Numerical control turning and milling composite machine tool

A compound machine tool, turning and milling technology, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, driving devices, etc., can solve the problems of unsatisfactory performance and work reliability, achieve good rigidity, improve positioning accuracy and processing accuracy, Effects that Guarantee Agreeableness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

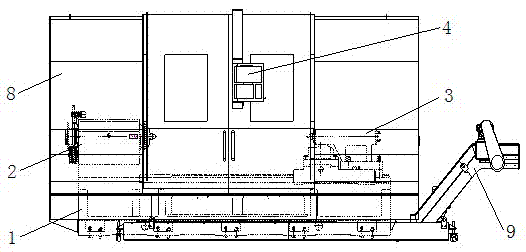

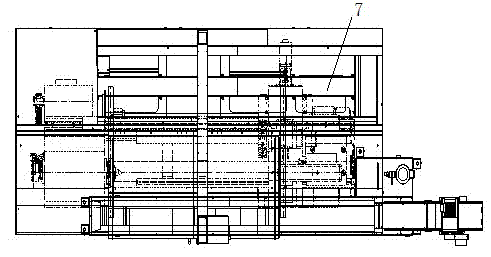

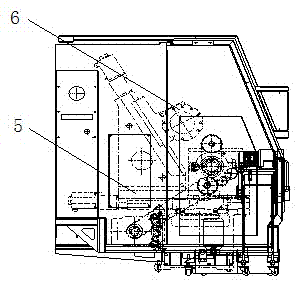

[0026] With reference to accompanying drawing, present embodiment comprises bed 1, and described bed 1 is provided with headstock 2, tailstock 3, control system 4, lubricating system and flat bed rear X-axis, Y-axis, Z-axis mechanism 5, so The spindle box 2 is provided with a motor, and the motor is connected to the main shaft of the spindle box through a transmission mechanism. The X-axis, Y-axis, and Z-axis mechanism 5 behind the flat bed are provided with a power turret 6. The bed 1 The rear side of the hydraulic system 7 is provided with the hydraulic system 7, and the hydraulic system 7 is respectively connected with the headstock 2, the tailstock 3, and the power turret 6. Axis and Z-axis mechanism 5 are connected.

[0027] The X-axis, Y-axis and Z-axis mechanisms 5 are placed behind the flat bed, including bed saddle, Y-axis ball screw nut pair,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com