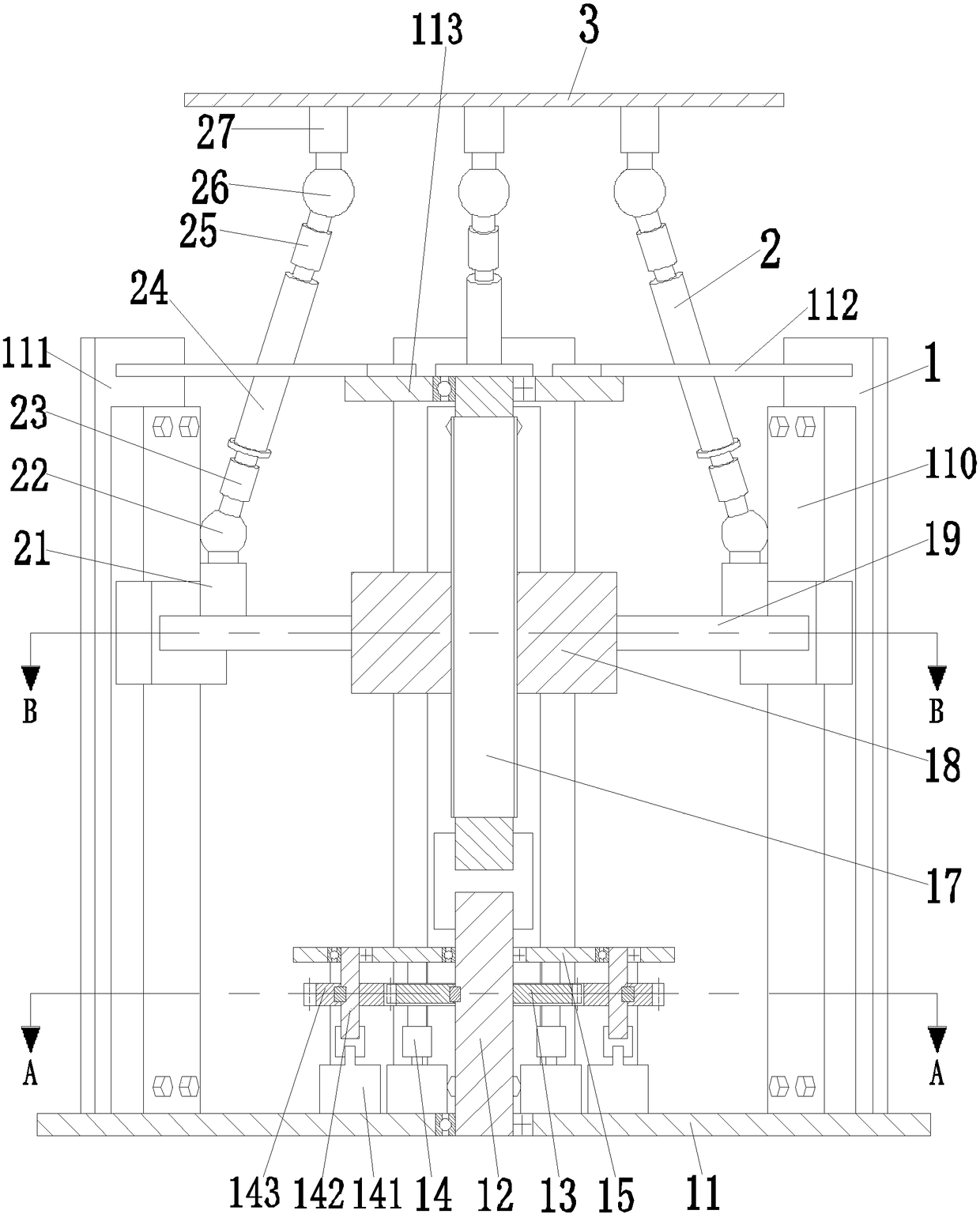

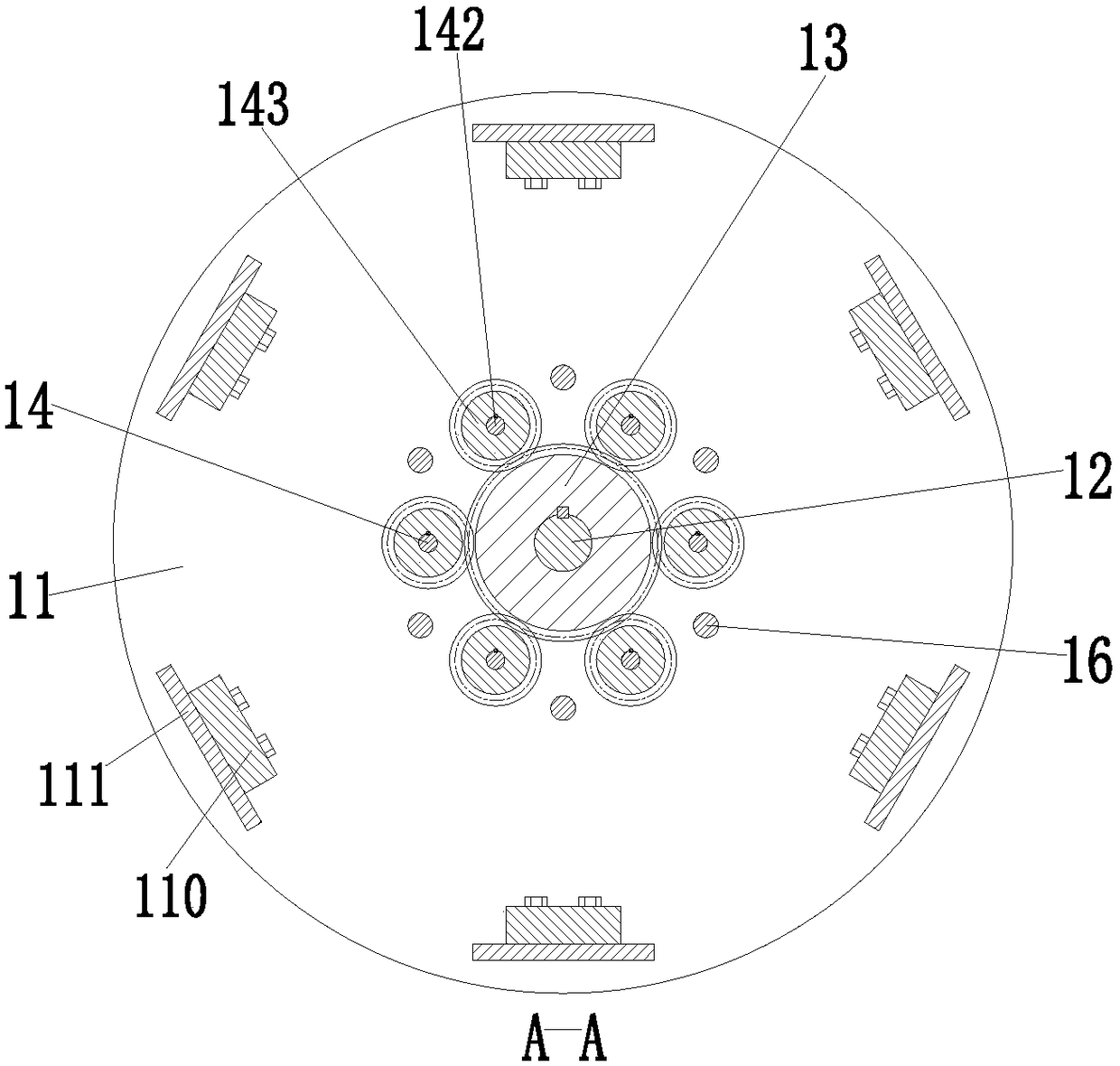

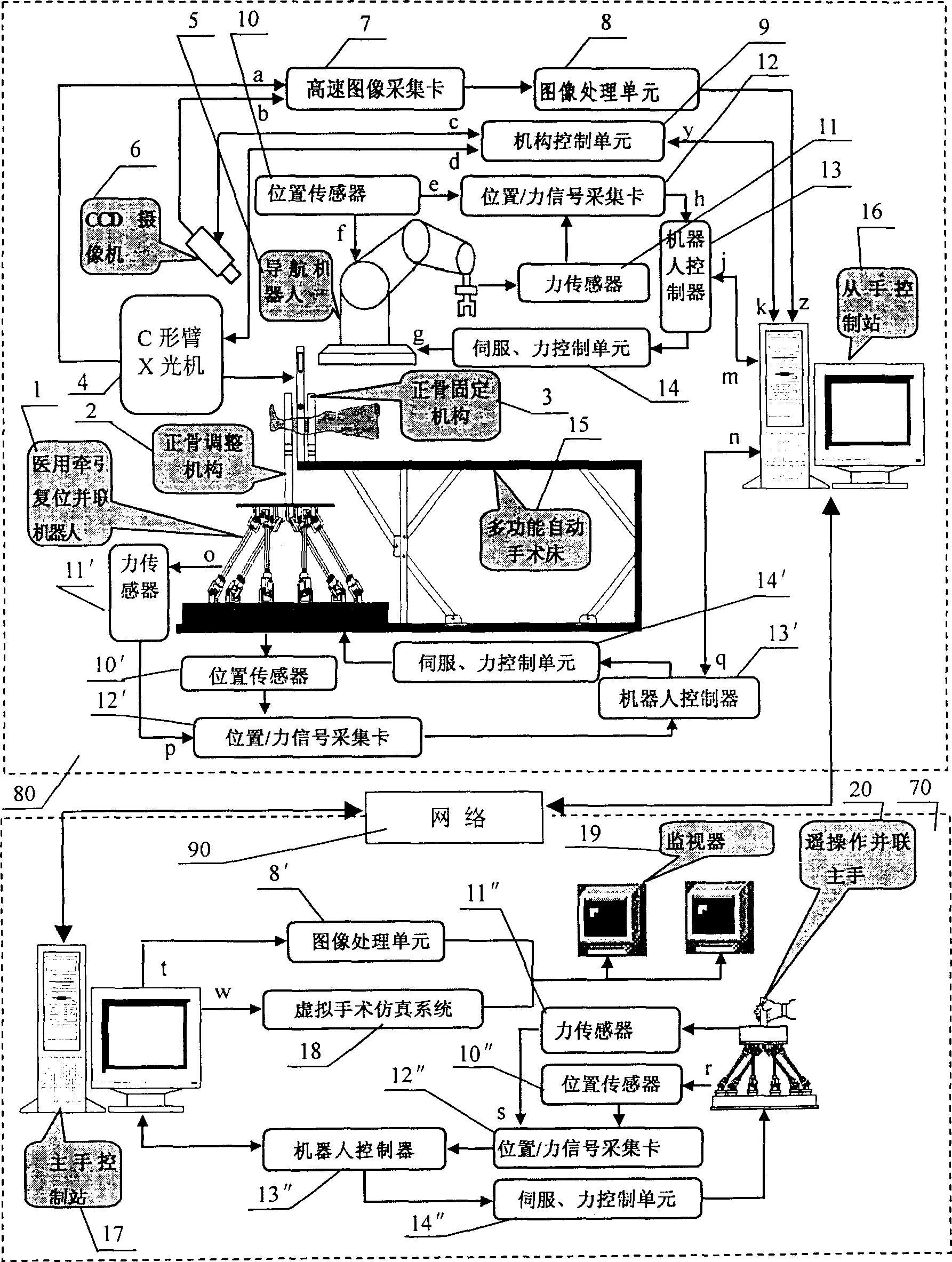

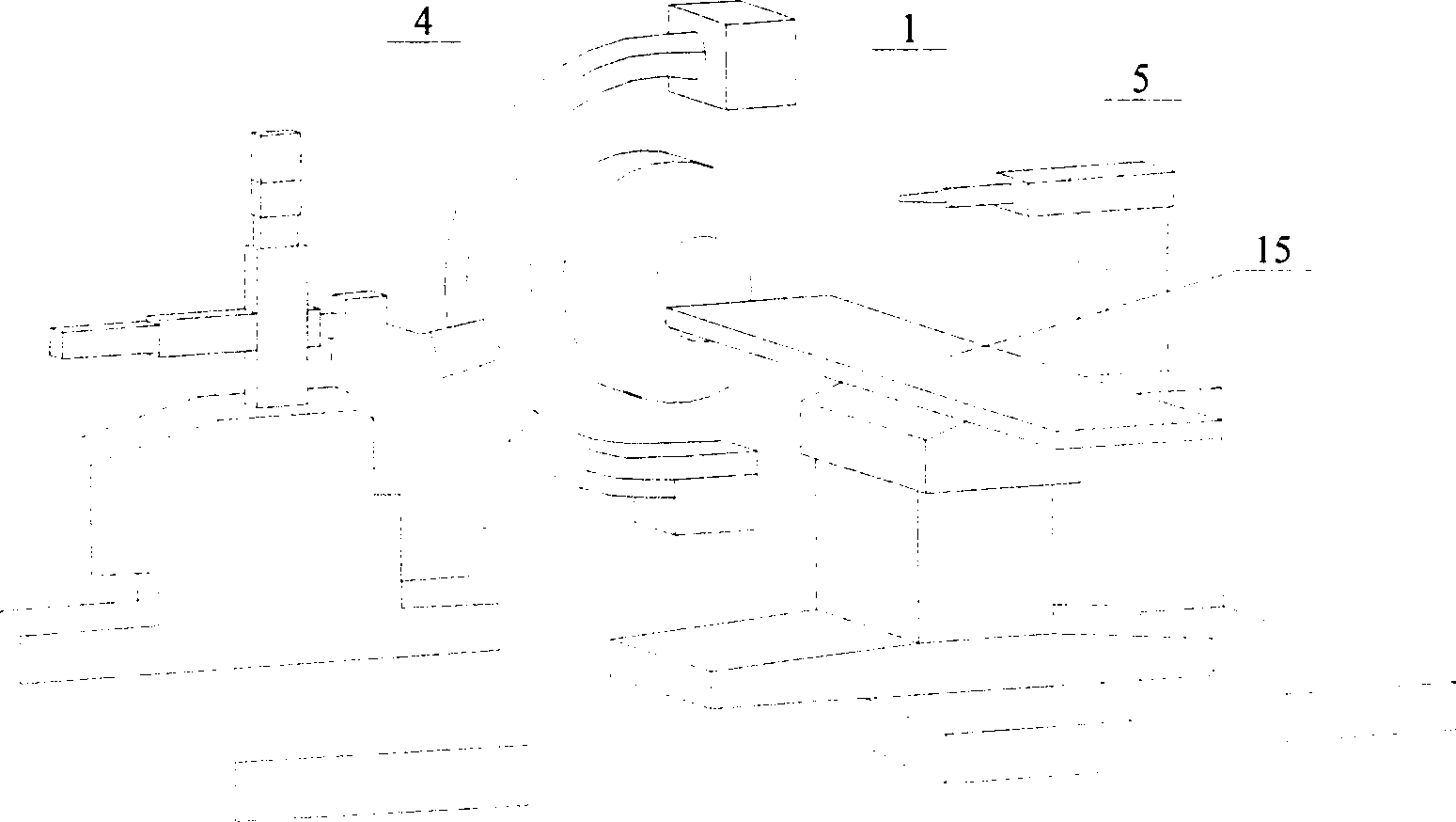

Robot assisted bone setting operation medical system with lock marrow internal nail

InactiveCN1561923AAchieve therapeutic effectImprove general performanceInternal osteosythesisDiagnosticsDistance HealingSimulation

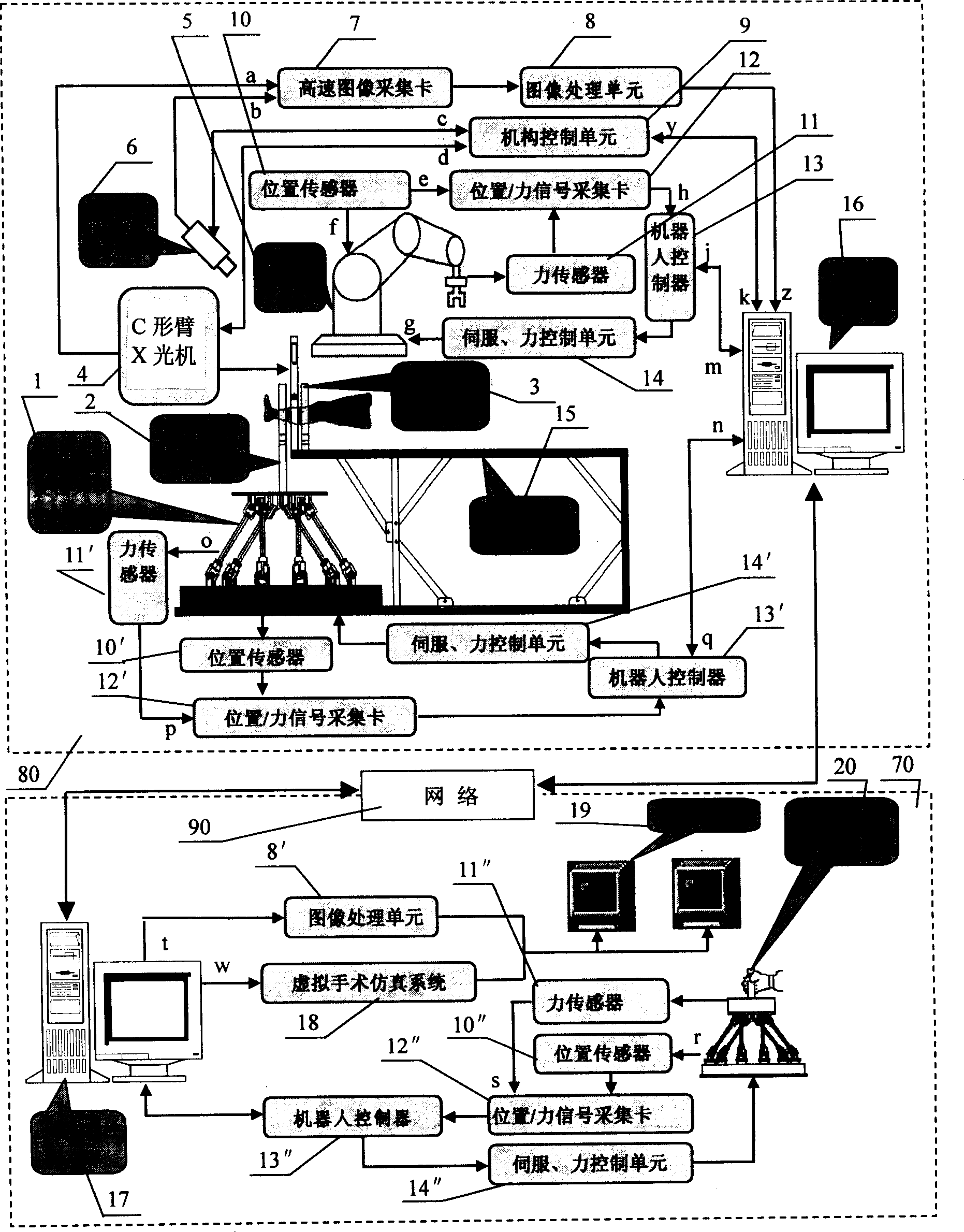

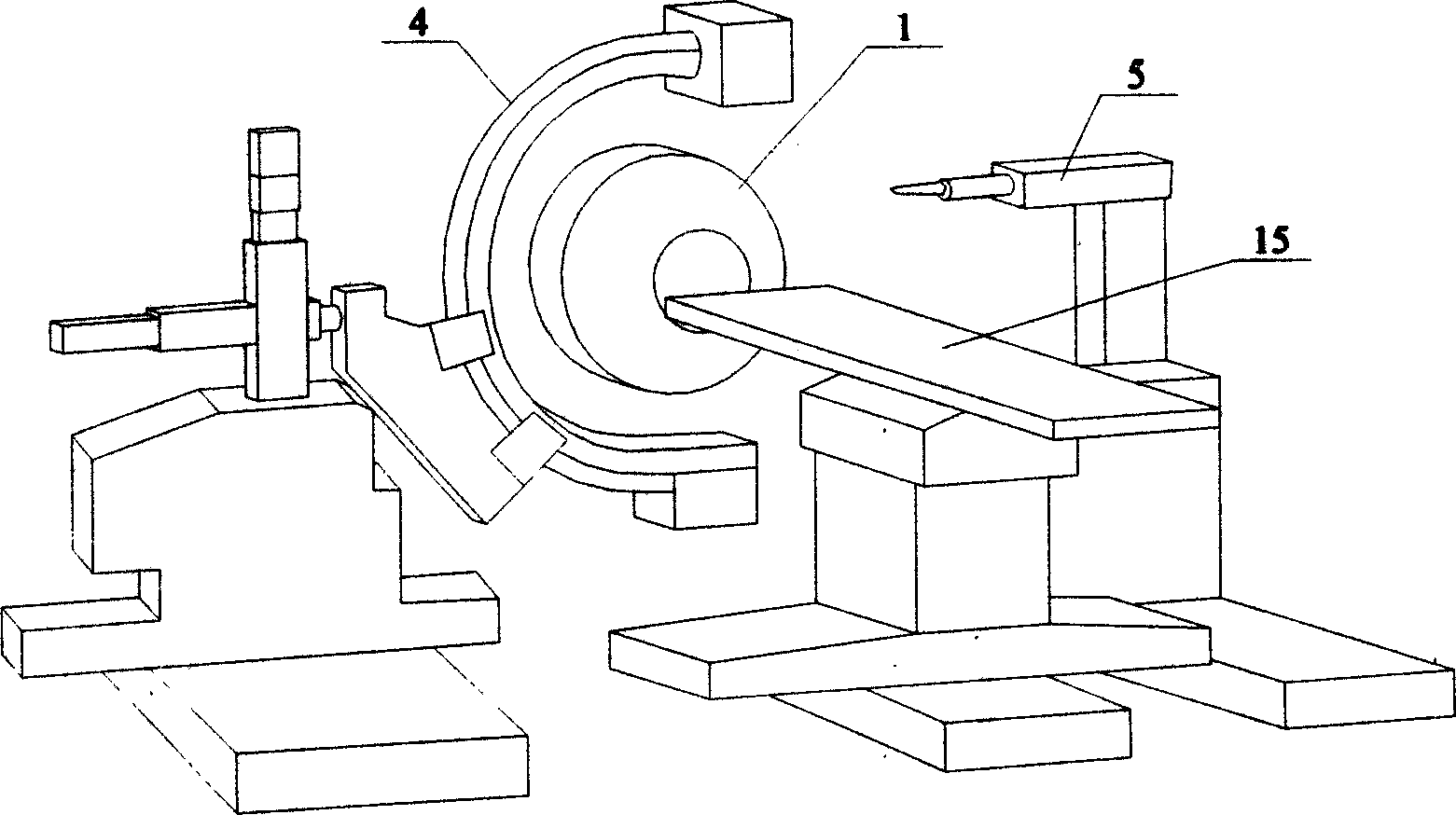

A robot aided surgical system for the bone setting operation with the locking intramedullary nail is composed of multifunctional automatic operation bed, robot, bone setting regulator on said robot, bone fixing mechanism, high-accuracy full-automatic X-ray machine with C-shaped arm, navigation robot, robot controller, master hand control station, and slave hand control station.

Owner:HARBIN INST OF TECH

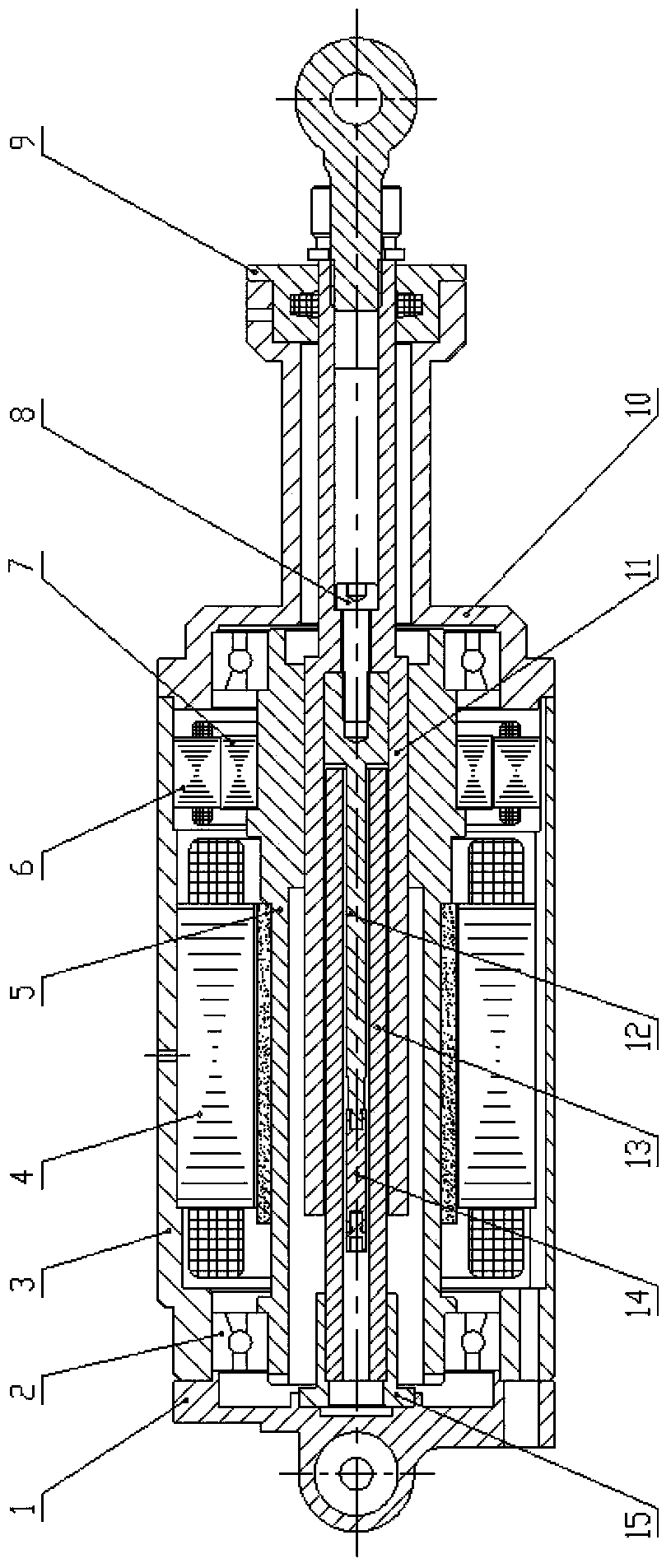

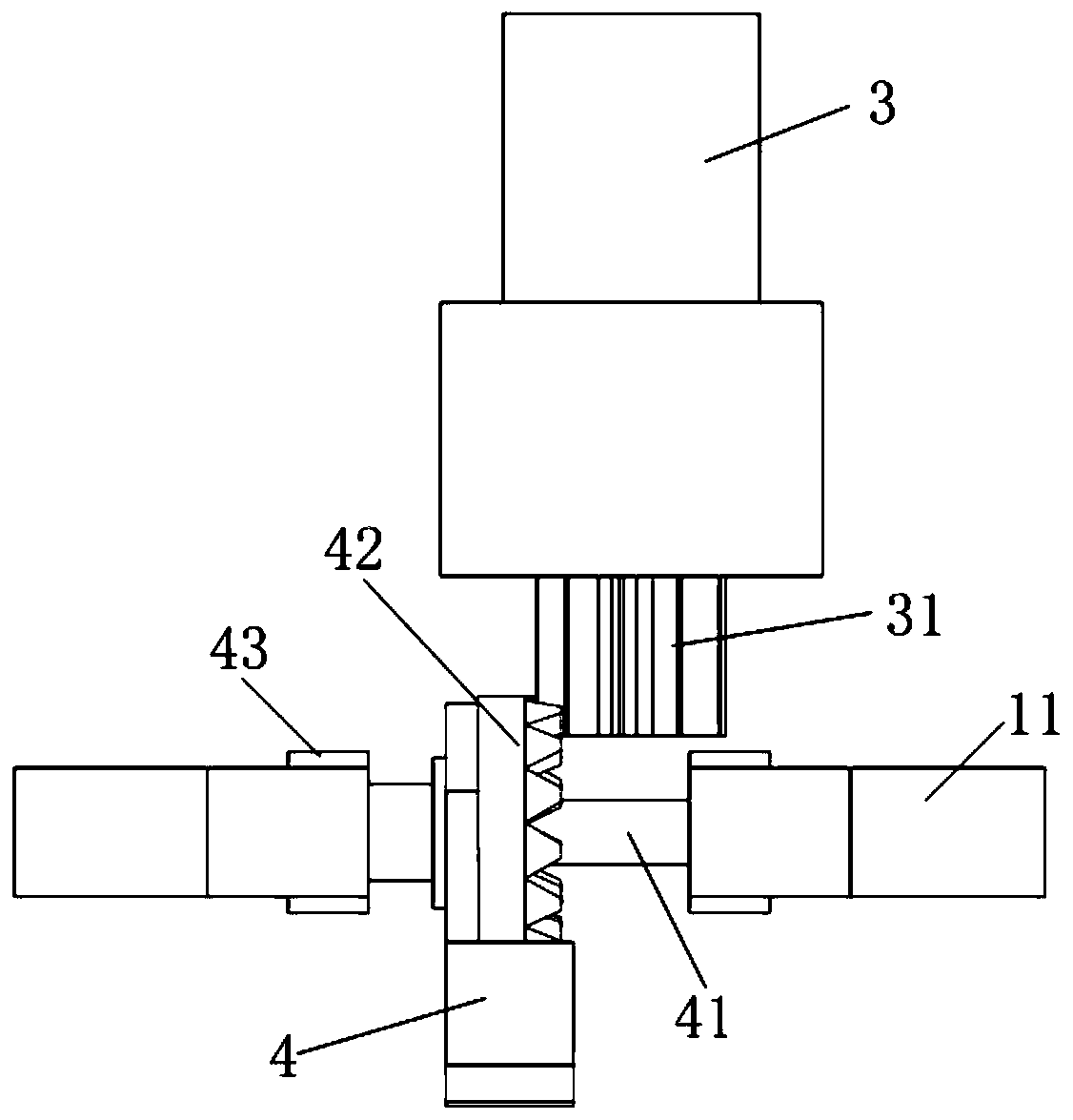

Highly-integrated electro-mechanical actuator and application method thereof

InactiveCN104218728AImprove transmission efficiencyReduce volumeStructural associationMechanical energy handlingActuatorScrew thread

The invention provides a highly-integrated electro-mechanical actuator and an application method thereof. The highly-integrated electro-mechanical actuator comprises a motor and a lead screw drive mechanism, the motor comprises a motor rotor which comprises a rotating shaft, the lead screw drive mechanism comprises a lead screw shaft and a lead screw guiding and supporting device, the rotating shaft is provided with an internal thread, the lead screw shaft is provided with an external thread which is meshed with the internal thread of the rotating shaft, and the lead screw guiding and supporting device used for supporting the lead screw shaft and limiting the lead screw shaft to rotate is mounted at the output end of the lead screw shaft. The highly-integrated electro-mechanical actuator has the advantages of small size, light weight, compact structure, high bearing capacity and high kinematic accuracy and drive efficiency.

Owner:北京华中星科技有限公司

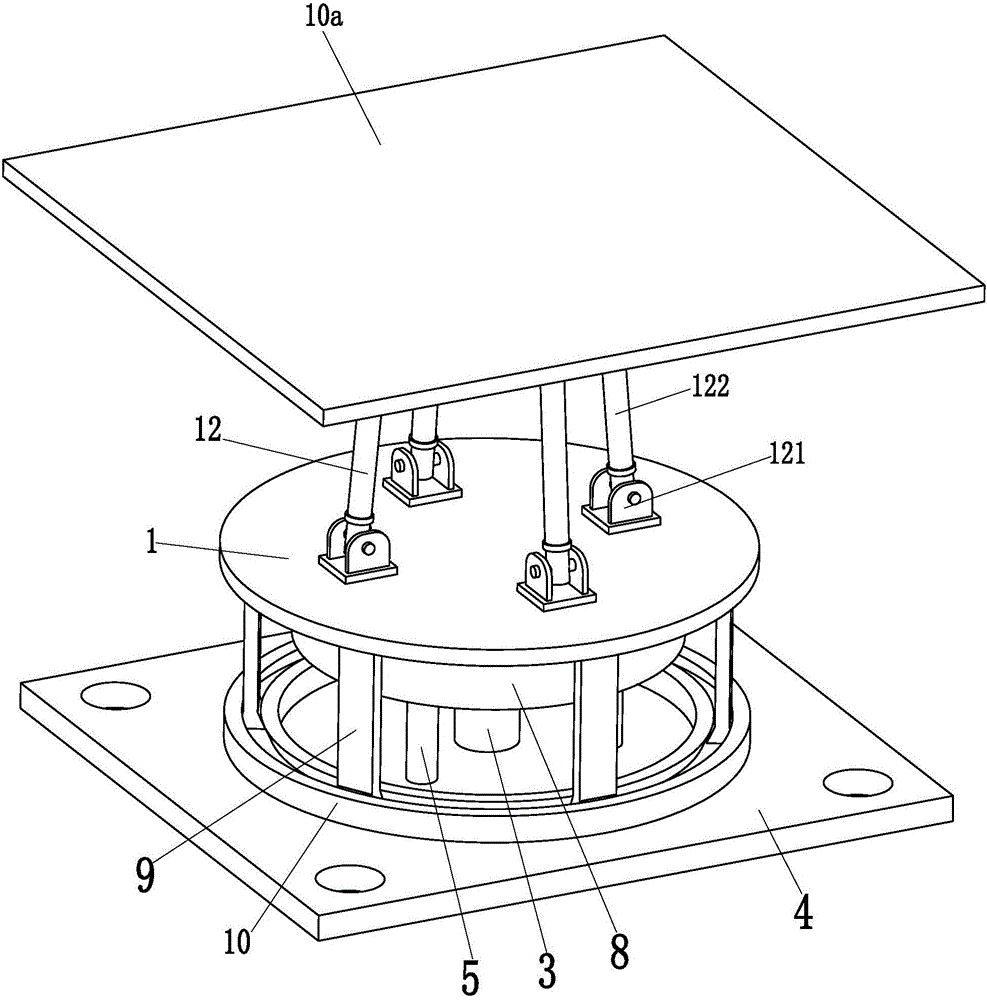

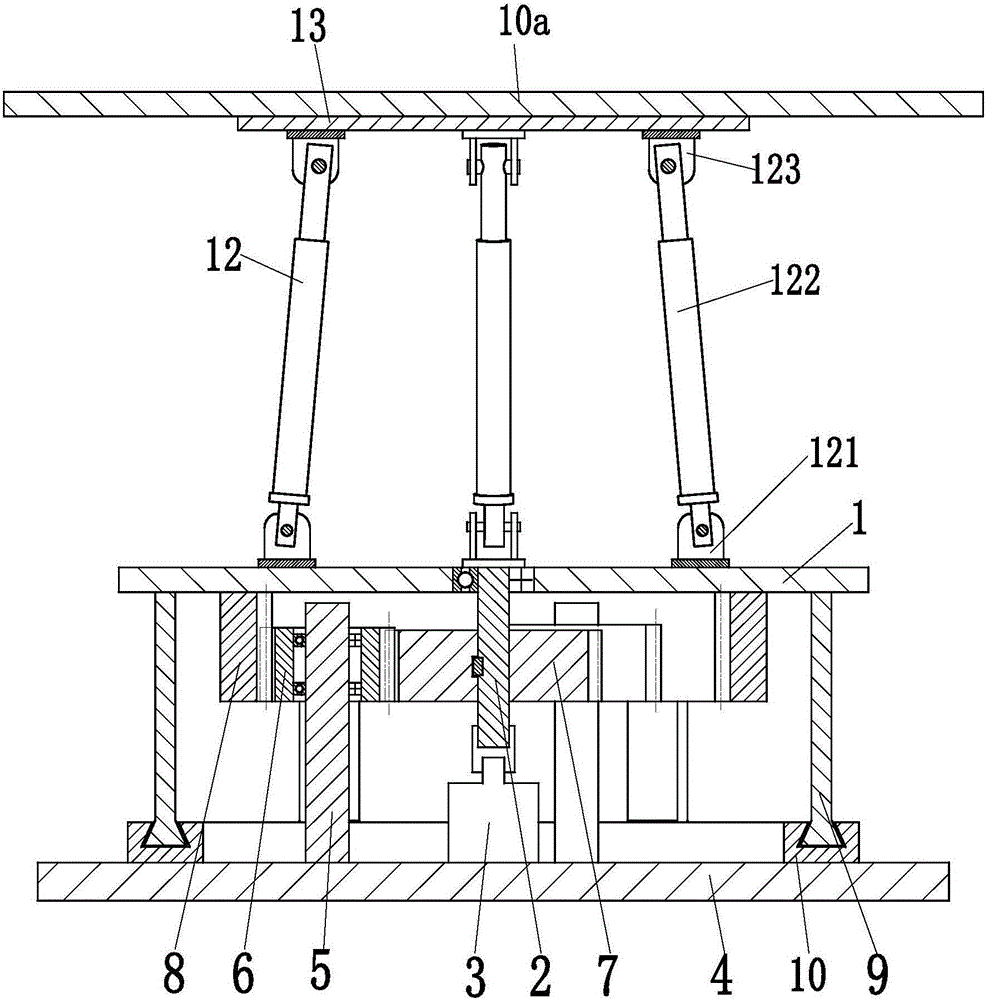

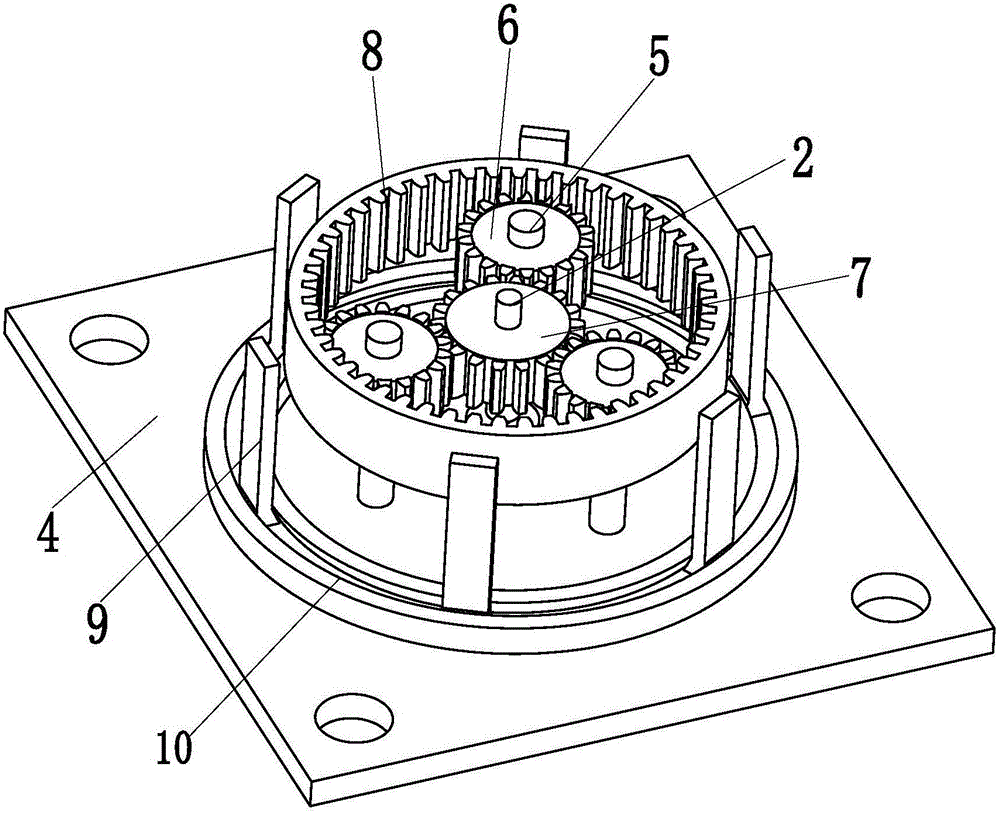

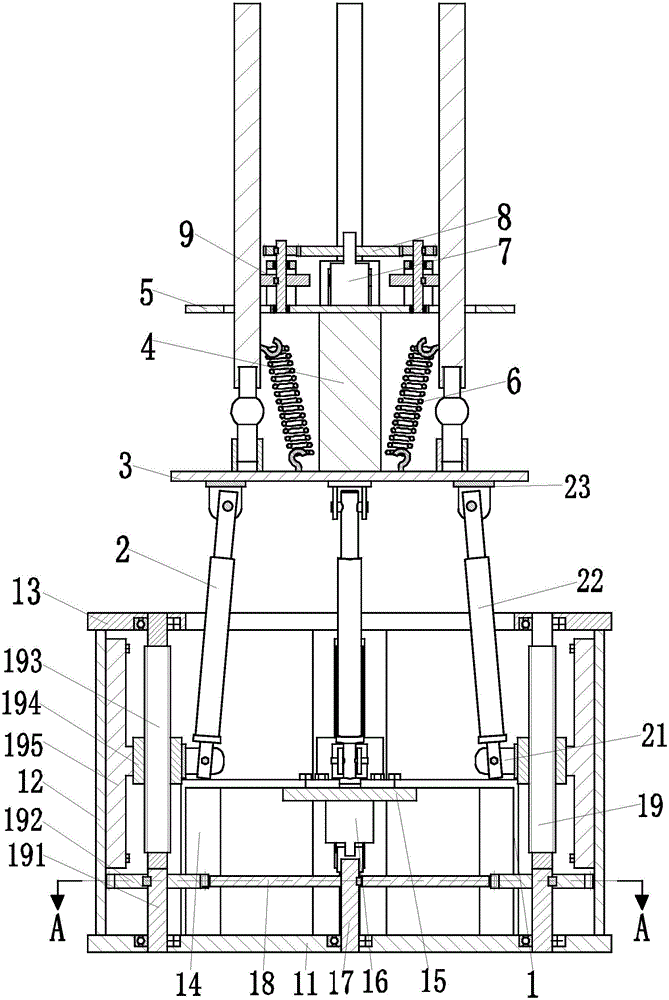

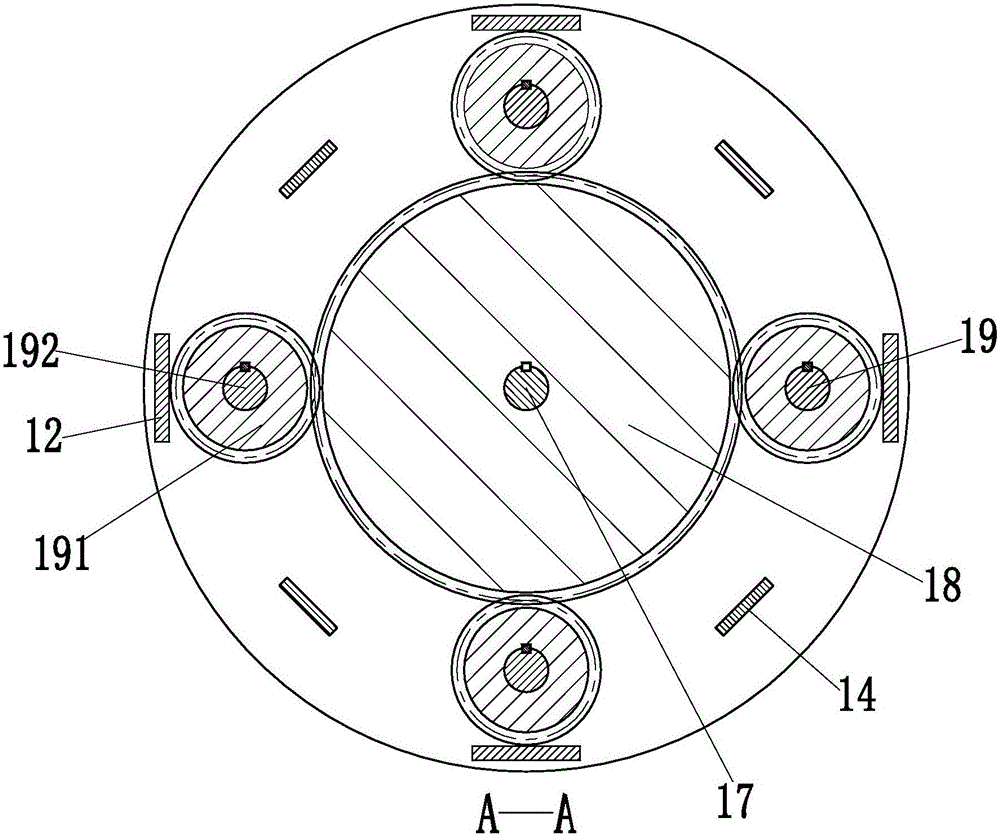

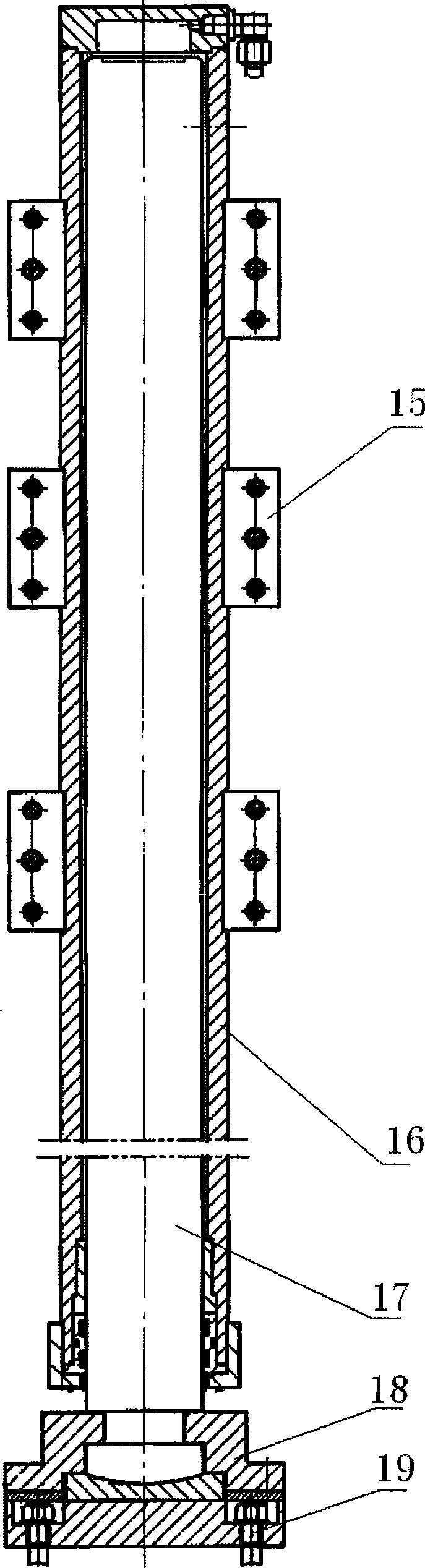

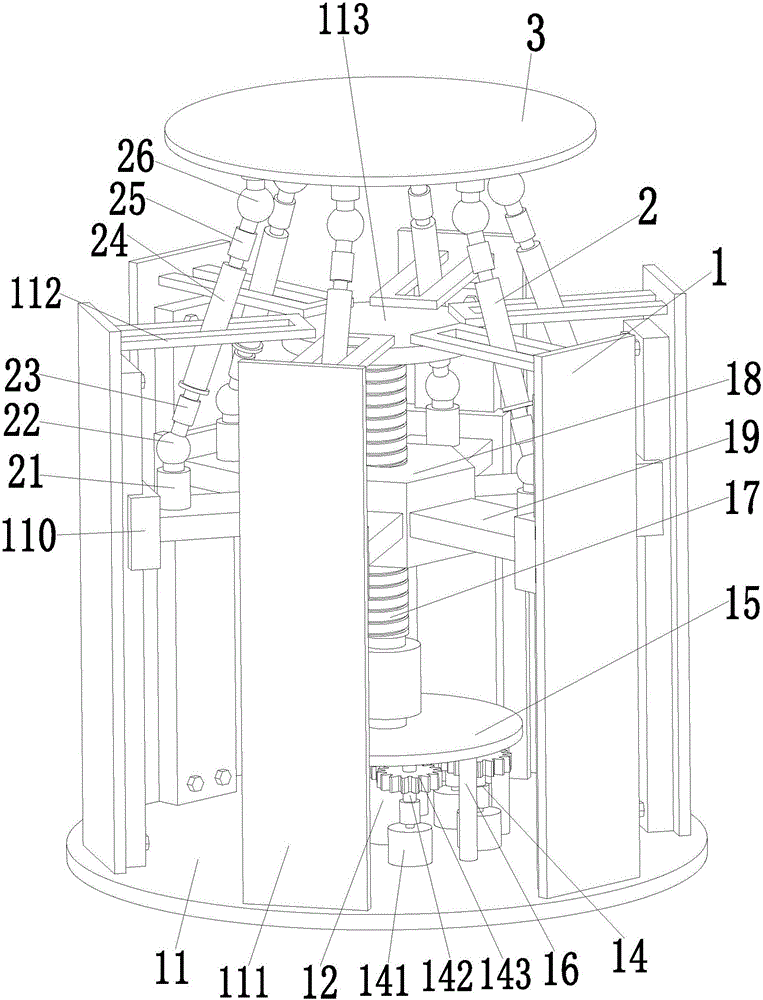

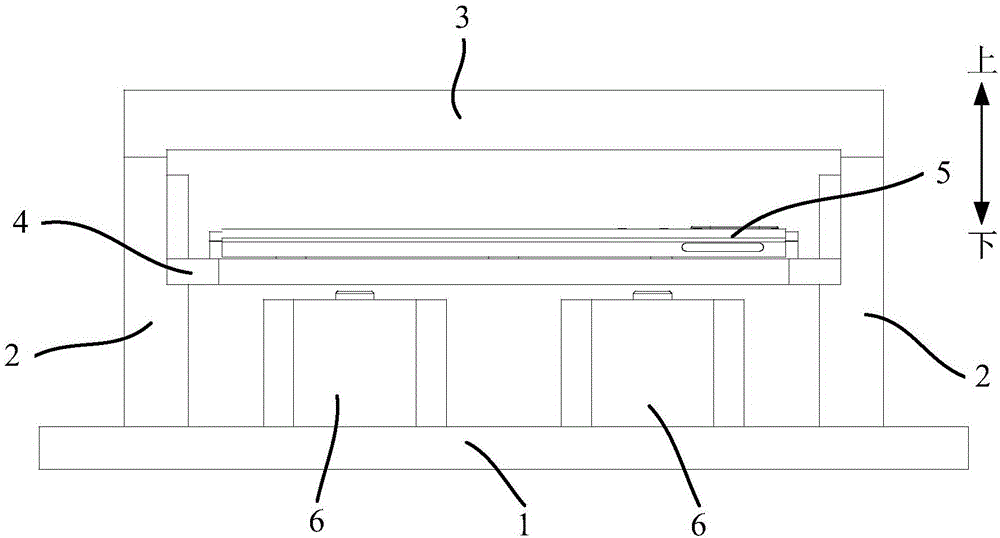

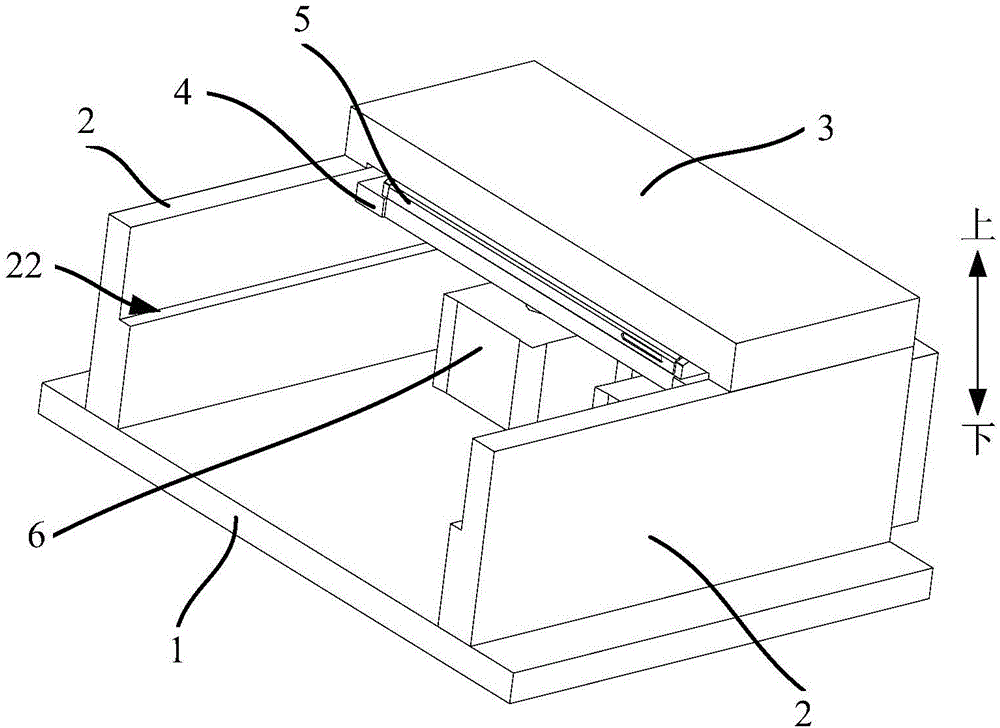

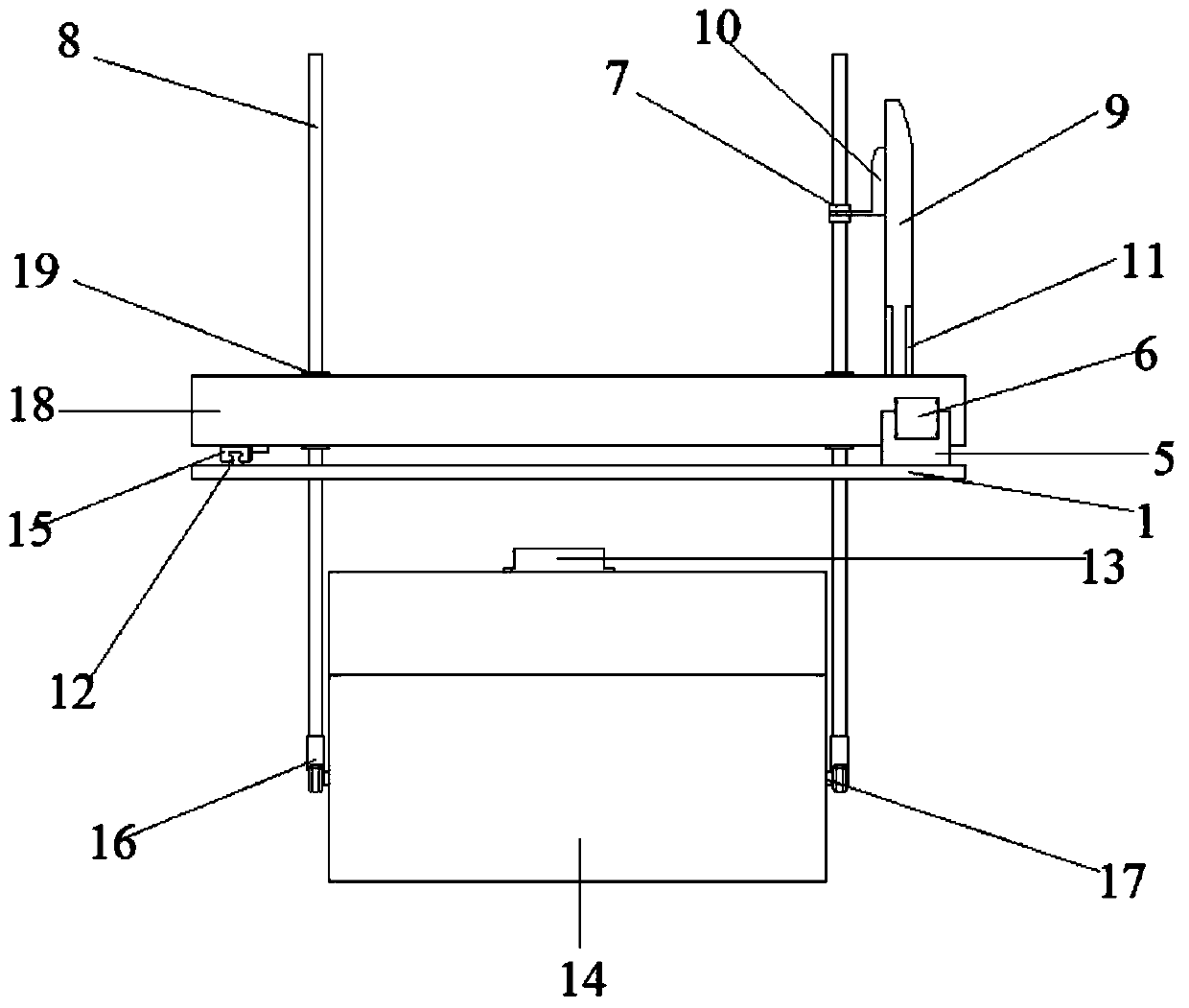

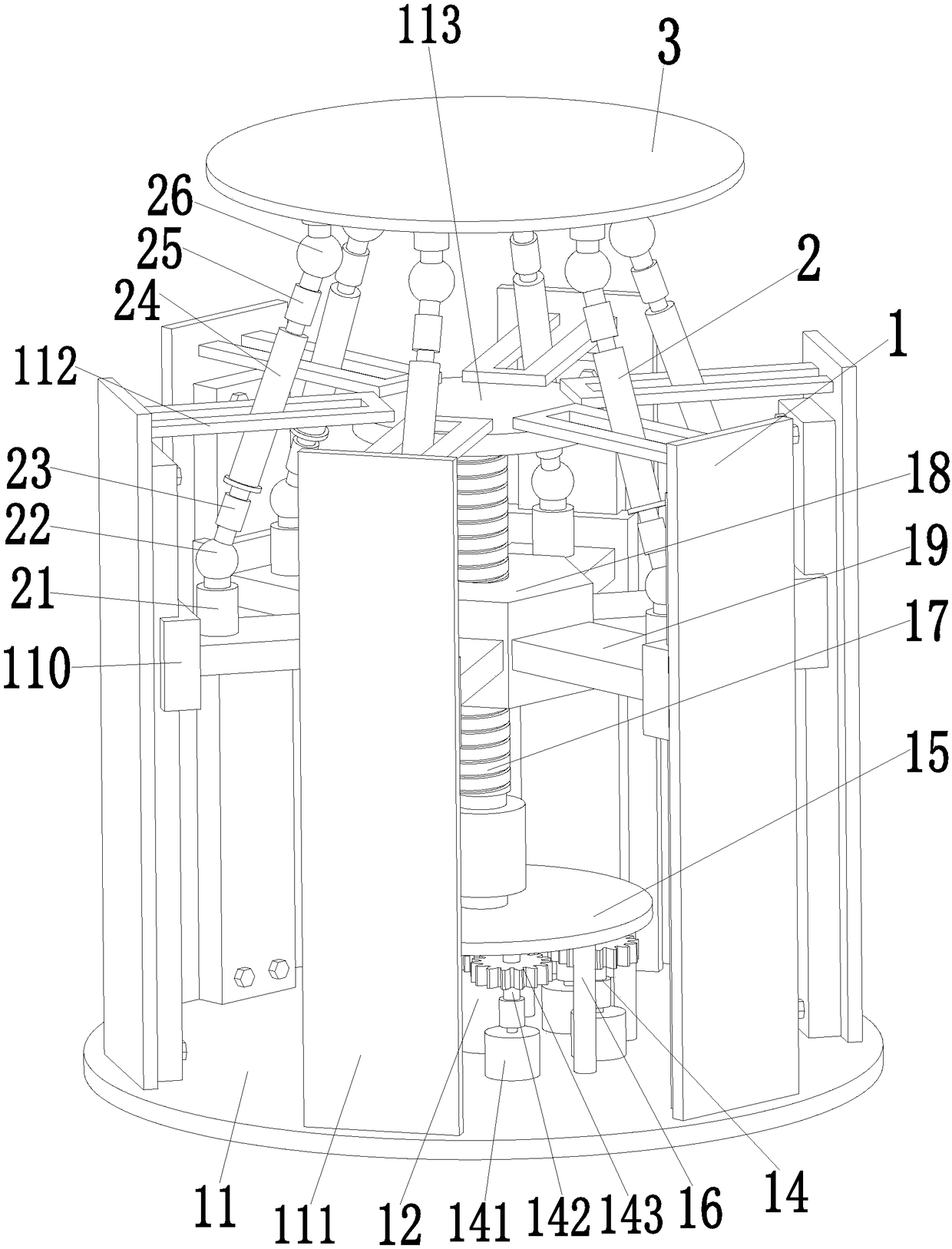

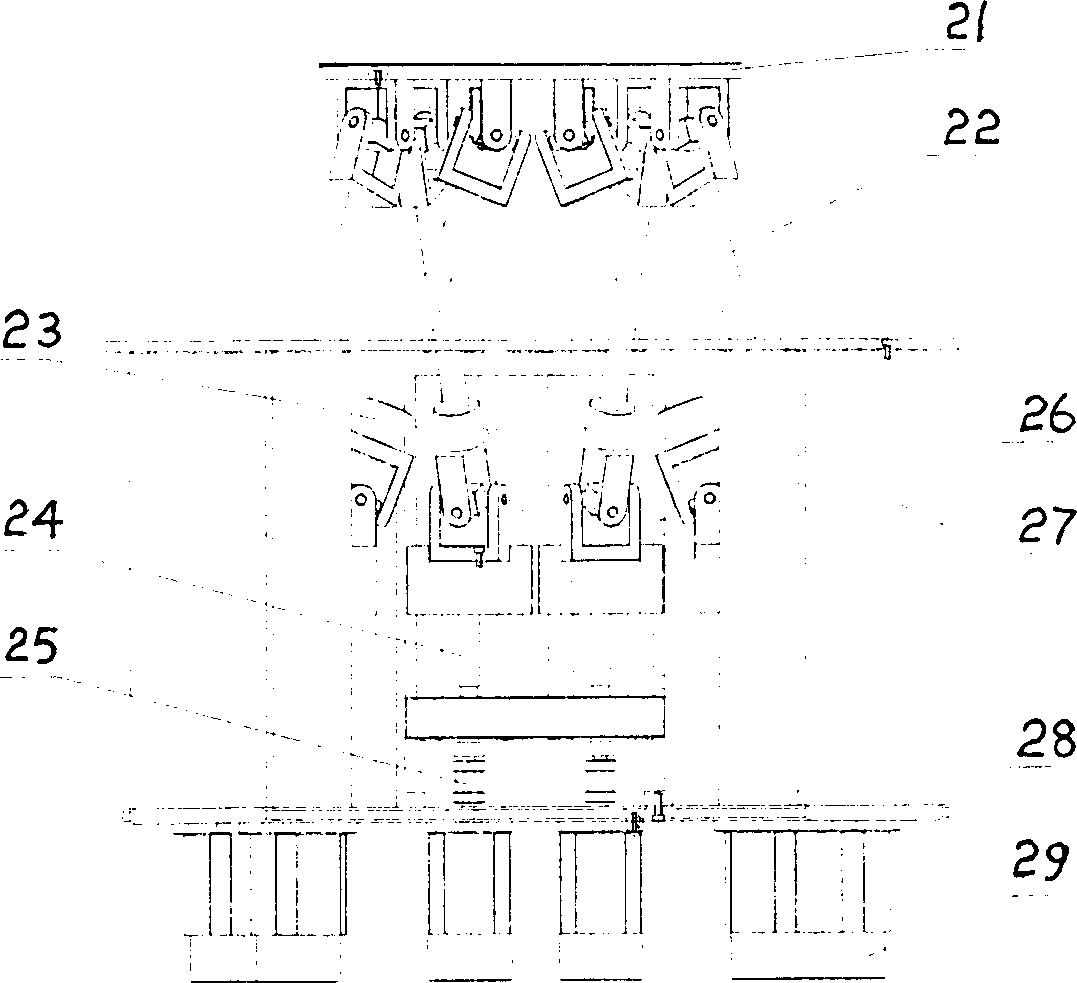

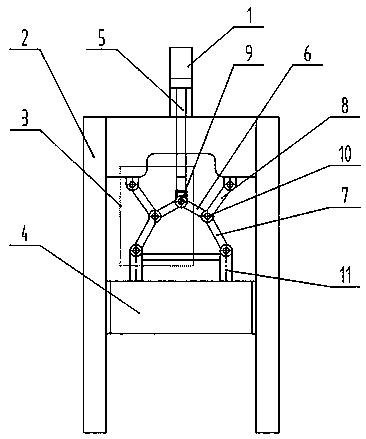

Electric power overhauling supporting device

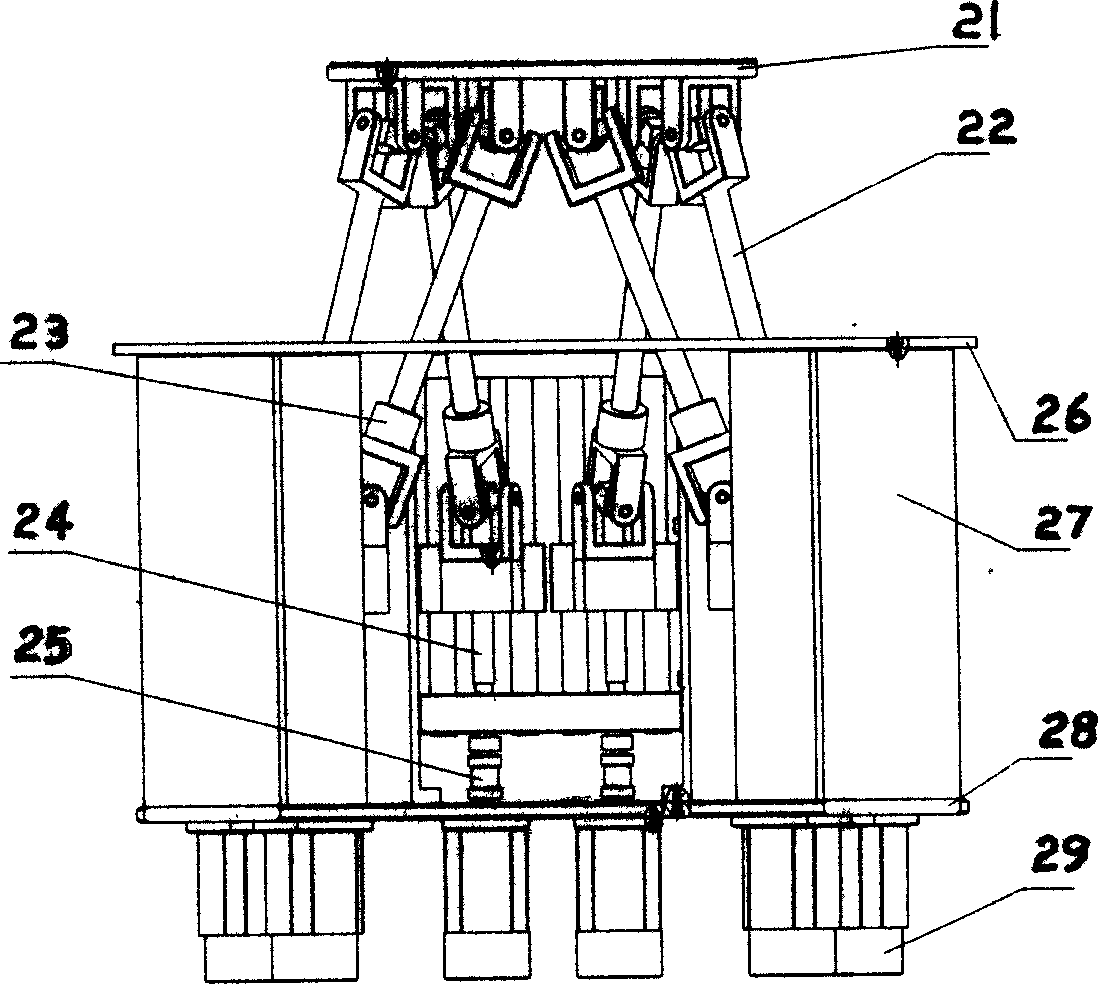

ActiveCN105858535AIncrease stiffnessHigh movement precisionLifting framesSwitchgearElectric power systemCoupling

The invention relates to an electric power overhauling supporting device. The electric power overhauling supporting device comprises a fixed platform. Four parallel supporting chains are symmetrically installed on the upper end surface of the fixed platform. An operating platform is installed at the top ends of the four parallel supporting chains. A rotating shaft is installed in the middle of the lower end surface of the fixed platform through a bearing. A rotating motor is connected to the lower end of the rotating shaft through a coupler and installed on a bottom plate through a motor base. Three fixing shafts are uniformly arranged on the upper end surface of the bottom plate in the axis direction of the fixed platform. Three planetary wheels are installed at the upper ends of the three fixing shafts through bearings correspondingly. The inner sides of the three planetary wheels are all engaged with a sun wheel. The sun wheel is installed on the rotating shaft through a key. The outer sides of the three planetary wheels are all engaged with an inner gear ring. The electric power overhauling supporting device is capable of solving the problems that an existing substation rigid support is poor in dynamic adjustment performance, nonadjustable in height, small in application scope and the like and has the advantages of being good in rigid supporting performance, height adjustment performance and stability performance, wide in application scope, high in working efficiency and the like.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD SUQIAN POWER SUPPLY BRANCH +2

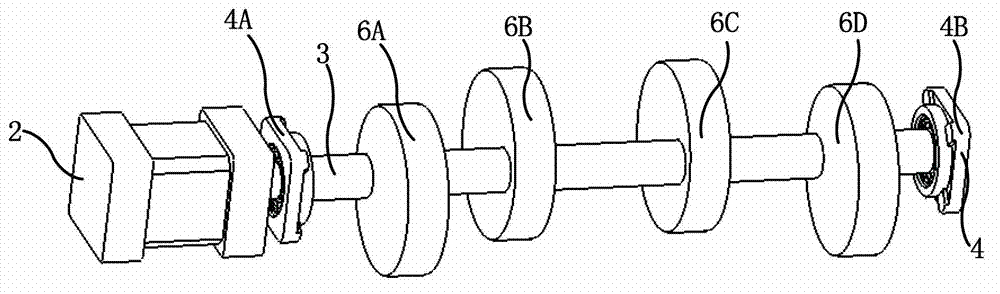

Robot device capable of walking stably

ActiveCN102897243AEasy to controlDoes not involve motor coordination problemsVehiclesMotor driveOperability

The invention discloses a robot device capable of walking stably. The robot device capable of walking stably consists of a support frame, a motor, a rotation shaft, a plummer block set, a weight set, a cam set and leg parts; the cam set comprises four cams, and every two cams form a group; and each group of the cams which are distributed at 180 degrees are fixedly connected to the rotation shaft. The motor drives the cam set on the rotation shaft to rotate and the four leg parts to move; compared with the prior art, the robot device has the advantages that all the leg parts can move by controlling one motor, so that the problems about the coordination of the motor and the initial state are not involved; therefore, the robot device is convenient to control; and the robot device can quickly move and is high in movement accuracy, high in stability, simple and compact in structure, strong in operability, and suitable for stable and quick movement occasions and moves safely and reliably.

Owner:ZHEJIANG UNIV

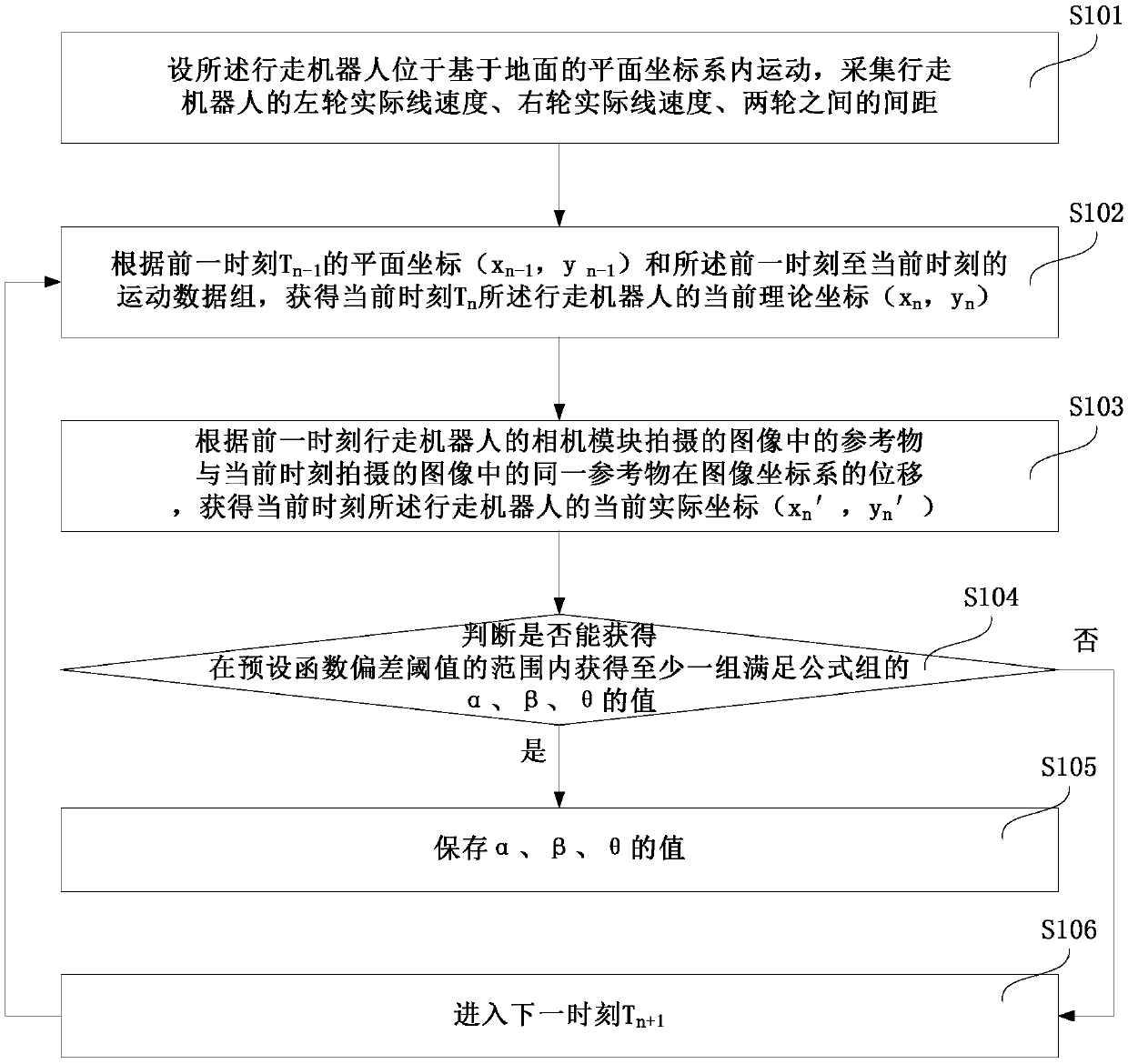

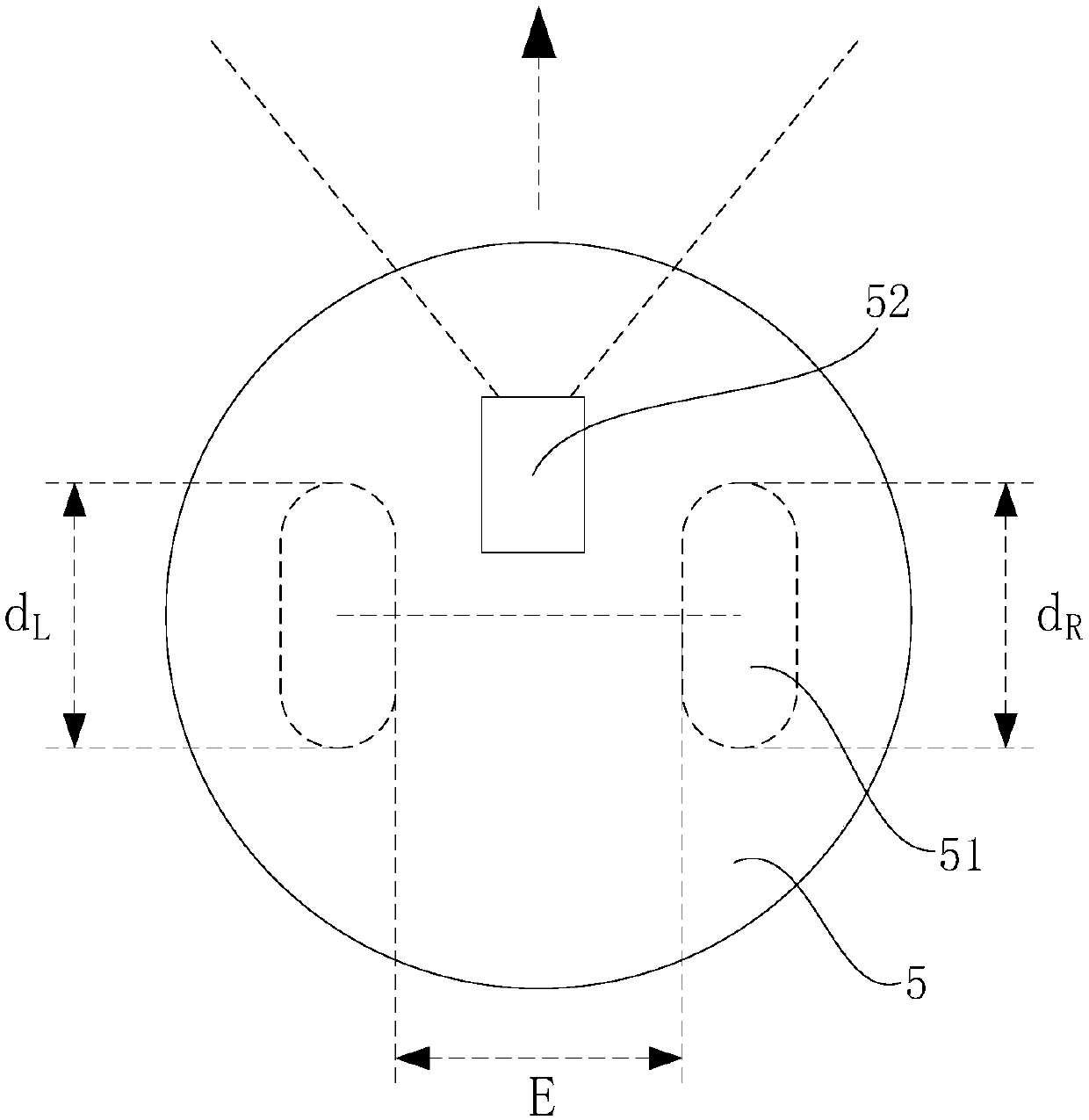

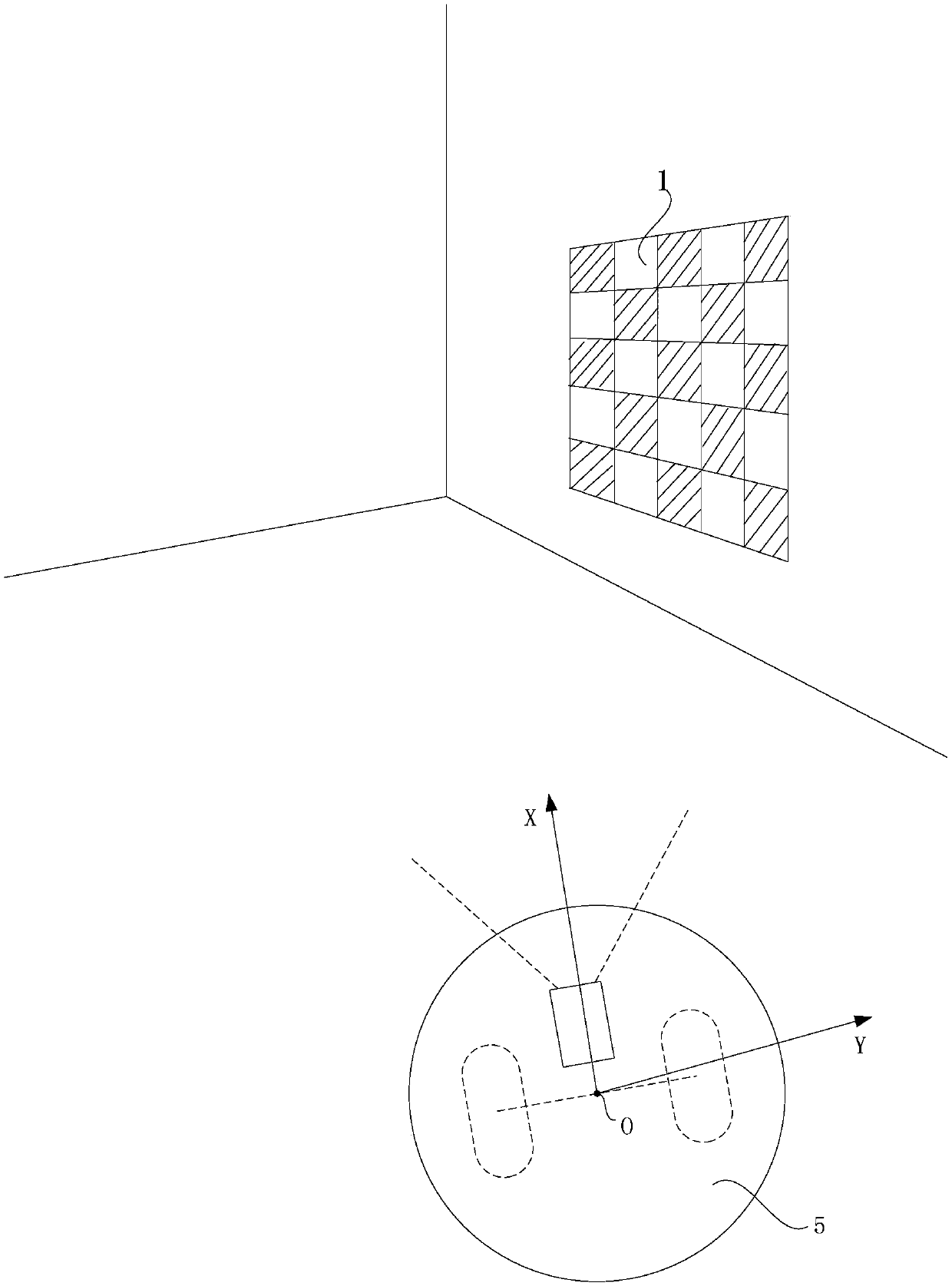

Walking robot self-adaptation calibration method, system and facility and storage medium

ActiveCN109676602AGood motion precisionImprove accuracyProgramme-controlled manipulatorWeight coefficientEngineering

The invention provides a walking robot self-adaptation calibration method, system and facility and a storage medium. The method comprises the steps that a first weight coefficient related to the leftwheel linear speed of a walking robot, a second weight coefficient related to the right wheel linear speed and a third weight coefficient related to the angular speed are set; current theoretical coordinates are obtained through positioning iteration, and current actual coordinates are obtained through video positioning; and according to deflection of the current theoretical coordinates and the current actual coordinates, at least one set of first weight coefficient, second weight coefficient and third weight coefficient are solved, so that the theoretical coordinates are obtained. According to the walking robot self-adaptation calibration method, system and facility and the storage medium, for different application scenes, according to scene changes and robot motion character changes, self-adaptation calibration can be conducted, the robot can achieve good motion precision under various scenes, and the calibration accuracy and flexibility of application to different scenes are greatlyimproved.

Owner:NEXTVPU SHANGHAI CO LTD

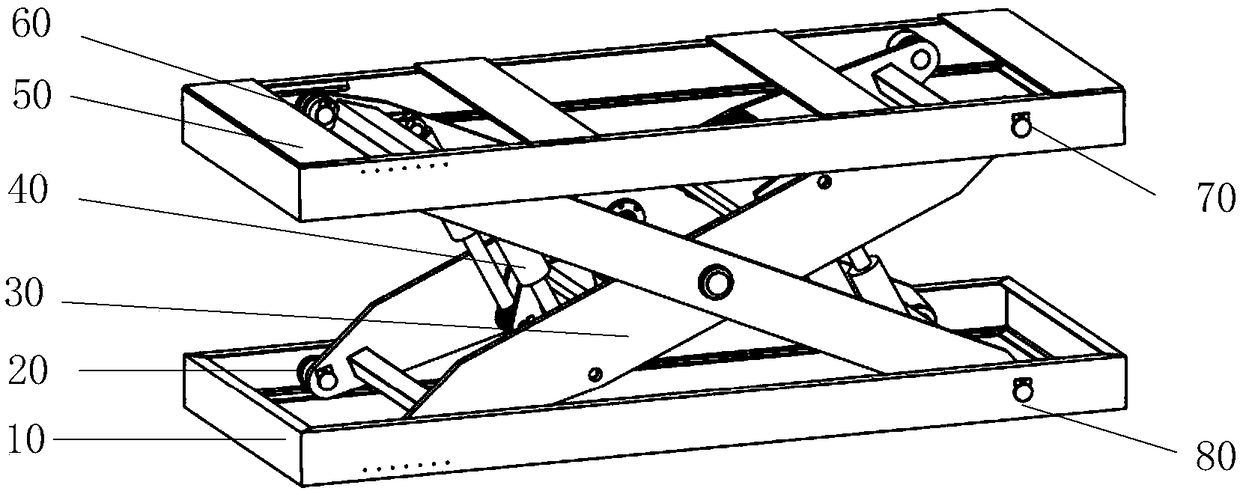

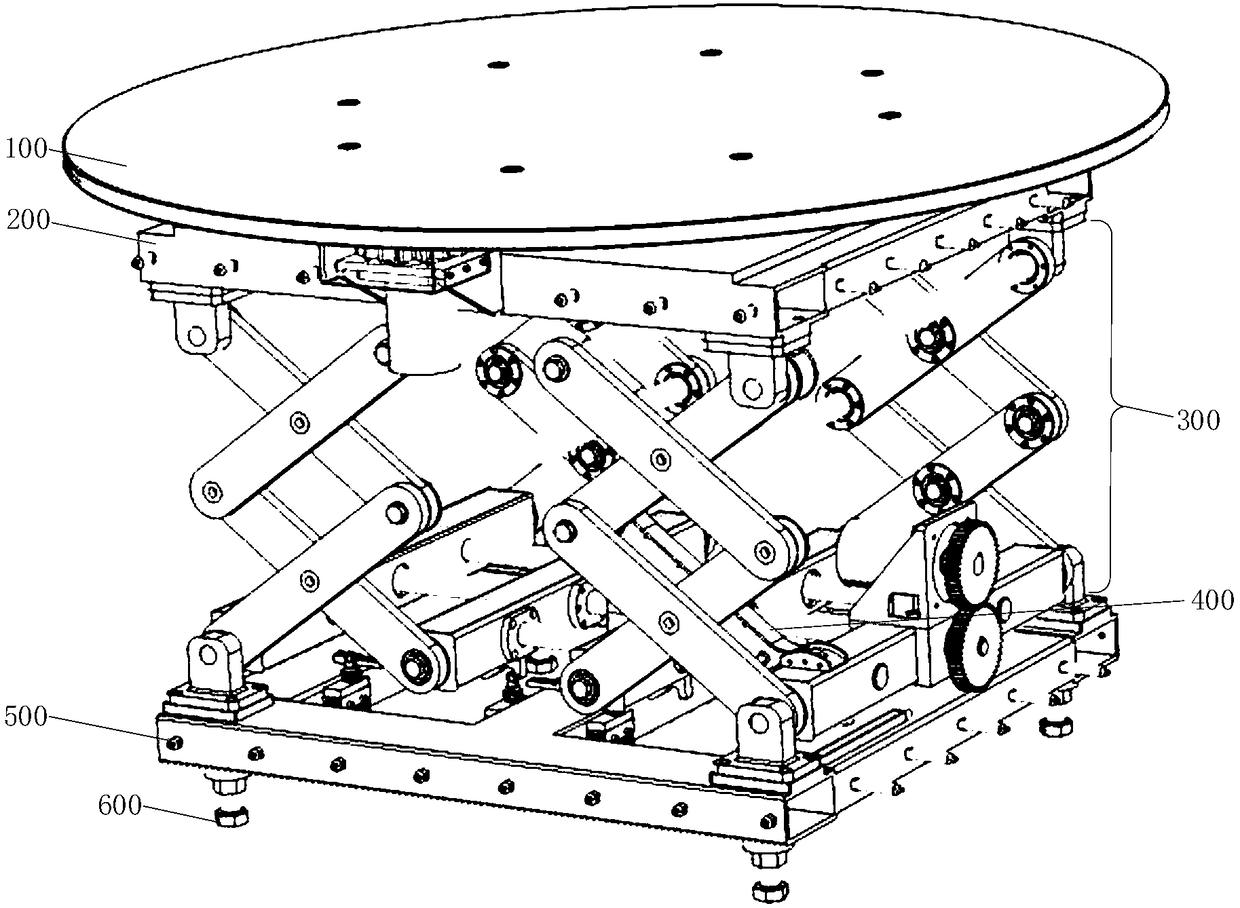

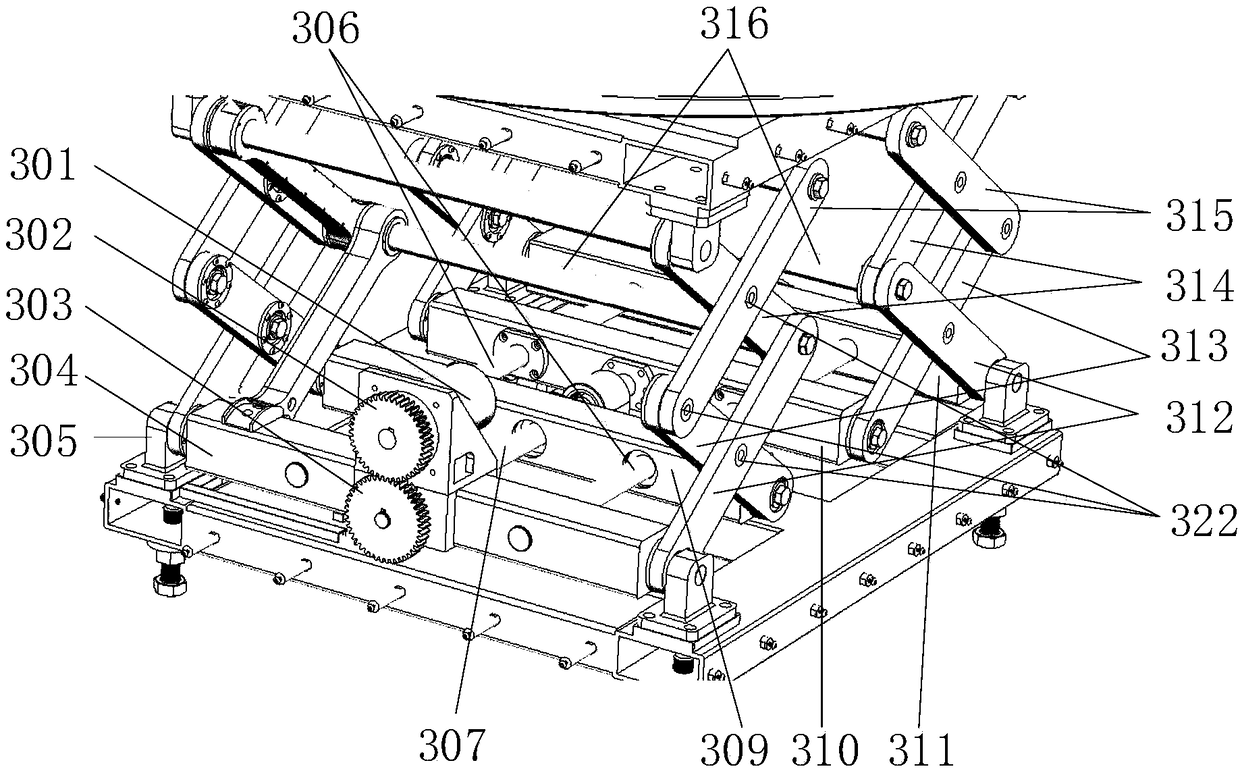

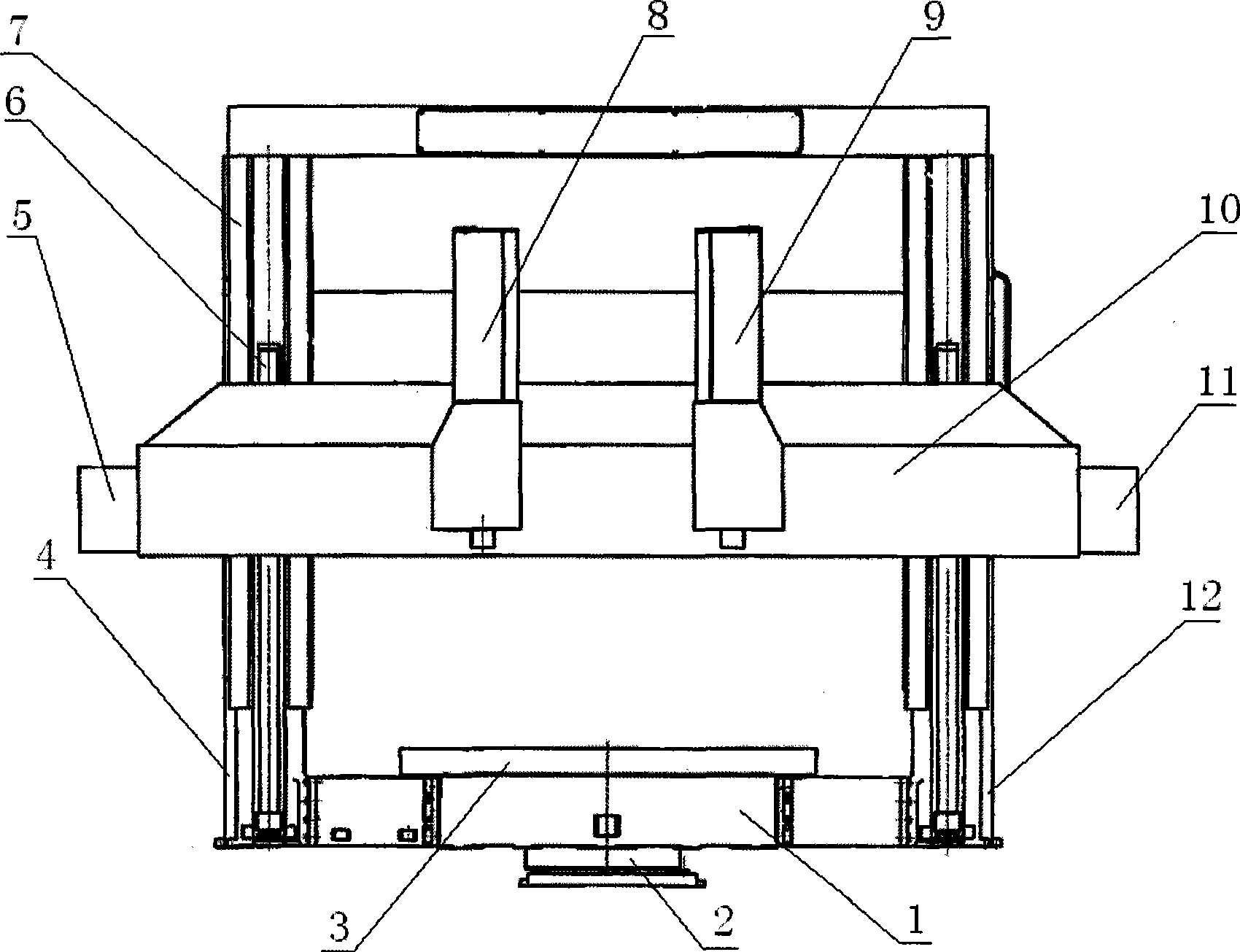

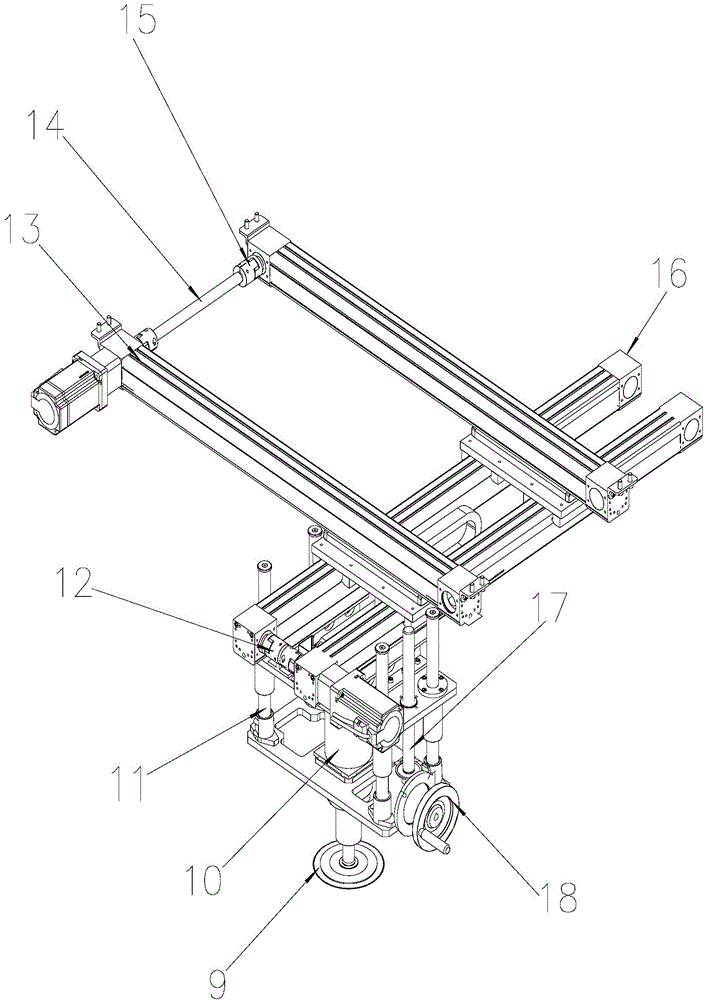

Double-scissors type rotary lifting table

InactiveCN108545656APrevent sideways movementPrevent sideways slidingLifting framesBall screwEngineering

The invention discloses a double-scissors type rotary lifting table. According to the double-scissors type rotary lifting table, a rotary table body is installed above an upper base, capable of rotating relative to the upper base and used for bearing to-be-borne objects, the upper base is installed at the top end of a double-scissors lifting mechanism and used for bearing the rotary table body; the double-scissors lifting mechanism is installed above a lower base and used for driving the upper base and the rotary table body to vertically ascend and descend; the double-scissors lifting mechanism controls two ball screws to rotate at the same time so as to make two ball nut bases in threaded connection with the two ball screws move away from or get close to a middle bearing base at the sametime; the two ball nut bases drive scissor mechanisms connected with the two ball nut bases to achieve ascending / descending movement of a platform; and the lower base is used for bearing the rotary table body, the upper base and the double-scissors lifting mechanism. The double-scissors lifting structure is adopted, lateral movement in the platform lifting process is avoided, and stability of thelifting process is ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

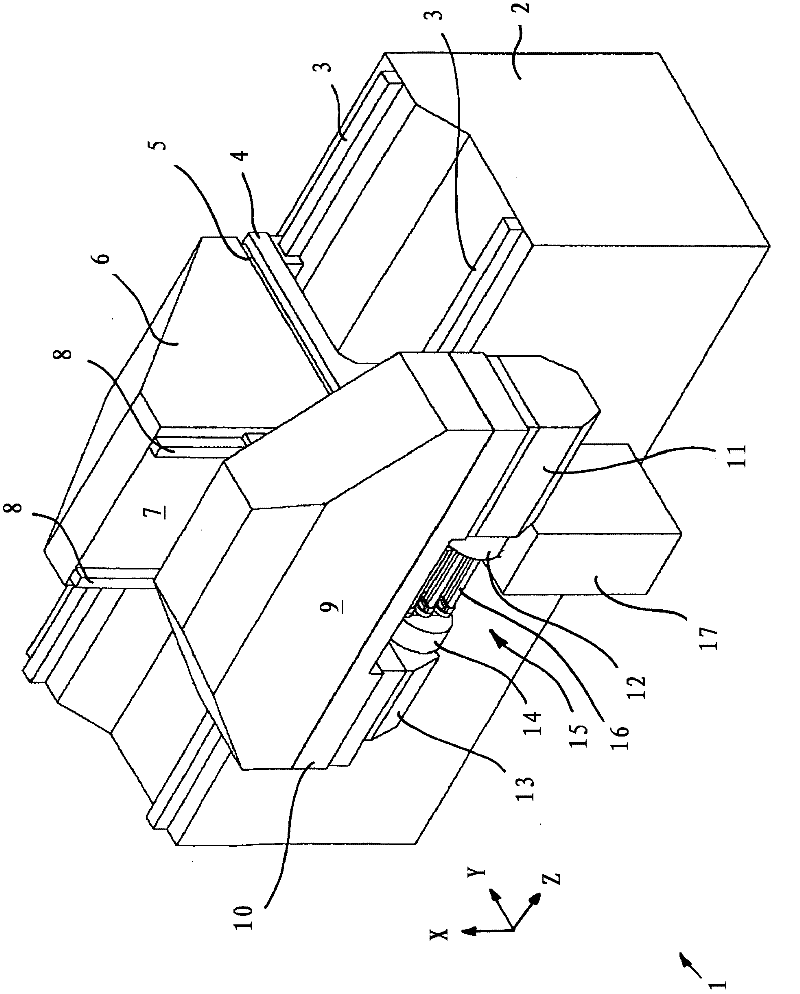

Over-constraint parallel mechanism with three degrees of freedom

InactiveCN102554918AIncrease the scope of applicationIncrease lateral stiffnessProgramme-controlled manipulatorThree degrees of freedomEffective length

The invention discloses an over-constraint parallel mechanism with three degrees of freedom, which comprises a fixed rack, a movable platform, three driving chains and a driven chain. The three driving chains and the driven chain are connected between the fixed rack and the movable platform, the third driving chain is connected with the driven chain by a reverse equal-ratio transmission which is connected between a near rack rod of the third driving chain and a near rack rod of the driven chain, the movable platform consists of four angle plates, four side rods and four parallel rods, effective lengths of the side rods are equal to those of the parallel rods, the four angle plates are symmetrically and uniformly distributed, each angle plate connected with two far rack rods of a corresponding one of four branch chains, the four side rods are sequentially connected by rotation pairs to form a rhombic structure, four vertexes of the rhombic structure are respectively connected with the four angle plates by rotation pairs, the center of the rhombic structure is coincident with a center formed by the four angle plates, each parallel rod is arranged between the corresponding two adjacent angle plates, lower connecting axes on each two opposite angle plates are parallel to each other, and lower connecting axes of each two adjacent angle plates are parallel to each other. The over-constraint parallel mechanism is novel and is fine in lateral rigidity.

Owner:TIANJIN UNIV

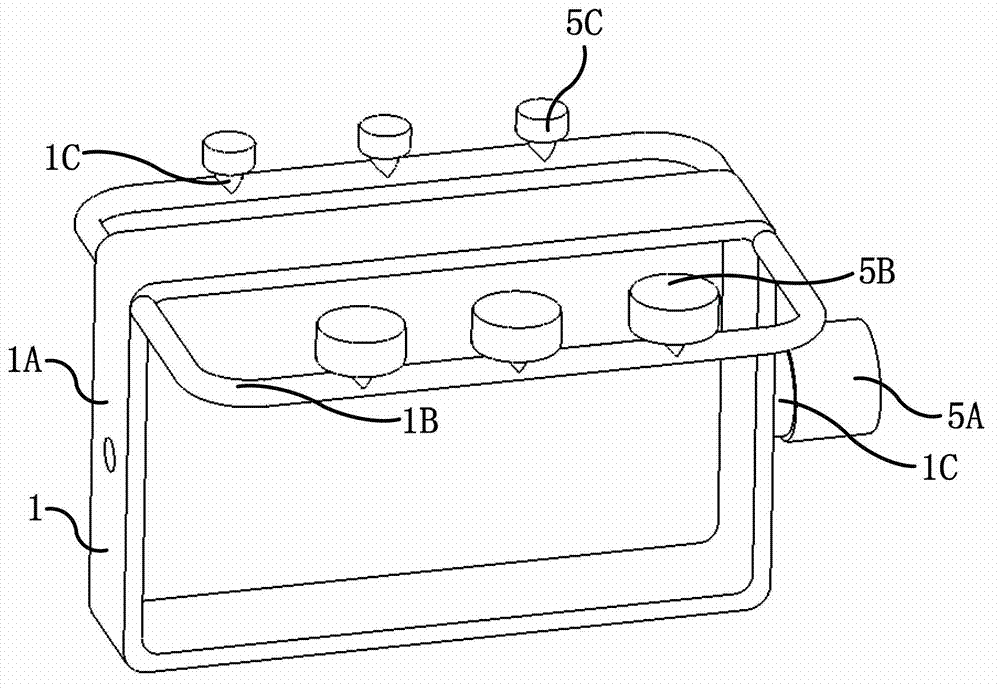

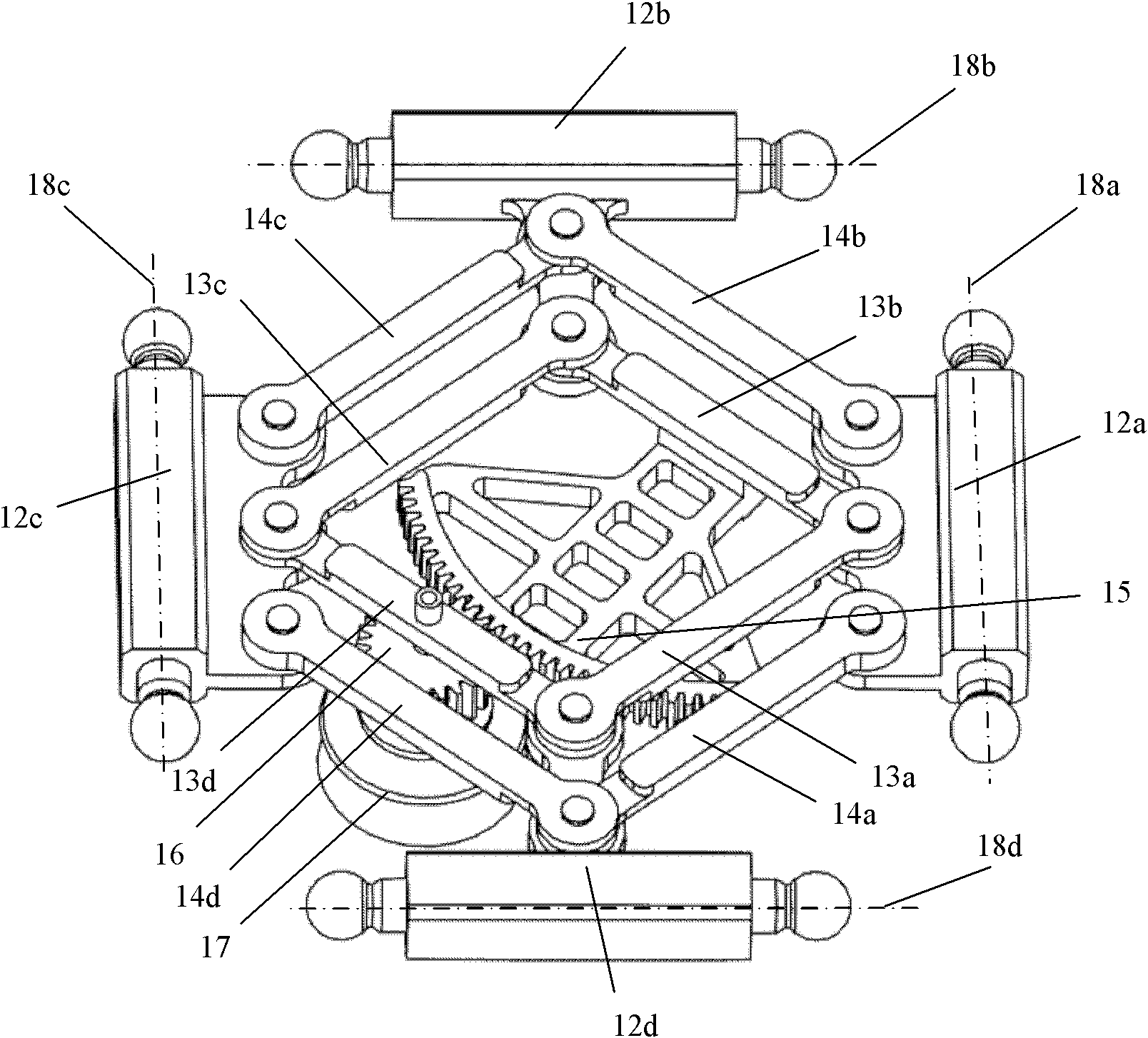

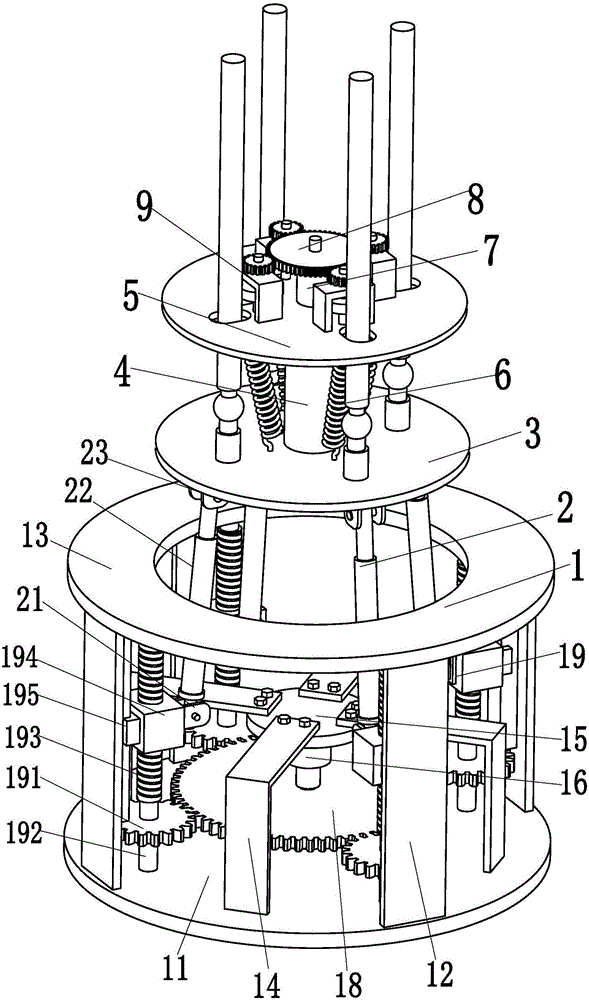

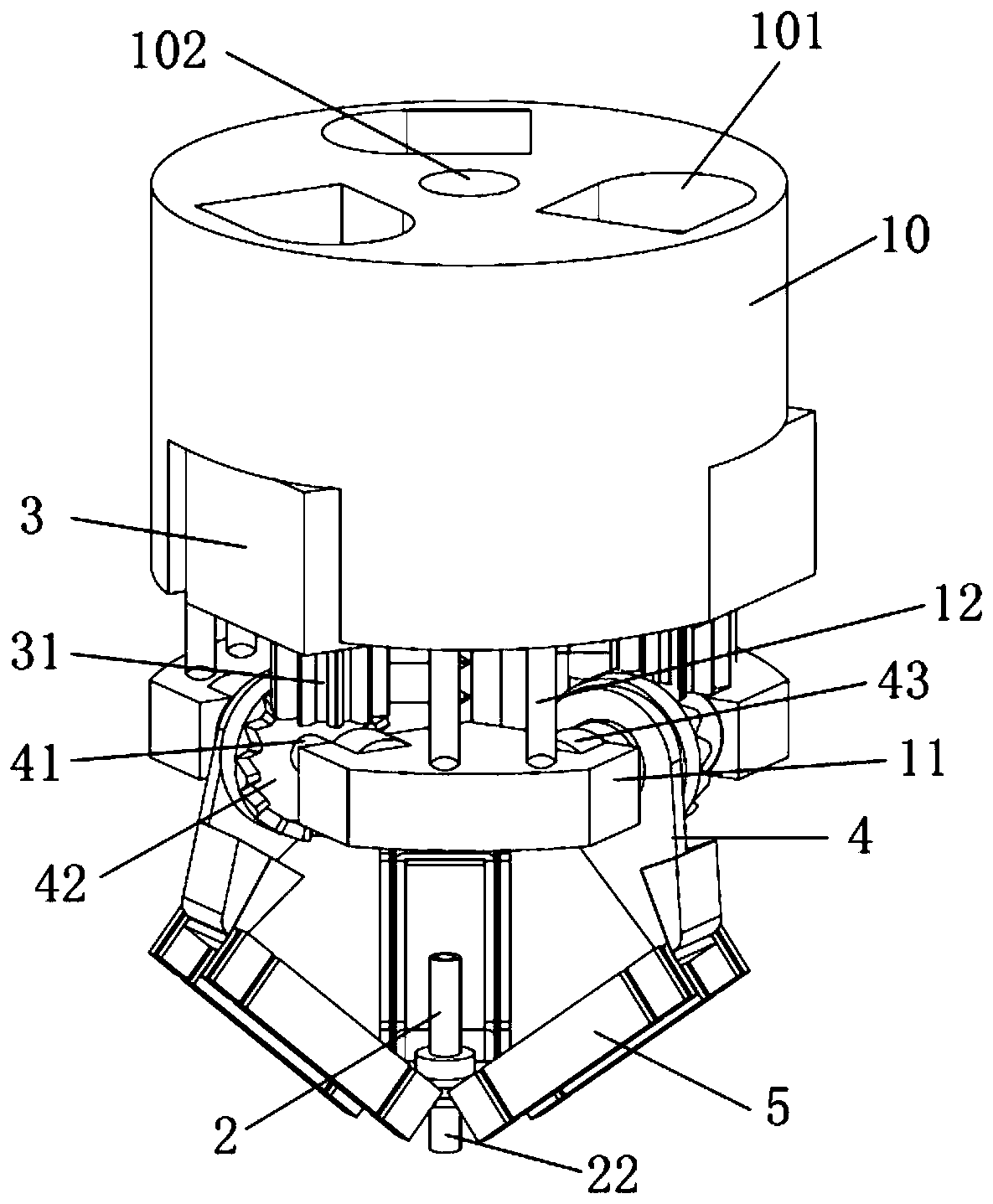

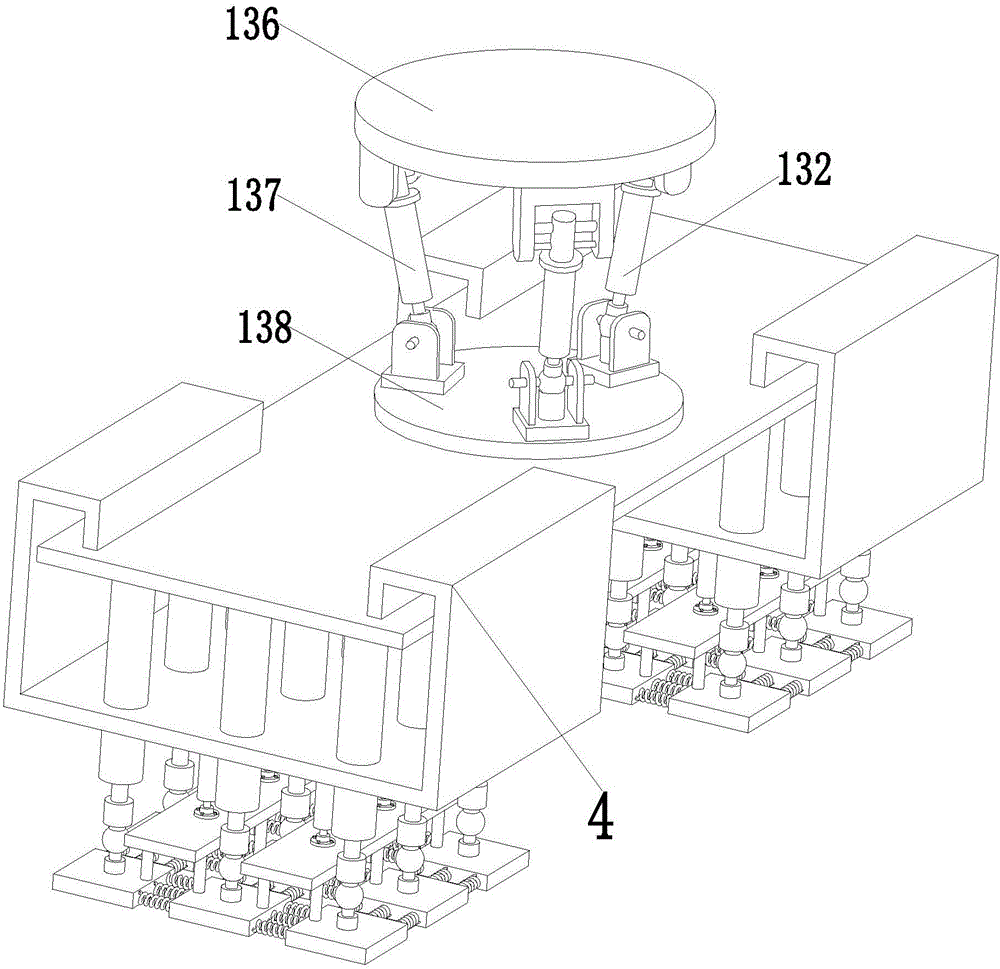

Building concrete pouring vibration robot

ActiveCN106012840ANo manual operationHigh degree of automationBridge erection/assemblyBuilding material handlingCircular discElectric machinery

The invention relates to a building concrete pouring vibration robot which comprises a fixing rack. Locating columns are arranged at the middle portion of the upper end face of an operation table. A limiting disc is welded to the upper ends of the locating columns. The locating columns achieve the effect of supporting the limiting disc. Four kidney-shaped limiting holes are evenly formed in the limiting disc in the axis direction. Four vibration branch chains are evenly installed on the operation table in the axis direction. The four vibration branch chains can conduct the high-frequency vibration movement on poured concrete at the same time, the concrete compacting speed is high, and the work efficiency is high. The middle portion of the upper end face of the limiting disc is provided with a transmission motor through a motor seat. A driving gear is fixedly installed at the output end of the transmission motor and engaged with four transmission branch chains. By the adoption of the robot, the function of compacting the poured concrete through multiple vibration bars at the same time can be achieved, the robot has the beneficial effects of being high in concrete compacting speed, good in damping performance, high in work efficiency, high in automation degree and the like, and a new way for automatically and quickly compacting the poured concrete is provided.

Owner:福建省东霖建设工程有限公司

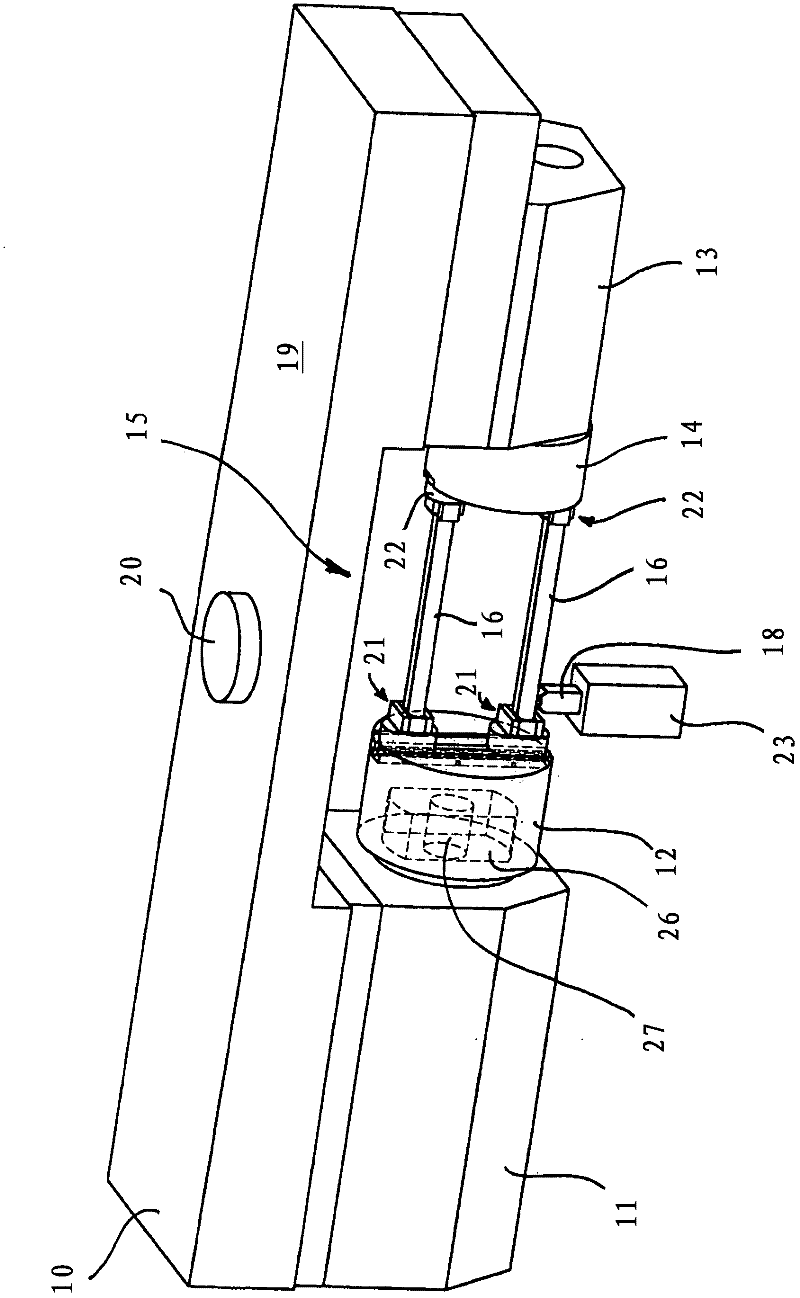

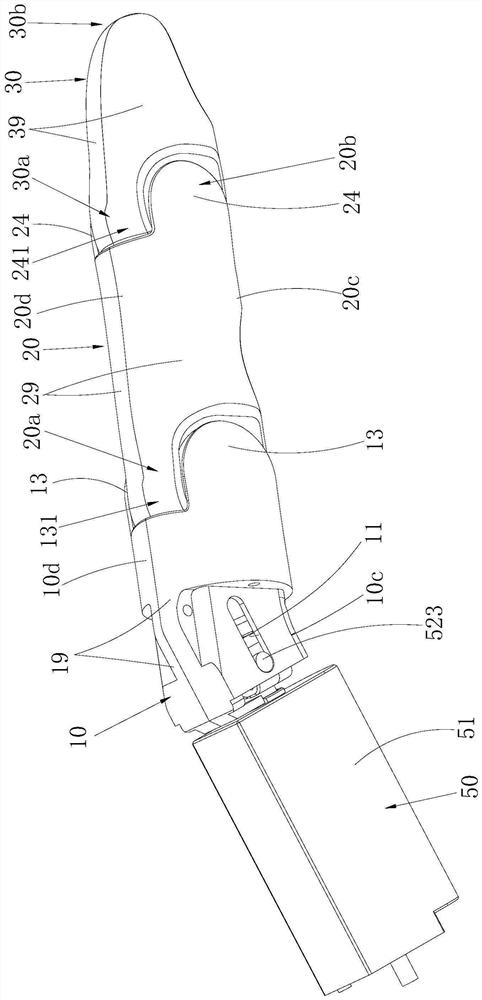

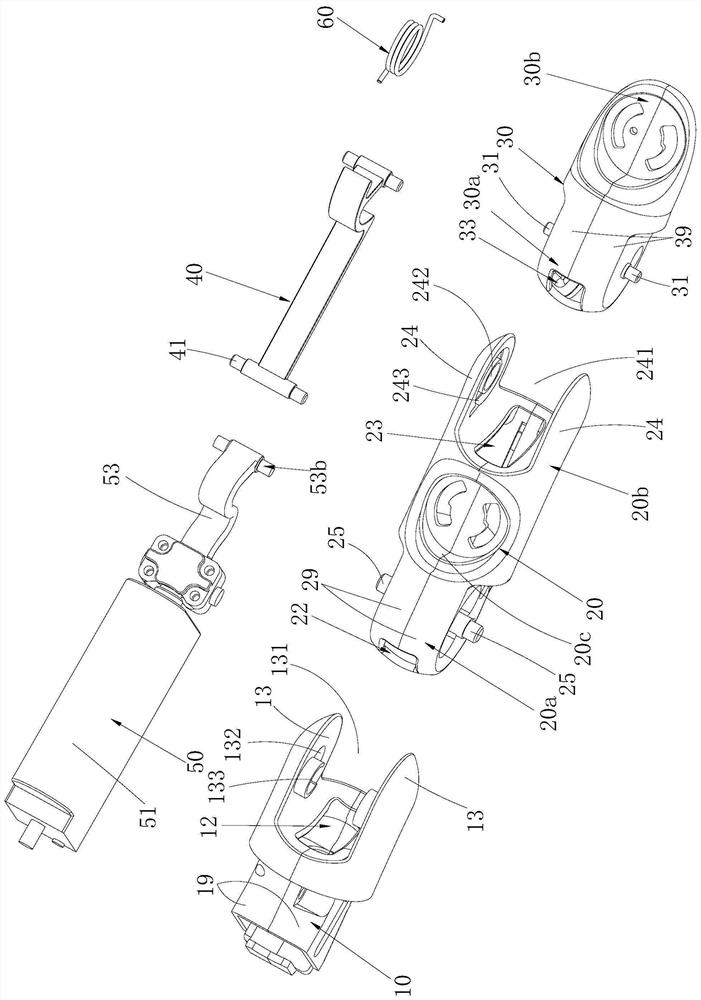

In-vivo additional material repair system and in-vivo repair device

The invention provides an in-vivo additional material repair system and an in-vivo repair device. The in-vivo repair device comprises a driving mechanism, a transmission mechanism and a printing device. The printing device prints a biological material; the driving mechanism drives the transmission mechanism to rotate; the transmission mechanism comprises a revolute pair assembly, and the revolutepair assembly comprises at least two revolute pairs; the printing device is connected to the transmission mechanism through the revolute pair assembly, and the revolute pair assembly is provided withat least two revolute axes perpendicular to each other. Each of the at least two revolute pairs has the following structures: two rigid bodies and a flexible film clamped between the two rigid bodies;the two rigid bodies are missing at corresponding positions so that each rigid body can form two discrete segments, the two discrete segments are connected together through the flexible film, and therevolute axes of the revolute pairs are formed at the missing positions of the rigid bodies. At least two revolute pairs with orthogonal revolute axes are adopted to replace spherical hinge revolutepairs, so that the processing difficulty of the in-vivo repair device is reduced, and the space required by operation is reduced.

Owner:TSINGHUA UNIV

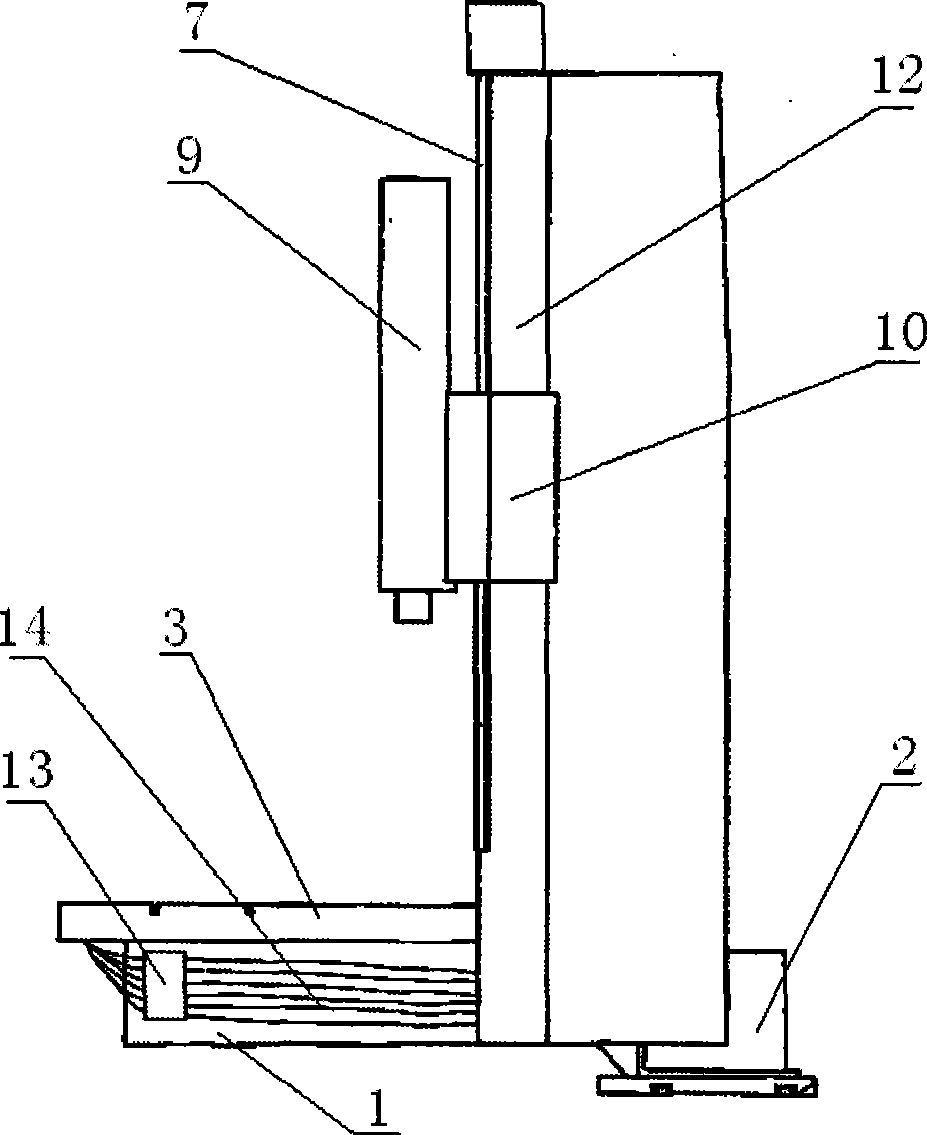

Double column vertical lathe

The invention discloses a double-post vertical lathe, which comprises a rotating worktable device, two upright posts, a crossbeam which performs reciprocating movement up and down along guide rails of the upright post, and a vertical tool post which performs reciprocating movement along a guide rail of the crossbeam, wherein a hydraulic balancing cylinder device of the crossbeam is arranged beside the upright posts and comprises hydraulic balancing cylinders of the crossbeam which are respectively positioned at the middle parts of the two upright posts, each hydraulic balancing cylinder of the crossbeam comprises a balancing cylinder base fixed on the ground, a cylinder sleeve and a piston in the cylinder sleeve, and the upper end of the cylinder sleeve is fixedly connected with the crossbeam through a fixing part. The double-post vertical lathe adopts the structure to reduce the load contrast during the ascending and descending process of the crossbeam, thereby ensuring that the performance of a machine tool is steadier, prolonging the service life of the machine tool, and reducing maintenance cost; and the double-post vertical lathe reduces processing cost, and a worktable has good kinematic accuracy and larger load resistant capability.

Owner:芜湖红旗机床制造有限公司

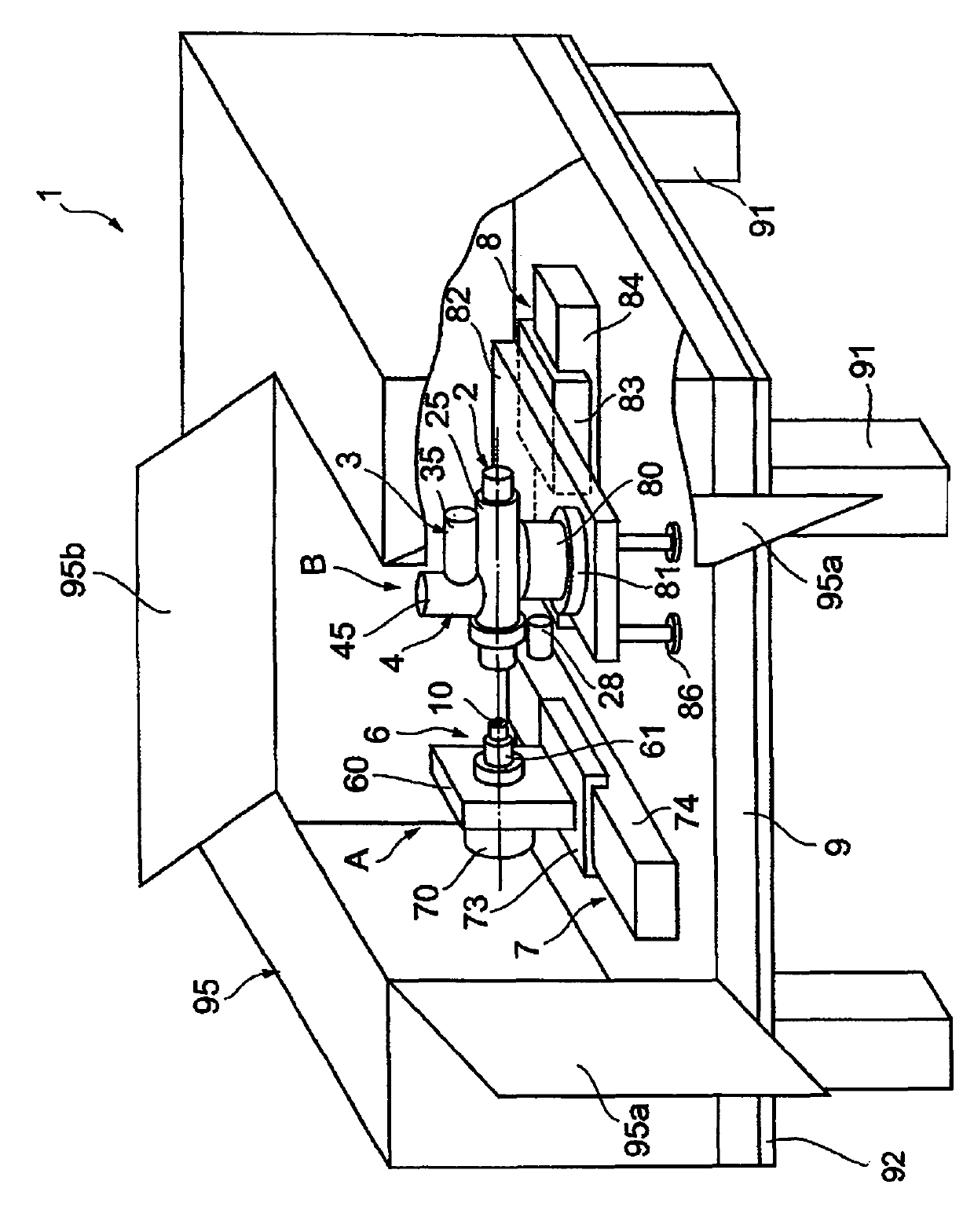

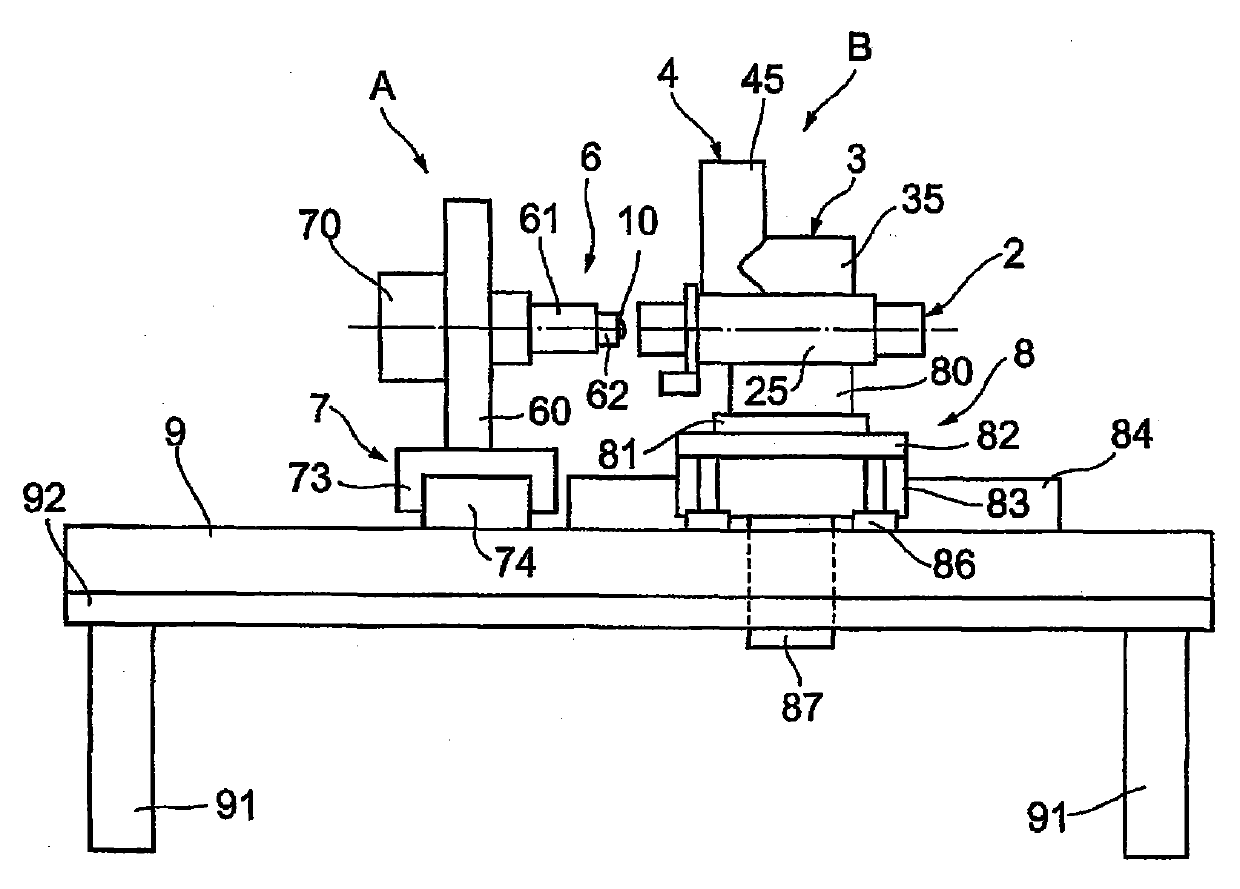

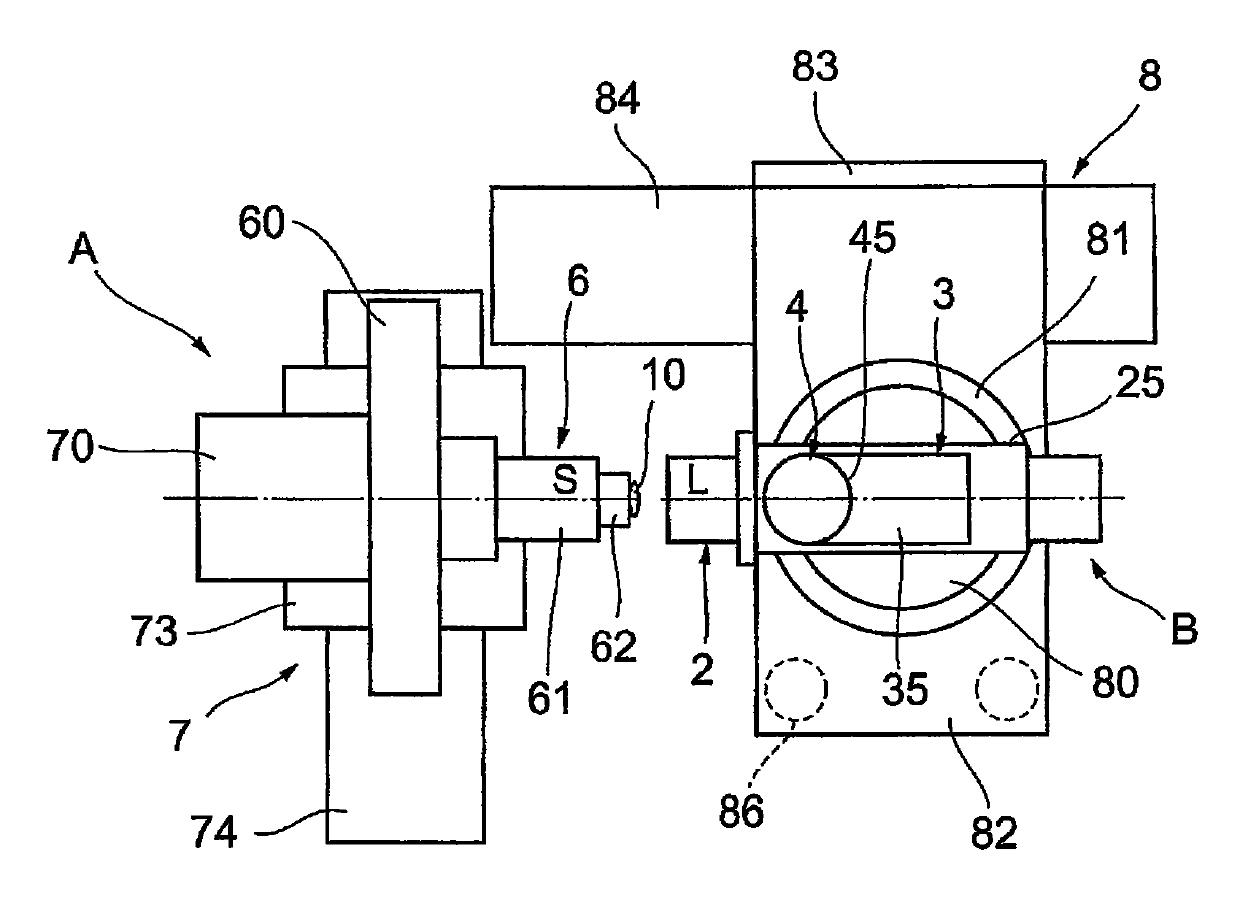

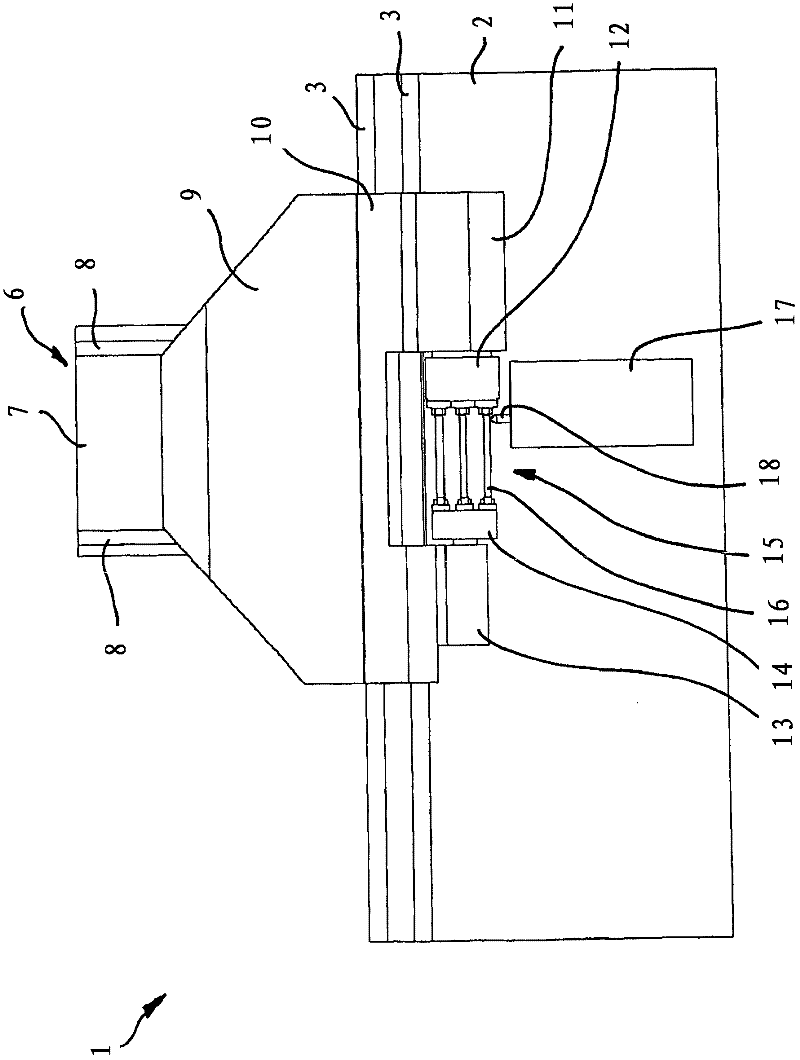

Aspheric surface measuring apparatus

InactiveCN102235853ASmall sizeReduce moving loadUsing optical meansGeometric properties/aberration measurementOptical axisComputational physics

An aspheric surface measuring apparatus includes a sample holder mechanism and an interferential optical mechanism, and performs optical interferometric measurement while rotating a sample every time a measurement angle is varied. The sample holder mechanism has a first air spindle for rotating the sample about a test surface axis and a first airslide. The first airslide carries the sample orthogonally or parallel to the test surface axis. The interference optical mechanism has an interference optical system, a first imaging system, and a second imaging system, a second air spindle, and a second airslide. The second spindle revolves or turns the interference optical system and the first and second imaging systems integrally to change a measurement angle between the measurement optical axis and the test surface axis. The second airslide carries the second air spindle orthogonally to the moving direction of the first airslide.

Owner:FUJIFILM CORP

Self-stabilizing platform for high-attitude shooting of unmanned aerial vehicle

ActiveCN106005458AImprove the effect of aerial photographyEliminate jitterVibration suppression adjustmentsGround installationsGear wheelCoupling

The invention relates to a self-stabilizing platform for high-attitude shooting of an unmanned aerial vehicle. The self-stabilizing platform comprises a fixing machine frame, wherein the fixing machine frame comprises a lower platform; a transmission shaft is mounted at the middle part of the upper end surface of the lower platform through a bearing; a transmission gear is mounted at the middle part of the transmission shaft through a key, and is meshed with six transmission branched chains in an axial direction; the upper ends of six driving shafts of the six transmission branched chains are respectively connected with a supporting platform through the bearings; the middle part of the supporting platform is connected with the transmission shaft through the bearings; six supporting columns are uniformly welded to the lower end surface of the supporting platform in the axial direction, and the lower end surfaces of the six supporting columns are respectively mounted on the lower platform; the upper end of the transmission shaft is connected with a transmission screw rod through a coupling; a transmission sliding block is mounted at the middle part of the transmission screw rod in a threaded connection manner. According to the self-stabilizing platform disclosed by the invention, a function of stable rise-and-fall aerial shooting of the unmanned aerial vehicle can be realized, and the self-stabilizing platform has the advantages of being simple in structure, good in stability quality of the mechanical structure, good in rise-and-fall aerial shooting performance, high in working efficiency and the like.

Owner:宿州市徽腾知识产权咨询有限公司

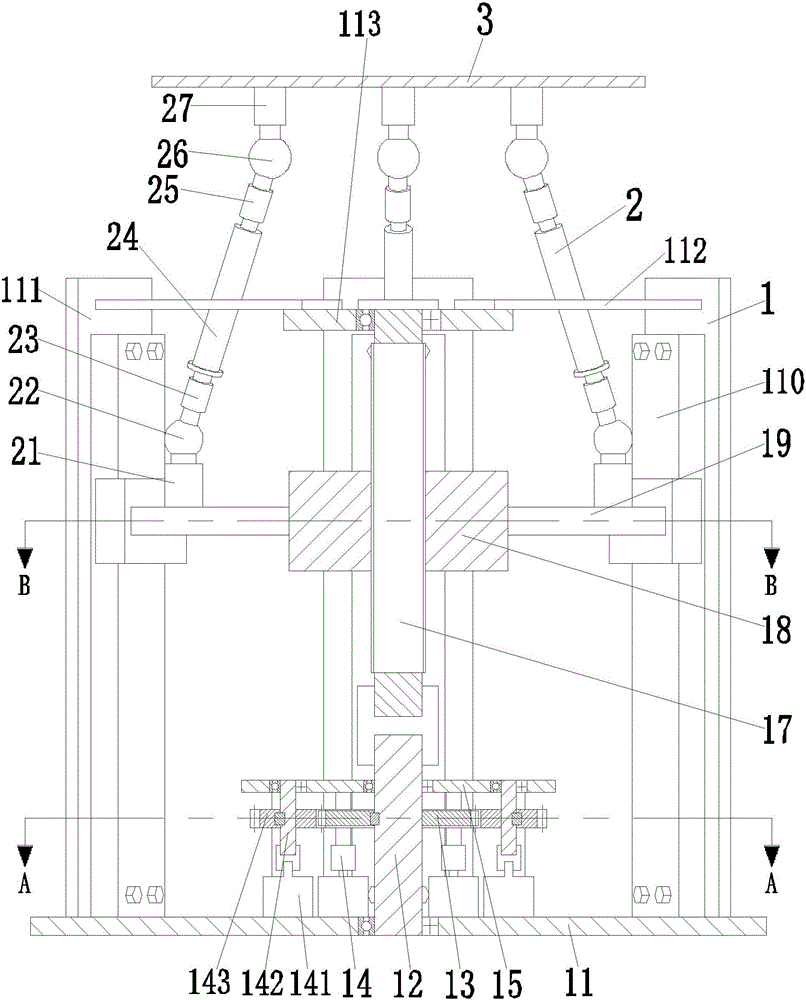

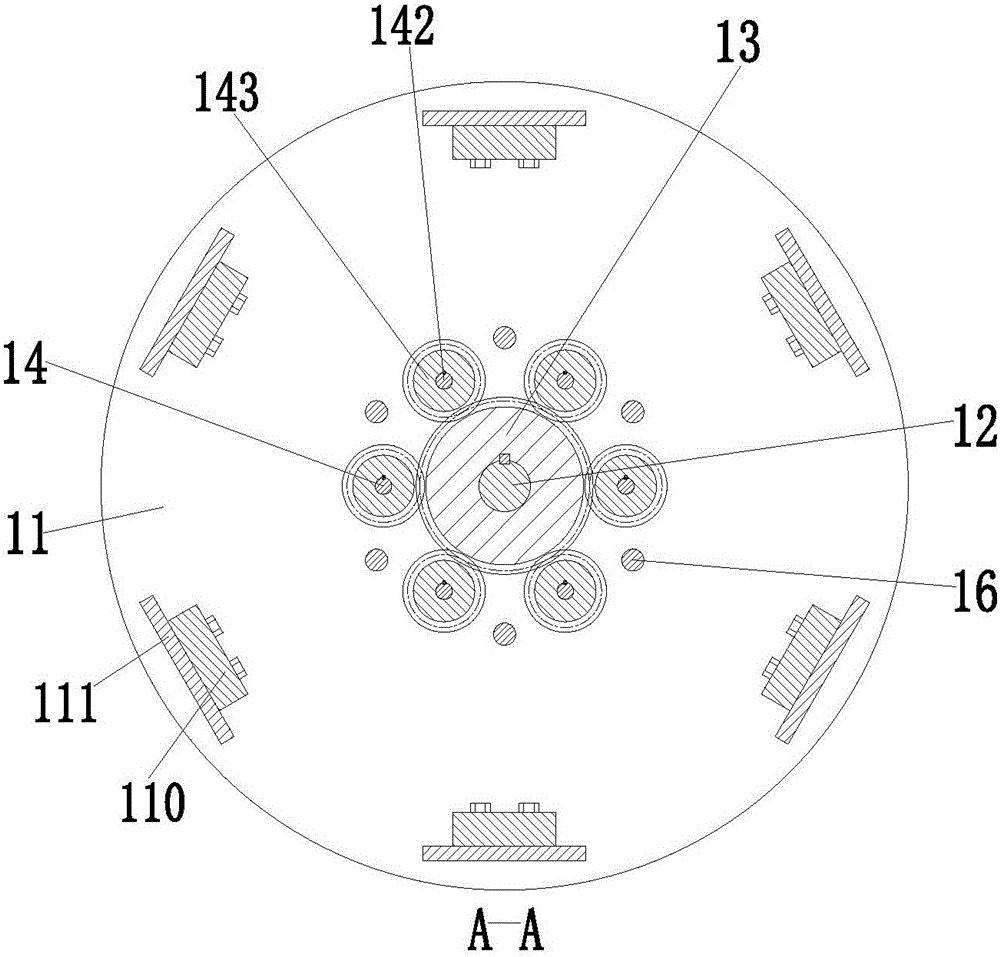

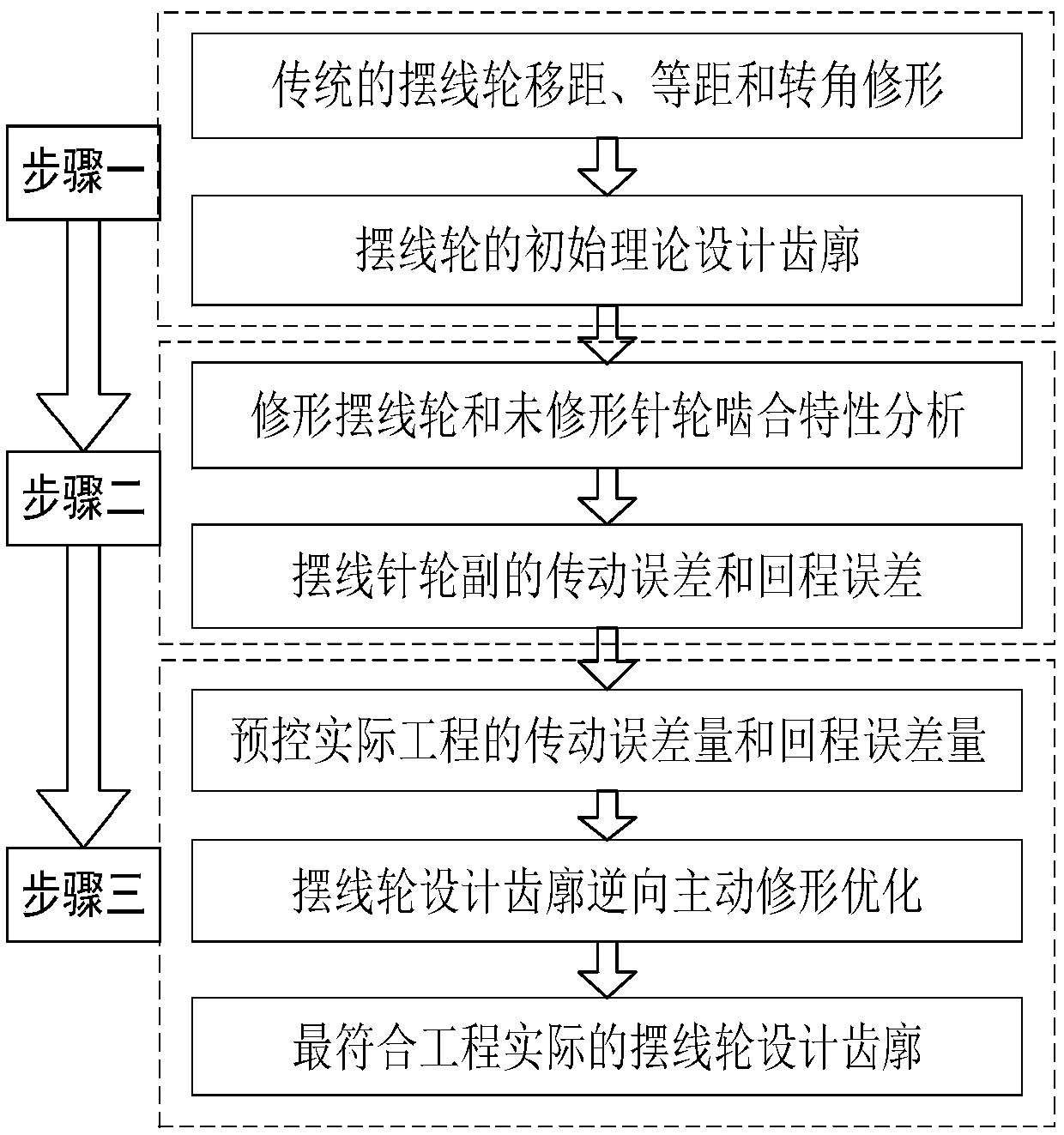

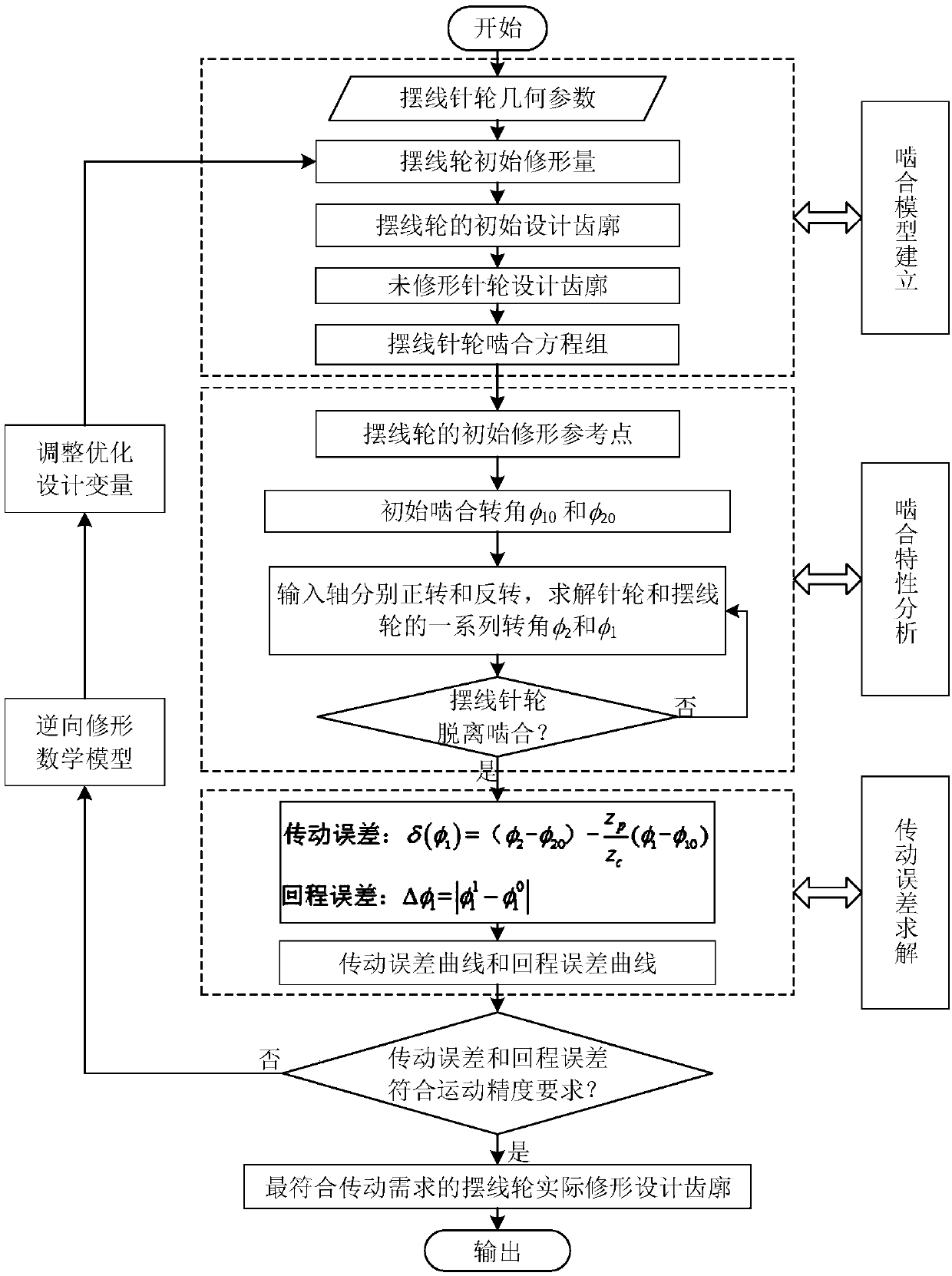

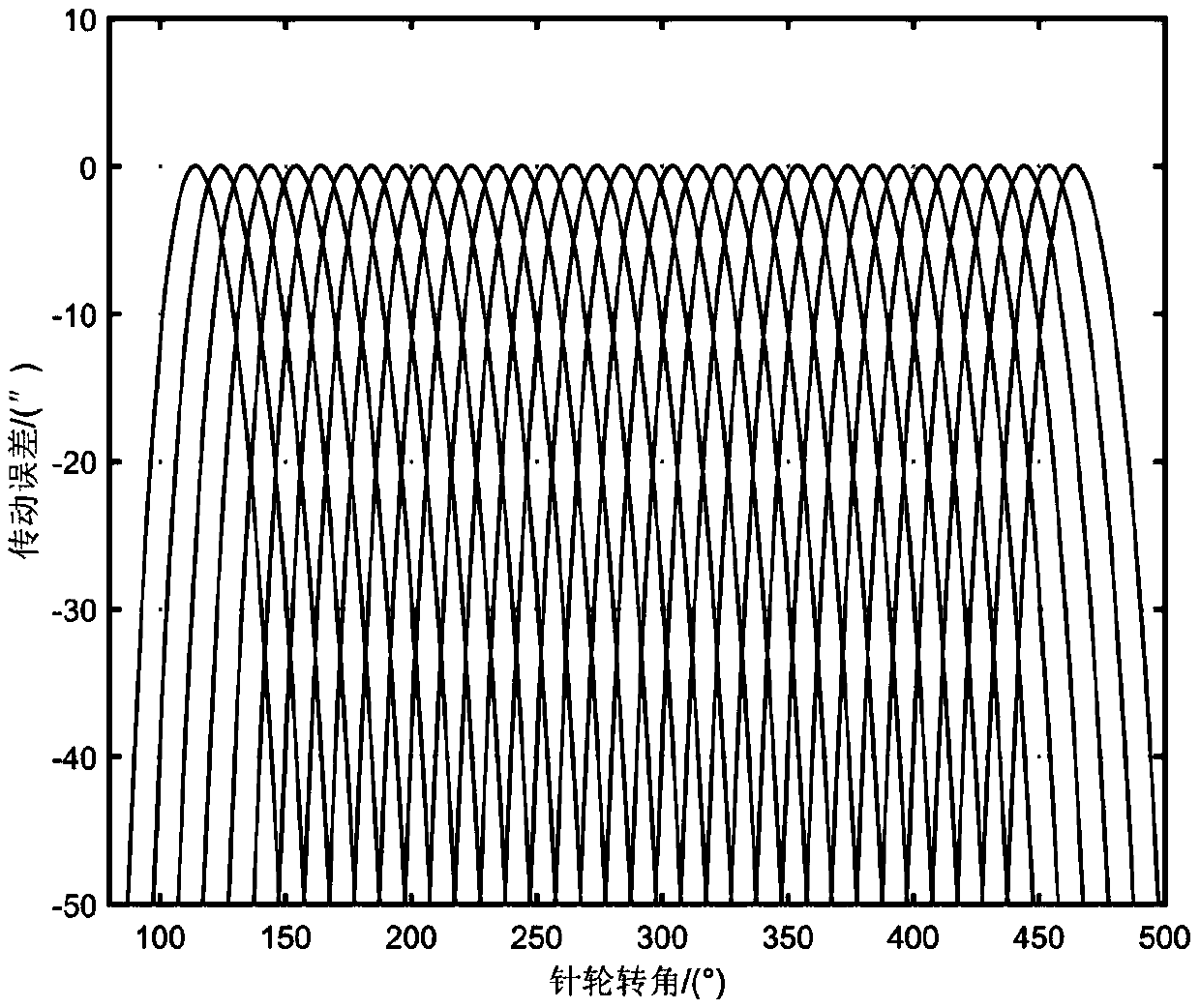

Cycloidal gear of RV reducer and reverse active tooth profile modification method thereof

ActiveCN108730480AQuality improvementGuaranteed assembly manufacturabilityPortable liftingGearing elementsShape changeEngineering

The invention provides a cycloidal gear of an RV reducer and a reverse active tooth profile modification method thereof. On the premise of comprehensive consideration of the actual transmission errorand hysterisis error requirements, reverse active profile modification design is carried out on a cycloidal gear tooth profile, a cycloidal gear design tooth profile more in line with the engineeringpractice is acquired while the meshed characteristics and movement precision are ensured, not only is the assembly manufacturability of an RV reducer cycloidal pin wheel set ensured, but also the interactive influence among the shape change of a cycloidal tooth profile, the meshed characteristics and the movement precision is comprehensively considered, so that the tooth profile modification quality and transmission quality are both effectively improved, and it is of great significance to the pre-control of the transmission performance and improvement of the movement precision of the RV reducer.

Owner:HENAN UNIV OF SCI & TECH

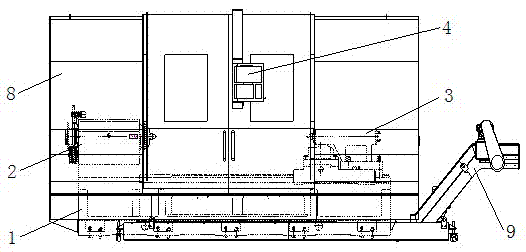

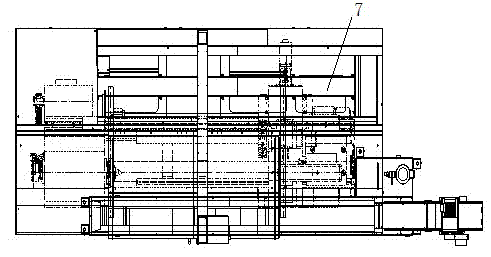

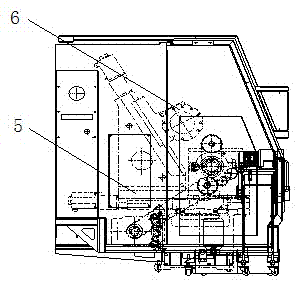

Numerical control turning and milling composite machine tool

InactiveCN102825463AStrong torsion resistanceImprove rigidityFeeding apparatusOther manufacturing equipments/toolsNumerical controlControl system

The invention discloses a numerical control turning and milling composite machine tool. The numerical control turning and milling composite machine tool comprises a machine tool body, wherein a main shaft box, a tail base, a control system, a lubricating system and a flat bed back X-axis, Y-axis and Z-axis mechanism are arranged on the machine tool body; a motor is arranged on the main shaft box and is connected with a main shaft of the main shaft box through a driving mechanism; a power cutter tower is arranged on the flat bed back X-axis, Y-axis and Z-axis mechanism; a hydraulic system is arranged on the rear side of the machine tool body and is respectively connected with the main shaft box, the tail base and the power cutter tower; and the control system is connected with the lubricating system, the hydraulic system and the flat bed back X-axis, Y-axis and Z-axis mechanism. The numerical control turning and milling composite machine tool is reasonable in internal structure layout, better in using performance and higher in work reliability.

Owner:CHANGSHA JINLING MACHINE TOOL

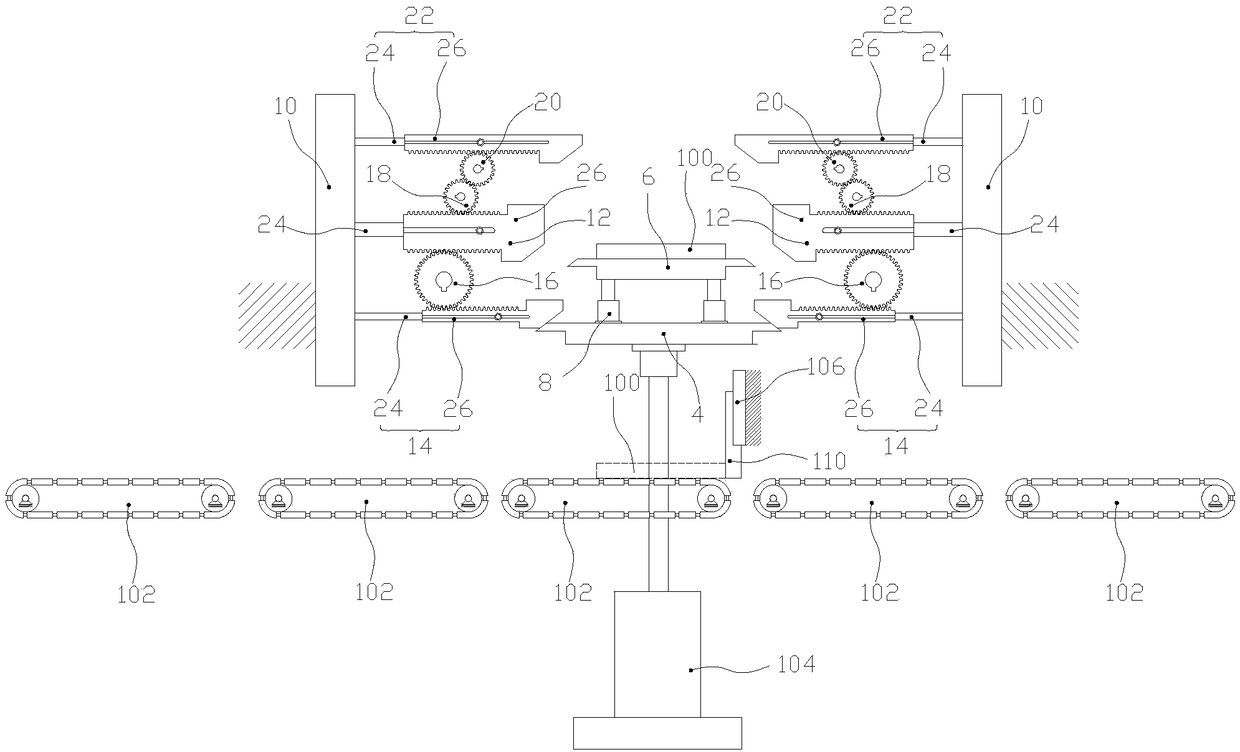

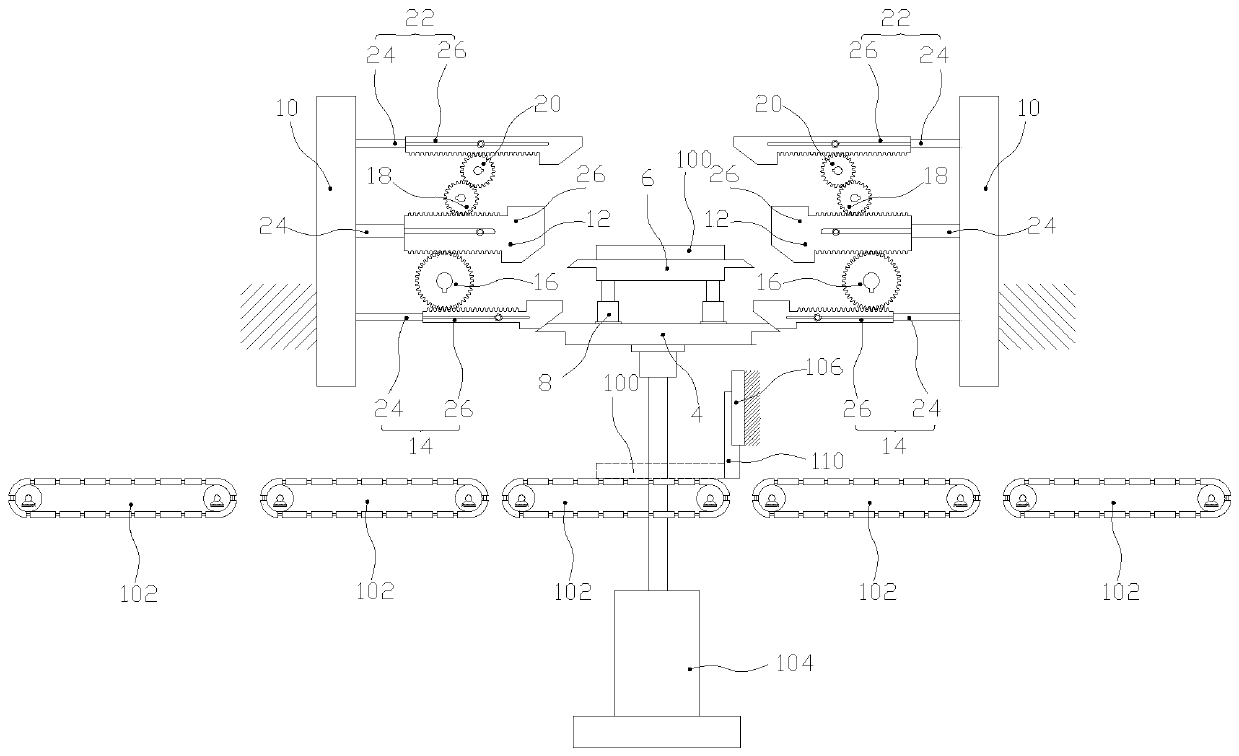

Automatic locating device

InactiveCN108313677AGuaranteed connectionHigh degree of automationConveyor partsRelative motionComputer engineering

The invention discloses an automatic locating device. The automatic locating device is characterized in that the automatic locating device comprises horizontal conveying mechanisms, an elevating mechanism, a limiting baffle and two limiting plates. According to the automatic locating device, firstly, a workpiece performs horizontal motion under the effect of the horizontal conveying mechanisms; when moving onto a horizontal workbench, the workpiece is in contact with the limiting baffle; the elevating mechanism drives the horizontal workbench to ascend, and the elevating height of the horizontal workbench is higher than a set standard position; after the horizontal workbench ascends and goes over the limiting plates, the limiting plates perform relative motion, so that the clearance between the limiting plates is smaller than the horizontal size of the horizontal workbench; and after ascending to a travel top point, the horizontal workbench is driven to descend and put onto the limiting plates, and at the moment, the position of the horizontal workbench is the standard position. By means of the automatic locating device, problems found in the prior art are well solved; linkage between the horizontal motion and the ascending-and-descending motion is guaranteed; and the automatic locating device is high in automation degree and good in motion precision.

Owner:昆山木利机械设计有限公司

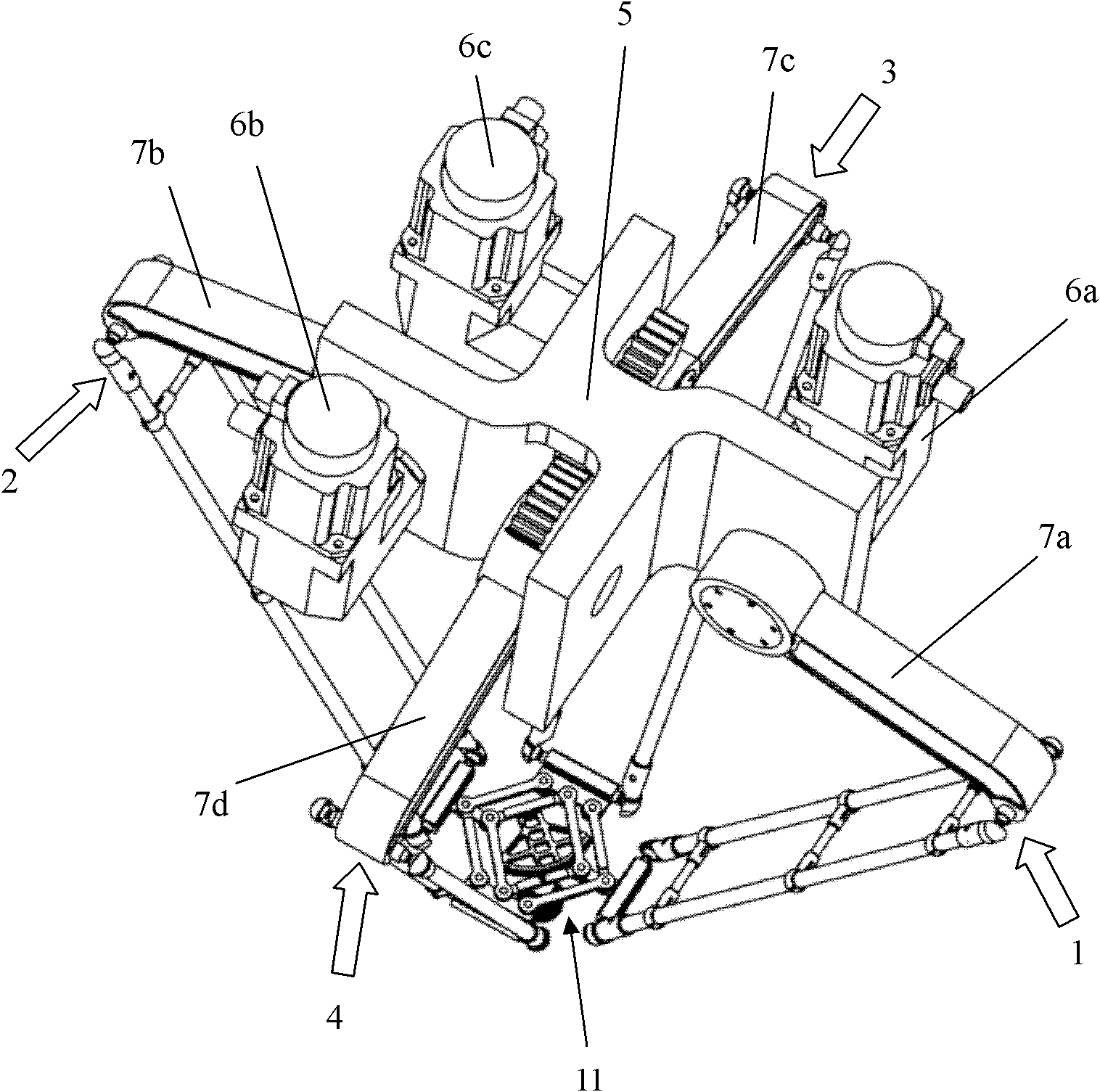

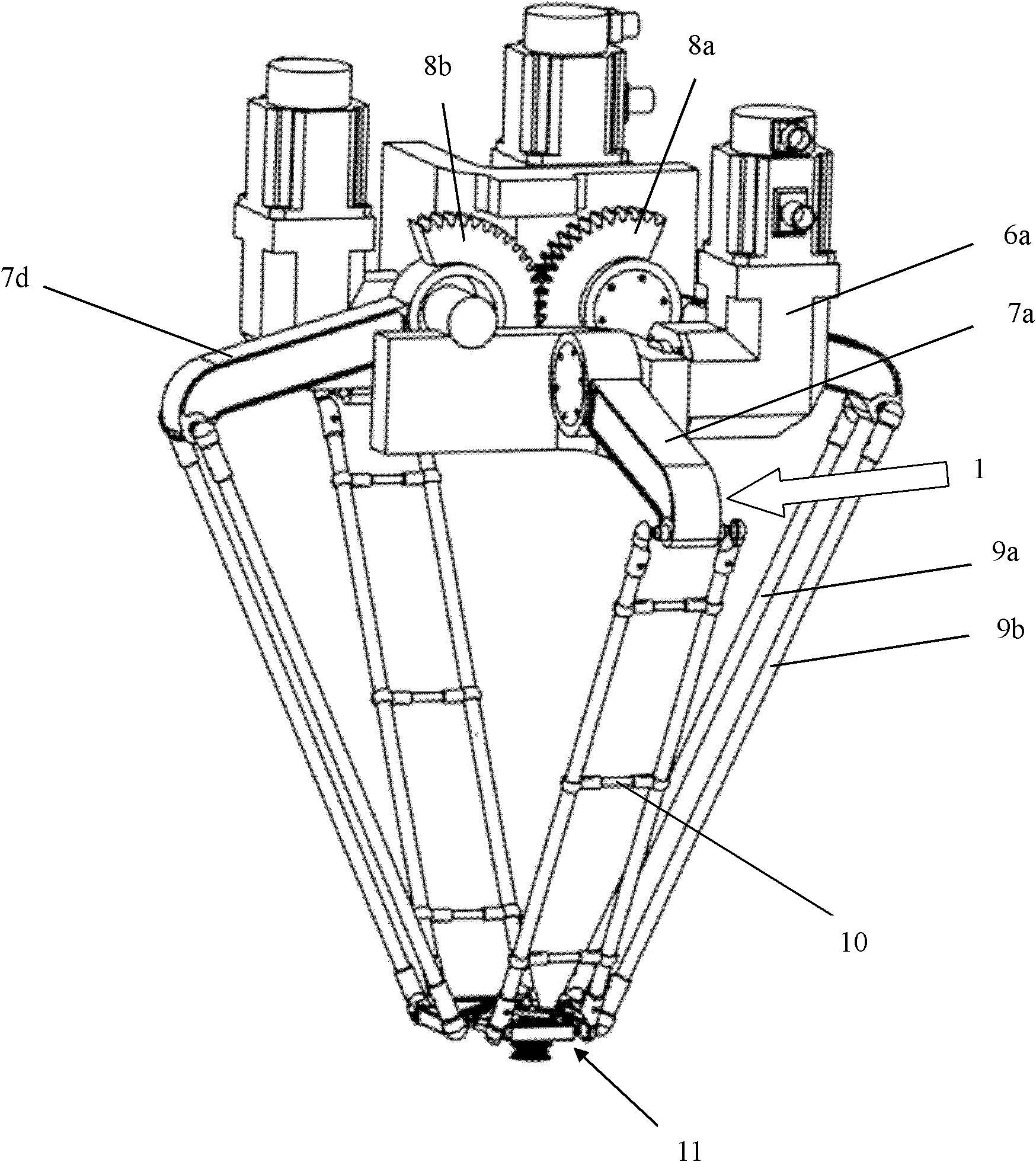

Parallel connection manipulator for concrete road water absorption equipment

ActiveCN106002953AEase of workImprove work efficiencyProgramme-controlled manipulatorRoad cleaningEngineeringRoad surface

The invention relates to a parallel connection manipulator for concrete road water absorption equipment. The parallel connection manipulator comprises a shock-absorbing support mechanism. The shock-absorbing support mechanism has good shock-absorbing performance and stability. An adjustable tightly-attaching device is welded to the lower end of the shock-absorbing support mechanism, and the working portion of the front end of the parallel connection manipulator can be completely locked to and supported onto the road surface through the adjustable tightly-attaching device, so that the parallel connection manipulator is suitable for the road plash work under different complex road conditions, the working difficulty of the complex road conditions is lowered, the application range is wide, and working efficiency is high; and the adjustable tightly-attaching device comprises an adjusting support plate welded to the lower end face of a movable platform, a first rib block is welded to the position between the upper end face of the adjusting support plate and each of the four side faces of the tail end of a bent supporting column and plays a role in enhancing the connecting strength of the bent supporting column and the adjusting support plate, and two tightly-attaching mechanisms are symmetrically arranged on the two sides of the adjusting support plate. By the adoption of the parallel connection manipulator, the stable locking and supporting functions can be achieved for the complex roads.

Owner:山东严格产业发展有限公司

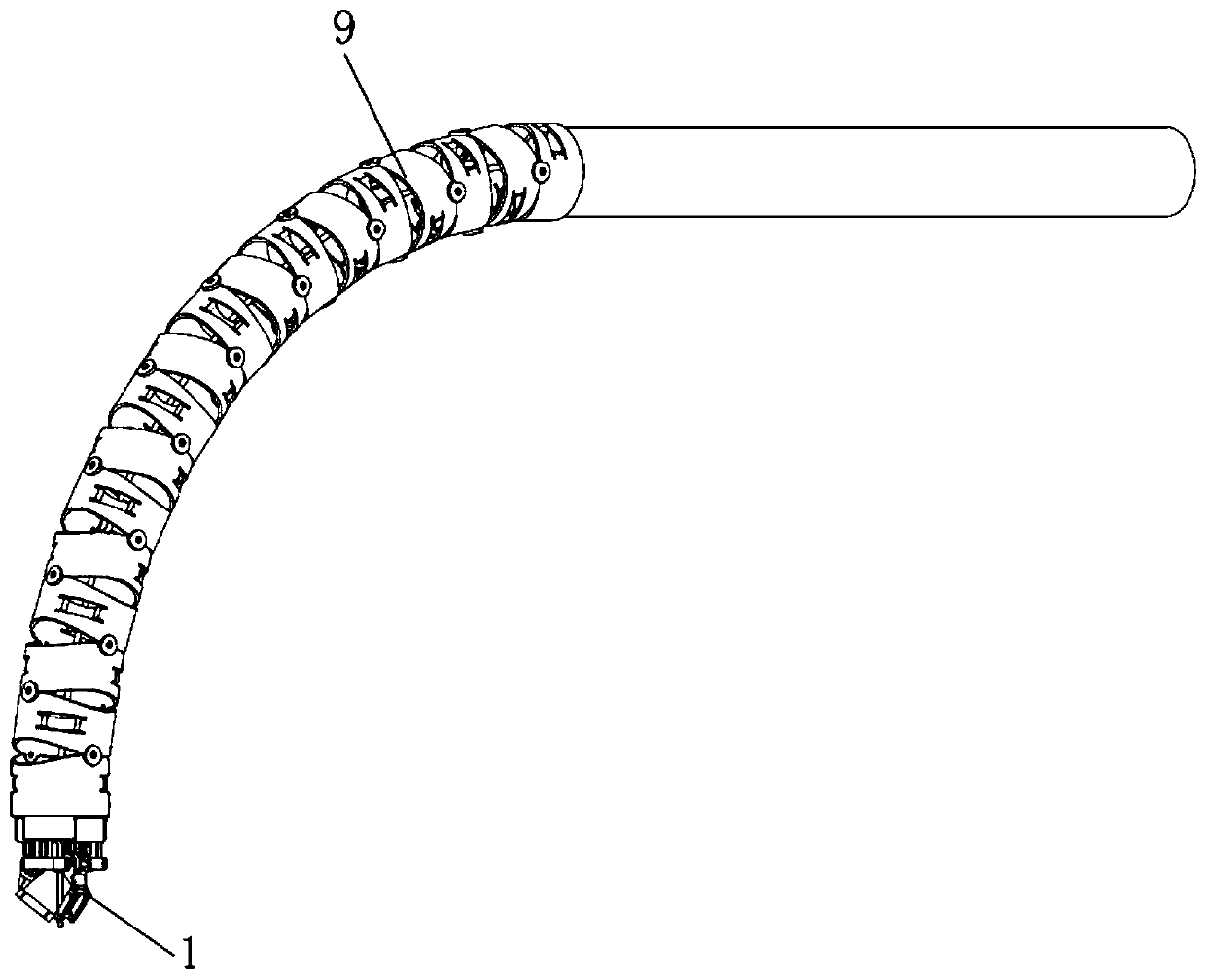

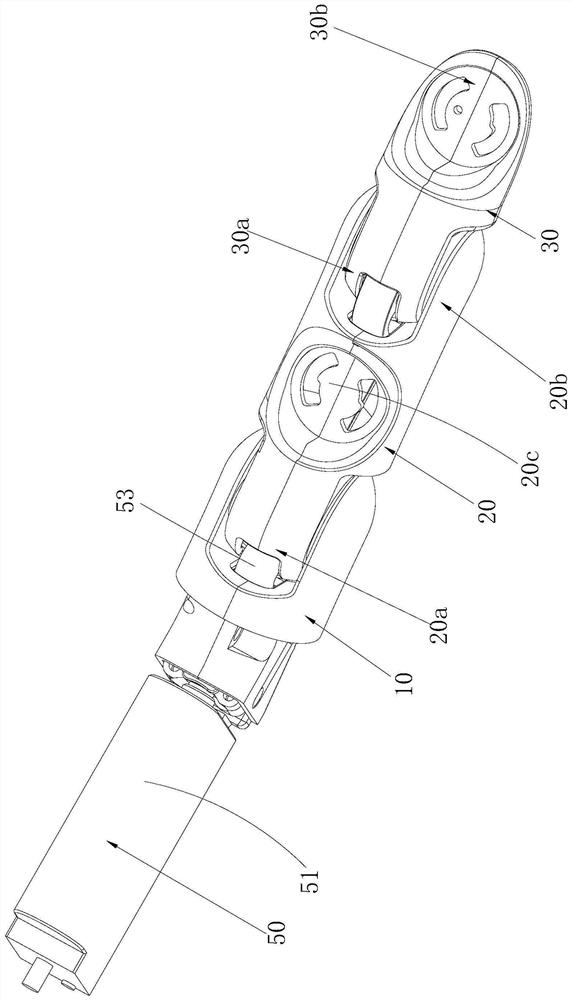

Modular multi-joint drive-by-wire robot

The invention provides a modular multi-joint drive-by-wire robot comprising a workbench, a plurality of joints connected in series, a jaw and a power mechanism; the bottom joint is arranged on the workbench, each joint comprises a shell and a connecting mechanism, and the two adjacent joints are connected via a rotating shaft fixedly connected with one of the joints; each rotating shaft is provided with a pull wheel; the power mechanism comprises a box body, a plurality of electric pull rods and pull wires connected to the electric pull rods one by one; each pull wheel is connected with one pull wire, and the jaw is connected with one pull wire. According to the modular multi-joint drive-by-wire robot, each rotating shaft can drive one of the joints to rotate and can be closely connected to another joint, and structures between the joints are compact; the pullback length of the pull wires can be accurately controlled by the electric pull rods, the rotating shafts are driven by the pullwheels, the pull wires and the electric pull rods to rotate, so that the joints driven by the rotating shafts can rotate accurately; each joint is controlled by the independent pull wire to rotate independently so as to have good motion precision.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

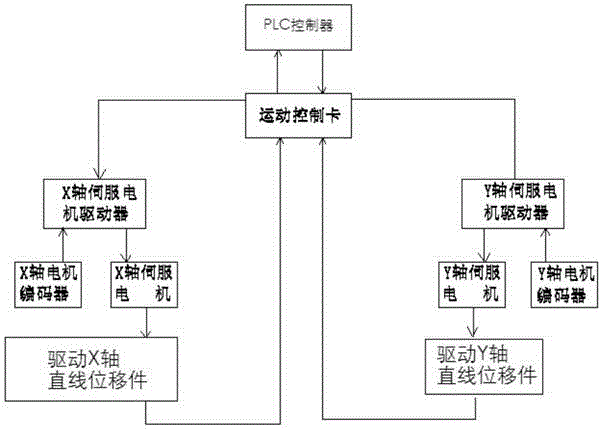

Semi-automatic carton opening machine

ActiveCN105564752ASimple structural designGood value for moneyArticle unpackingElectricityProgrammable logic controller

The invention relates to a semi-automatic carton opening machine which comprises a PLC (Programmable Logic Controller), a quadratic element movement mechanism, a conveying roller, a pneumatic side pressing device, a front block, a sensor, a touch screen, a control cabinet, a control cabinet support, an organ type protection cover, a part taking and placing station and a cutting station. The touch screen is located on the outer side of the control cabinet. The organ type protection cover is located on the side edge of the control cabinet support. The part taking and placing station is located on one side of the organ type protection cover. The cutting station is located at the lower portion in the control cabinet. The front block is located on one side of the conveying roller. The pneumatic side pressing device is located on one side of the cutting station. The sensor is arranged on the front block. The PLC is electrically connected with a servo motor system of the quadratic element movement mechanism, the sensor, the touch screen, a conveying roller motor, a front block starting switch and a starting switch for starting a pressure testing device. The semi-automatic carton opening machine is simple in structural design and high in performance cost ratio, the quadratic element movement mechanism is high in movement speed and good in movement precision, and extremely-high cutting efficiency can be provided.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

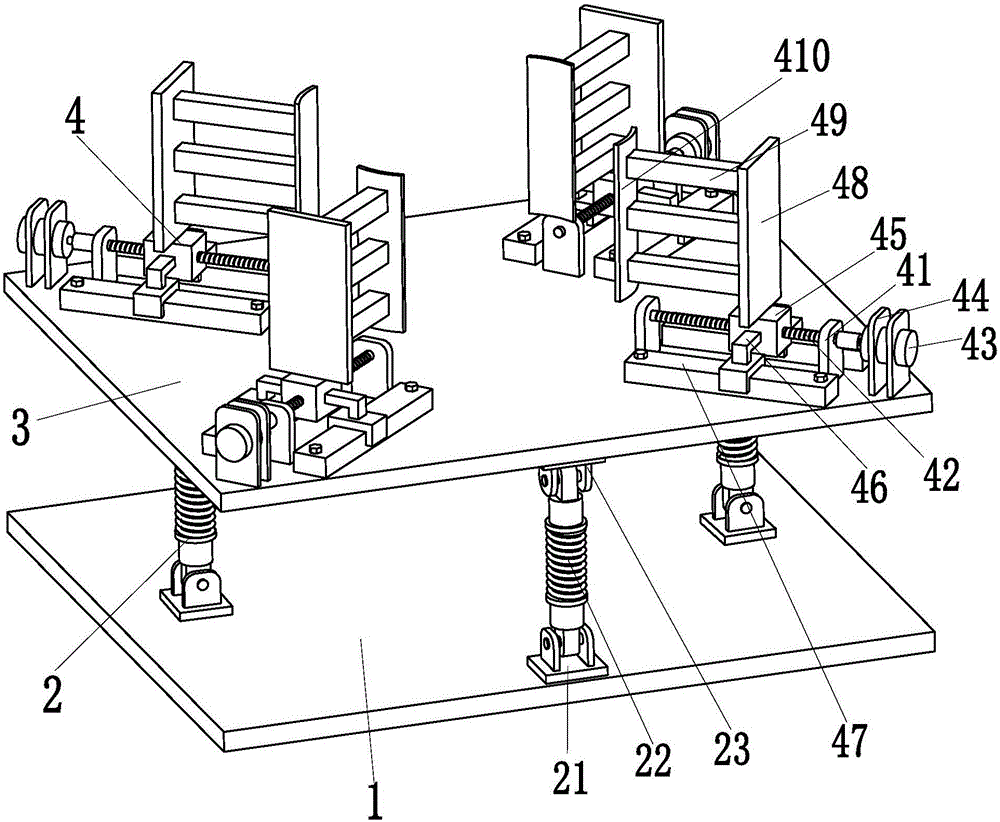

Transporting device used for pesticide spraying unmanned aerial vehicle

InactiveCN106114888AReduce shock forceRealize the locking transport functionPortable landing padsAgricultural engineeringUncrewed vehicle

The invention relates to a transporting device used for a pesticide spraying unmanned aerial vehicle. The transporting device comprises a base plate. Four shock absorption branch chains are symmetrically arranged on the upper end face of the base plate and have the good shock absorption performance. An operation table is installed on the upper end faces of the four shock absorption branch chains. Four locking branch chains are symmetrically arranged on the upper end face of the operation table, can achieve the function of automatically locking the pesticide spraying unmanned aerial vehicle which takes off or lands and have the good locking performance. Each shock absorption branch chain comprises a lower lug seat installed on the upper end face of the base plate. A shock absorber is connected to the middle of each lower lug seat through a pin shaft. The upper end of each shock absorber is connected to an upper lug seat through a pin shaft. Each upper lug seat is installed on the lower end face of the operation table. By the adoption of the transporting device, the problem that an existing pesticide spraying unmanned aerial vehicle needs to be taken and transported manually in the take-off and landing process, locking equipment is not available, and consequently the existing pesticide spraying unmanned aerial vehicle is impacted and damaged can be solved, and the transporting device can achieve the locking and transporting functions of the pesticide spraying unmanned aerial vehicle and has the beneficial effects of being easy and convenient to operate, good in locking performance, good in stability performance and the like.

Owner:安庆米锐智能科技有限公司

Clamp

InactiveCN106312638AReduce driving difficultyReduce setup costsWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention provides a clamp, which is used for clamping a to-be-processed part, and comprises a base, two clamping plates, a pressing plate, a supporting plate and a first driving device, wherein the two clamping plates are arranged on the base in a spaced manner; the pressing plate is arranged above the base, and two oppositely arranged ends of the pressing plate are separately connected to the two clamping plates; the supporting plate is arranged between the base and the pressing plate and is used for holding the to-be-processed part; and the first driving device is connected with the supporting plate, and is used for driving the supporting plate to drive the to-be-processed part to move to be attached to the pressing plate. When the to-be-processed part is clamped by the clamp provided by the technical scheme, as the pressing plate is fixed, the face, near the base, of the pressing plate and the face, far away from the support plate, of the to-be-processed part are installation reference planes, while for the to-be-processed part, such as a metal battery cover and the like, the upper surface of the to-be-processed part is a to-be-processed surface when a highlight C corner is processed, so that the installation reference planes are consistent with the to-be-processed surface, and therefore, the installation accuracy of the to-be-processed surface of the to-be-processed part, such as a metal battery cover and the like, can be increased, the accuracy of the processed highlight C corner can be further ensured, and the aesthetic property of the to-be-processed part, such as a metal battery cover and the like, can be improved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

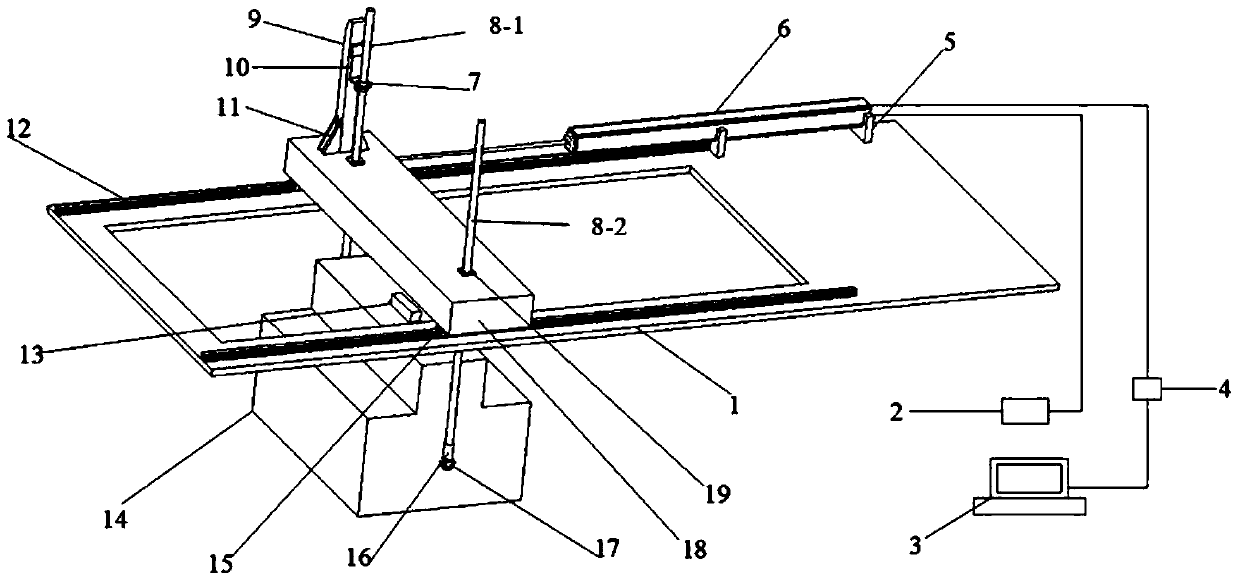

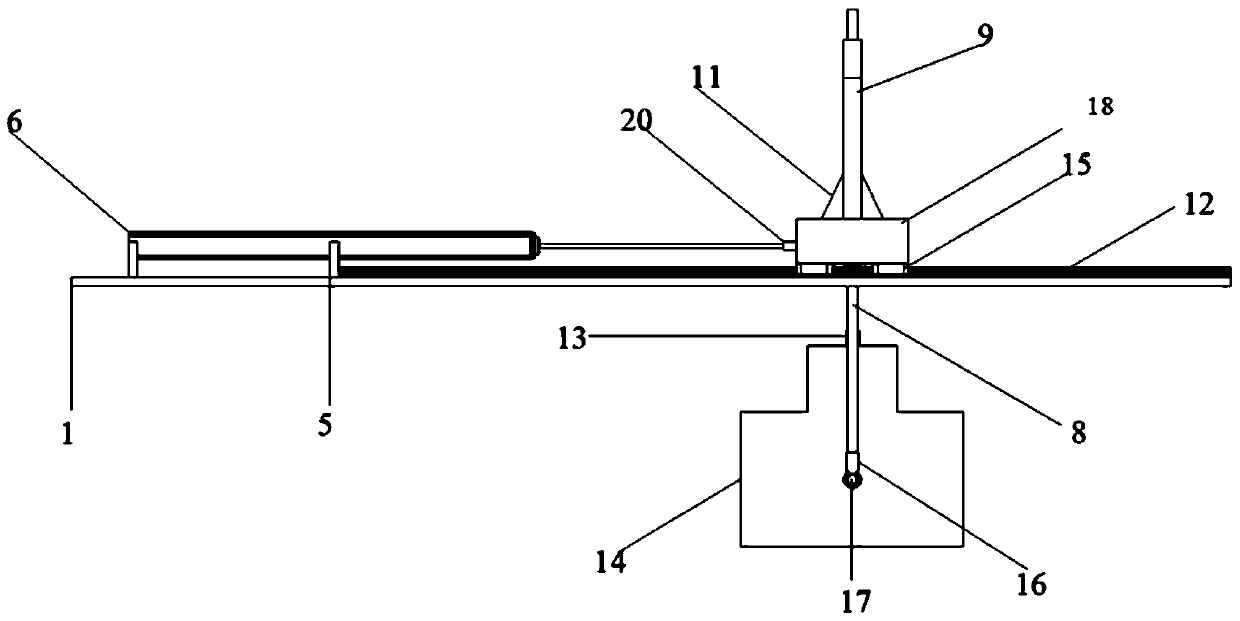

A two-dimensional deck wave experimental device

ActiveCN104700702BSimple structureEasy to manufactureHydrodynamic testingEducational modelsExperimental researchOptical axis

Owner:HARBIN ENG UNIV

Method for machining by lathing, and lathe

ActiveCN102481634AMultiple Turning ContoursShort processing timeLathesTurbinesRotational axisEngineering

The invention relates to a lathe (1), wherein the work piece (16) to be lathed with a tool (18) is clamped with the longitudinal axis of the work piece parallel to the rotational axis (29) of the rotating clamping device (15) such that the rotational axis (29) does not intersect the work piece (16), and that between two machining steps of the machining process by lathing, the position of the work piece (16) in the clamping device (15) is changed such that surface areas (30, 36) not previously machined are moved into the working area of the tool (18).

Owner:J G WEISSER SOHNE

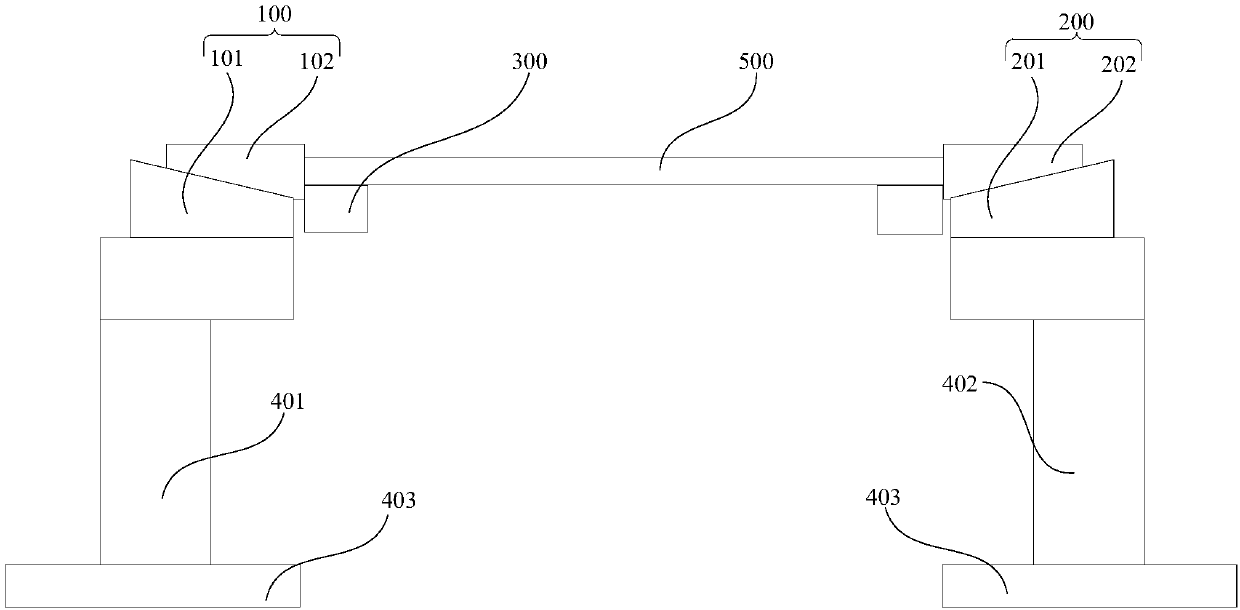

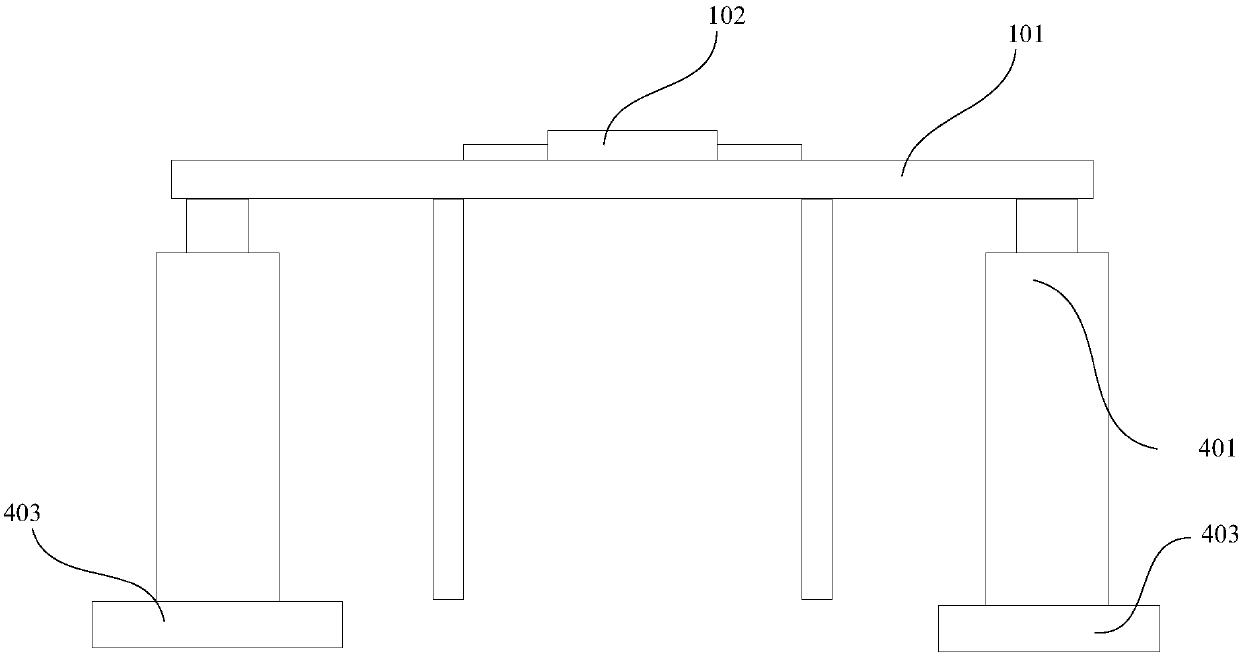

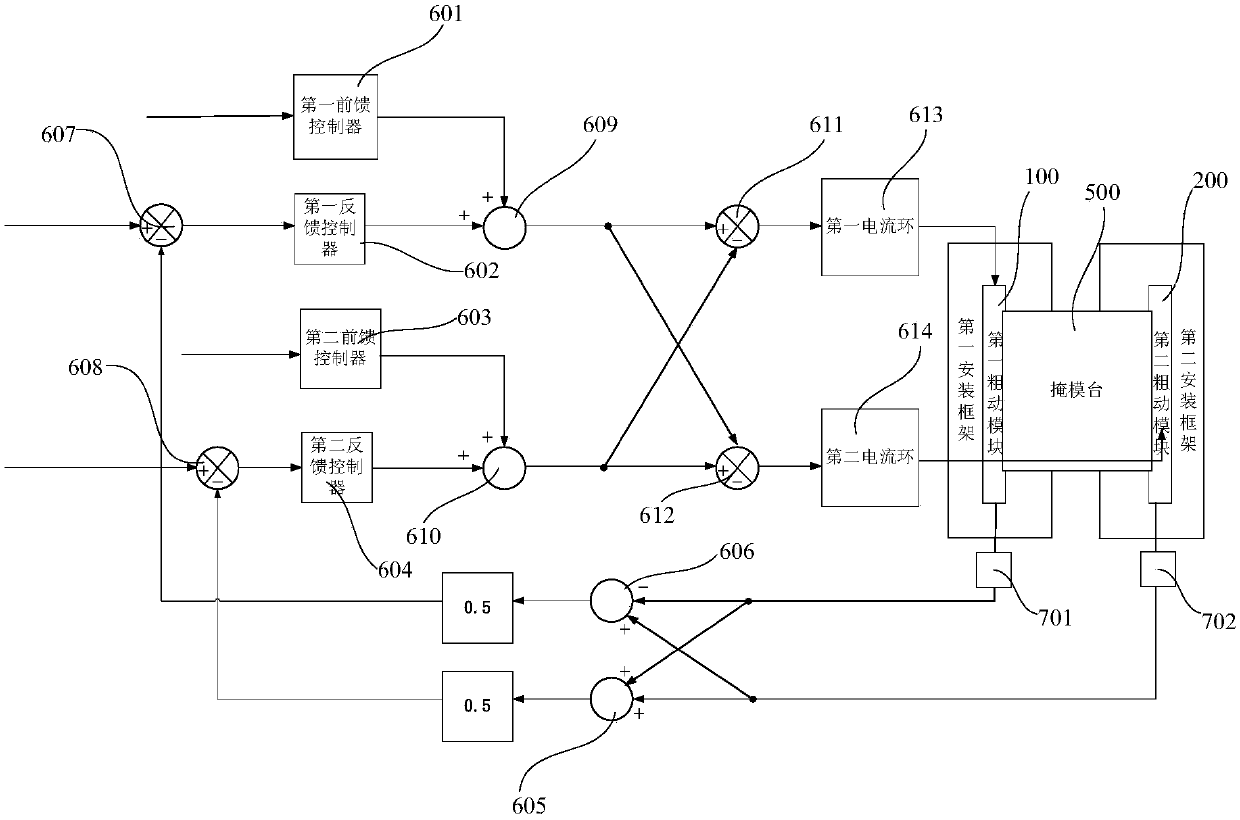

Motion control device, motion control method, mask stage system and photoetching machine

ActiveCN110320756AReduce distractionsHigh movement precisionPhotomechanical exposure apparatusControl using feedbackComputer moduleMovement control

The invention provides a motion control device, a motion control method, a mask stage system and a photoetching machine, which are used for controlling a first motion module and a second motion moduleto synchronously move and enabling the positions and motion track signals of the first motion module and the second motion module to meet preset requirements. The first motion module and the second motion module are respectively arranged on a first mounting frame and a second mounting frame. The motion control device comprises a first position feedback unit, a first track acceleration feedforwardunit, a first frame acceleration feedforward unit, a first addition operation module, a second position feedback unit, a second track acceleration feedforward unit, a second frame acceleration feedforward unit and a second addition operation module. The motion precision of the first motion module and the second motion module can be improved, and the mutual interference of the first motion moduleand the second motion module caused by asynchronous motion can be reduced, thereby improving the control precision of the motion control device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

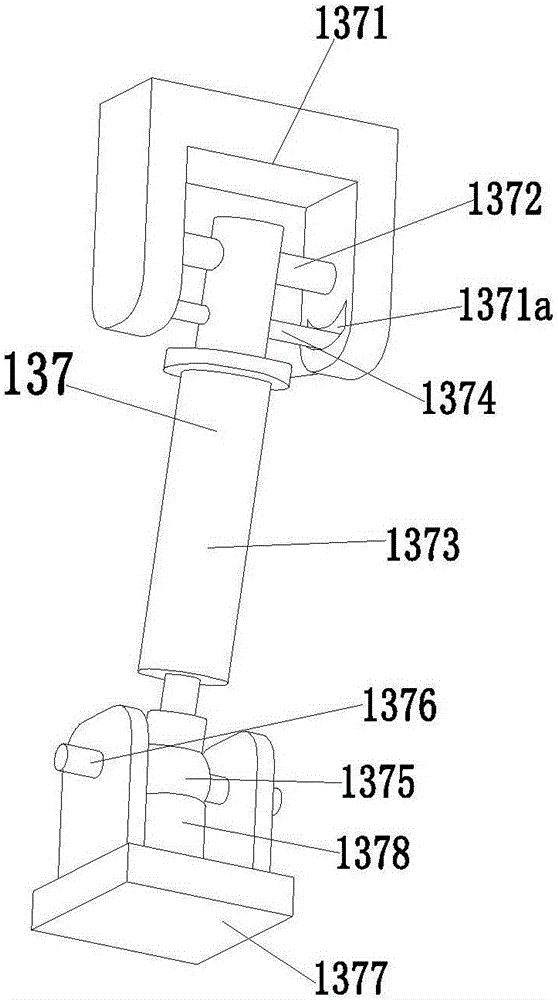

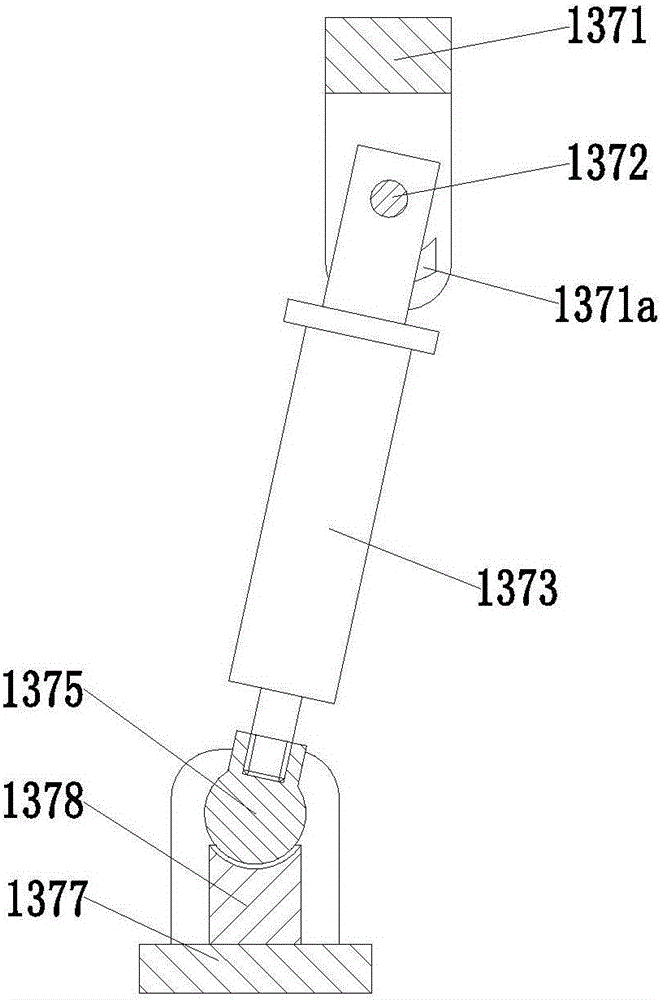

Aerial photography self-stabilization cradle head with multiple degrees of freedom for unmanned aerial vehicle

InactiveCN108216667AImprove the effect of aerial photographyEliminate jitterVibration suppression adjustmentsGround installationsCouplingDrive shaft

The invention relates to an aerial photography self-stabilization cradle head with multiple degrees of freedom for an unmanned aerial vehicle. The aerial photography self-stabilization cradle head comprises a fixing framework. The fixing framework comprises a lower platform, a transmission shaft is mounted in the middle of the upper end surface of the lower platform via bearings, a transmission gear is mounted in the middle of the transmission shaft via keys and meshes with six transmission branch chains along the axial directions, and the upper ends of six driving shafts on the six transmission branch chains are connected with a support table by bearings; the middle of the support table is connected with the transmission shaft by bearings, and six support columns are uniformly welded on the lower end surface of the support table along the axial directions; the lower end surfaces of the six support columns are mounted on the lower platform; the upper end of the transmission shaft is connected with a transmission lead screw by couplings; a transmission slider is mounted in the middle of the transmission lead screw in a threaded connection manner. The aerial photography self-stabilization cradle head has the advantages that the aerial photography self-stabilization cradle head can have unmanned aerial vehicle stable lifting aerial photography functions, and is simple in structure, good in mechanical structural stability and lifting aerial photography performance and high in work efficiency, and the like.

Owner:程岚

Robot assisted bone setting operation medical system with lock marrow internal nail

InactiveCN1259891CAchieve therapeutic effectRelieve painInternal osteosythesisSurgical navigation systemsDistance HealingSimulation

A robot aided surgical system for the bone setting operation with the locking intramedullary nail is composed of multifunctional automatic operation bed, robot, bone setting regulator on said robot, bone fixing mechanism, high-accuracy full-automatic X-ray machine with C-shaped arm, navigation robot, robot controller, master hand control station, and slave hand control station.

Owner:HARBIN INST OF TECH

Automatic positioning device

ActiveCN109879015AGuaranteed connectionHigh degree of automationConveyor partsRelative motionRisk stroke

The invention discloses an automatic positioning device. The automatic positioning device is characterized by comprising a horizontal conveying mechanism, a lifting mechanism, a limiting baffle and two limiting plates. According to the automatic positioning device, a workpiece does a horizontal motion under the action of the horizontal conveying mechanism first; when the workpiece moves to a horizontal workbench and makes contact with the limiting baffle, the horizontal workbench is driven to lift by the lifting mechanism, and the lifting height is higher than the set standard position; afterthe horizontal workbench rises and crosses the limiting plates, the limiting plates do a relative motion, so that the gap of the limiting plates is less than the horizontal size of the horizontal workbench; and after the horizontal workbench rises to a stroke peak, the horizontal workbench is driven to descend and put on the limiting plates by the lifting mechanism, and the position of the horizontal workbench is the standard position at the moment. According to the automatic positioning device, the problems of the prior art are effectively solved, the engagement of the horizontal motion and the lifting motion is guaranteed, and the automatic positioning device has the advantages of high degree of automation and good kinematic accuracy.

Owner:昆山华悦金属家具制品有限公司

Connecting rod structure, robot fingers and robot

ActiveCN113103278AAchieve active bendingAchieve straighteningJointsGripping headsEngineeringPassive motion

The invention belongs to the technical field of robot accessories, and particularly relates to a connecting rod structure, robot fingers and a robot. In the connecting rod structure, a fixing frame, a first rod piece, a second rod piece and a connecting rod form a four-rod mechanism, and active bending, straightening and passive bending movement of the four-rod mechanism can be achieved in combination with a driving assembly and an elastic piece; no matter whether a linear driving piece works or not, when the second rod piece is subjected to external force, the second rod piece can swing, the elastic piece is compressed to store energy, the first rod piece is in linkage with the connecting rod, the first rod piece swings in the swinging direction of the second rod piece, and passive bending movement is achieved; during passive bending movement, interference between the first rod piece and a transmission rod is avoided, and the situation that the four-rod mechanism is damaged due to external force is reduced; and after the external force is removed, the elastic piece releases energy to drive the second rod piece to reset, and the first rod piece, the connecting rod, the transmission rod and a push rod are in linkage to achieve straightening motion. The connecting rod structure can be applied to occasions requiring bidirectional active movement and unidirectional passive movement, such as the robot fingers.

Owner:UBTECH ROBOTICS CORP LTD

Hybrid driven punch

InactiveCN110743998AHas a boosting effectAdjustable strokeForging press drivesHydraulic ramEngineering

The invention relates to a hybrid driven punch. A hydraulic oil cylinder and a mechanical connection rod mechanism are adopted and combined with each other. The hybrid driven punch comprises the hydraulic oil cylinder and a machine body. A piston rod is installed in the hydraulic oil cylinder. A slider is installed in the machine body and is connected with the piston rod through the connection rodmechanism. The innovation points lie in that the oil cylinder is adopted for driving two sets of symmetrically connected toggle rod mechanisms so as to achieve the purposes of secondary force increase and speed increase effects and adjustable working stroke and speed. The hybrid driven punch has the advantages that the slider is connected with the piston rod through a double toggle mechanism, thus the slider has the speed increase and force increase effects, thereby reaching the needed forge-press force in the mode that the hydraulic oil cylinder only needs to give small force to the double toggle mechanism, energy consumption is lowered greatly, energy is saved, and meanwhile the purpose of the adjustable stroke and speed of the slider can be achieved by controlling the stroke and speedof the hydraulic oil cylinder.

Owner:NANTONG METALFORMING EQUIP

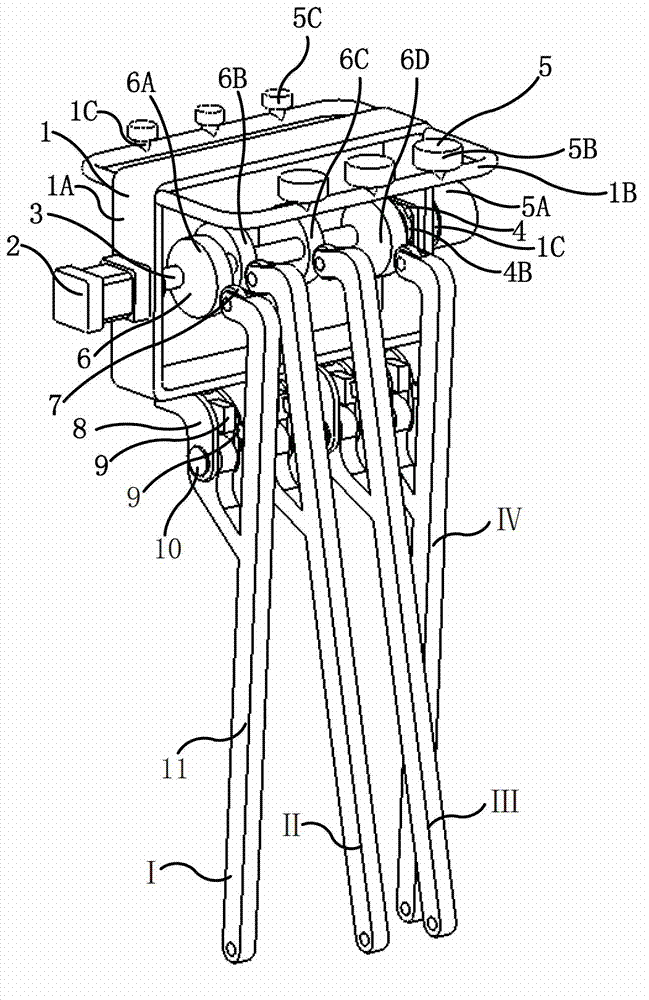

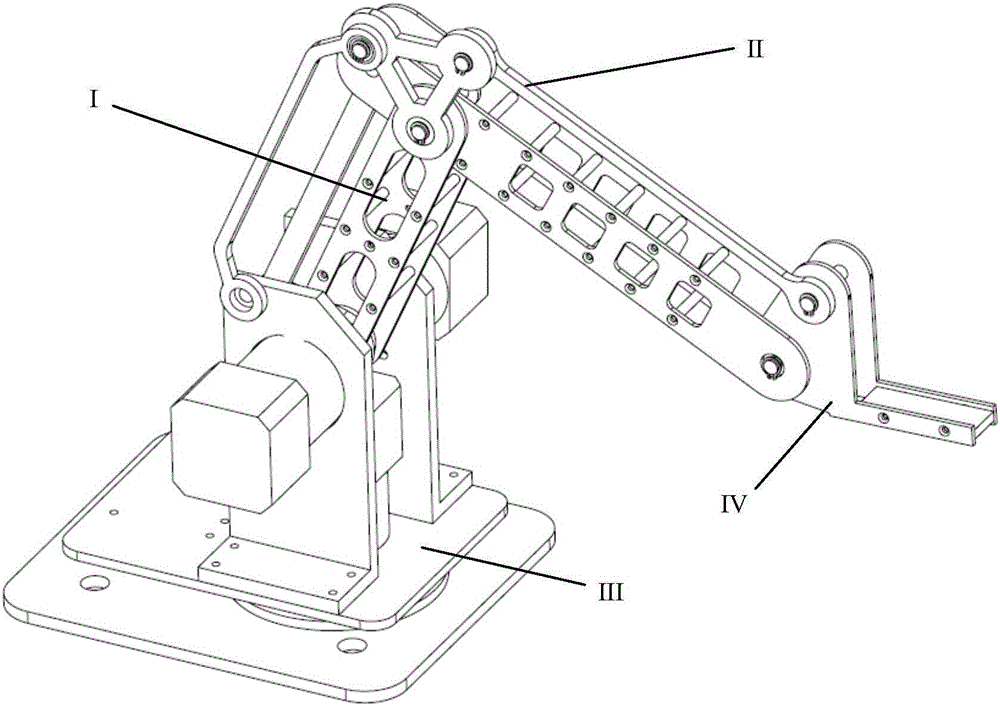

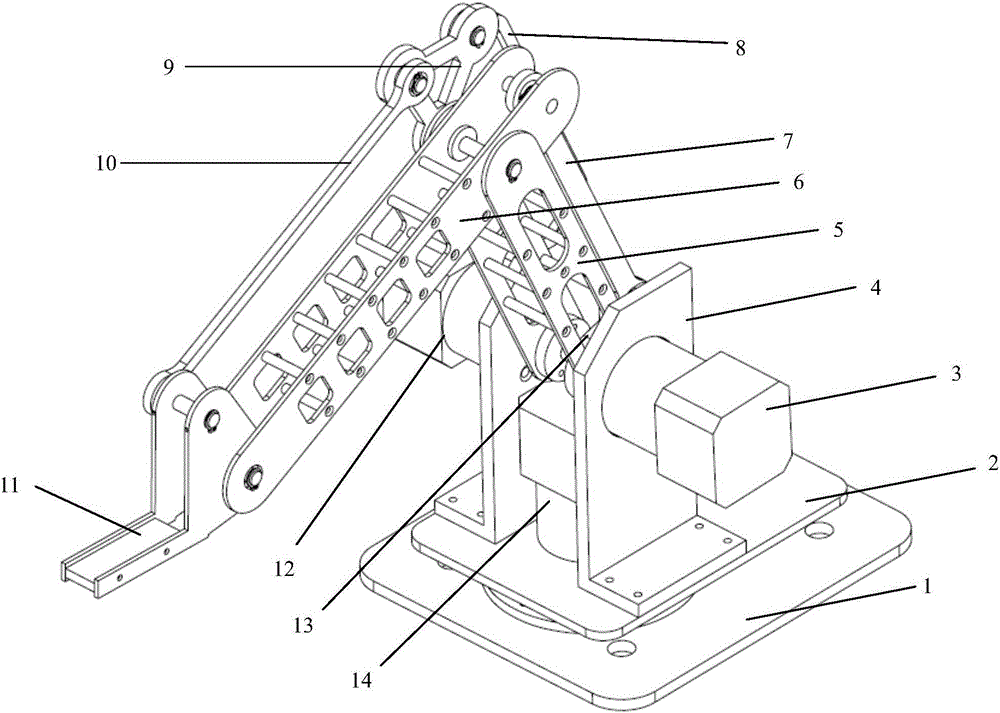

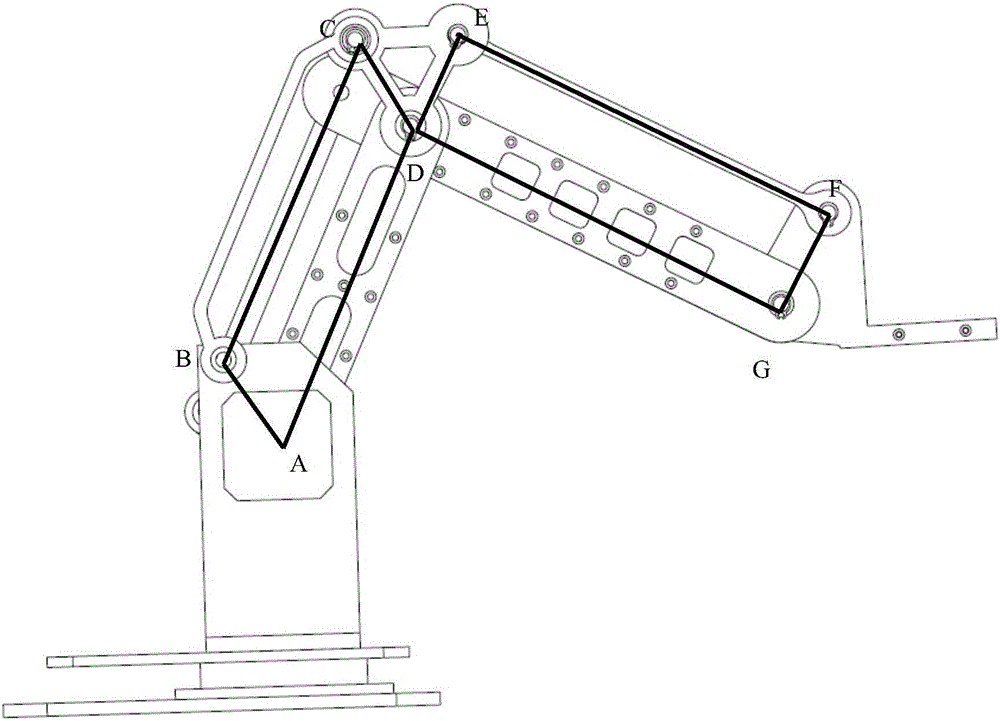

Three-freedom-degree teaching robot

InactiveCN105869508AReduce body weightGood stiffness and motion precisionEducational modelsEngineeringPower transmission

The invention discloses a three-degree-of-freedom teaching robot, which comprises a driving branch chain I, a driven branch chain II, a base III and an end flange IV. The present invention changes the driving arrangement form of the traditional series arm, and uses the parallelogram mechanism formed by the intersection of the driving branch chain I and the driven branch chain II to transmit the power of the driving device to the end flange; the upper arm structure of the driving branch chain I adopts split arms The rod and the arm plates on both sides are fixed with copper guide posts to ensure the rigidity and convenience of the body. The invention has a compact structure, is convenient for students to operate, is safe and convenient; the end is provided with a universal flange, which can realize various purposes of teaching, and improves the practicability of the robot in the field of educational technology.

Owner:单家正

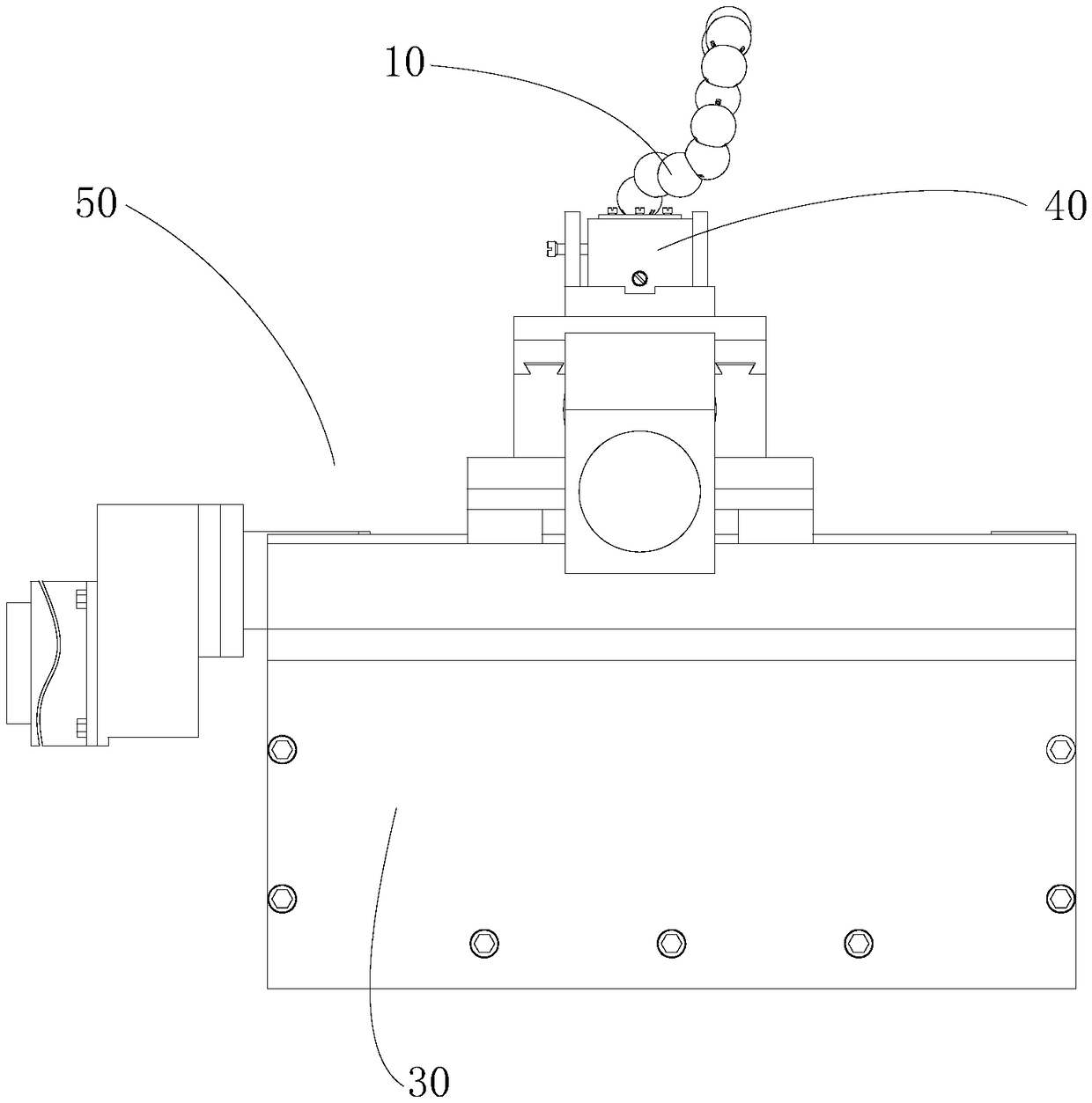

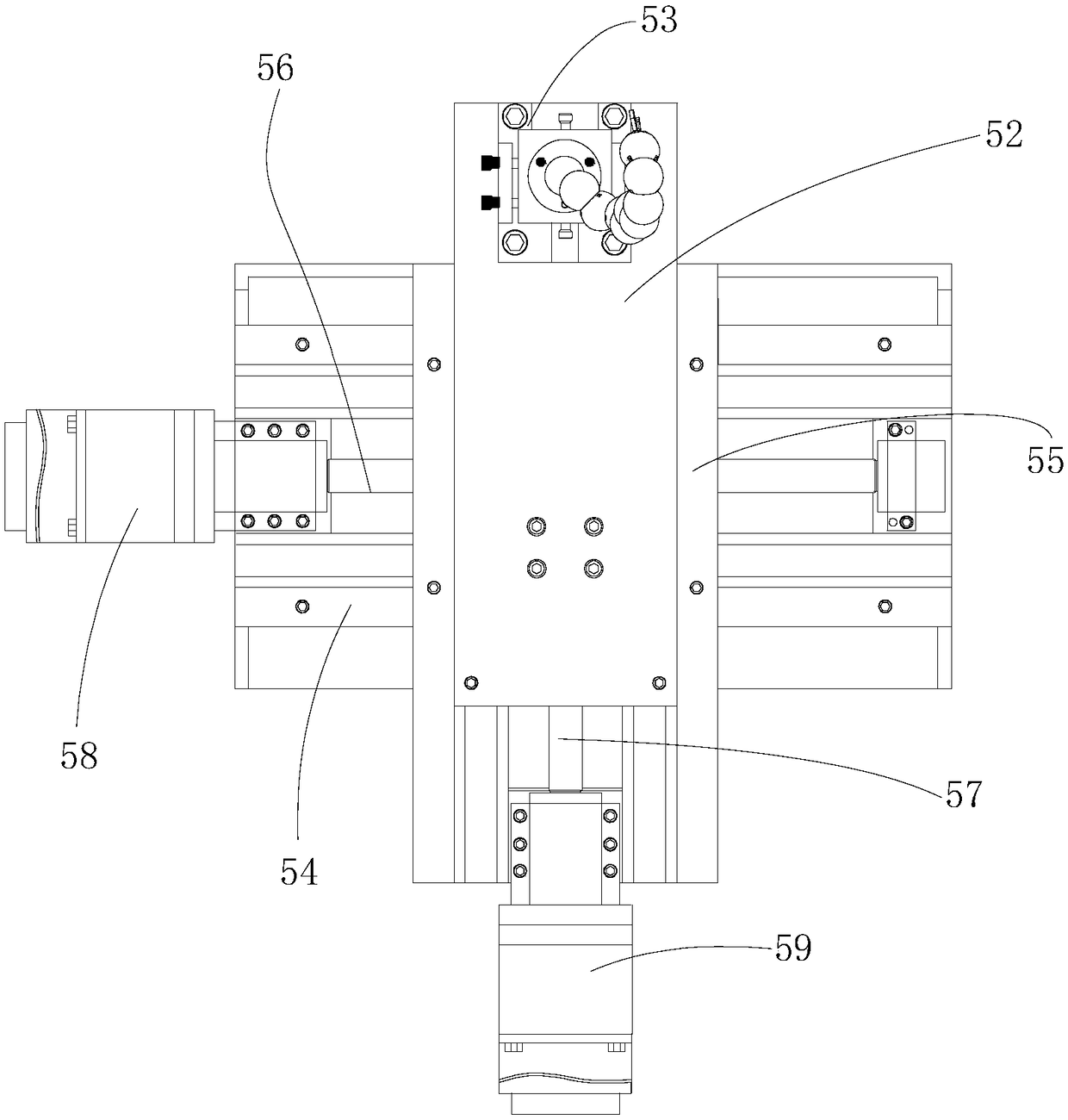

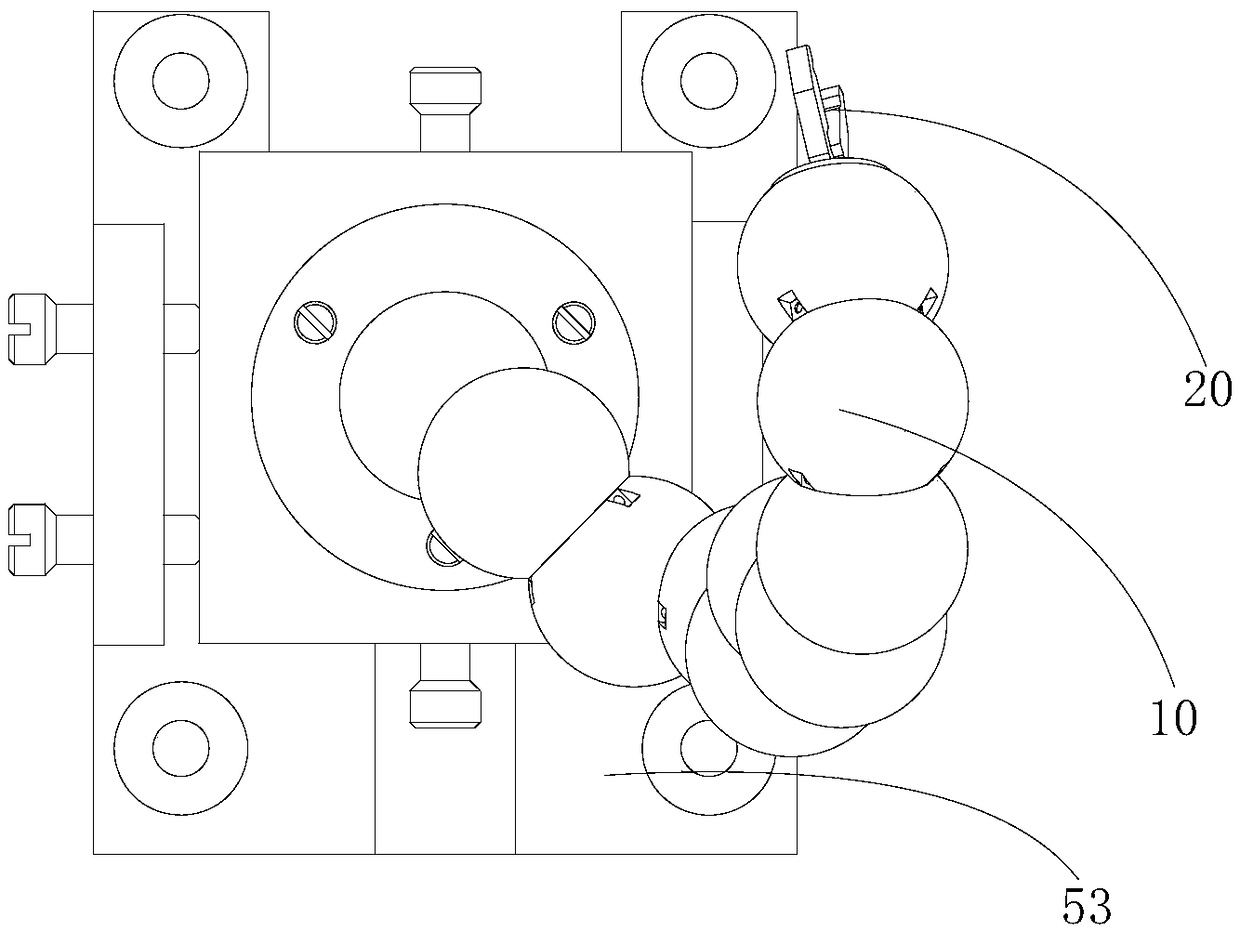

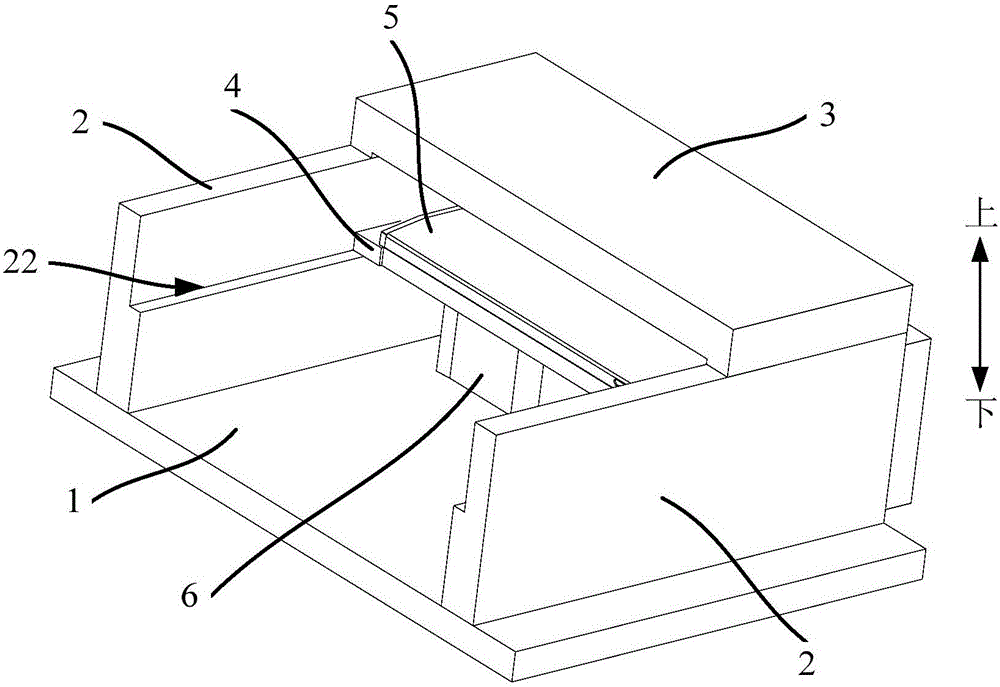

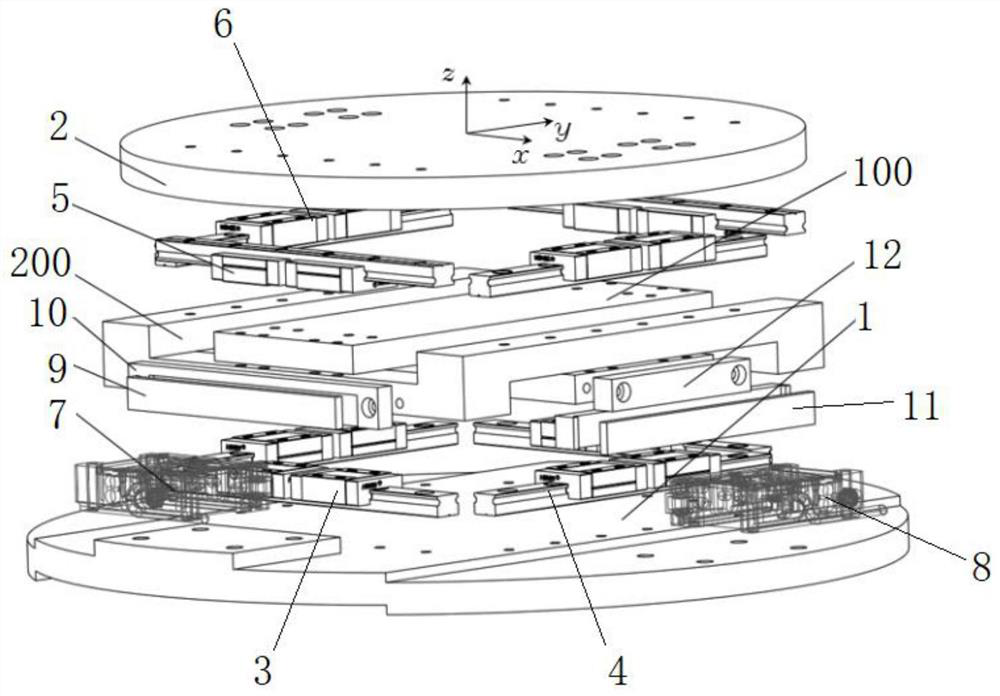

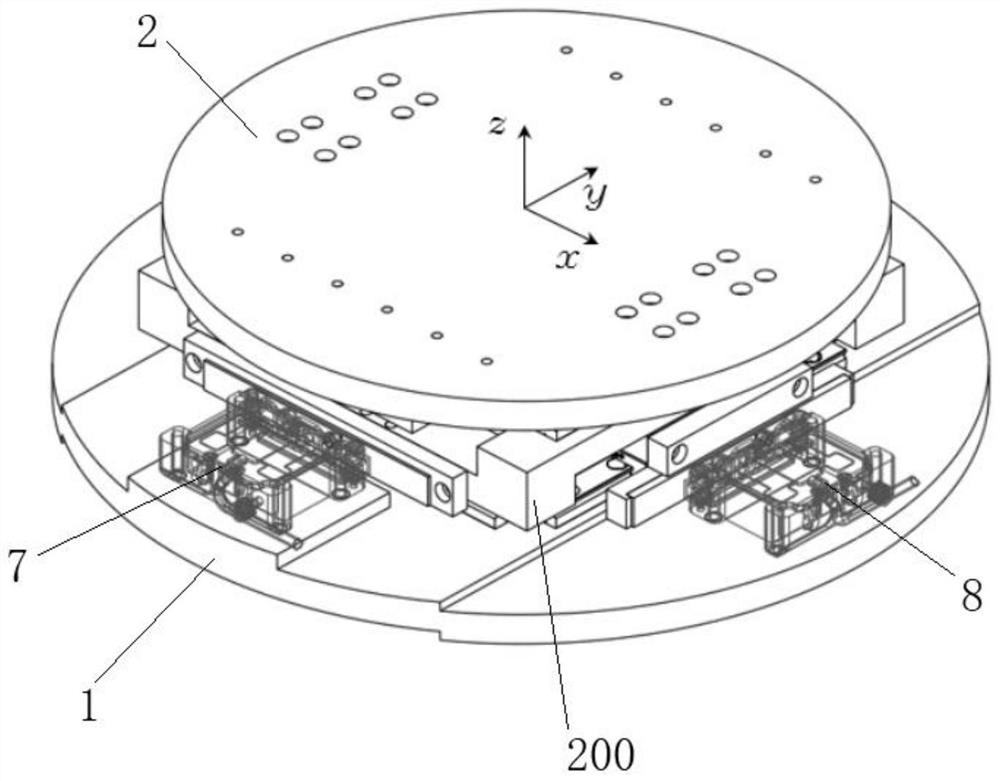

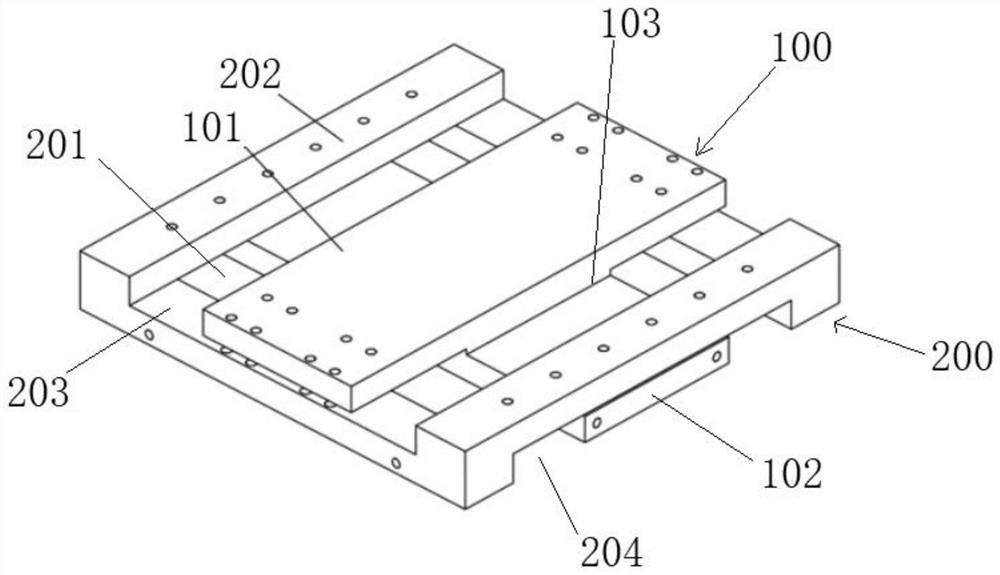

Motion platform suitable for packaging optical communication device

ActiveCN111761552AImprove space utilizationIncrease stiffnessWork benchesOptical communicationMechanical engineering

The invention discloses a motion platform suitable for packaging an optical communication device. The motion platform suitable for packaging the optical communication device comprises a base, an objective table, a cross table movably arranged on the base, a frame table with a middle hole, a pair of first guide rail mechanisms guiding in the x direction respectively and a pair of second guide railmechanisms guiding in the y direction respectively, wherein the cross table comprises an upper plate and a lower plate which are perpendicularly arranged in a crossed mode, the upper plate is locatedabove the middle hole, the lower plate is located below the middle hole, the cross table does not make contact with the frame table all the time, the pair of first guide rail mechanisms are connectedbelow the two ends of the frame table respectively, and the pair of second guide rail mechanisms is connected below the two ends of the lower plate respectively. The motion platform suitable for packaging the optical communication device aims at solving the technical problems that in the prior art, an optical communication device related plane motion platform is poor in efficiency and precision and poor in space utilization rate.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com