Patents

Literature

137results about How to "Butt tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

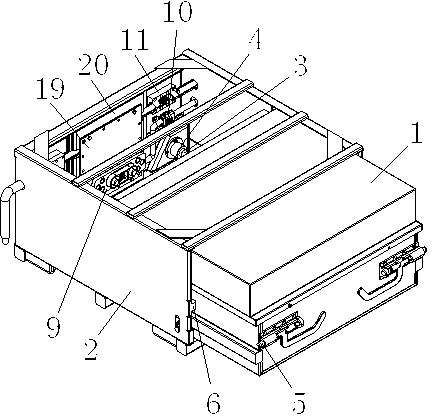

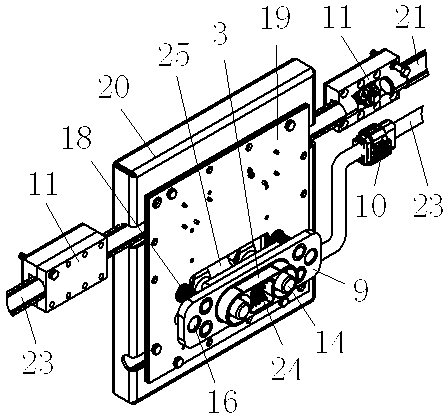

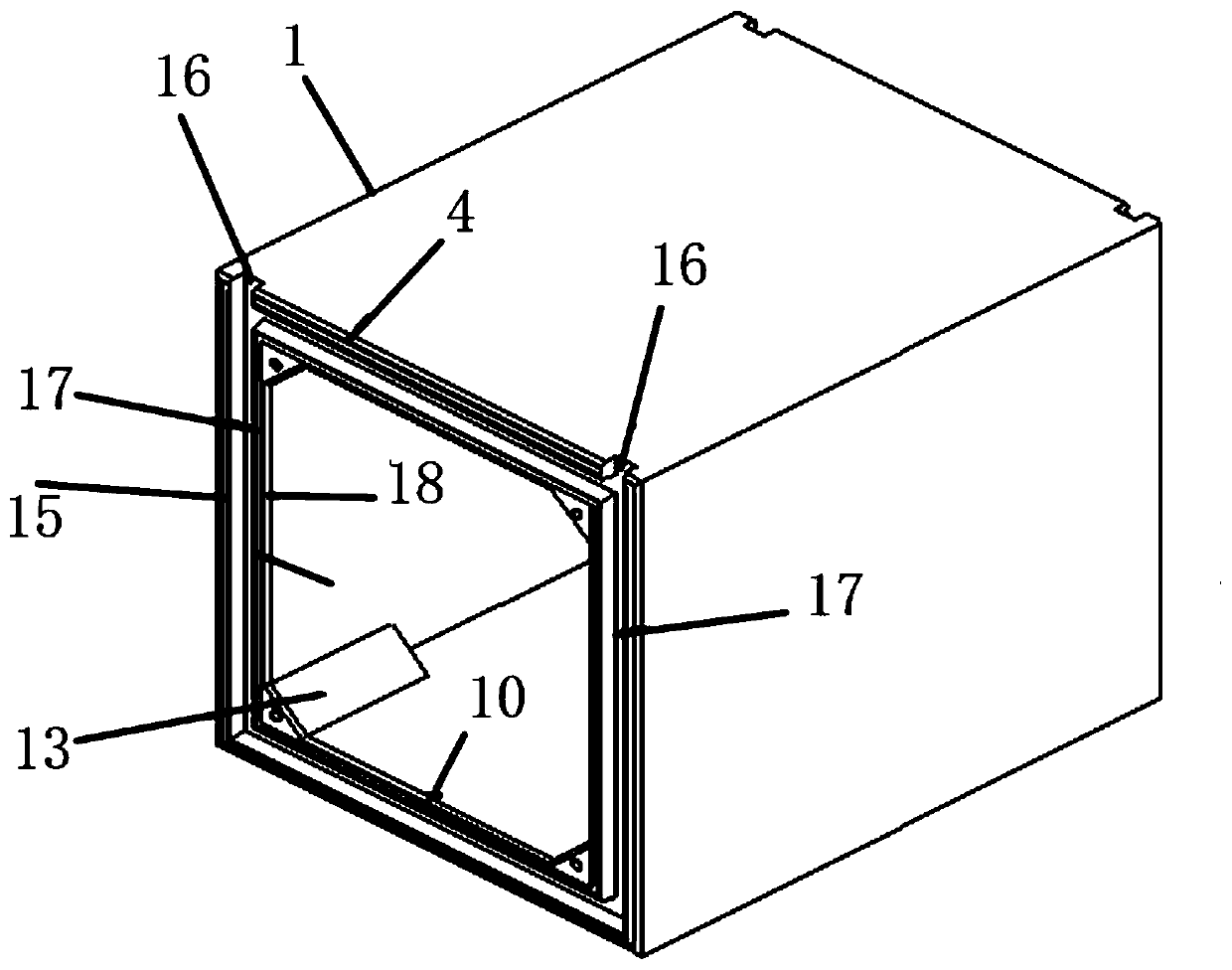

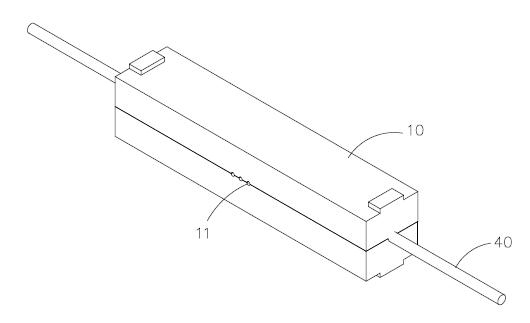

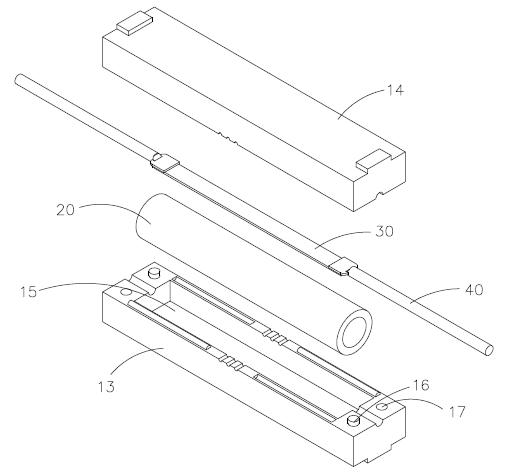

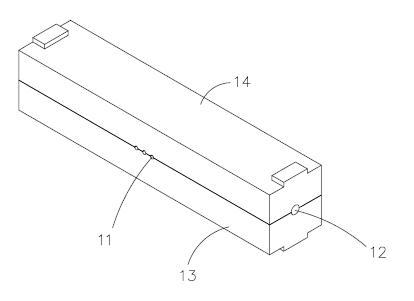

Method for connecting electric vehicle battery internal and external tanks, and structure thereof

ActiveCN103117365AAvoid restrictionsAvoid influenceElectric propulsion mountingCouplings bases/casesElectric-vehicle batteryElectrical battery

The invention discloses a method for connecting electric vehicle battery internal and external tanks, and a structure thereof. A battery internal tank is inserted to a battery external tank in a drawer type structure manner, and is rapidly replaced and positioned through fixing by inserting a dead bolt to a lock hole; impact force generated during vehicle accelerating or braking can be alleviated through applying pre-thrust to the battery internal tank by an elastic spacing seat arranged at the inner side of the rear panel of the battery external tank; and an electrical connecting piece arranged between the battery external tank and the battery internal tank is prevented from squashing through restricting the smallest limit distance between the battery internal tank and the battery external tank by a rigid spacing table arranged at the bottom of the elastic spacing seat. A whole socket assembly and an insulation plate are used as a whole installation module, so the assembling and dismounting are convenient. The socket assembly is flexibly connected with an external cable through an adapter to guarantee the tight butt of a plug assembly and the socket assembly and make a socket connector well and stably work. Two first defense lines for dust and water prevention are possessed in the invention, so the safety and the reliability of the connector are enhanced.

Owner:GUIYANG PUTIAN LOGISTICS TECH

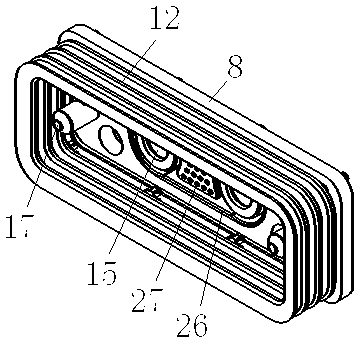

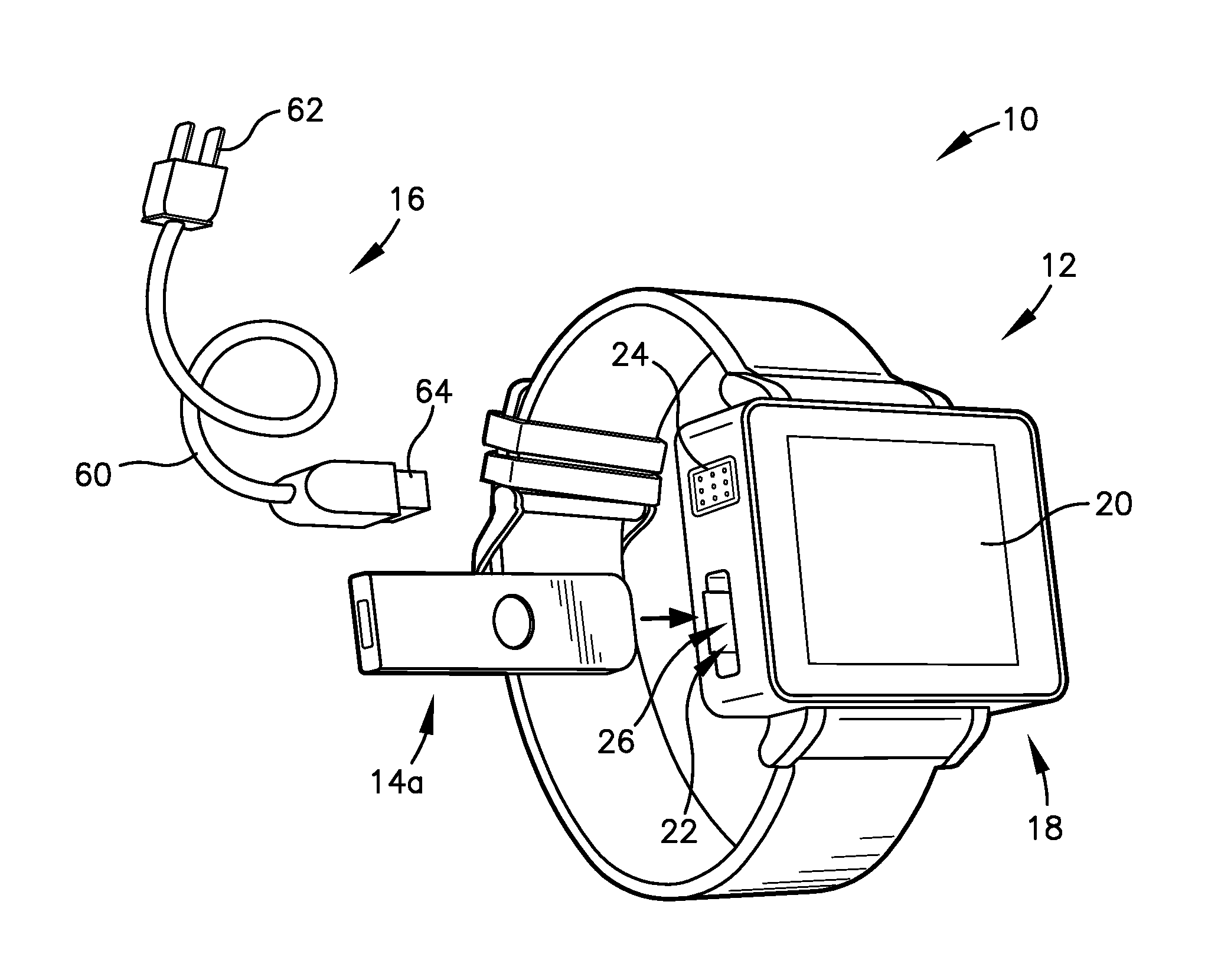

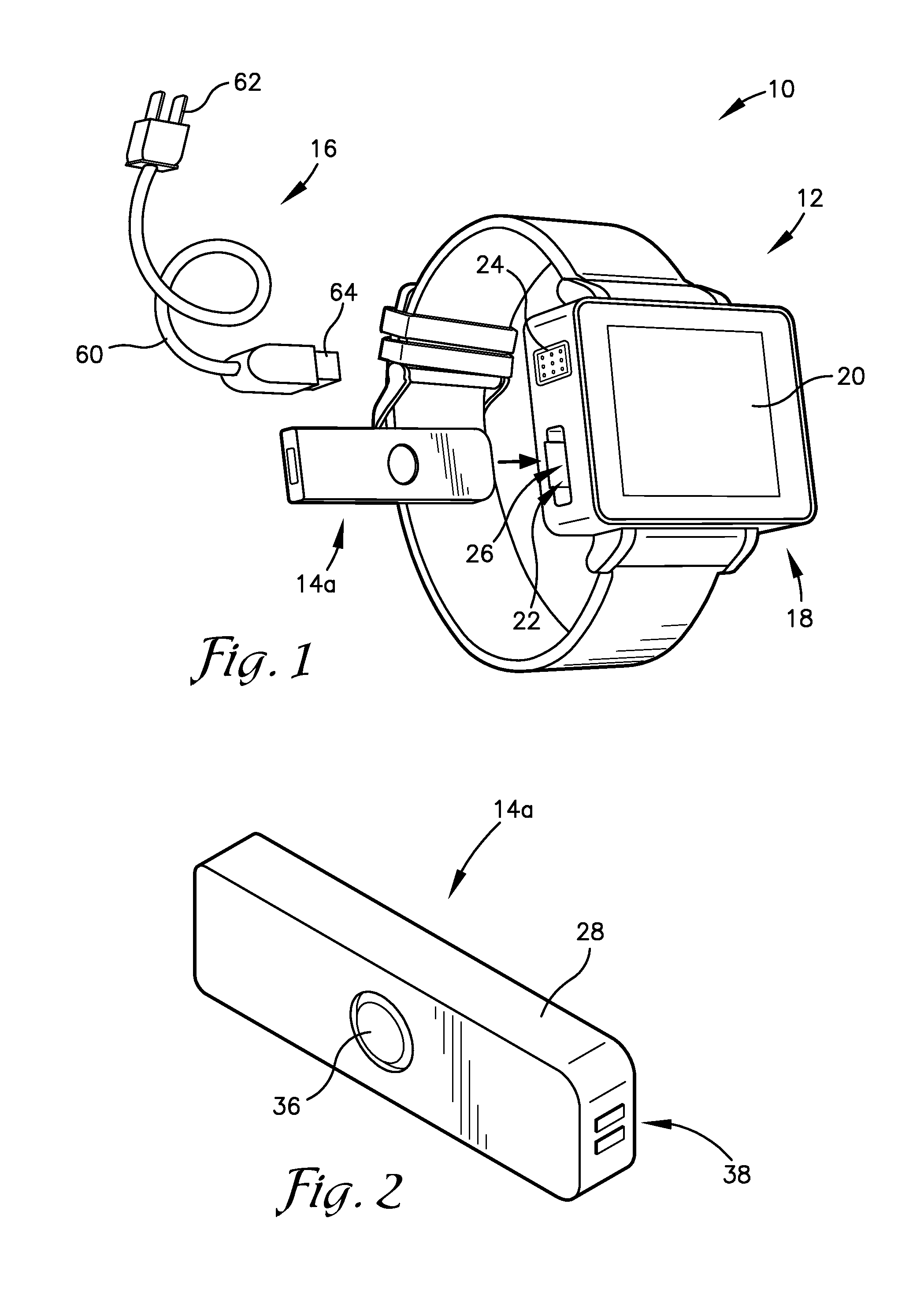

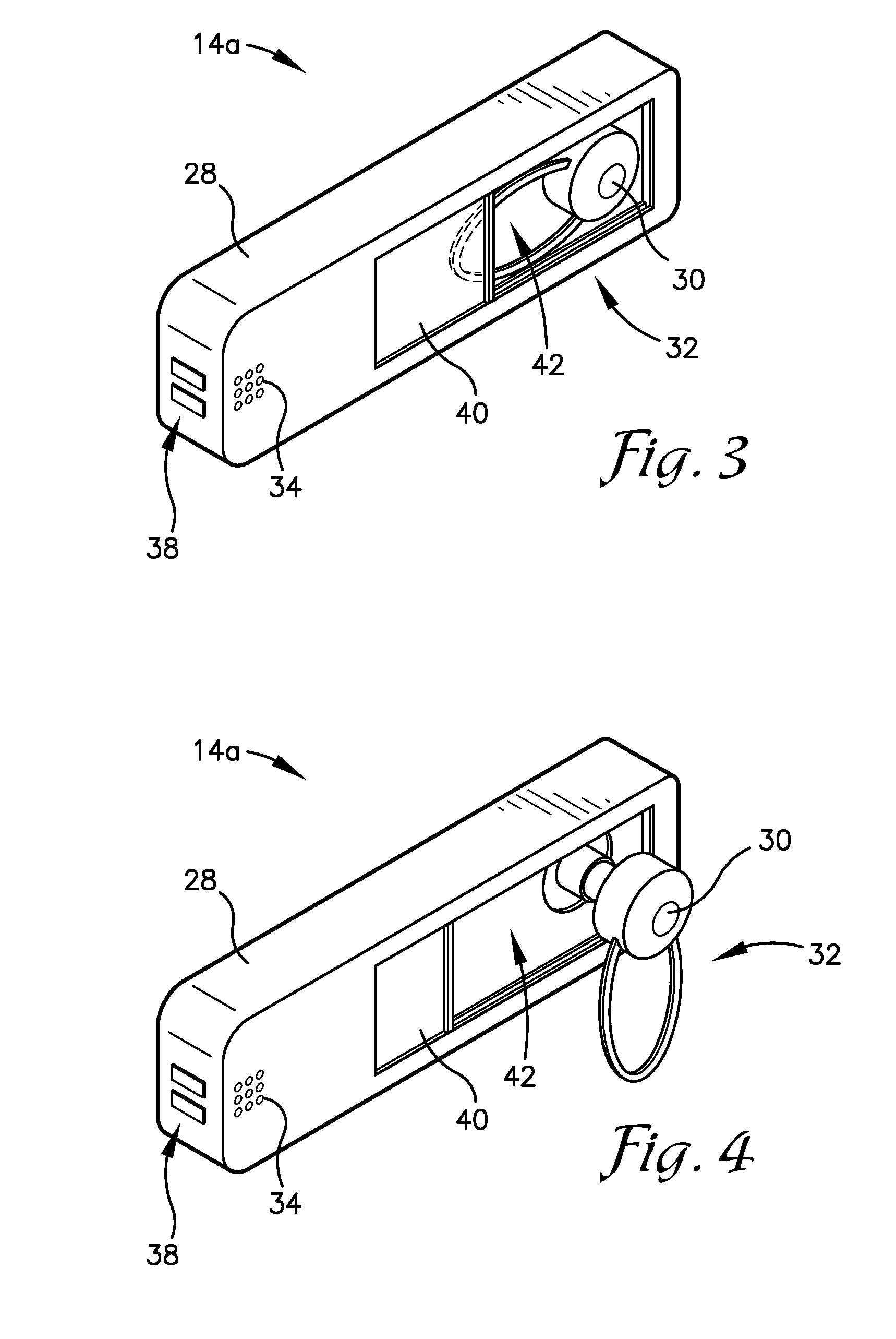

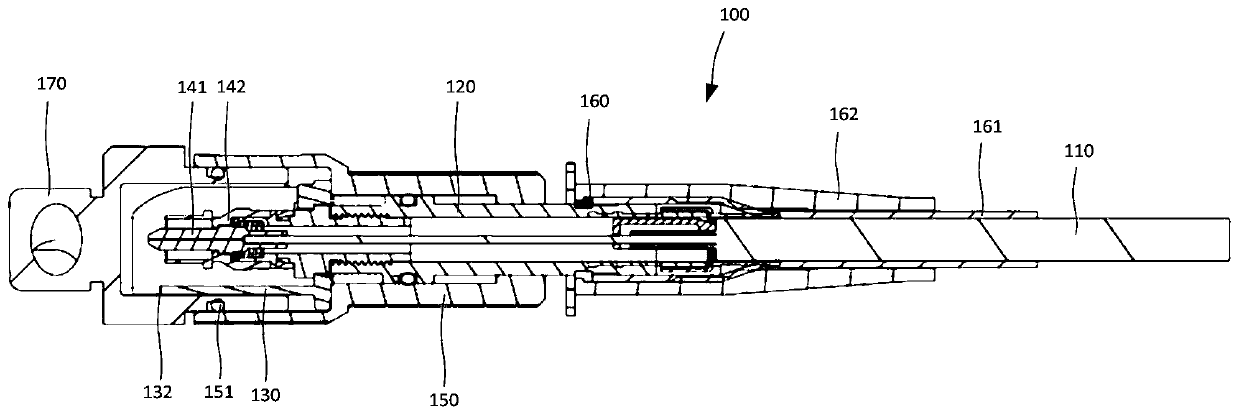

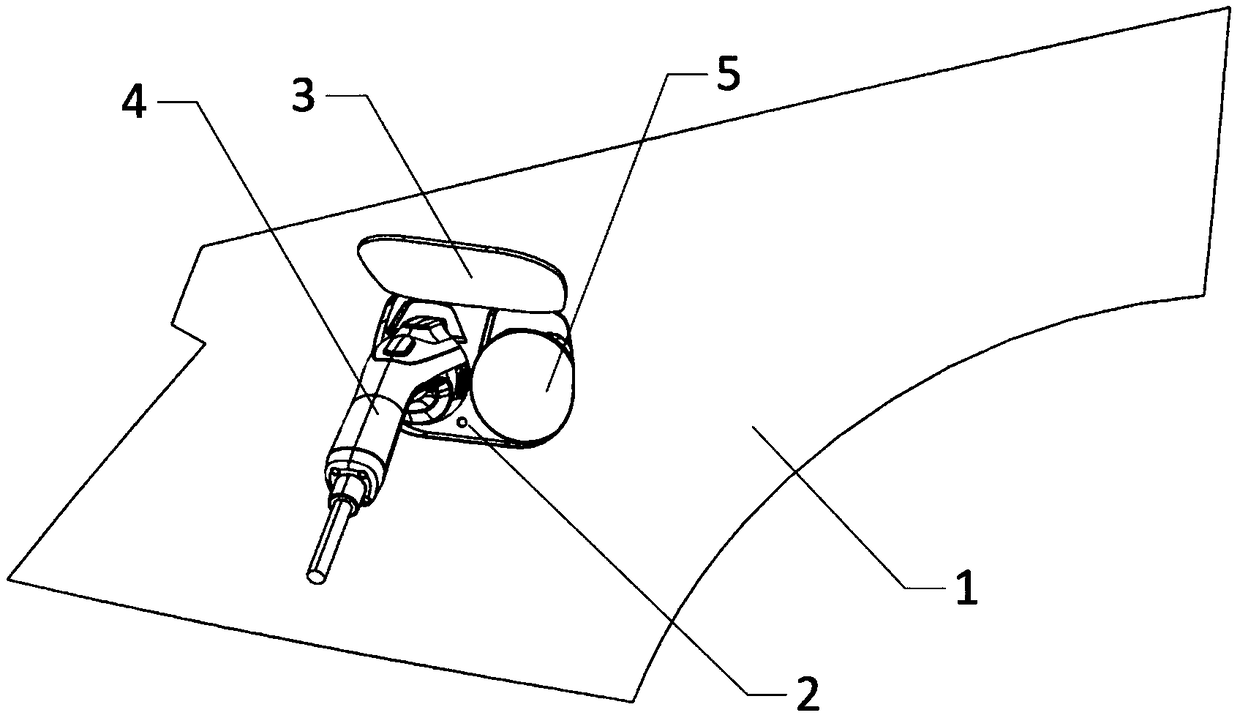

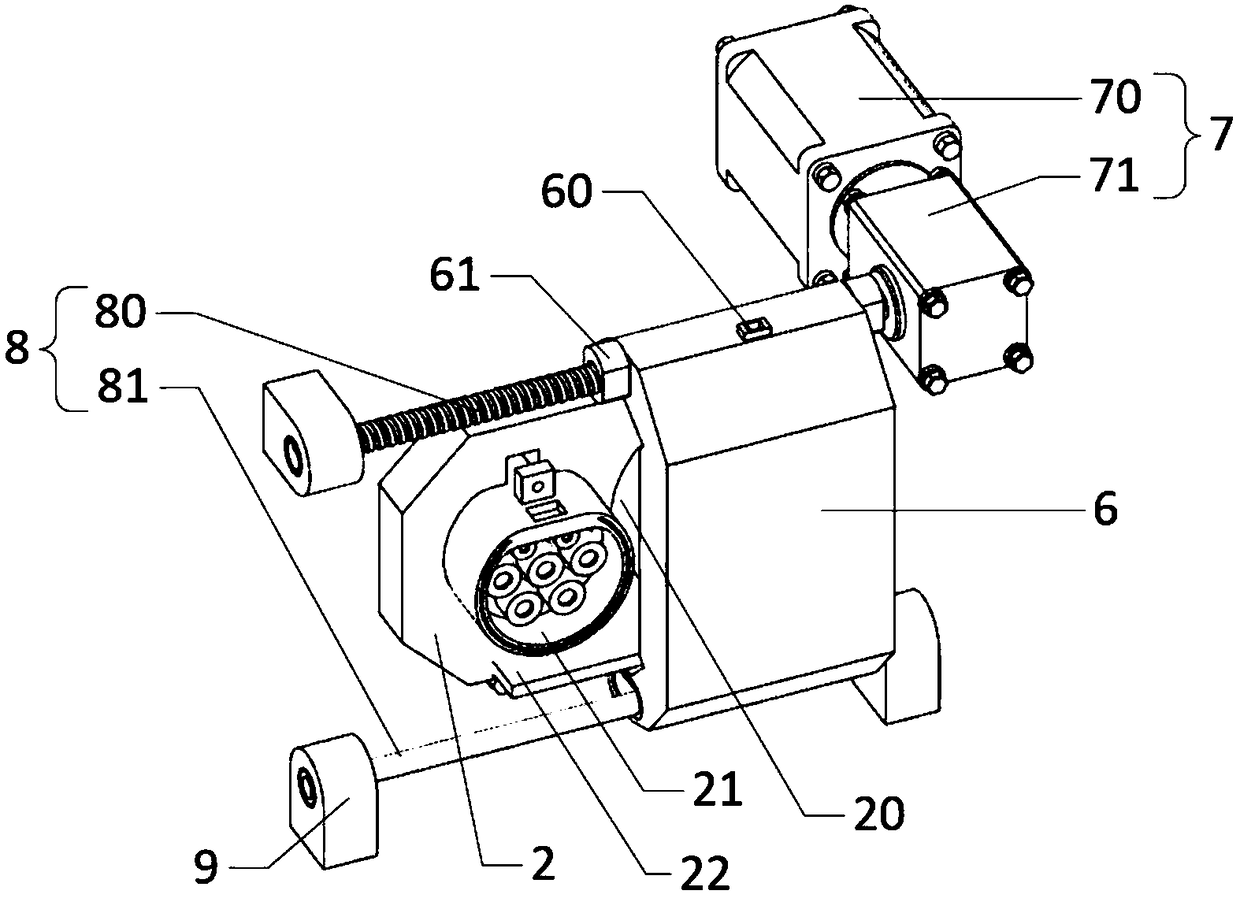

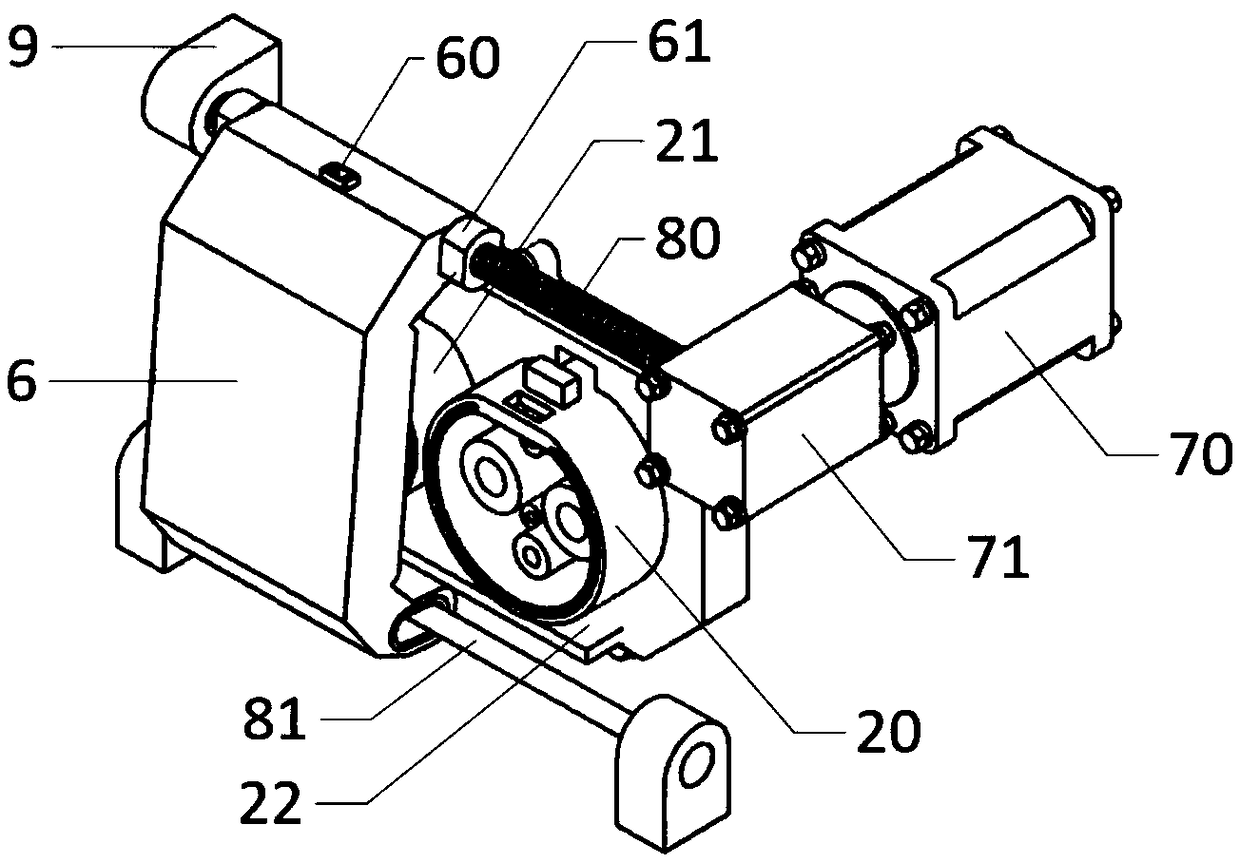

Integrated wireless headset system for electronic devices

ActiveUS20140270234A1Butt tightEasy to disassembleMicrophonesLoudspeakersElectronic systemsHeadphones

An integrated wireless electronic system comprises an electronic device, a headset, a charger, and an accessory. The electronic device includes a charger port and a headset port for connecting the charger and the headset to the electronic device. The headset includes a speaker and an earpiece that are retractable into an interior chamber of the headset for inserting the headset into the electronic device. The headset includes a connector end for simultaneously charging the electronic device and the headset with the charger.

Owner:IP BUDS LLC

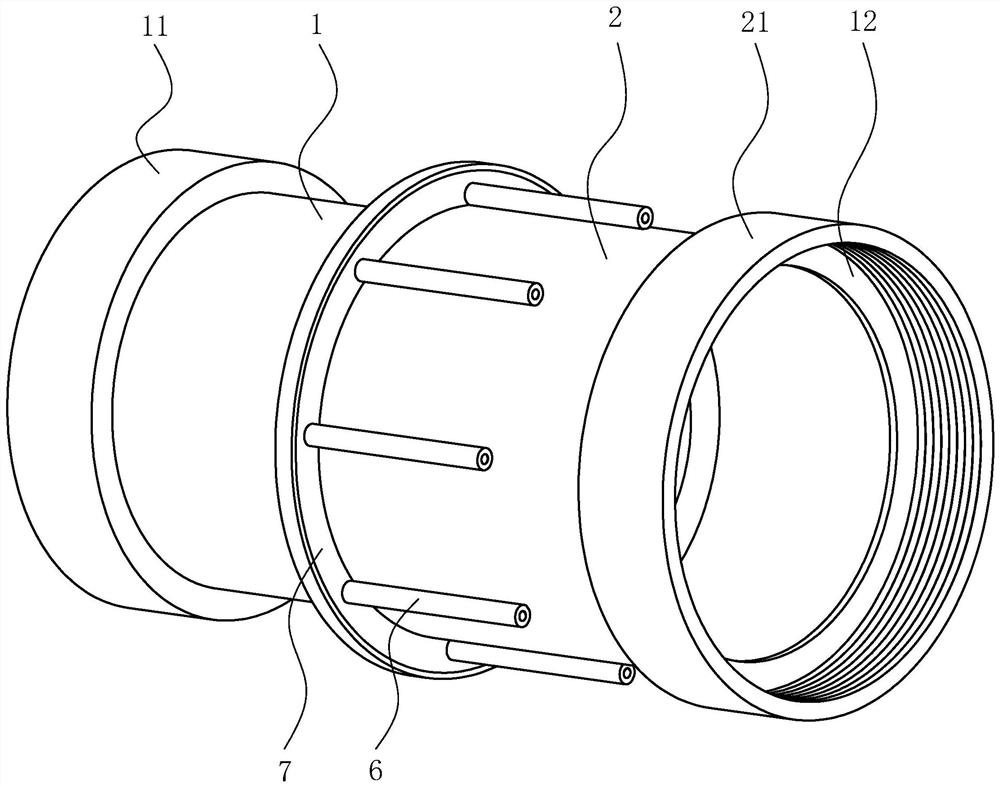

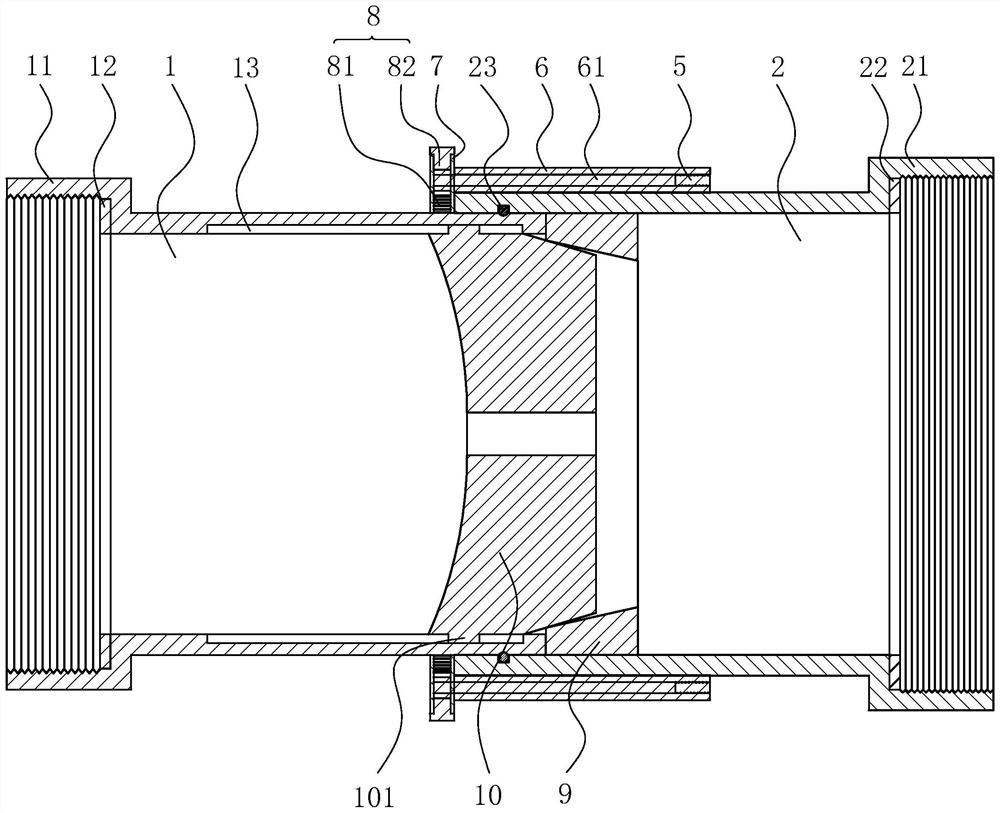

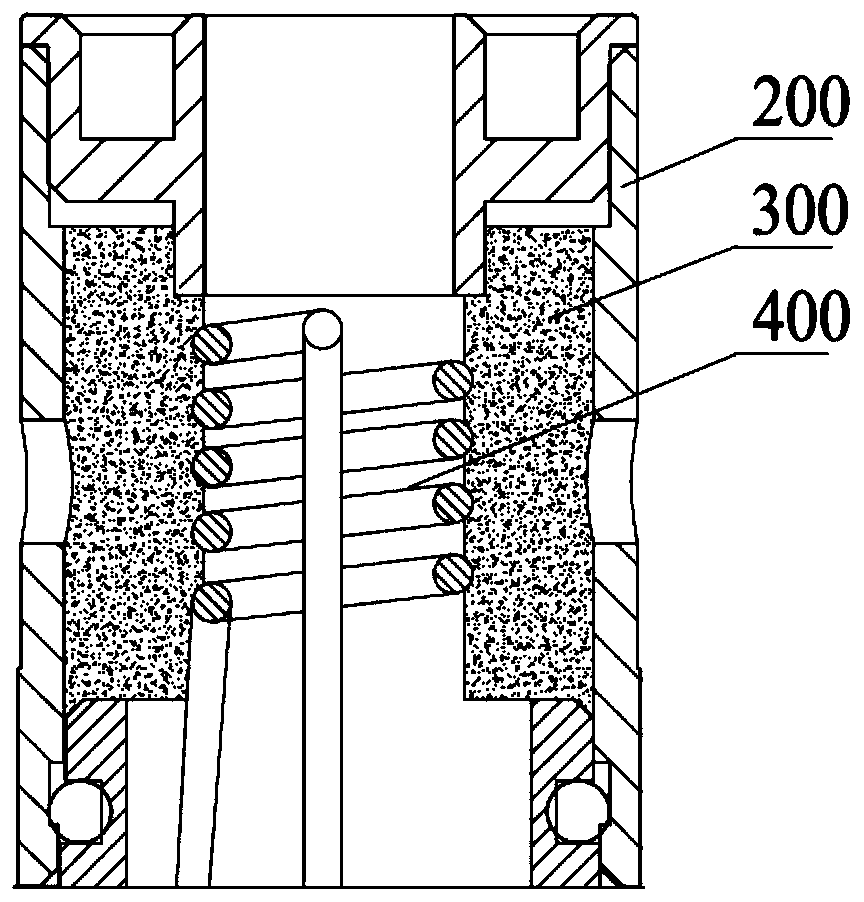

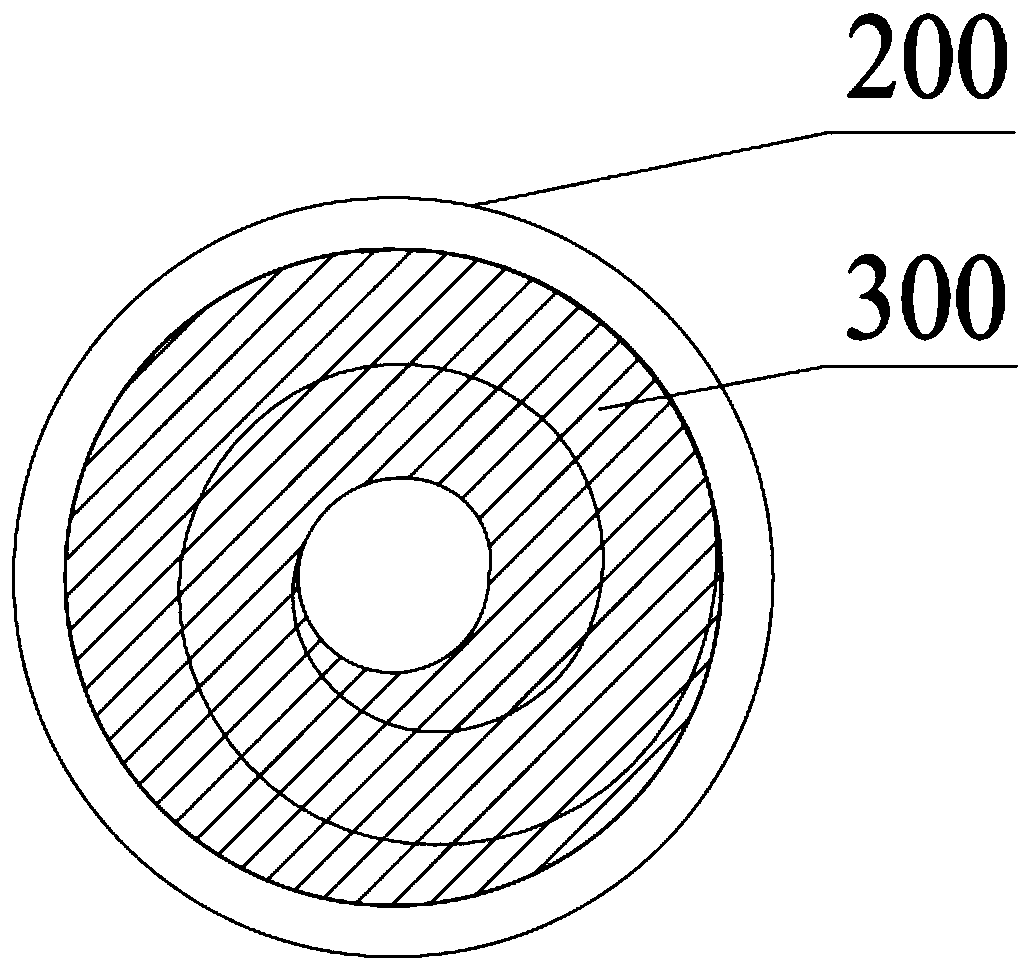

Optical fiber connector plug, optical fiber adapter and optical fiber connector

ActiveCN111308615AImprove coupling efficiencyButt tightCoupling light guidesEngineeringFiber-optic communication

The invention provides an optical fiber connector plug, an optical fiber adapter and an optical fiber connector, relates to the technical field of optical fiber communication, and aims at solving theproblem of poor butt joint of two optical fiber connector plugs in the optical fiber adapter. The optical fiber connector plug comprises an optical fiber, an insertion core, a connecting piece and a guide cylinder, the insertion core is fixedly connected with the optical fiber, the connecting piece sleeves the optical fiber and is fixedly connected with the insertion core, and the guide cylinder sleeves the connecting piece and surrounds the insertion core; in a butt joint state, the front end of the insertion core convexly extends out of the front end of the guide cylinder; an optical fiber adapter flange and an insertion core butt joint sleeve are included, a first cavity, a sleeve accommodating cavity and a second cavity are communicated in sequence in the flange, a first insertion groove formed in the periphery of the first cavity and a second insertion groove formed in the periphery of the second cavity are formed in the flange, and the insertion core butt joint sleeve used for enabling two insertion cores to be in butt joint in the insertion core butt joint sleeve is arranged in the sleeve accommodating cavity; the optical fiber connector comprises the optical fiber connectorplug and the optical fiber adapter, and the coupling efficiency of optical signals is improved.

Owner:HUAWEI TECH CO LTD

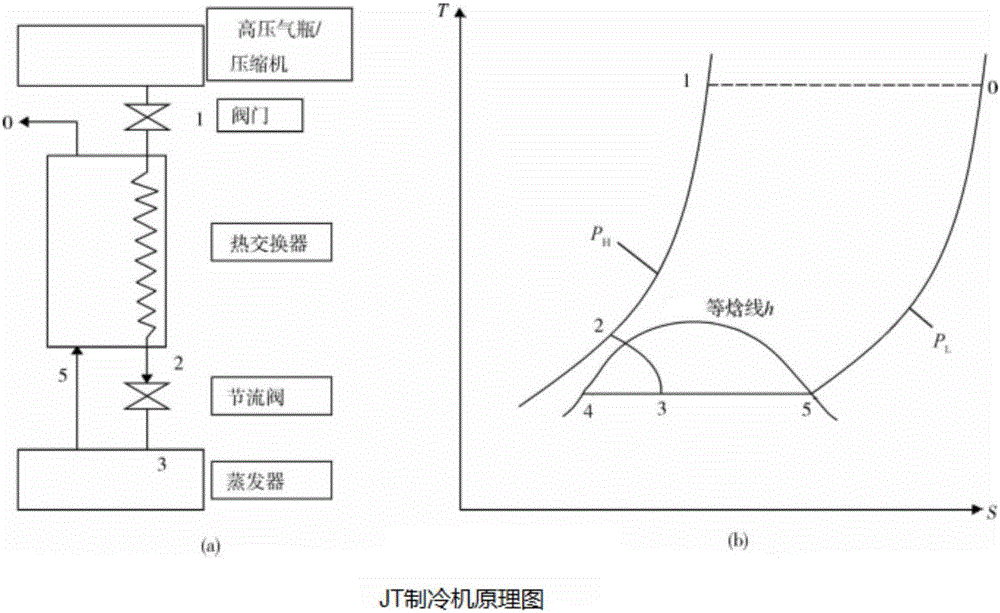

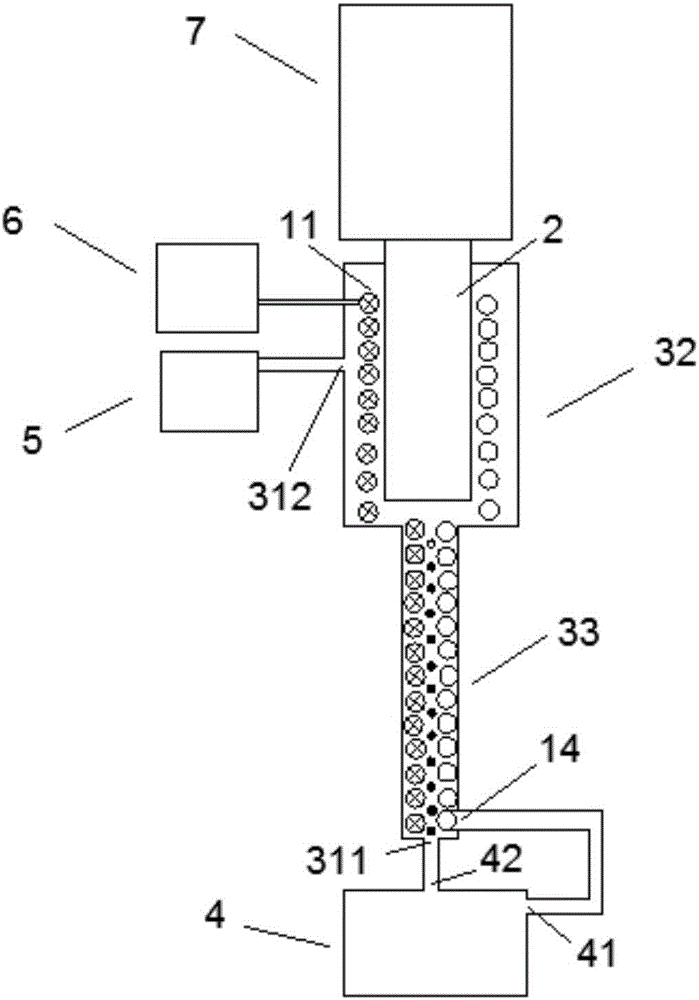

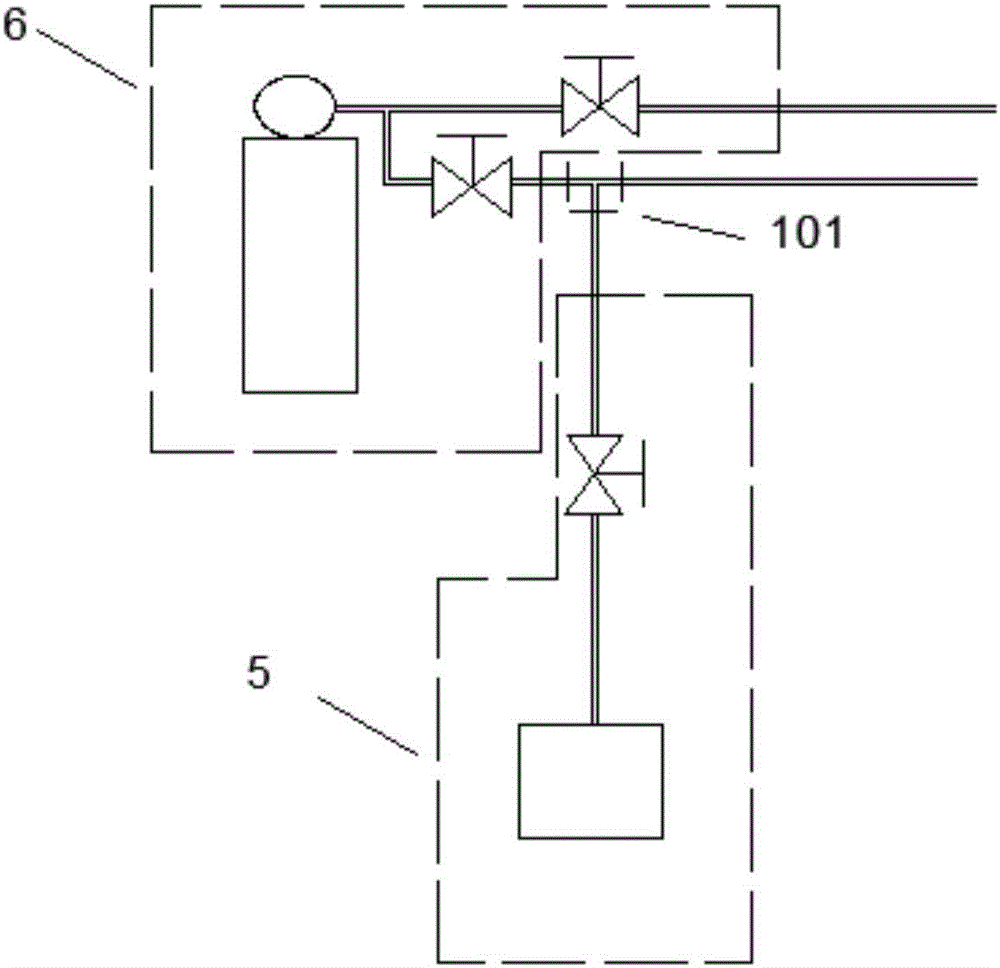

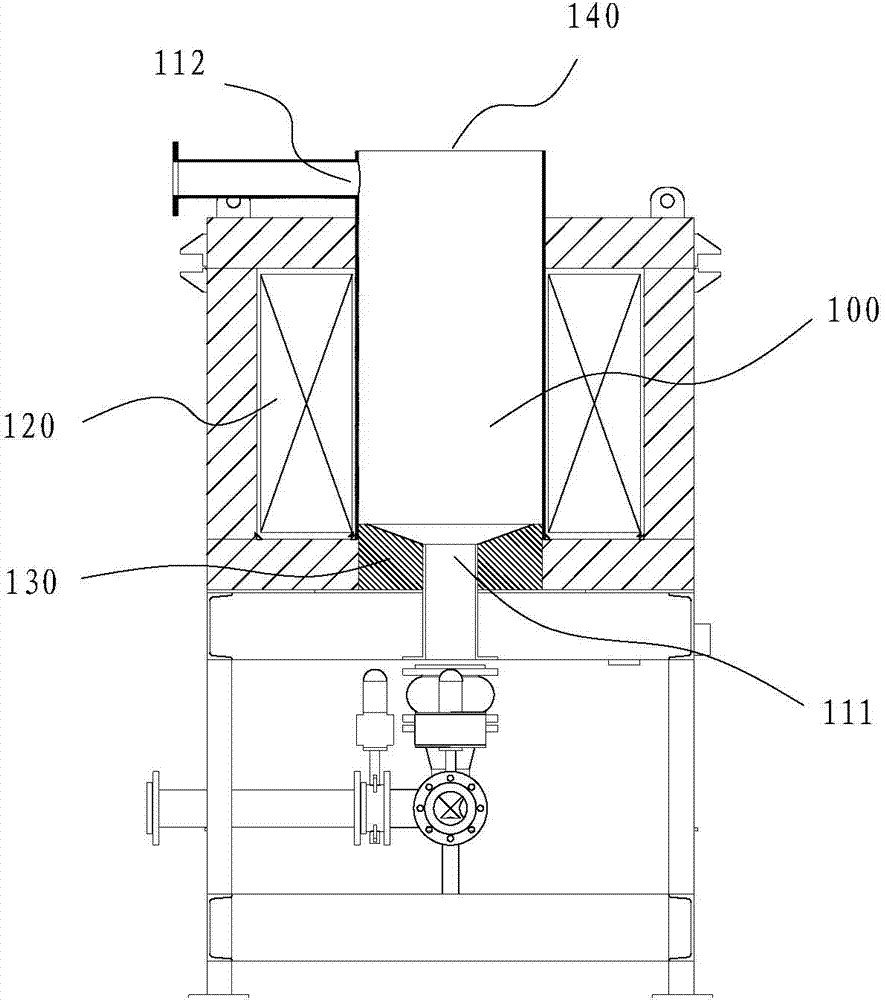

Compact type liquid-helium-free 1K low-temperature refrigeration device suitable for ultrahigh vacuum environment

ActiveCN106524554ASmall surface areaSmall amount of deflationCompression machinesUltra-high vacuumLiquid state

The invention provides a compact type liquid-helium-free 1K low-temperature refrigeration device suitable for ultrahigh vacuum environment. The device comprises a gas conveying pipe, a pre-cooling end, a protection cover, a pressure reduction pool and an air exhaust device. The device has the beneficial effects that firstly, the protection cover reduces the surface area of a refrigeration machine exposed in a vacuum cavity and can be used for the ultrahigh vacuum environment; secondly, the protection cover serves as a backflow channel of refrigeration working media, conductance of the backflow channel is improved, it is ensured that liquid refrigeration working media in the pressure reduction pool have the low vapour pressure, and the lower refrigeration temperature is achieved; thirdly, at the initial cooling stage, the backflow channel can be inflated with helium exchange gas so as to rapidly cool the portion of the pressure reduction pool, and the cooling time is shortened; fourthly, due to design of the second segment of the protection cover, the whole heat exchange efficiency is improved; fifthly, the refrigeration device has the beneficial effects of being compact in structure, easy to demount, mount and maintain, adjustable in refrigeration amount and the like.

Owner:FERMION INSTR SHANGHAI CO LTD

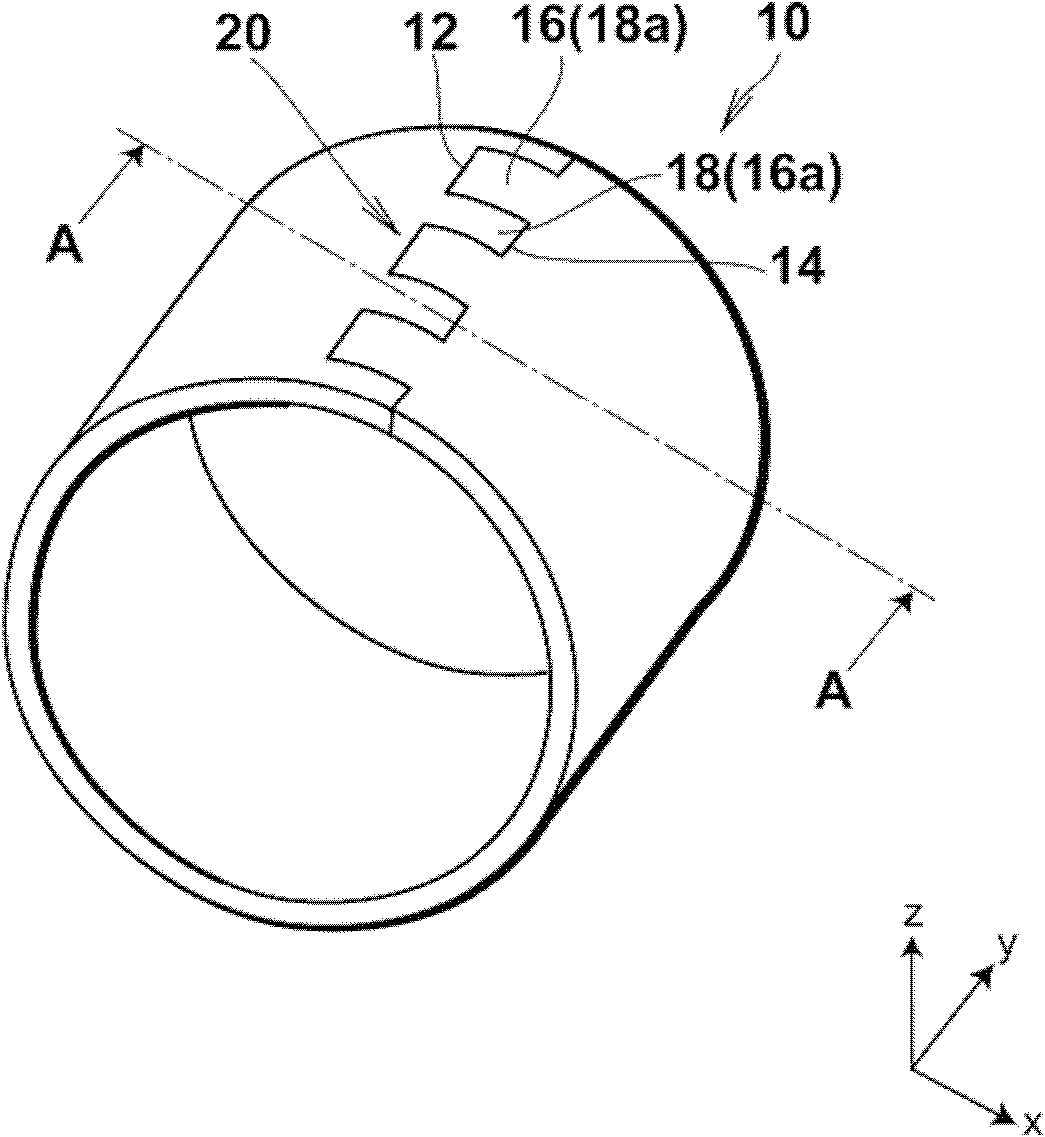

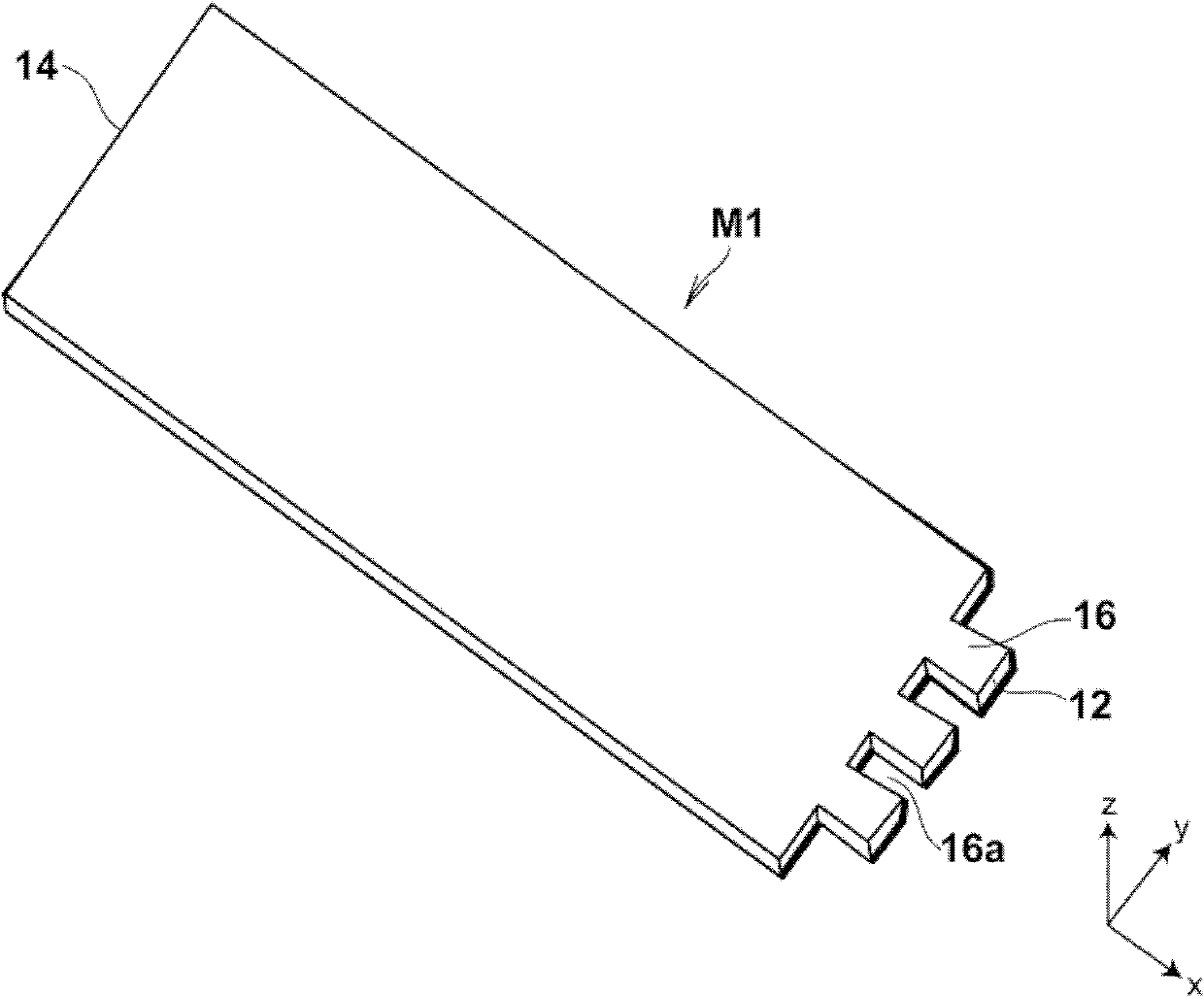

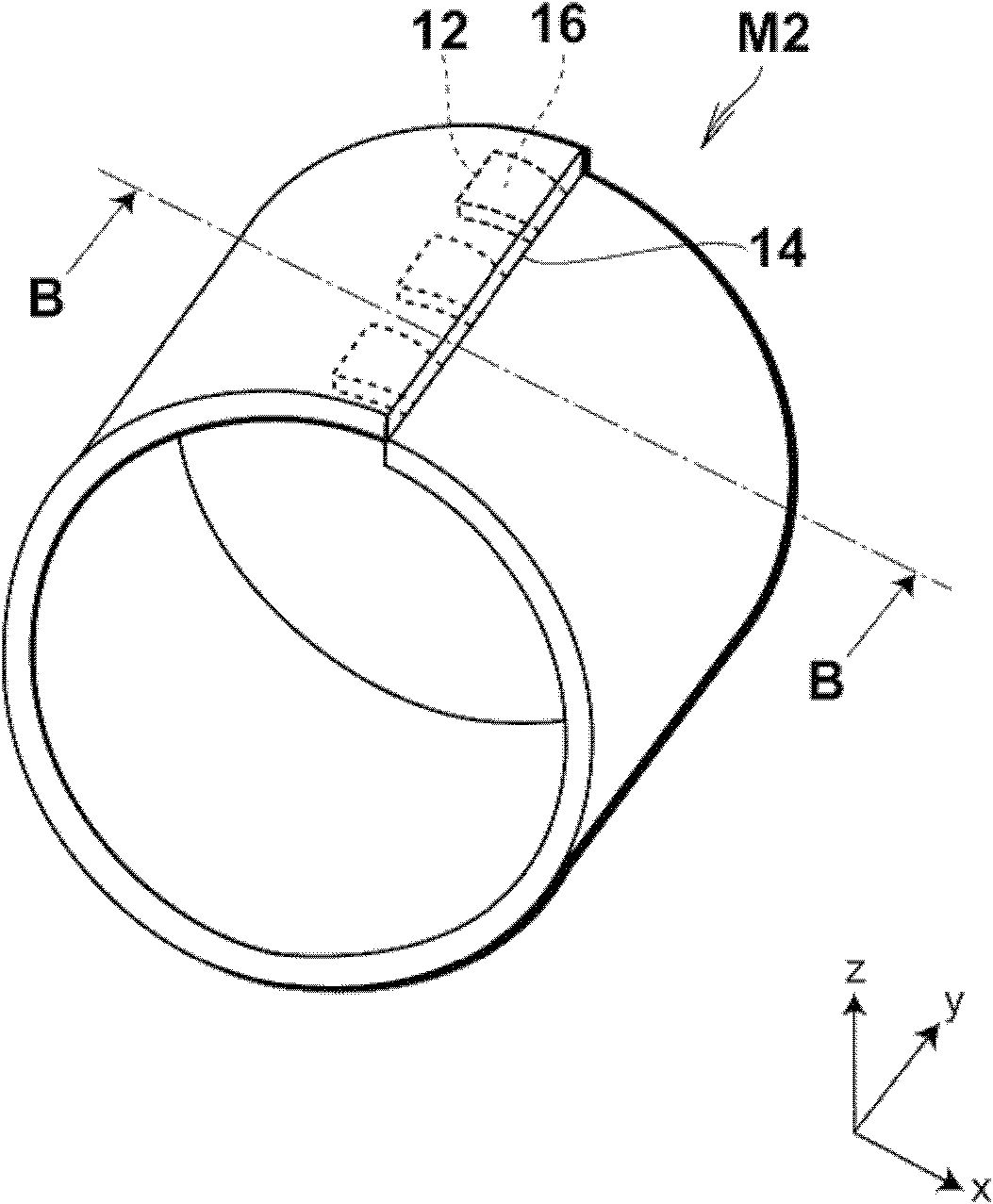

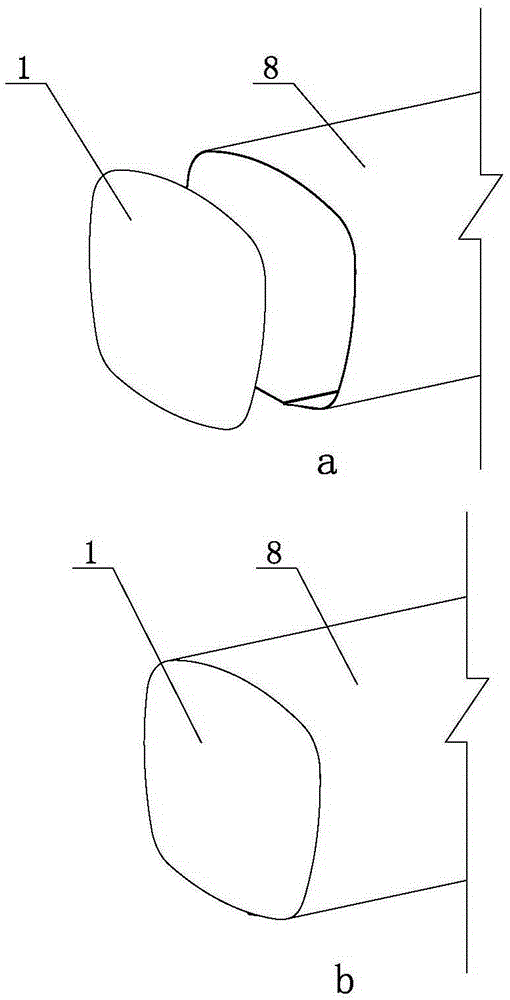

Fitting member

InactiveCN102233800AButt tightGuaranteed StrengthSpringsShaft and bearingsEngineeringUltimate tensile strength

The invention provides a fitting member capable of ensuring strength in a necessary and sufficient manner with a simplified structure without using a welding process or the like. A fitting member (10, 100) is provided with a first end portion (12, 112), a second end portion (14, 114) facing to the first end portion, and a fitting structure (20, 120) having a first engagement portion (16, 16a, 118) and a second engagement portion (18, 18a, 116) to connect the first end portion and the second end portion with each other by fitting the first engagement portion and the second engagement portion with each other. The fitting structure is defined by making the first engagement portion and the second engagement portion engaged with each other, while making the second engagement portion formed by punching a preform body of the fitting member through the first engagement portion.

Owner:F TECH INC

Vehicle-mounted aluminum alloy tank production process

The invention discloses a vehicle-mounted aluminum alloy tank production process. The vehicle-mounted aluminum alloy tank production process includes the following steps of firstly, barrel plate machining, secondly, separation plate and end socket machining, thirdly, locating, hoisting and transferring, fourthly, tank wrapping and forming, fifthly, longitudinal seam shaping and longitudinal seam welding, sixthly, inner annular seam welding and seventhly, outer annular seam welding. For the feature of tank body machining, the process is designed into a manufacturing method facilitating mechanical line production, and manufacturing accuracy and efficiency can be improved greatly. Through multiple years of experiment practice and summarization, in the process, the edges of two end sockets of a straight-cylinder tank body are milled into the straight edges so that the edges can be matched with the milled straight edges of the tank body so as to guarantee that the edges of the end sockets is in tight butt joint with the edges of the tank body, and single-face welding and double-face forming are conducted through tig side face welding, so that the pass rate of flaw detection reaches 100%; and the reducing part of the middle portion of the reducing tank body is shaped through a die, the edges are milled so as to be in tight butt joint with the tank body, and the pass rate of flaw detection reaches 100% by conducting single-face welding and double-face forming through tig side face welding.

Owner:SHANDONG SHUIBO WELDING & CUTTING EQUIP MFG CO LTD

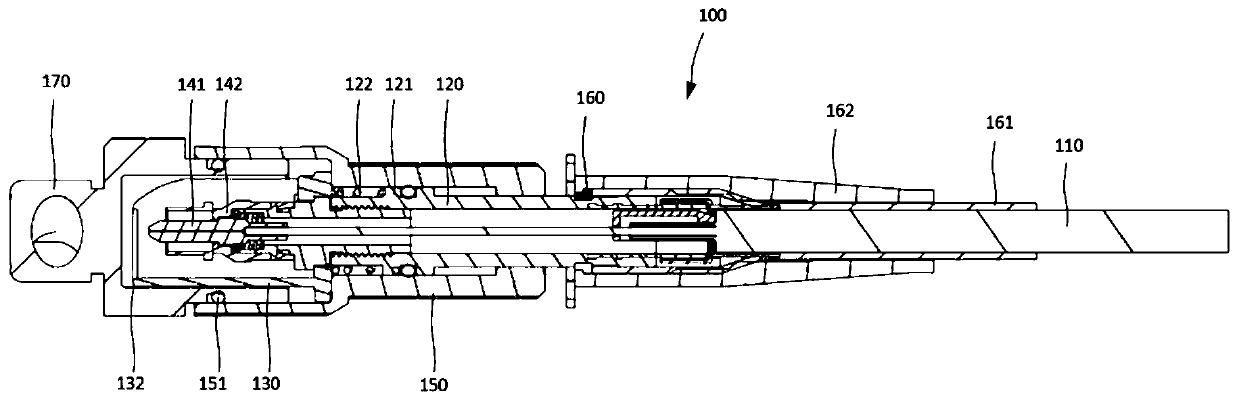

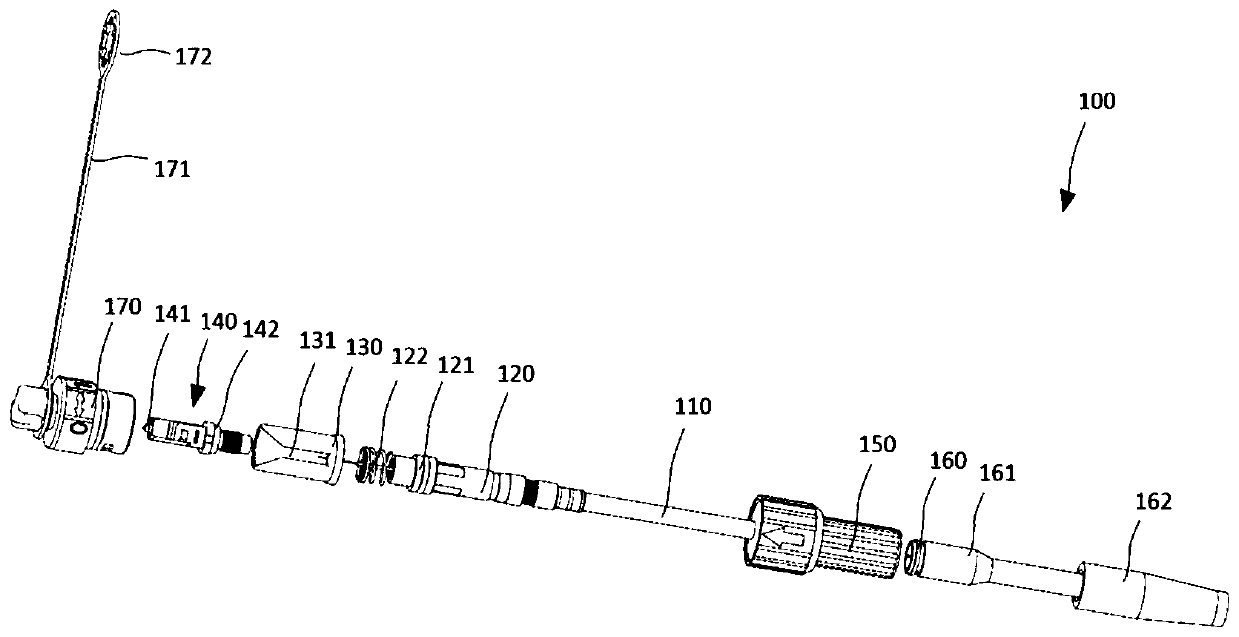

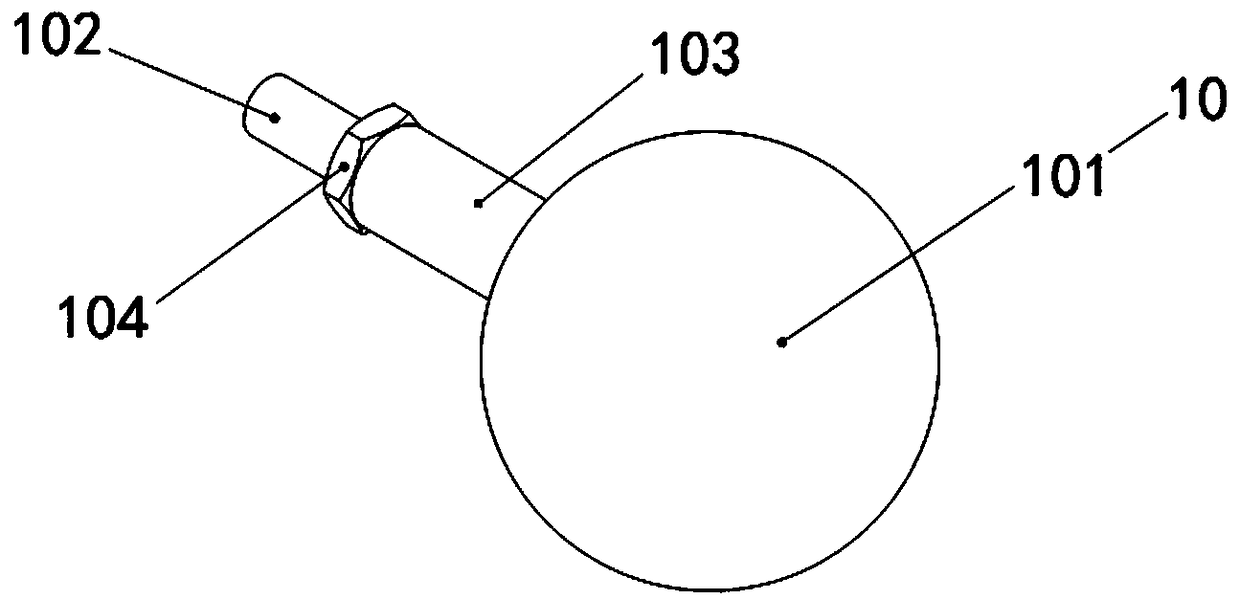

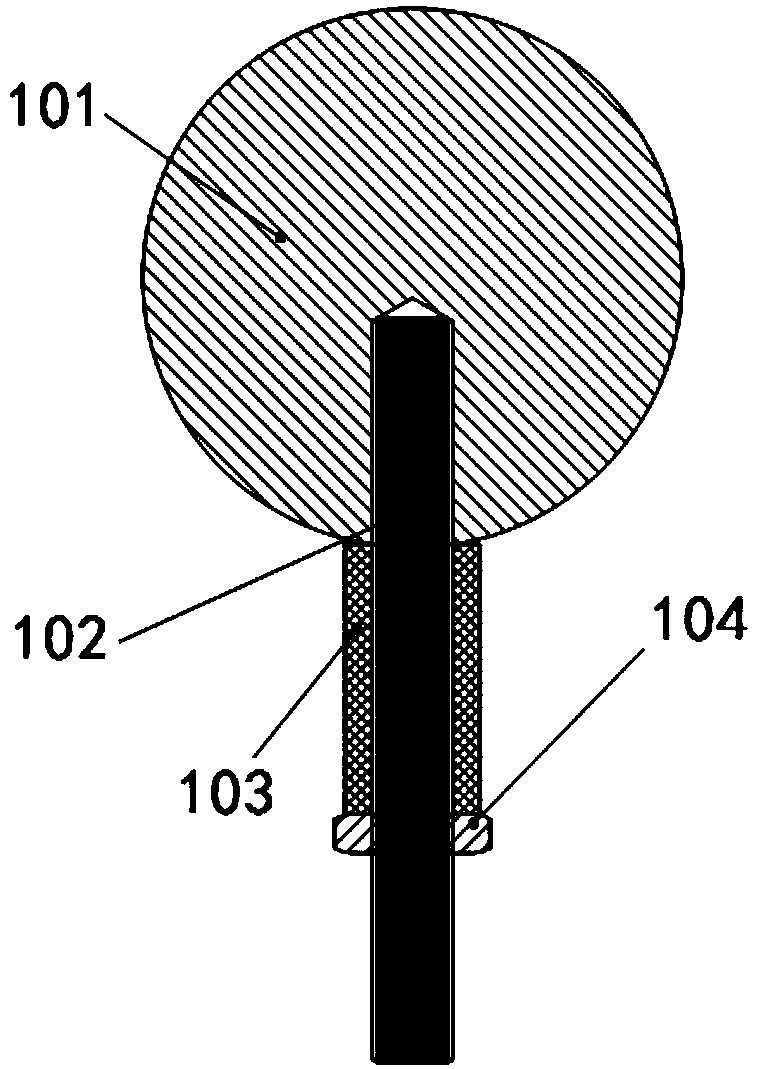

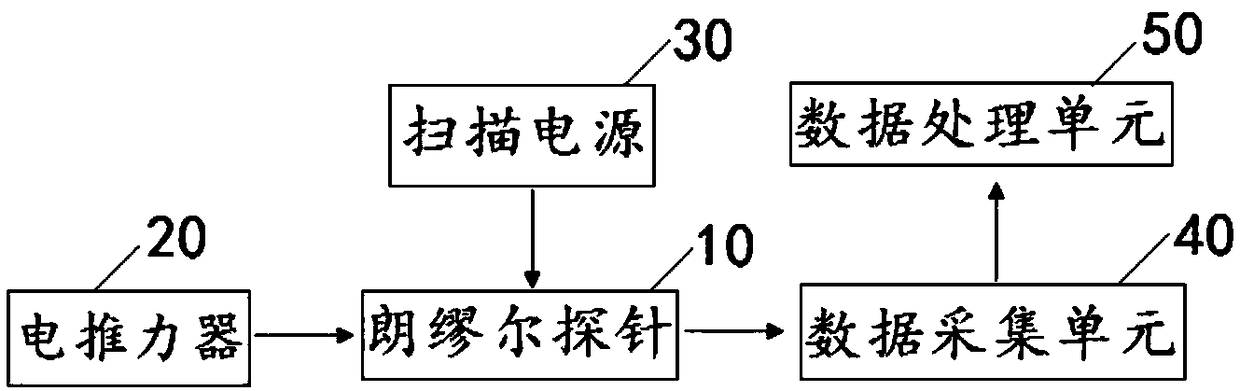

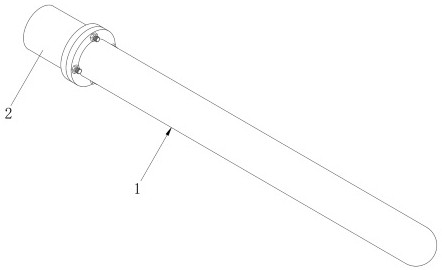

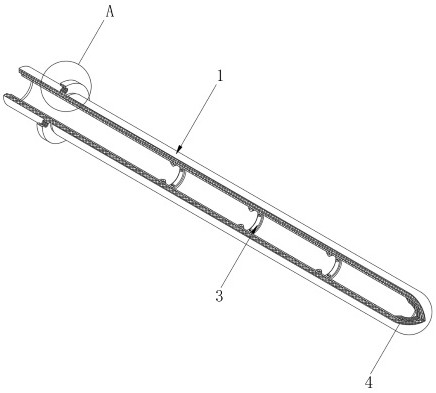

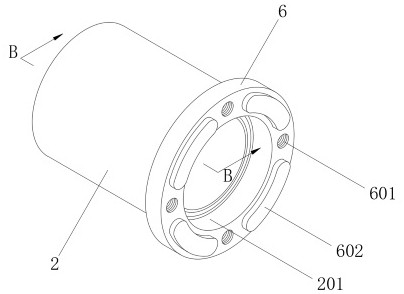

Langmuir probe, Langmuir probe diagnostic system and diagnostic method thereof

InactiveCN109104805AEliminate distractionsClosely connectedPlasma techniqueLangmuir probeEngineering

The invention discloses a Langmuir probe, a Langmuir probe diagnostic system and a diagnostic method thereof, which relate to the technical field of plasma. The Langmuir probe according to the invention comprises a collector, an electrically conductive screw lead, a ceramic sheath and a hexagon nut; the conductive screw lead is screwed into the collector and connected with the collector, the ceramic sheath is arranged on the conductive screw lead, and one end part is in contact with the collector, and the hexagon nut is screwed with the conductive screw lead and in contact with the other end part of the ceramic sheath; The Langmuir probe can avoid the contact between the lead wire and the plasma, eliminate the lead wire interference and reduce the measurement error.

Owner:BEIHANG UNIV

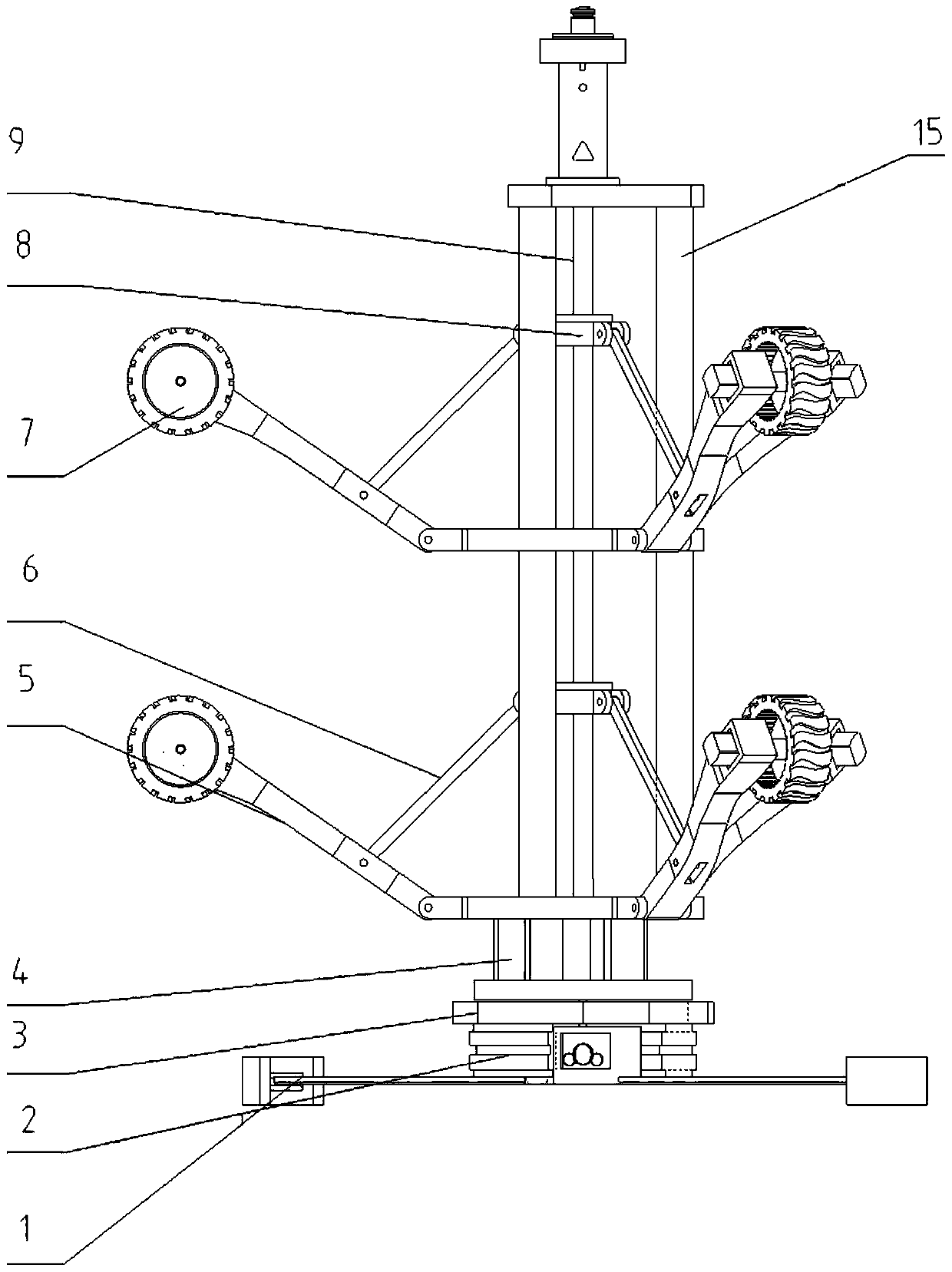

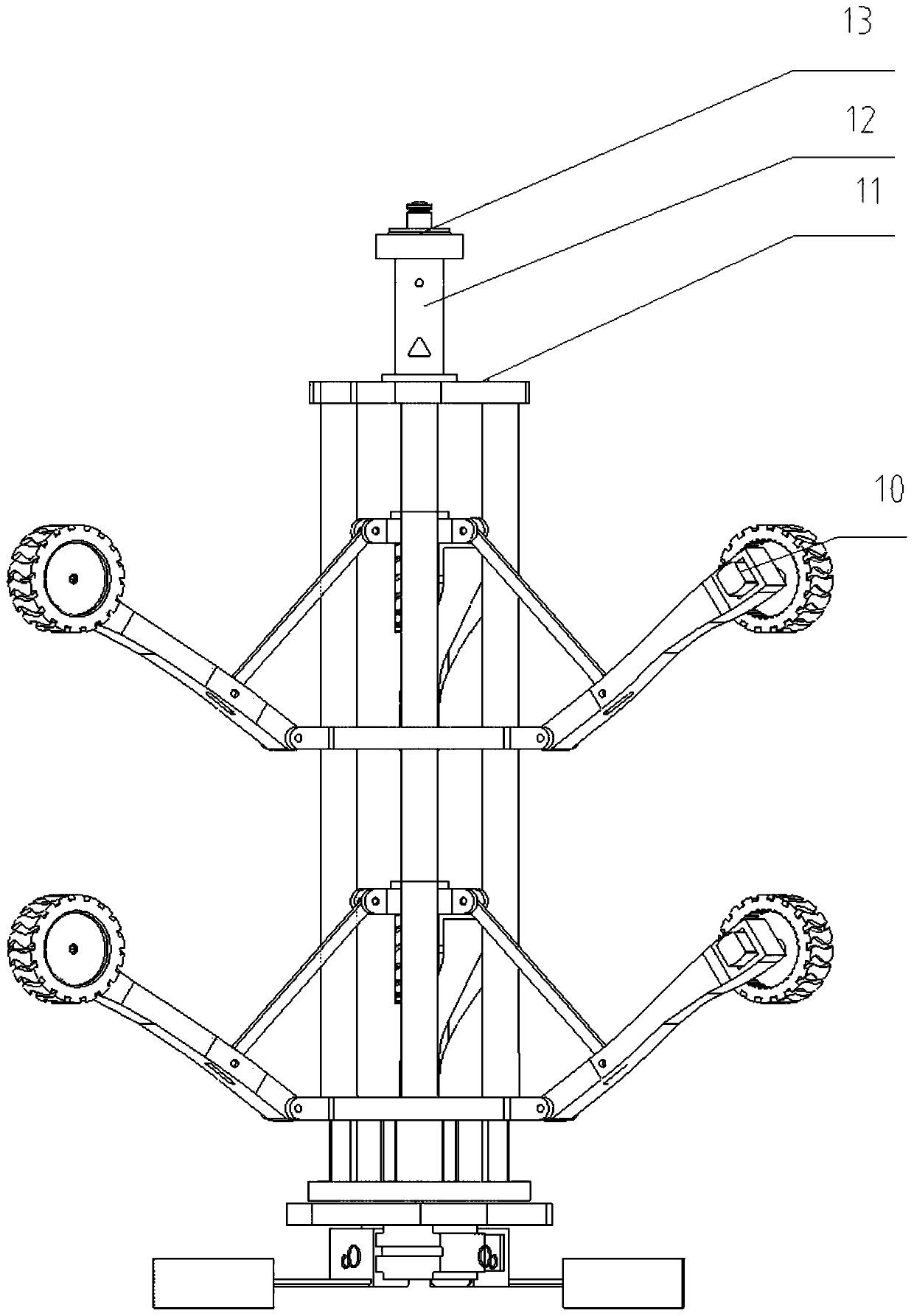

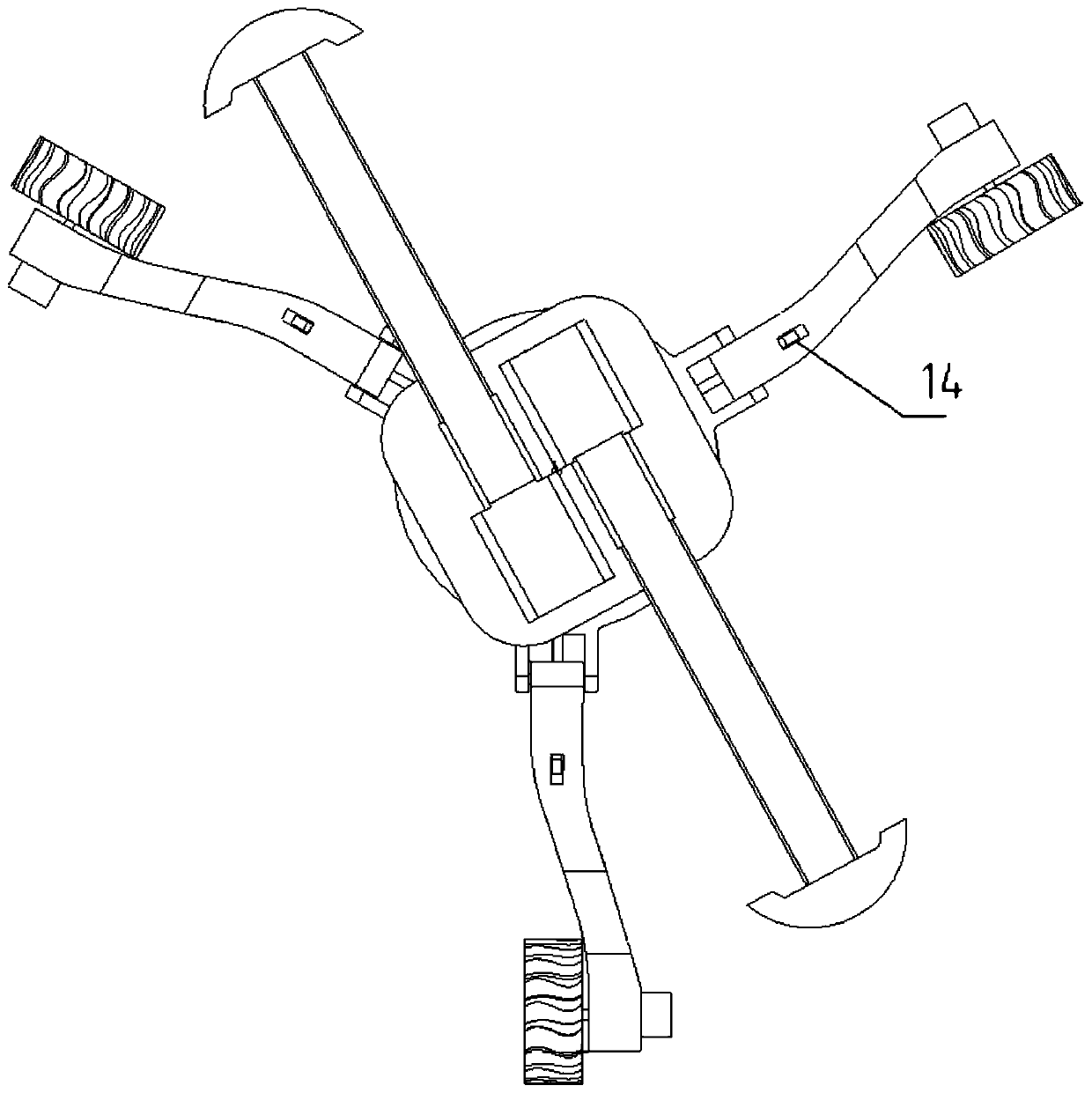

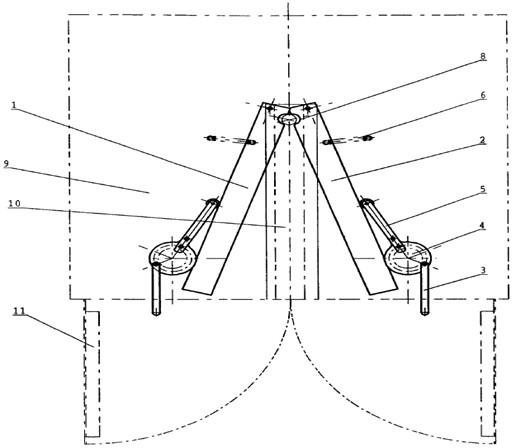

Pipeline intelligent inspection system

InactiveCN110762336AImplementation driveEasy to controlHollow article cleaningPigs/molesInformation controlCommunication unit

A pipeline intelligent inspection system comprises a pipeline inspection robot, a detection unit, an image display unit, a communication unit, a remote control unit and the like. The pipeline intelligent inspection system controls a rolling wheel to abut against the inner wall of a pipeline according to pipeline inner diameter information transmitted by the detection unit, then a walking r6obot isdriven to operate, the pipeline inspection robot is driven to walk in the pipeline, and meanwhile, a cleaning head is driven to rotate and scrape dirt off the surface of the inner wall of the pipeline. The rolling wheel at the end of a support arm can be controlled correspondingly according to the size of the pipeline, thereby keeping closely abutting against the inner wall of the pipeline, the position of the pipeline inspection robot in the pipeline can be maintained through the abutting effect of the rolling wheel, and driving and control of up-down operation of the pipeline inspection robot are achieved. Therefore, through the pipeline intelligent inspection system, the pipeline inspection robot keeps certain pipeline passing capacity and can also have a certain speed.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Charging interface protection module and electric vehicle

ActiveCN109301591AAvoid lossImprove experienceVehicle connectorsCharging stationsCurrent electricEngineering

The present invention relates to the technical field of electric vehicle charging wickets, and the objective of the invention is to solve the problems that the seal cap connection piece of a current electric vehicle charging interface is easily damaged and the charging operation is not convenient. The present invention provides a charging interface protection module and an electric vehicle. The charging interface comprises a charging socket, the protection module comprises a protection cover and a drive part, and the drive part is connected with the protection cover to drive the protection cover to be butted against the charging socket to facilitate seal of the socket outlet of the charging socket. The charging interface protection module is provided with the protection cover and the drivepart configured to drive the protection cover to allow the protection cover to be butted against or separated from the charging socket under the drive of the drive part to achieve automatic seal or opening of the socket outlet. For the electric vehicle equipped with the protection module, when the charging socket is needed to use, the protection cover does not need to be manually stripped off andto be manually put so as to simplify the operation steps, avoid the problem that a chain scratches a vehicle body or the hinge is damaged to lose a seal cover and improve the user experience.

Owner:NIO ANHUI HLDG CO LTD

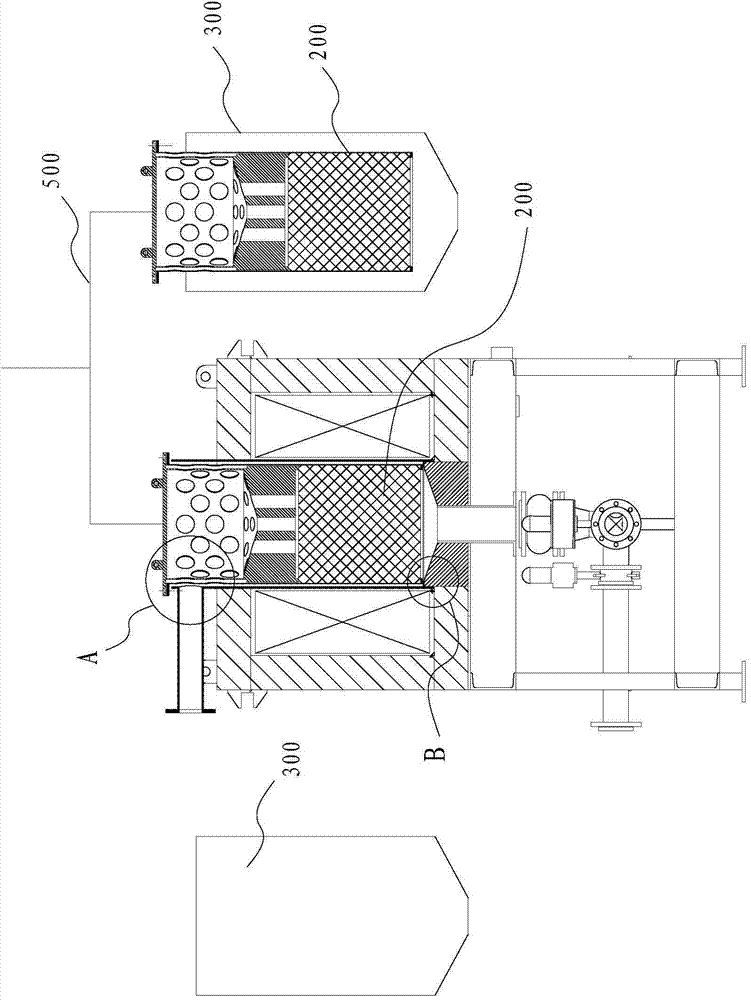

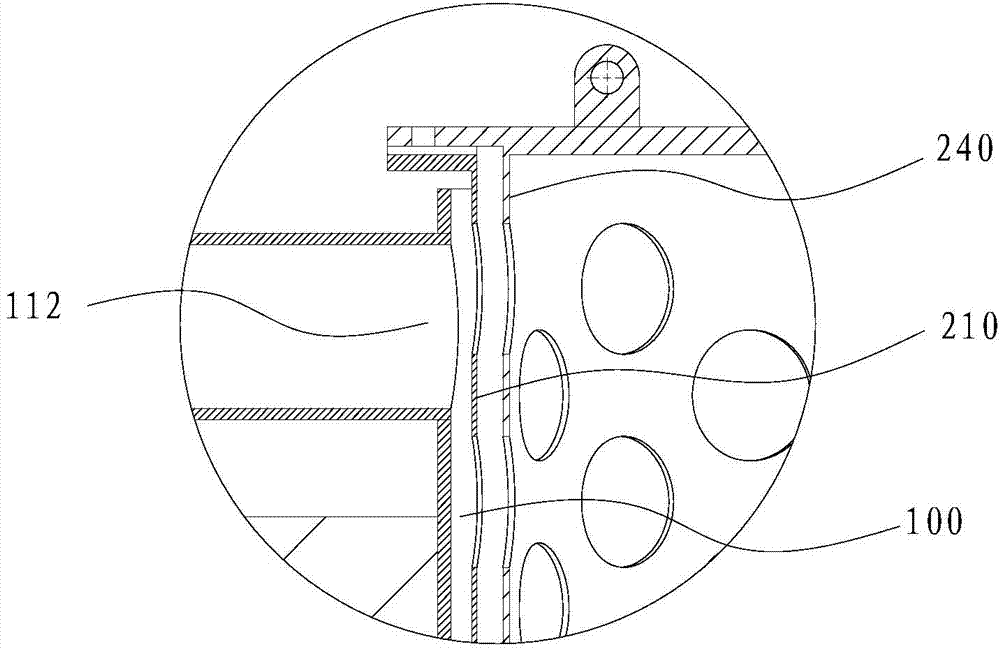

Adsorption device and adsorption method

ActiveCN104722398AImprove adsorption capacityImprove filter qualityMagnetic separationCleaning using liquidsIron removalCleaning station

The invention discloses an adsorption device and an adsorption method. The adsorption device comprises an adsorption chamber, at least two adsorbers, a cleaning station and a switching device, wherein liquid is fed into the adsorption chamber from a first liquid inlet, when the liquid flows through the adsorbers, impurities in the liquid are attached to the adsorbers, and then the liquid subjected to adsorption and filtering flows out of a first liquid outlet; and after one adsorber adsorbs impurities, the switching device is adopted for switching the adsorber from the adsorption chamber to the cleaning station, and after the other adsorber is switched to the adsorption chamber, a cleaning device is adopted for cleaning the adsorbers. The cleaning station and the adsorption chamber are independently arranged, and the cleaning process of the adsorber does not take up the impurity adsorption time, so that the iron removal efficiency is greatly improved; and the device is simple in structure, easy to control and convenient to maintain.

Owner:广州粤有研矿物资源科技有限公司

Sealing device for cleaning chamber of lifting hook type shot blasting machine

InactiveCN102699824AStrong impact resistanceIncreased strength of flexible hair rowEngine sealsAbrasive machine appurtenancesButt jointEngineering

The invention discloses a sealing device for a cleaning chamber of a lifting hook type shot blasting machine. The sealing device is provided with two hard plugging blocks, the two hard plugging blocks can be in butt joint or be separated from each other, each hard plugging block is provided with a driving mechanism, rotary shafts are disposed at ends of the same sides of the two hard plugging blocks, each driving mechanism consists of two connecting rod rotating mechanisms and a return elastic body, and each connecting rod rotating mechanism comprises a direct-acting push rod and a rotating eccentric mechanism. The sealing device is high in impact resistance, good in sealing effect and long in service life.

Owner:刘芝英

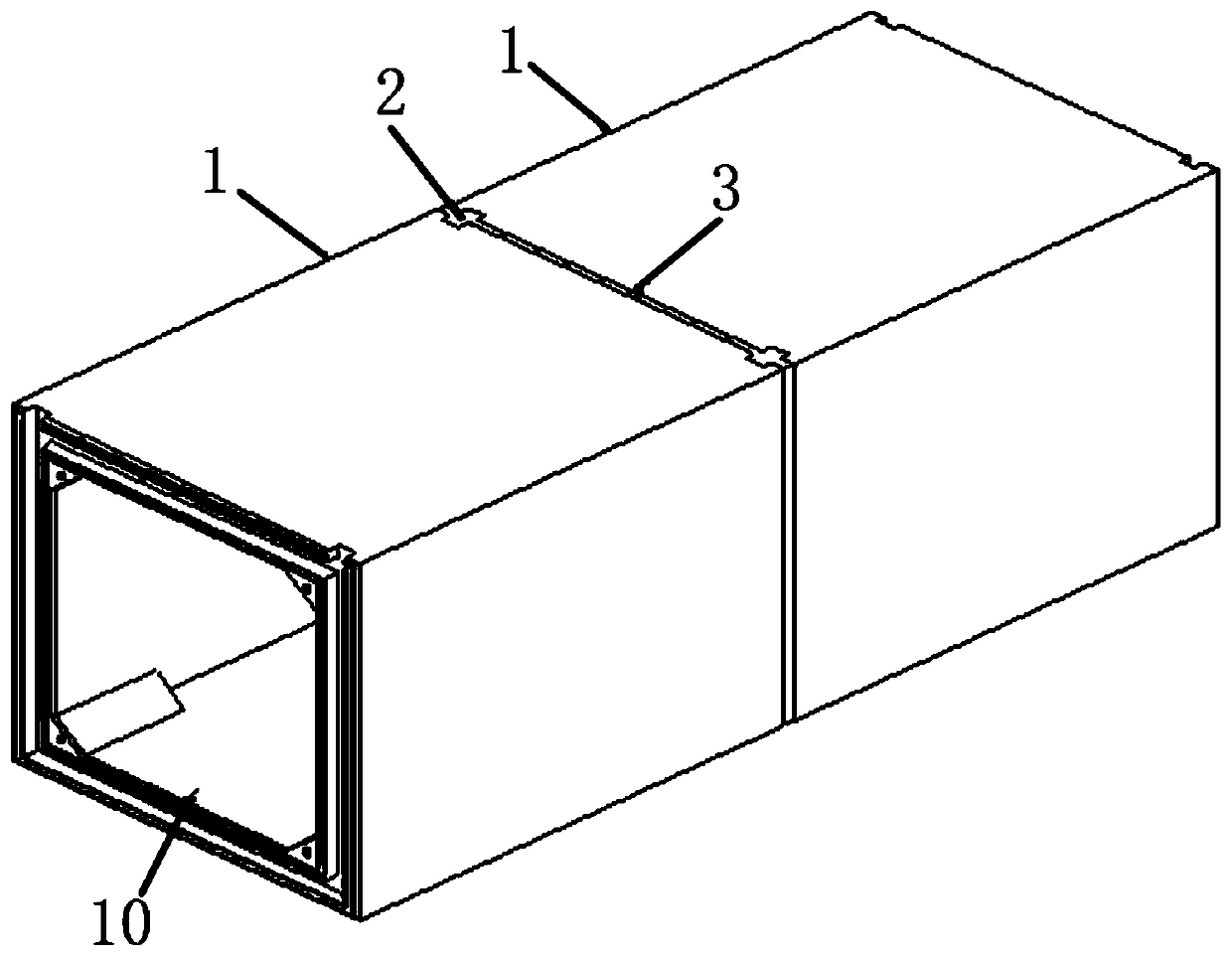

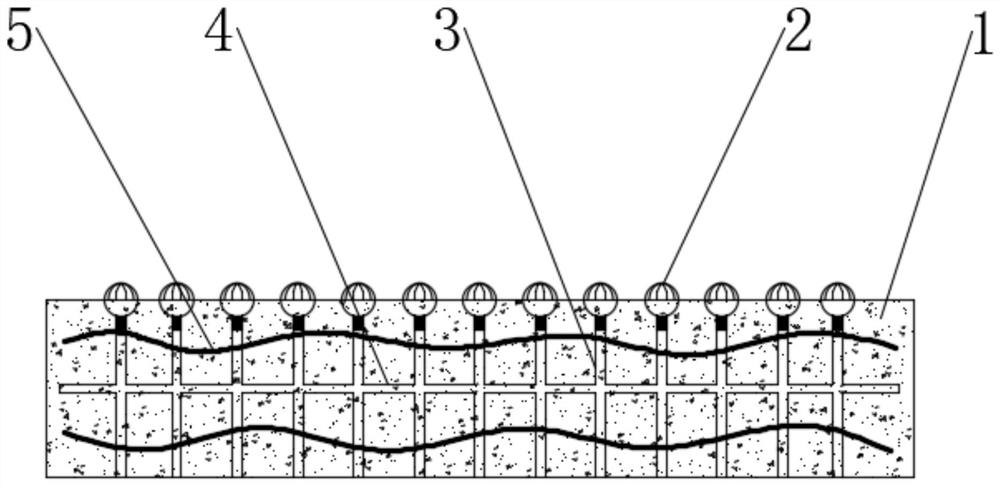

Prefabricated comprehensive pipe gallery joint waterproof connecting structure

PendingCN111364517AEliminate errorsImprove reliabilityArtificial islandsUnderwater structuresRubber ringPre stress

The invention discloses a prefabricated comprehensive pipe gallery joint waterproof connecting structure. The joint waterproof connecting structure comprises an inner sealing rubber strip groove, an outer sealing rubber strip groove, a grouting groove, a grouting hole, exhaust grooves, a prestress tensioning anchorage body and prestress tendons. For one end face of a pipe gallery, the inner edge and the outer edge of the end face are provided with an inner chamfered edge and an outer chamfered edge respectively. After two adjacent pipe galleries are spliced, the spliced portions of the two outer chamfered edges and the two inner chamfered edges are filled with mortar or sealant for smoothing, the two inner sealing rubber strip grooves and the two outer sealing rubber strip grooves are provided with water-swelling water stopping strips, and a grouting cavity formed by splicing the two grouting grooves is internally provided with an annular inflatable rubber ring or filled with concrete.According to the structure, sealing is achieved through smoothing of the inner and outer chamfered edges, sealing of the two water-swelling water stopping strips and concrete grouting of the groutingcavities, five waterproof sealing structures can be formed at the joint part of the pipe gallery from outside to inside, the waterproof and water-stopping effects are good, connection is firm, the service life is long, and the installation is convenient.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

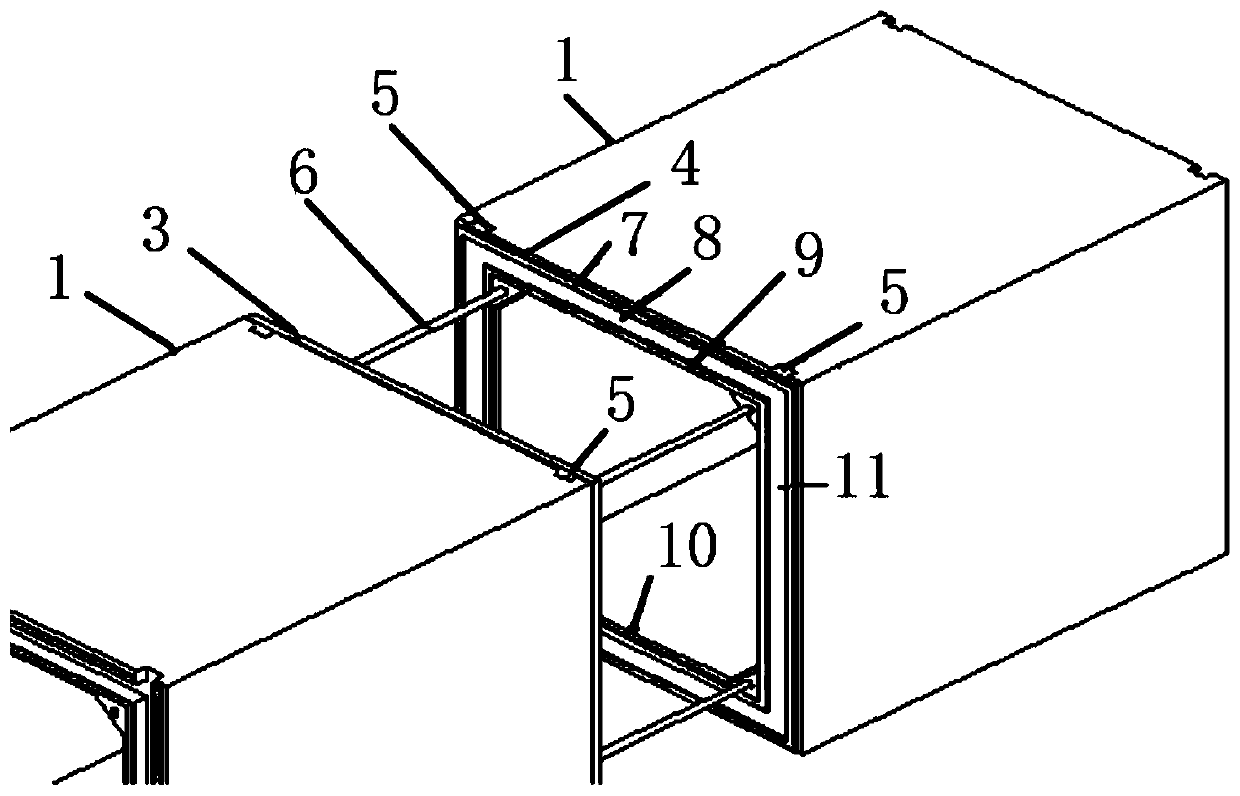

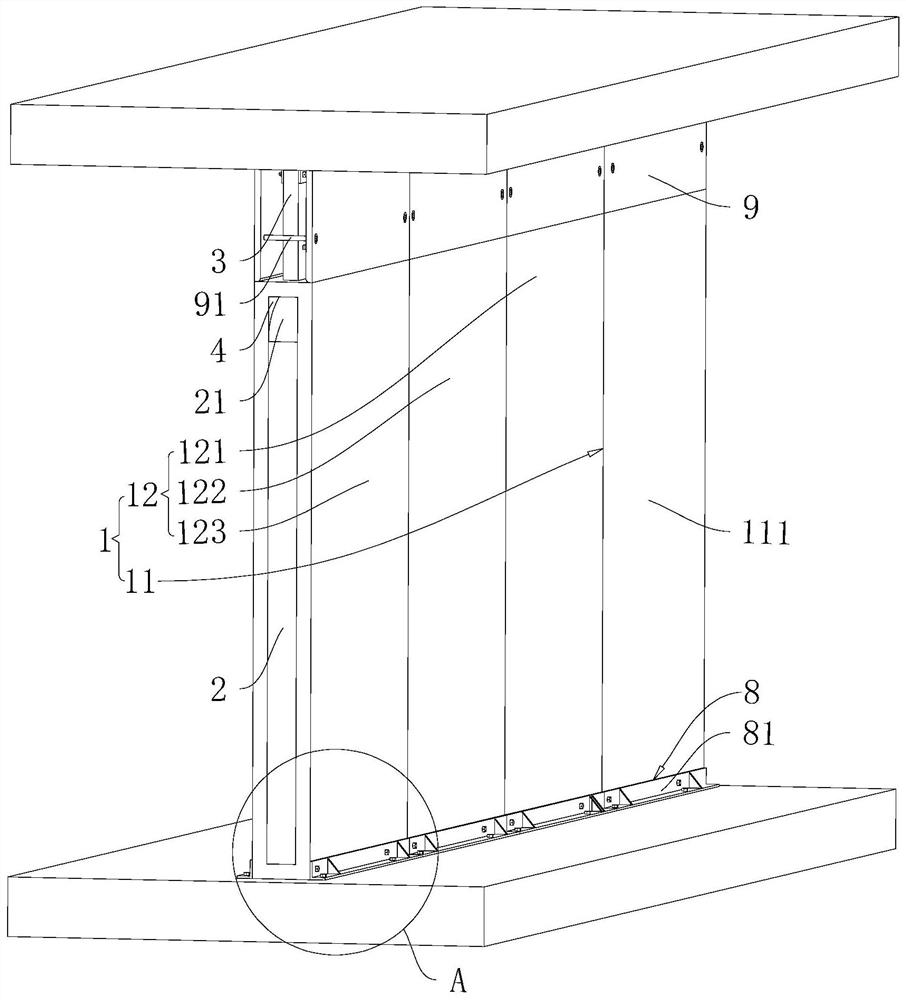

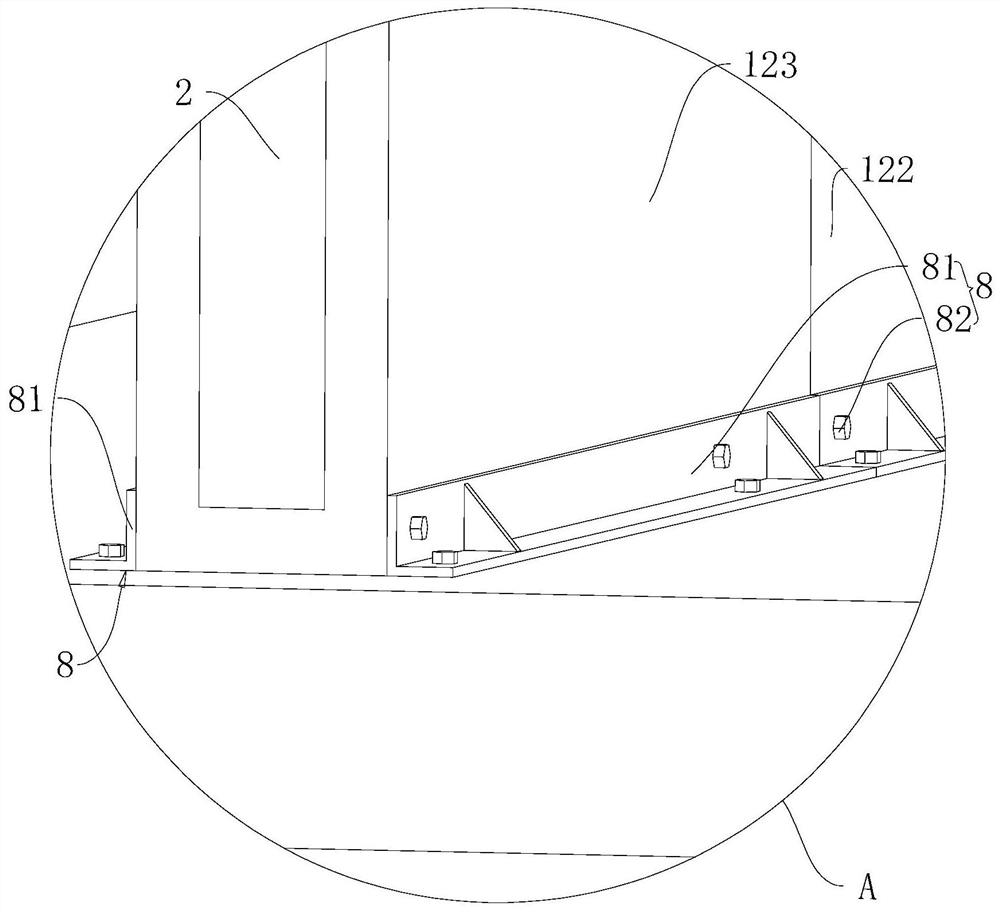

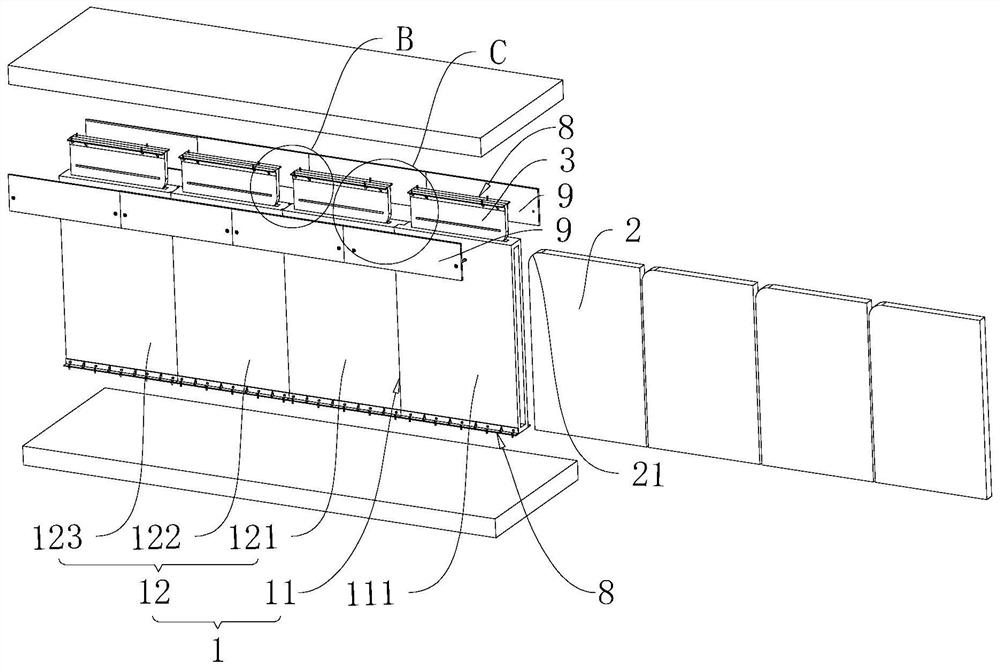

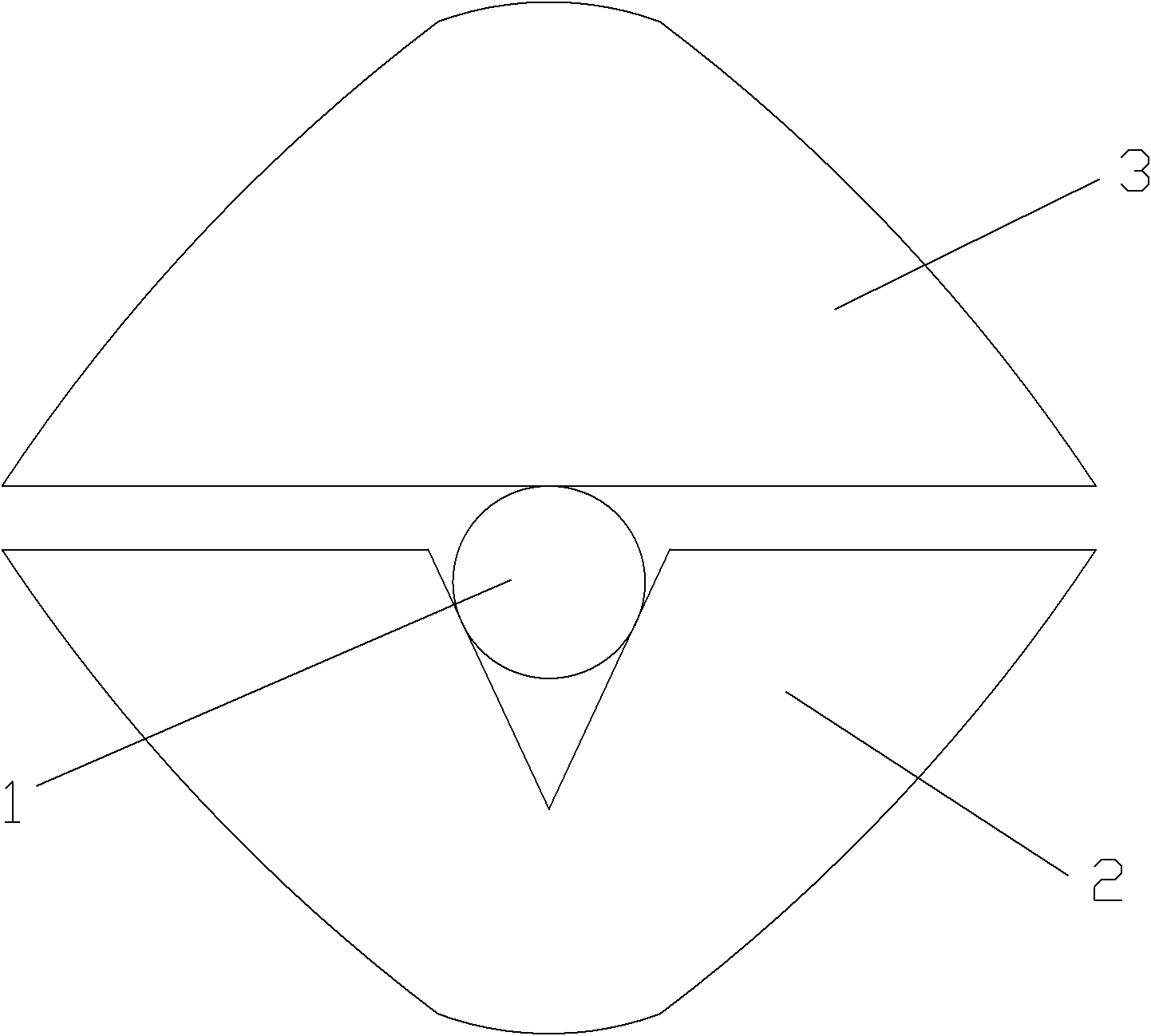

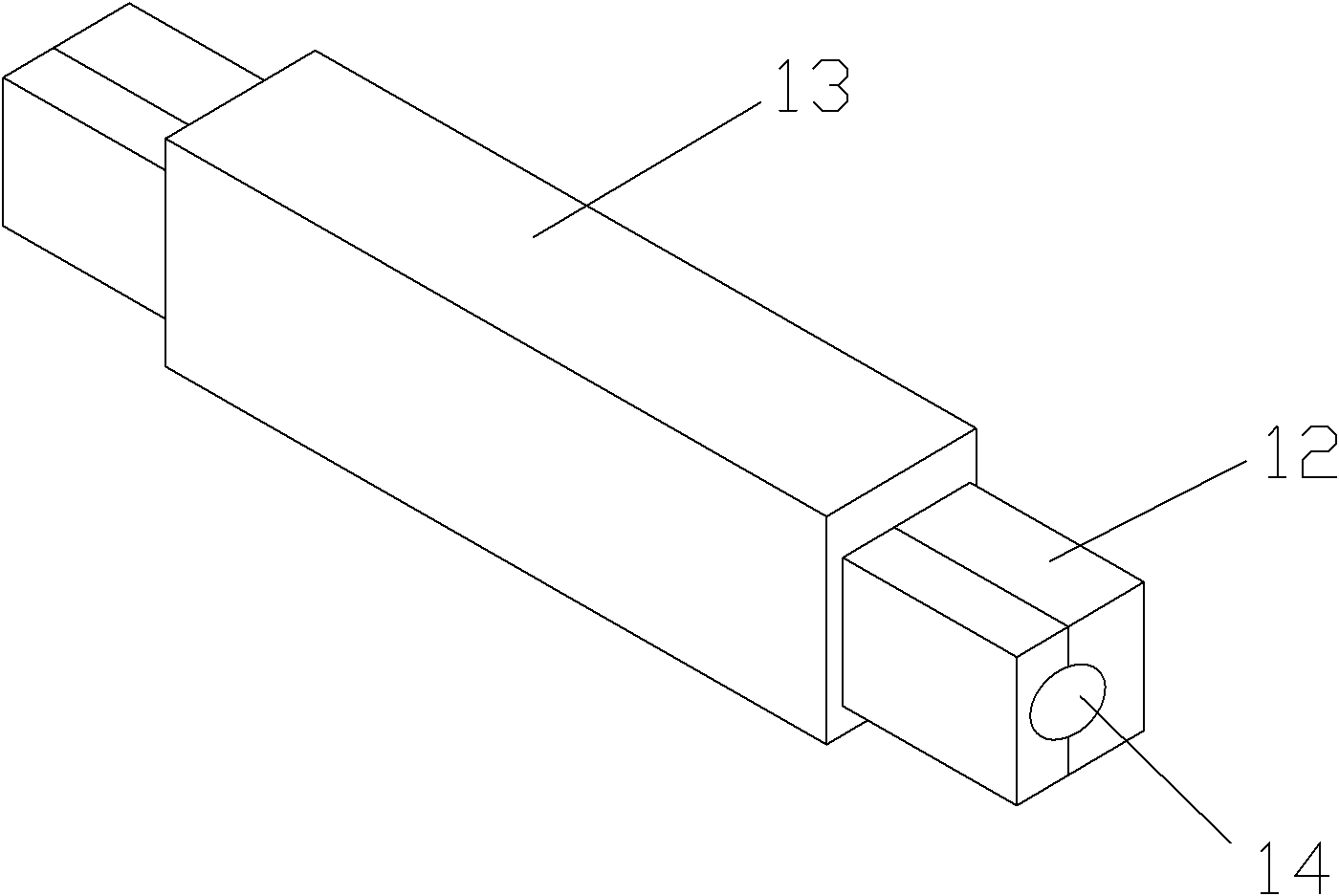

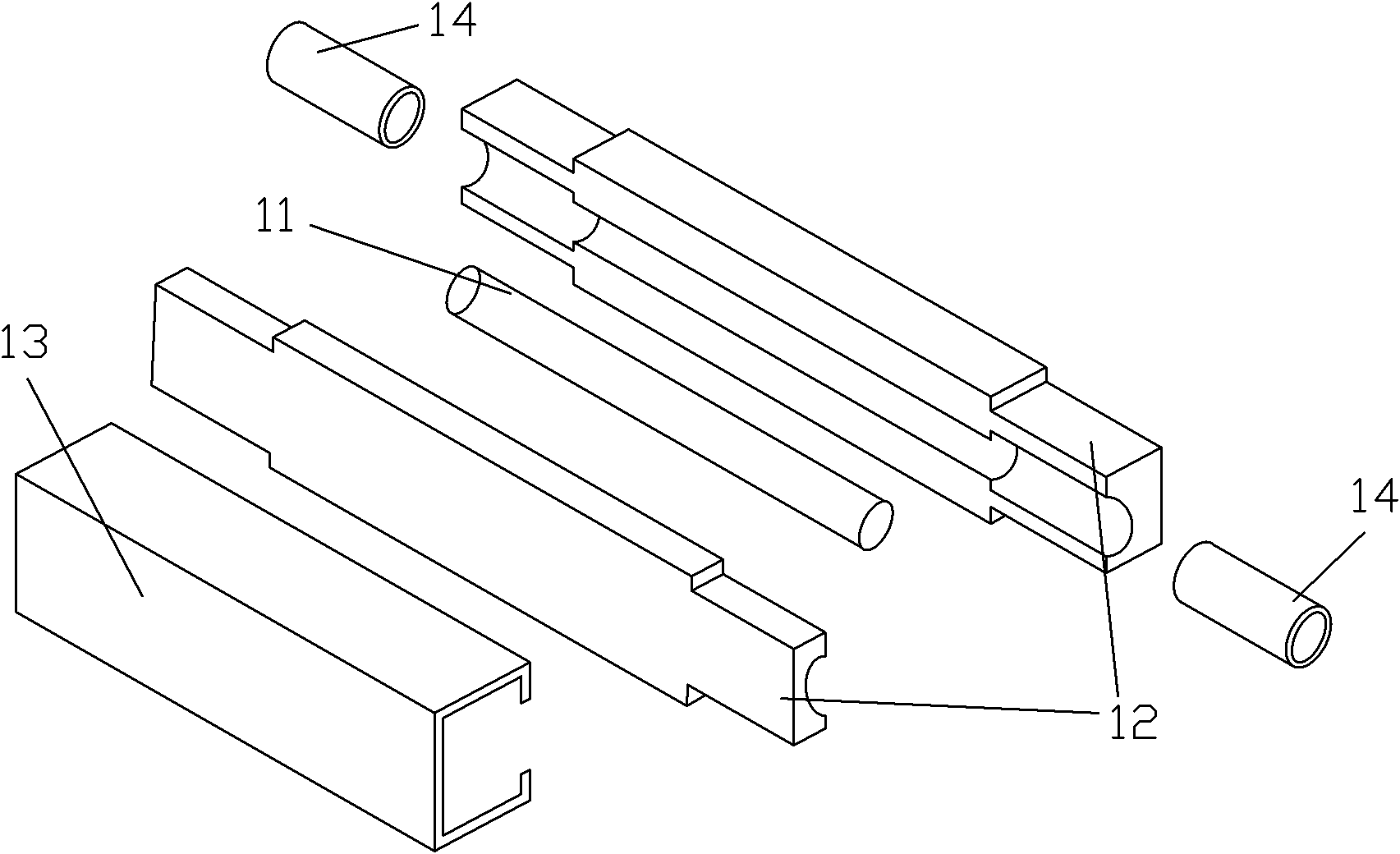

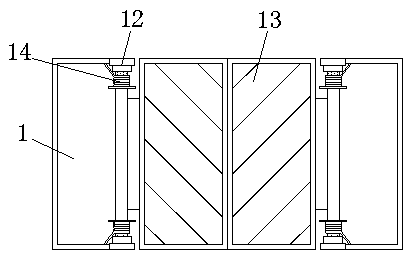

Dry-process connecting assembly type partition wallboard

The invention relates to the technical field of partition wallboards, in particular to a dry-process connecting assembly type partition wallboard. The dry-process connecting assembly type partition wallboard comprises a header partition wallboard frame and a supporting plate which is arranged in the header partition wallboard framework in a penetrating mode, wherein the header partition wallboardframework is in sliding fit to the supporting plate; a slide slot is formed in the top end of the header partition wallboard framework; a slide plate is arranged in the slide slot in the penetrating mode; the slide plate is in sliding fit to the slide slot; the slide plate abuts against the top end of the supporting plate; and the slide plate extrudes and clamps a floor top plate. The dry-processconnecting assembly type partition wallboard has the effects of making resisting between the partition wallboard and the floor top plate more compact and being good in mounting quality of the partition wallboard.

Owner:HUACHUANG ARCHITECTURAL DESIGN CO LTD

Ceramic optical fibre cold coupler

The invention discloses a ceramic optical fibre cold coupler comprising a ceramic hollow tube, a fixed base and a stainless steel sleeve. The fixed base is connected by using a Hough structure; the ceramic hollow tube is arranged in the fixed base; the stainless steel sleeve is sleeved on the outer side of the fixed base; and the shape of the inner side of the stainless steel sleeve is matched with that of the fixed base. As the optical fibre is fixed by using the ceramic hollow tube and the cavity in the ceramic hollow tube is sealed, the adoption of the ceramic optical fibre cold coupler cannot cause deformation inside the ceramic hollow tube under the external environment, and pollution and loss of matching oil in the cavity, and the ceramic optical fibre cold coupler is convenient for field operators to operate, can improve the assembling efficiency and the coupling reliability of the optical fibres, is suitable for various severe environments and beneficial to the reduction of later faults, and has remarkable practical value.

Owner:XIANGJIANG TECH

A virtual server capable of automatically switching a plurality of USB devices

InactiveCN109376107AAvoid breakingFlexibleCouplings bases/casesElectric digital data processingBobbinSoftware engineering

The invention discloses a virtual server capable of automatically switching a plurality of USB devices, including a housing and a second rotational shaft. The middle part of the left side of the frontside of the shell is provided with a bobbin, and the upper and lower ends of the front side of the bobbin are provided with the first springs, and the upper end and the lower end of the bobbin are embedded with the first rotating shafts. A sliding rail is connected in the middle part of the front side of the shell, a cylinder is arranged at the right side of the front side of the sliding rail, and the upper end of the cylinder is fixed with an electric motor. The upper end of the electric motor is provided with a support plate, the upper end of the support plate is provided with a second rotary shaft, and the upper end of the second rotary shaft is embedded with a USB interface column. The virtual server capable of automatically switching the plurality of USB devices is provided with a bobbin post for a virtual server and can be used for winding a connecting wire between the server and the USB interface post, and the bobbin can rotate along the first rotation axis, so that when the USB interface column rotates, the bobbin can rotate along with the USB interface column to contract and extend the connecting wire.

Owner:广州勤加缘科技实业有限公司

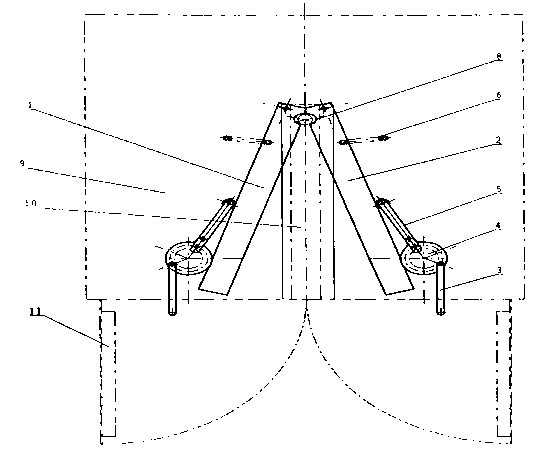

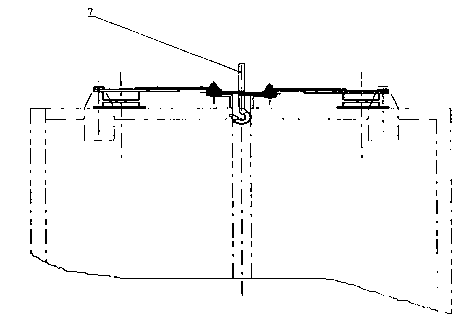

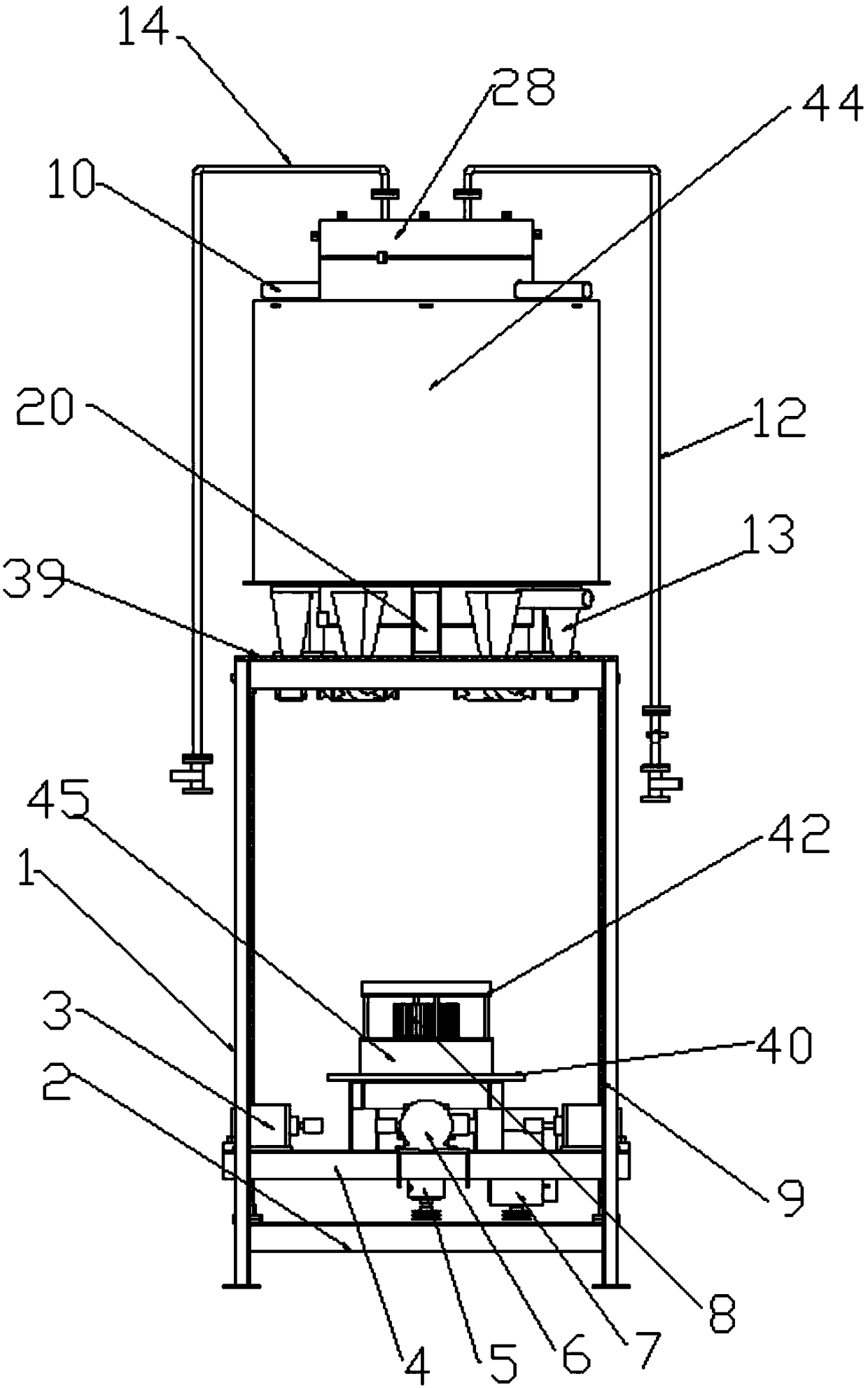

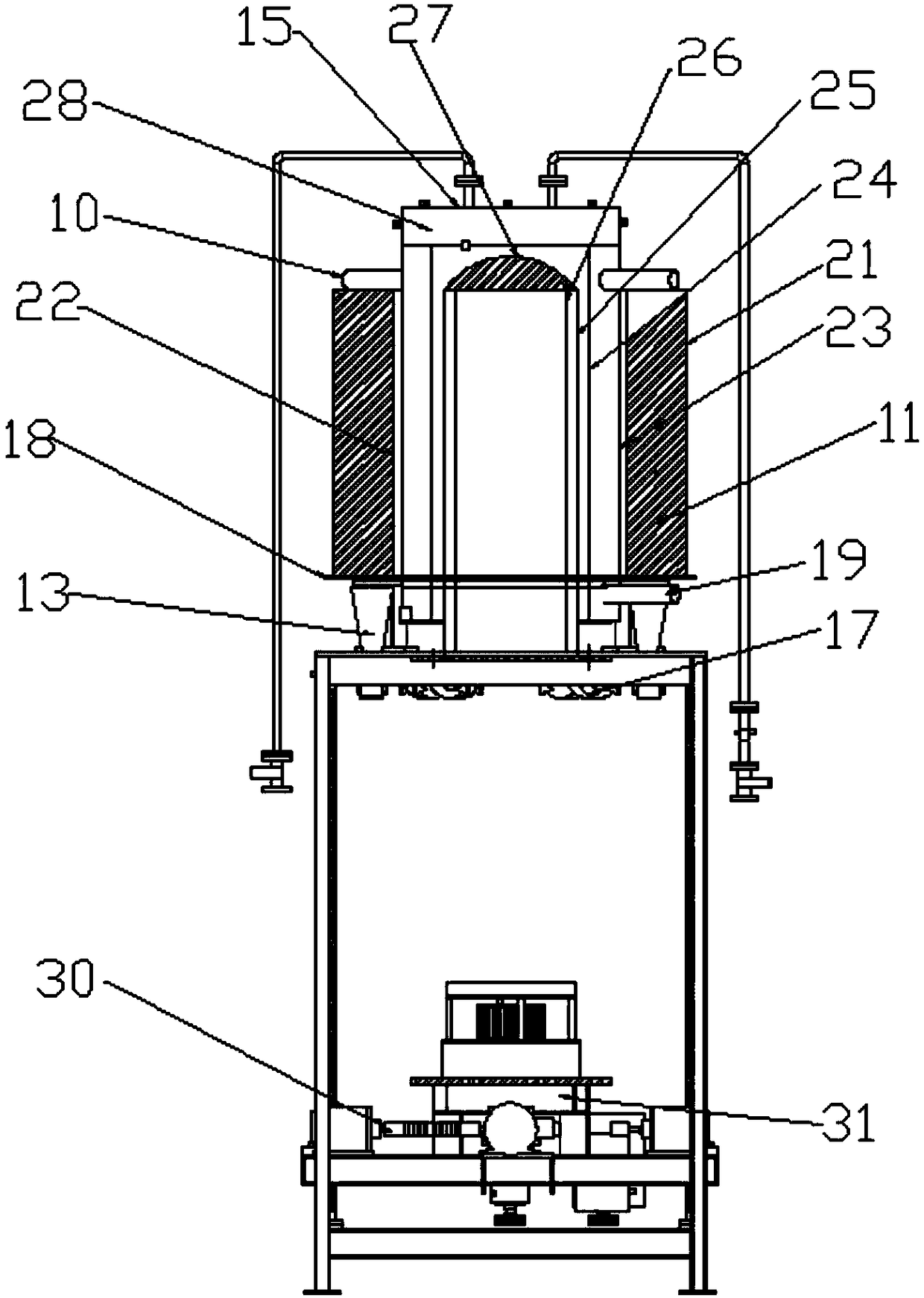

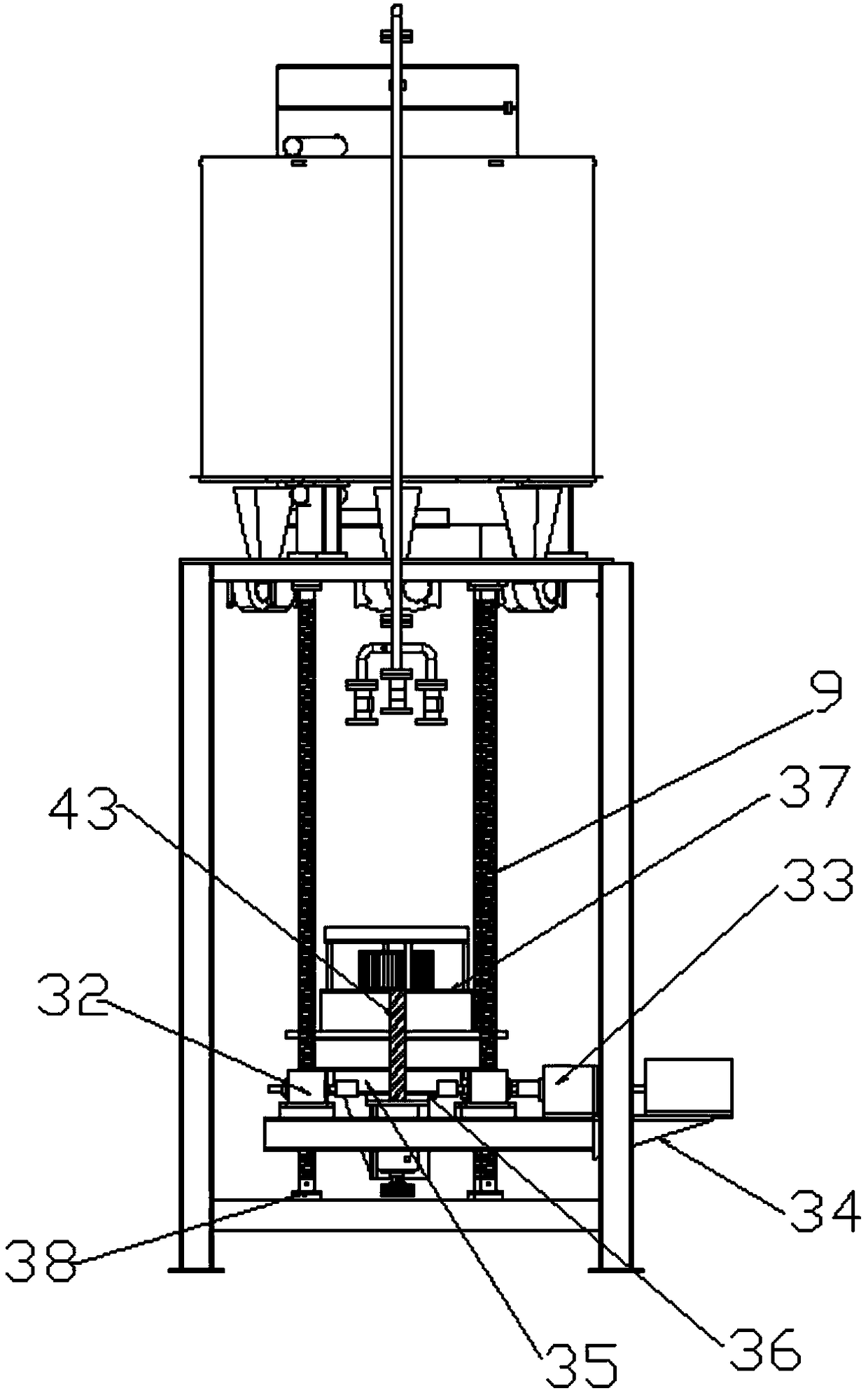

Novel vertical type lifting transverse magnetic furnace

InactiveCN109182712AMove up and down steadilyEasy to get in and out of the ovenFurnace typesInductances/transformers/magnets manufactureEngineeringTransverse magnetic

The invention discloses a novel vertical type lifting transverse magnetic furnace. The furnace comprises a machine frame, a furnace body, a heating device, a magnetizing device, a lifting device and acontrol cabinet, wherein a machine frame plate is arranged at the top of the machine frame, the furnace body is installed on the machine frame plate, the heating device and the magnetizing device areinstalled in the furnace body, the lifting device is installed on the machine frame, and the lifting device and the furnace body are matched with each other. According to the furnace, bottom feedingis adopted, the original top feeding mode is changed, the feeding is more convenient, the production efficiency is greatly improved, the production cost is saved, and meanwhile the safety during working is improved.

Owner:杭州曼德新材料有限公司

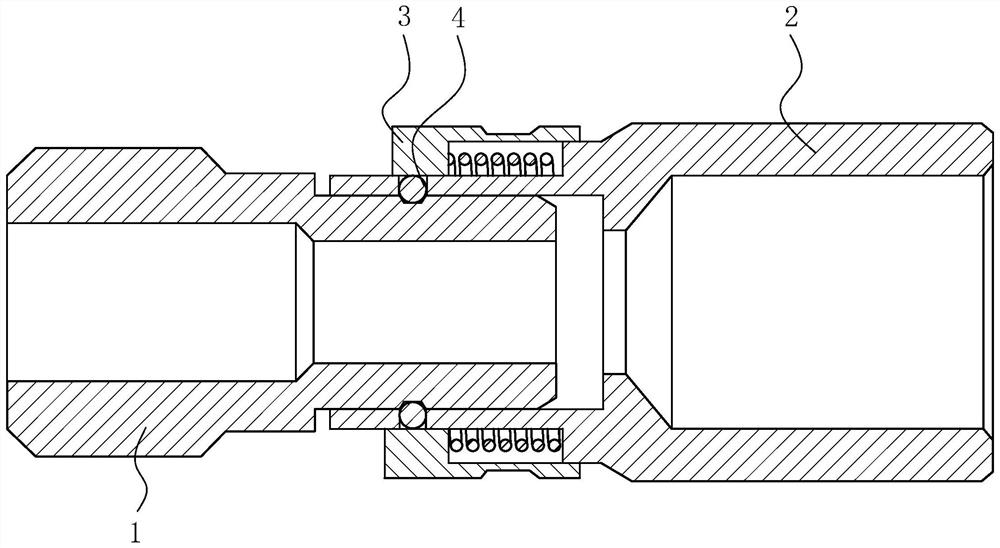

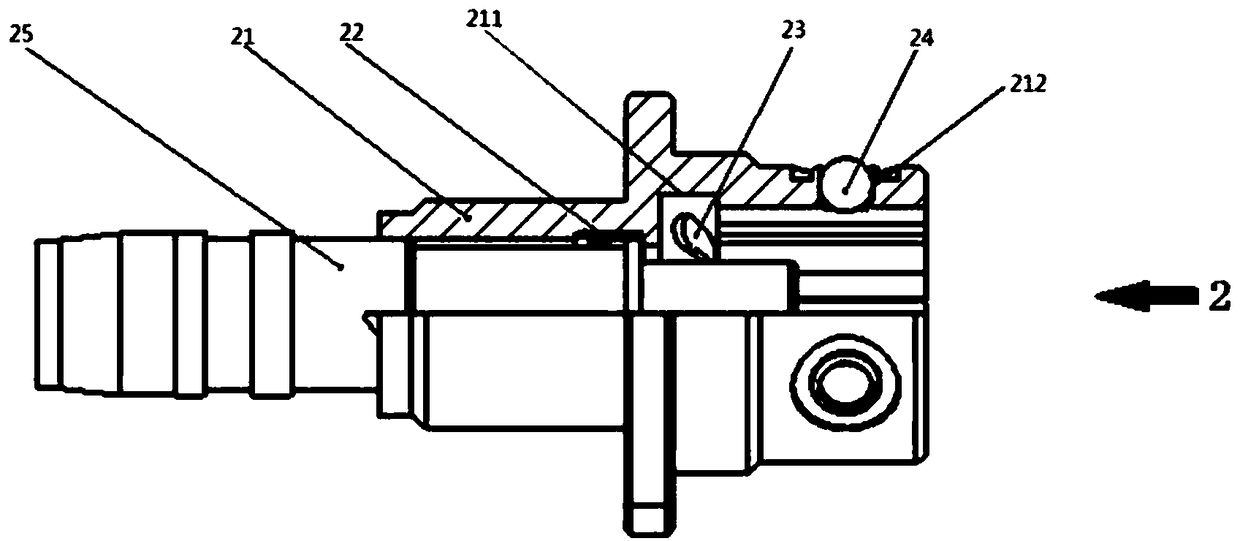

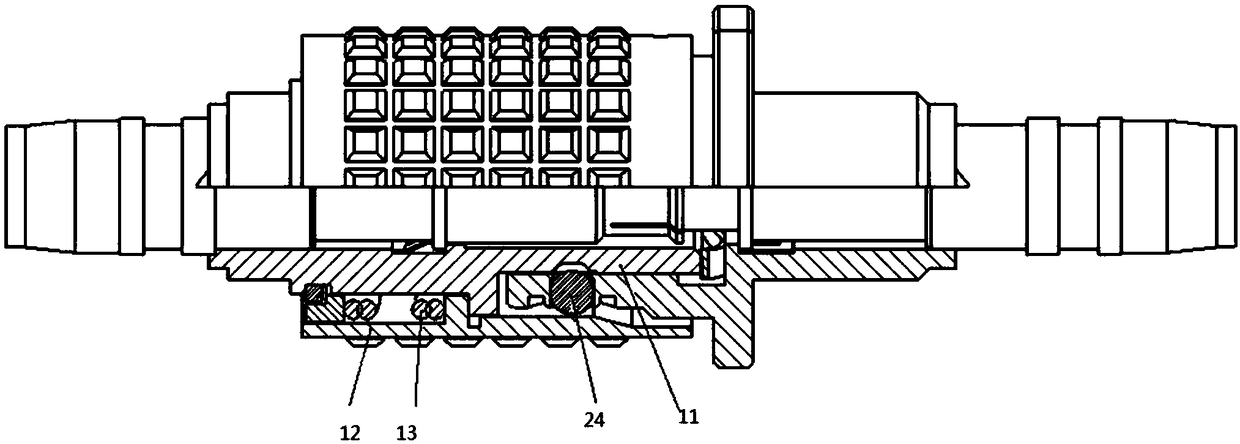

Quick joint for liquid pipeline

InactiveCN112628491AReduces the possibility of relative tiltReduce water leakageSleeve/socket jointsScrew threaded jointsAnatomyEngineering

The invention relates to the field of pipeline joints, in particular to a quick joint for a liquid pipeline. The quick joint comprises a male joint body and a female joint body, the male joint body and the female joint body are both in circular tube shapes, one end of the male joint body abuts against the interior of one end of the female joint body in a sealed mode, the quick joint for the liquid pipeline further comprises screws and sleeves, the sleeves and the screws are parallel to the female joint body, the sleeves are fixedly connected to the outer wall of the female joint body and are evenly distributed in the circumferential direction of the female joint body, the screws are located in the sleeves and connected with the sleeves in a threaded mode, and the outer wall of the male joint body is fixedly sleeved with an annular plate which is rotationally connected with the screws. The sleeves and the screws are circumferentially distributed along the connecting position of the female joint body, so that the possibility of relative inclination between the female joint body and the male joint body can be reduced, and the quick joint of the liquid pipeline is uniformly sealed and stressed in the circumferential direction at the moment, so that the water leakage in the connection position of the male joint body and the female joint body can be reduced, and the purpose of improving the sealing performance of the quick joint for the liquid pipeline is achieved.

Owner:象山兴驰液压润滑有限公司

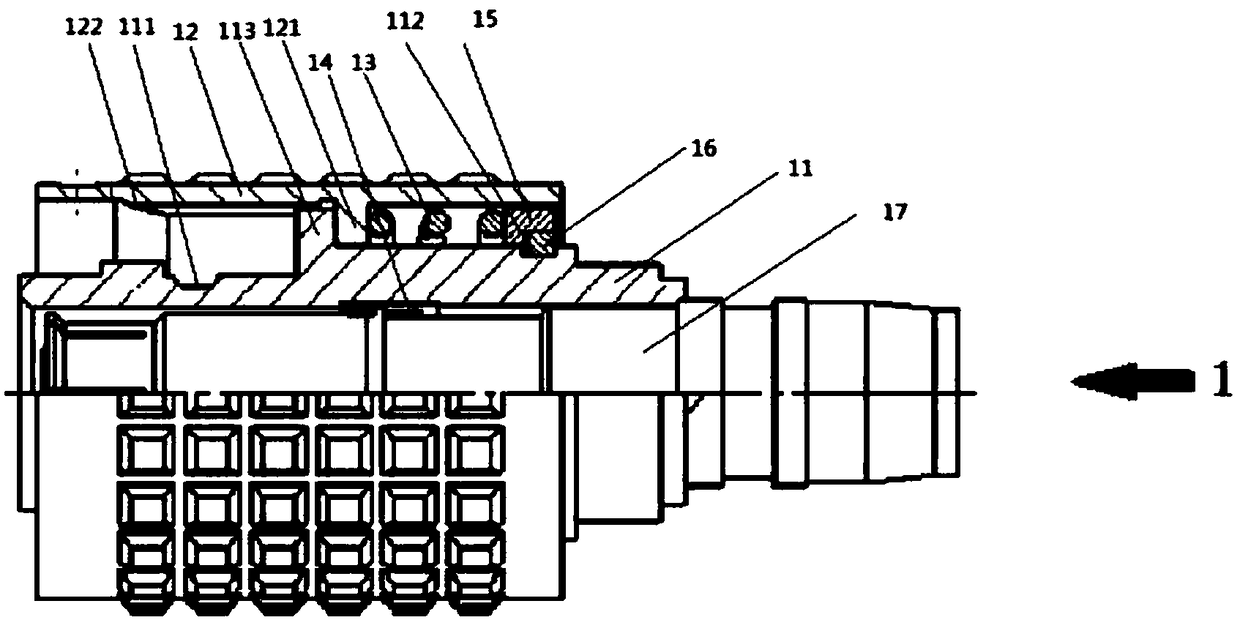

Direct insertion optical fiber connector

PendingCN108535817AGuaranteed transmission performanceButt tightCoupling light guidesOptical fiber connectorSeparation process

The invention provides a direct insertion optical fiber connector suitable for the technical field of optical fiber connectors. A technical problem of the cumbersome and inconvenient operation of an optical fiber connector in the prior art is solved. The direct insertion optical fiber connector includes a plug and a socket. The plug includes a plug housing, a connecting nut, a spring, a pressure ring and a clamping spring, and the socket includes a socket square disk housing, a corrugated spring and a plurality of ceramic balls. According to the direct insertion optical fiber connector, in theconnection and separation processes of the plug and the socket, a pull-out structure is triggered to operate by compressing the plug spring and pressing the socket ceramic balls, thus the connectionand separation of the plug and the socket are achieved, wrong insertion is prevented, the direct insertion optical fiber connector can be widely used in a direct insertion optical fiber connector andhas a considerable market prospect.

Owner:沈阳兴华航空电器有限责任公司

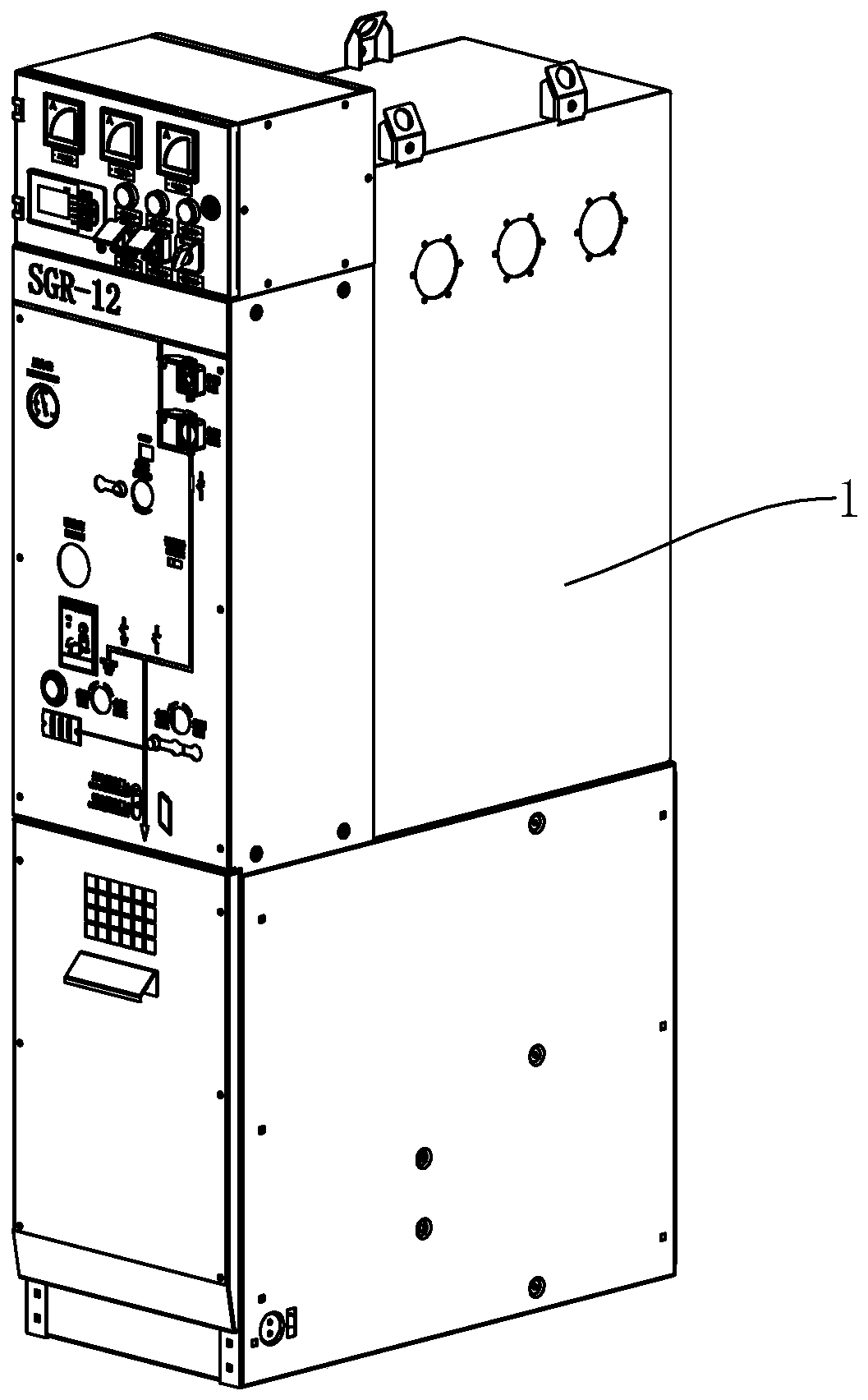

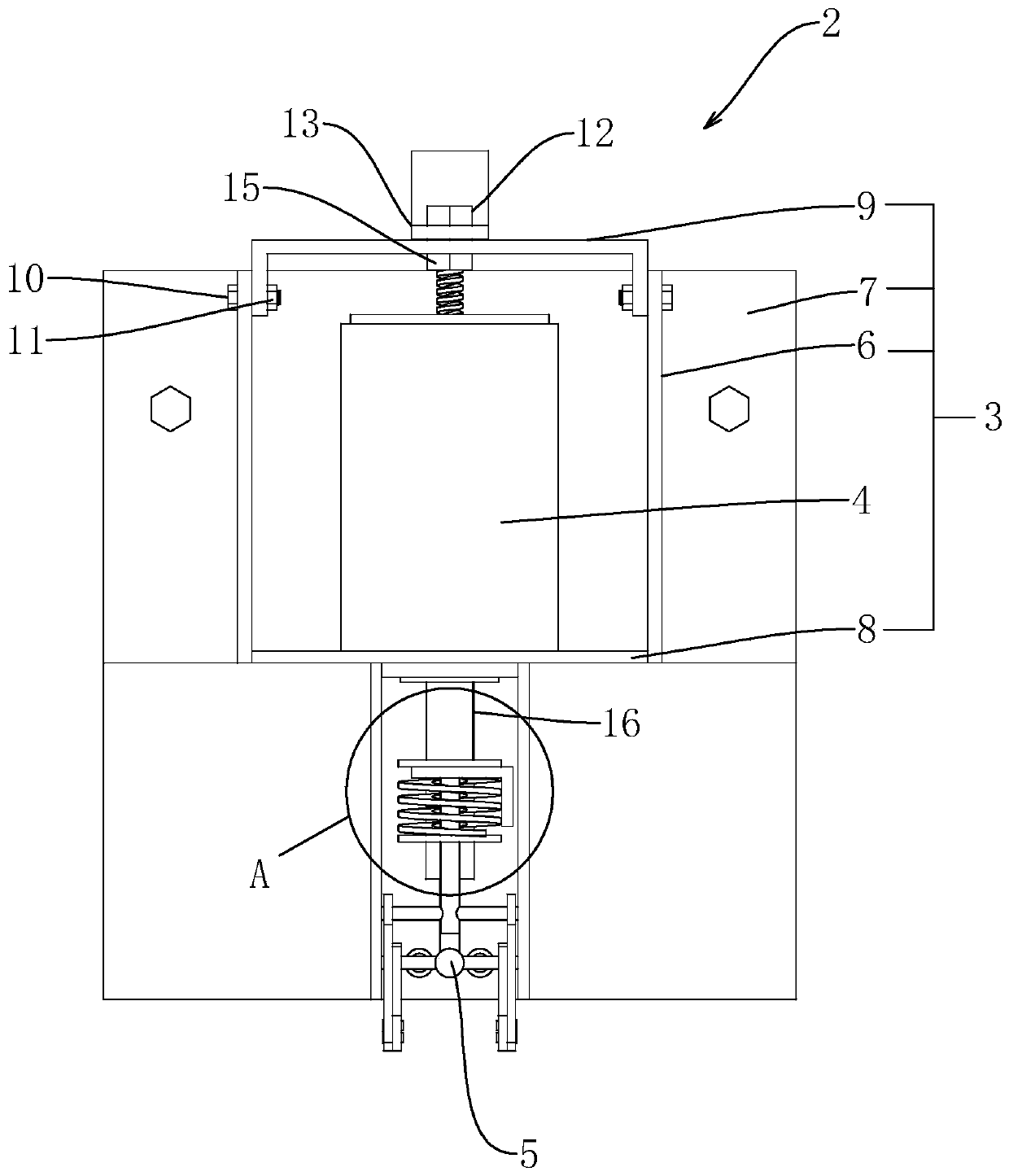

Ring main unit

ActiveCN110137026AButt tightReliable electrical connectionSubstation/switching arrangement casingsHigh-tension/heavy-dress switchesBiochemical engineeringElectrical connection

The invention relates to the technical field of power distribution cabinets, in particular to a ring main unit. The ring main unit comprises a unit body and a breaker located in the unit body, the breaker comprises a support frame, an arc extinguish chamber installed on the support frame and an operation mechanism controlling on-off of a circuit, a copper sleeve is fixed at the lower end of the arc extinguish chamber, a first butt ring having a diameter larger than the copper sleeve is integrally formed at the lower end of the copper sleeve, an insertion rod having an upper end connected witha moving contact is inserted into the copper sleeve, the diameter of the insertion rod is equal to the inner diameter of the copper sleeve, a first butt ring is formed at the position at the lower portion of the first butt ring on the insertion rod, a lower copper row penetrates the position at the upper portion of the second butt ring on the insertion rod, and a first strong spring sleeves the position between the lower copper row and the second butt ring on the insertion rod. The copper row is extruded upwards under the action of the first strong spring and is butted against the first butt ring to allow the copper row to be tightly butted against the first butt ring for stable electrical connection.

Owner:ZHEJIANG KANGGE ELECTRIC CO LTD

Atomization core oil guide body assembling method, special tool and atomization core structure thereof

ActiveCN111096495AUniform distribution of poresNeat and consistent crimping gapTobaccoFiberMechanical engineering

The invention discloses an atomization core oil guide body assembling method, a special tool and an atomization core structure, which are suitable for a fiber oil guide material, and comprise the following steps of: pressing and cutting the fiber oil guide material to prepare a strip-shaped oil guide body; wrapping an atomization core heating body with the strip-shaped oil guide body, and rollinginto a cylinder shape;inserting the cylindrical oil guide body covering the heating body into a first tool; performing abutting joint on the first tool with the cylindrical oil guide body with the atomization core shell; ejecting the cylindrical oil guide body wrapping the heating body by a second tool , and separating the cylindrical oil guide body from the first tool and entering the atomization core shell. According to the oil guide body assembled through the method, due to the fact that the oil guide body is not manually processed any more in the middle process, the uniformity and consistency of the oil guide body can be guaranteed.

Owner:INNOKIN TECH

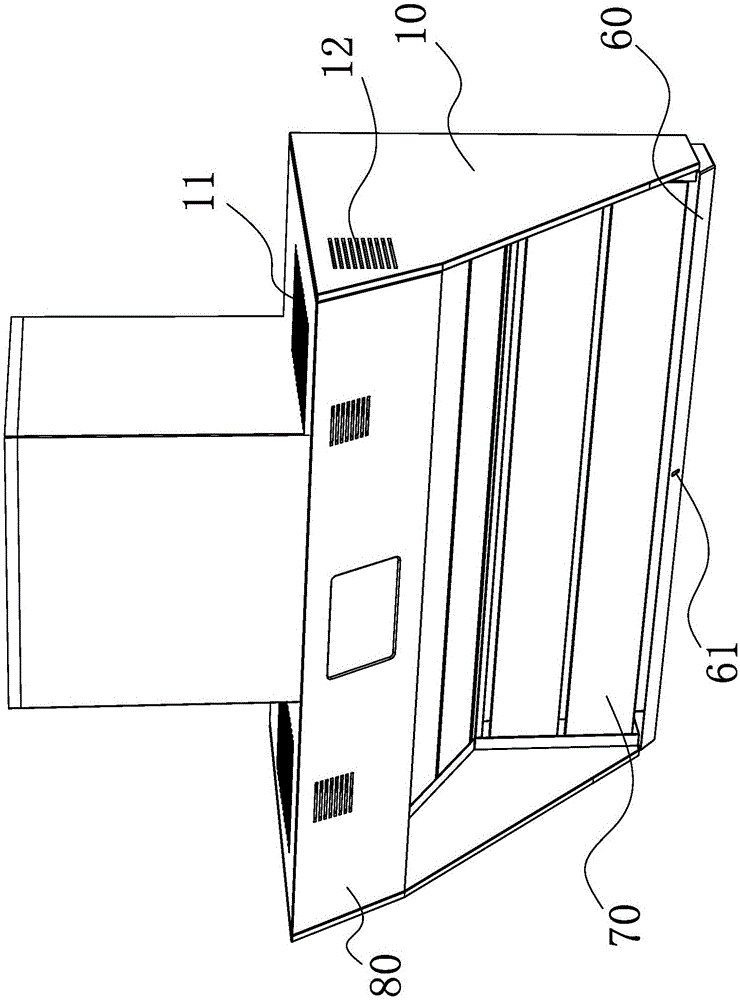

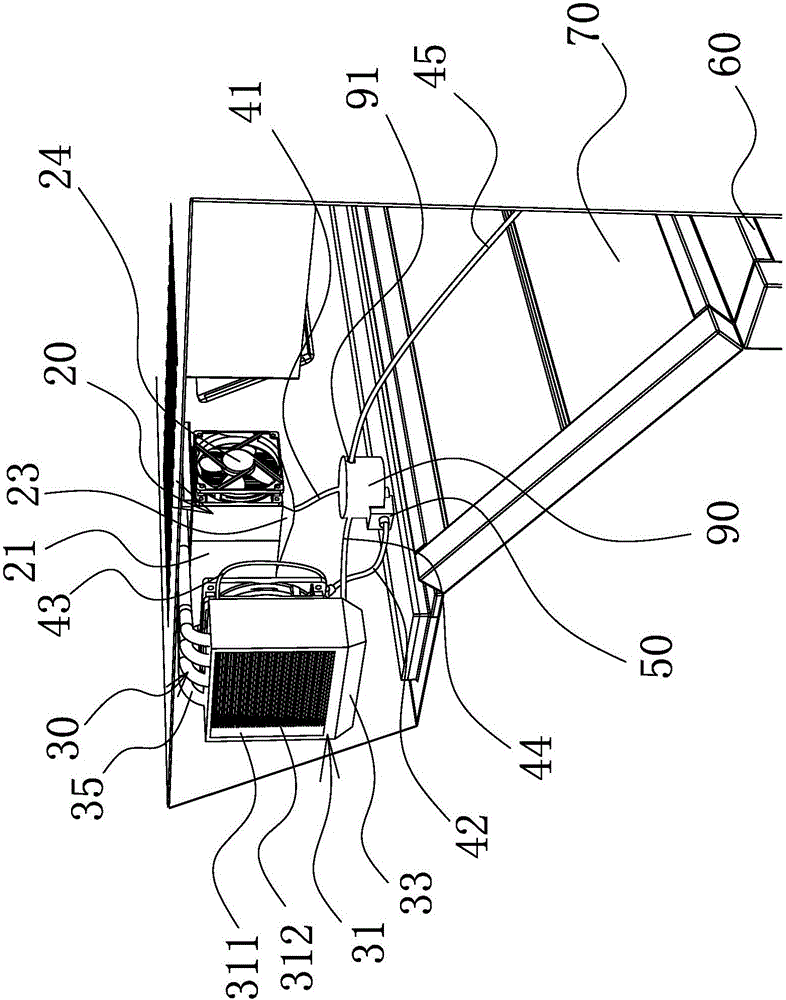

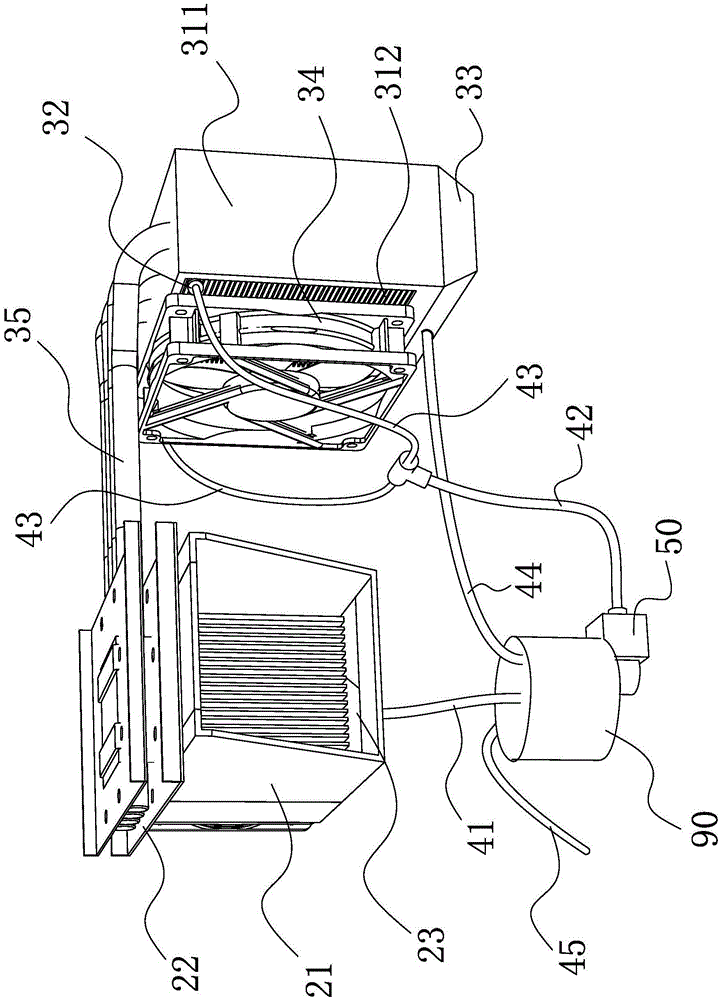

Improved range hood

ActiveCN106196222AButt tightHave storageDomestic stoves or rangesCooking fumes removalElectrical equipmentCondensed water

The invention provides an improved range hood and belongs to the technical field of kitchen electric appliances. The improved range hood comprises a machine shell, at least one refrigerating mechanism, an evaporating mechanism and a water accumulating cup. The refrigerating mechanism is installed on the machine shell. The evaporating mechanism is used for evaporating condensed water to the outside. The water accumulating cup is used for receiving the condensed water generated by the refrigerating mechanism and sending the condensed water into the evaporating mechanism. The improved range hood has the beneficial effect that the condensed water can be automatically removed.

Owner:NINGBO OULIN KITCHEN UTENSILS

Intelligent robot battery assembly facilitating heat dissipation

ActiveCN113517494AImprove cooling effectFacilitate conductionCell temperature controlBattery isolationEngineeringMechanical engineering

The invention relates to the technical field of battery assemblies, in particular to an intelligent robot battery assembly facilitating heat dissipation. The battery assembly comprises a shell, a main body mechanism is arranged in the shell, a heat dissipation mechanism is arranged on the shell and the main body mechanism, an adjusting mechanism is arranged on the main body mechanism and the heat dissipation mechanism together, an air cooling mechanism is arranged in the main body mechanism, a sealing mechanism is arranged on the shell, and a placement mechanism is arranged on the shell; the heat dissipation mechanism is arranged on the shell and the main body mechanism, through the heat dissipation mechanism and under the cooperation of the adjusting mechanism, the heat dissipation effect on the main body mechanism is conveniently achieved, the influence of too high temperature on the battery assembly is avoided, and meanwhile potential safety hazards are reduced; the sealing mechanism is arranged on the shell, a better packaging effect on the main body mechanism is conveniently achieved through the sealing mechanism, and a large amount of dust is prevented from being attached to the battery assembly, so that the power loss of the battery assembly is reduced in the long-time use process, and meanwhile, the heat dissipation capability of the battery assembly is also improved.

Owner:江苏润杨机器人有限公司

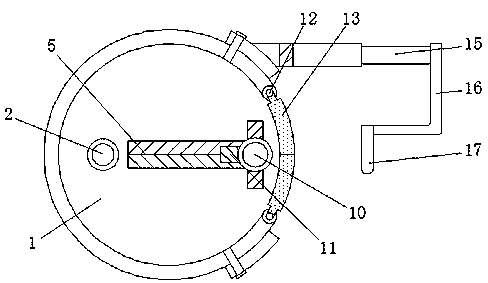

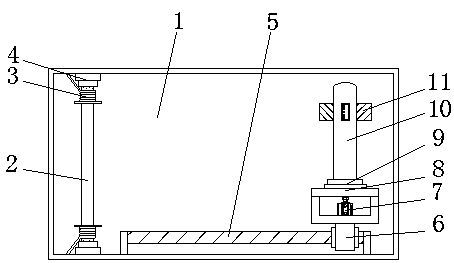

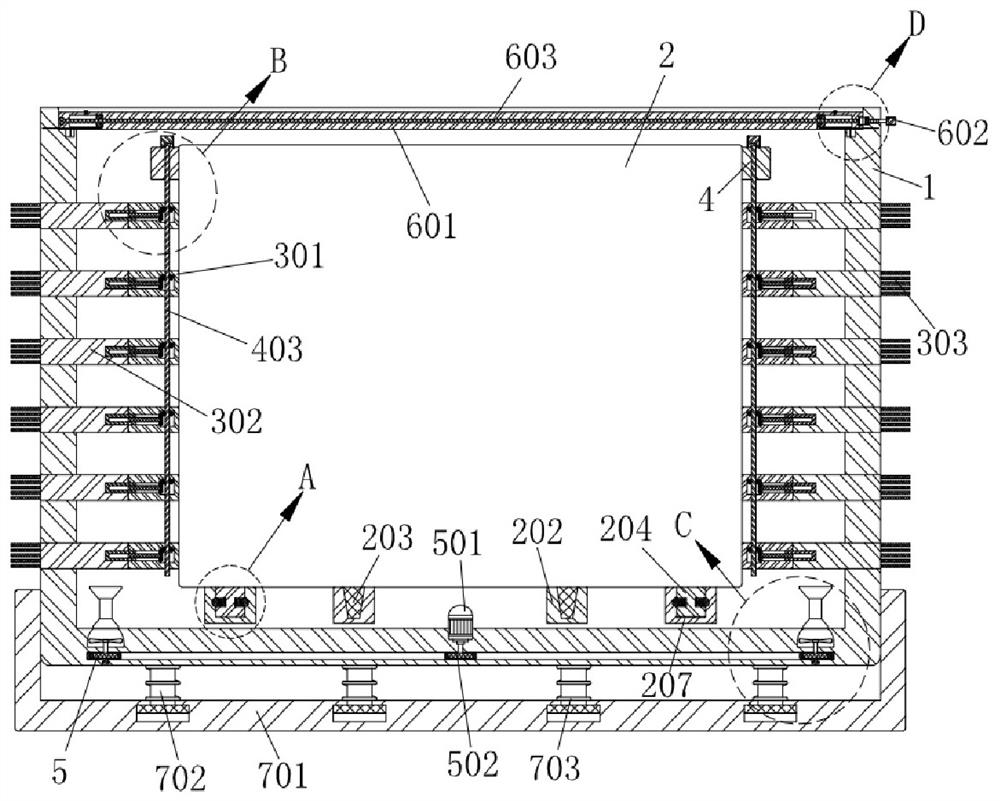

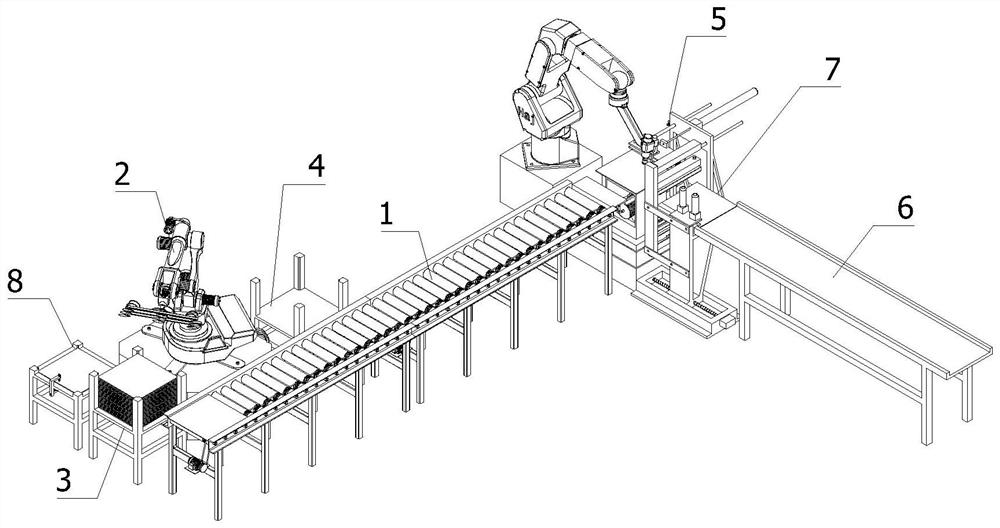

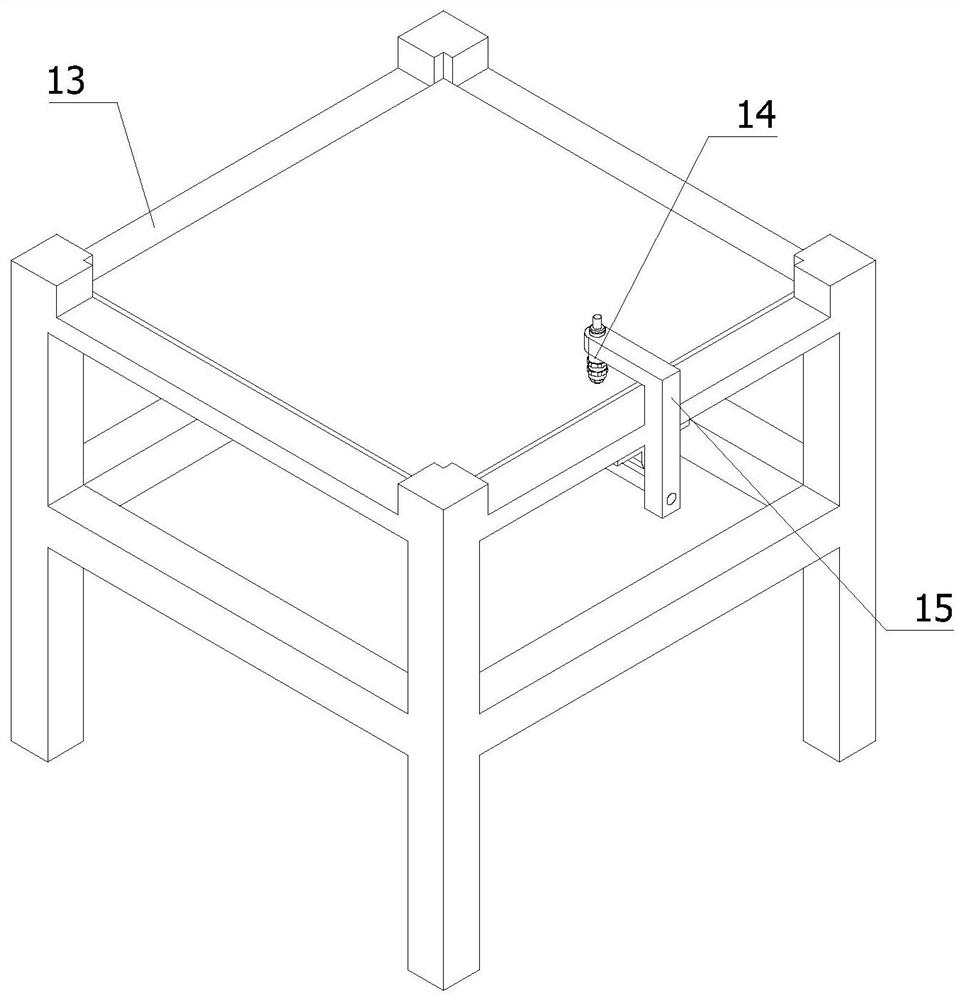

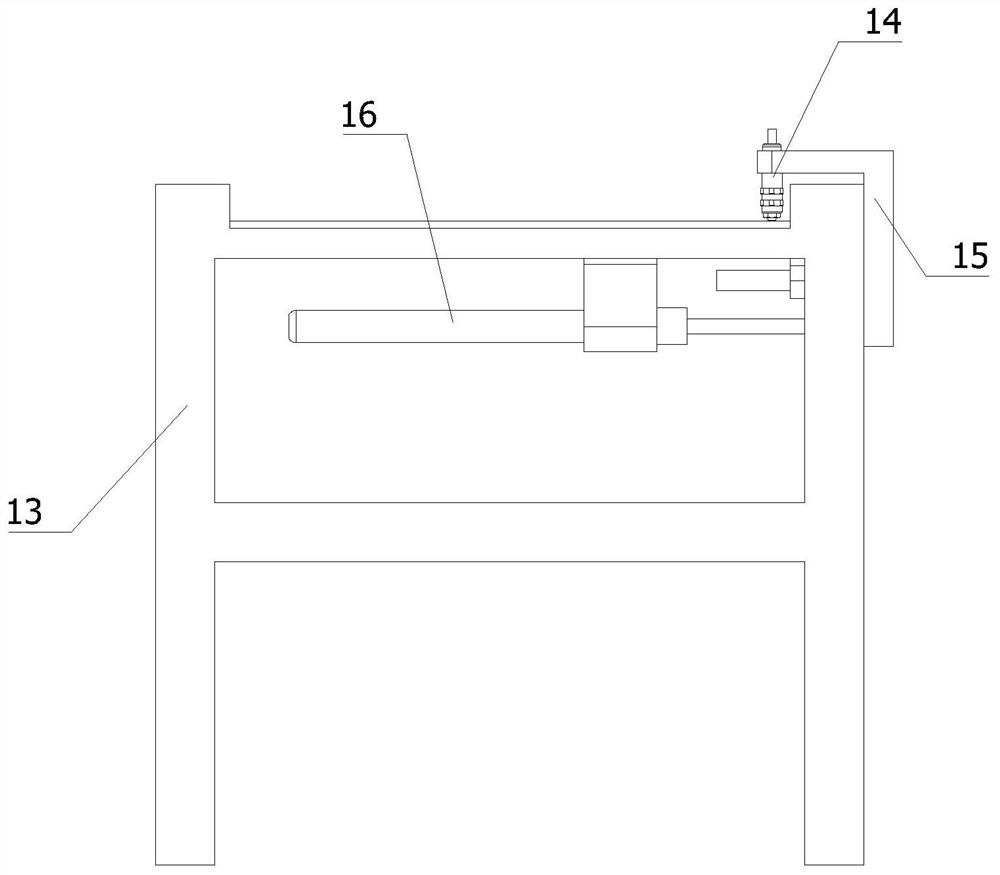

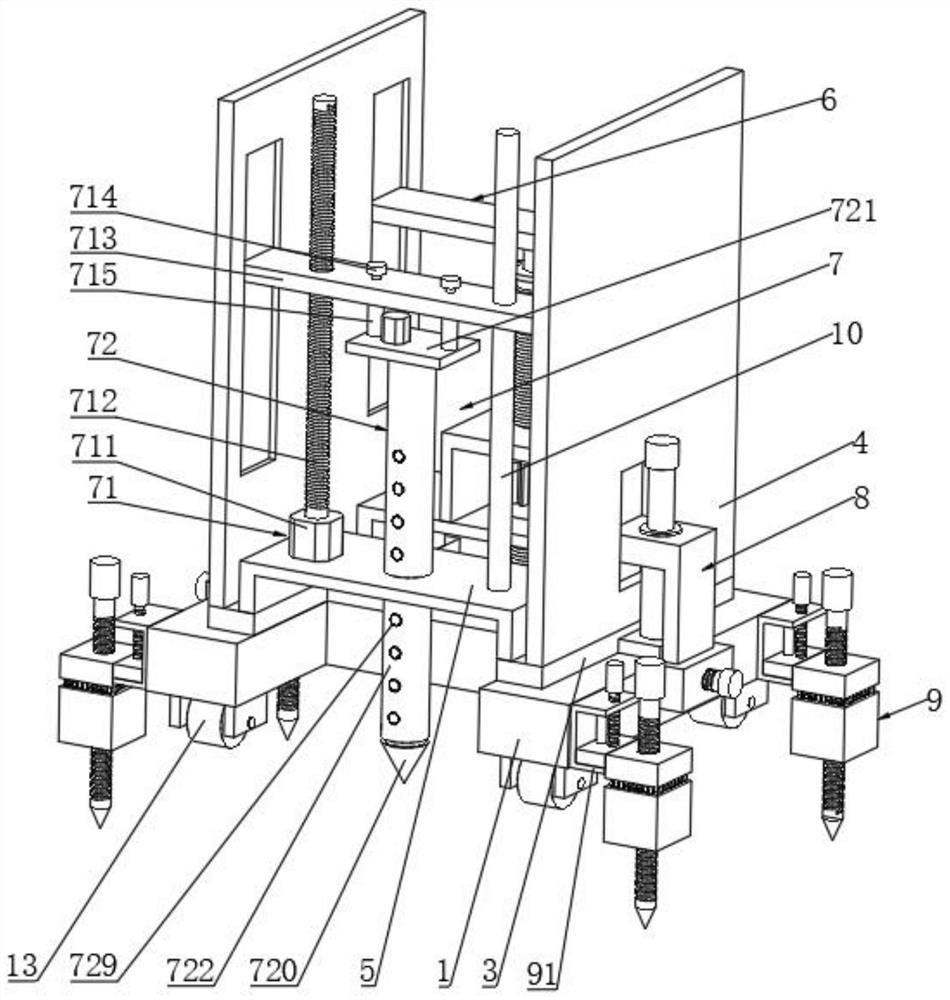

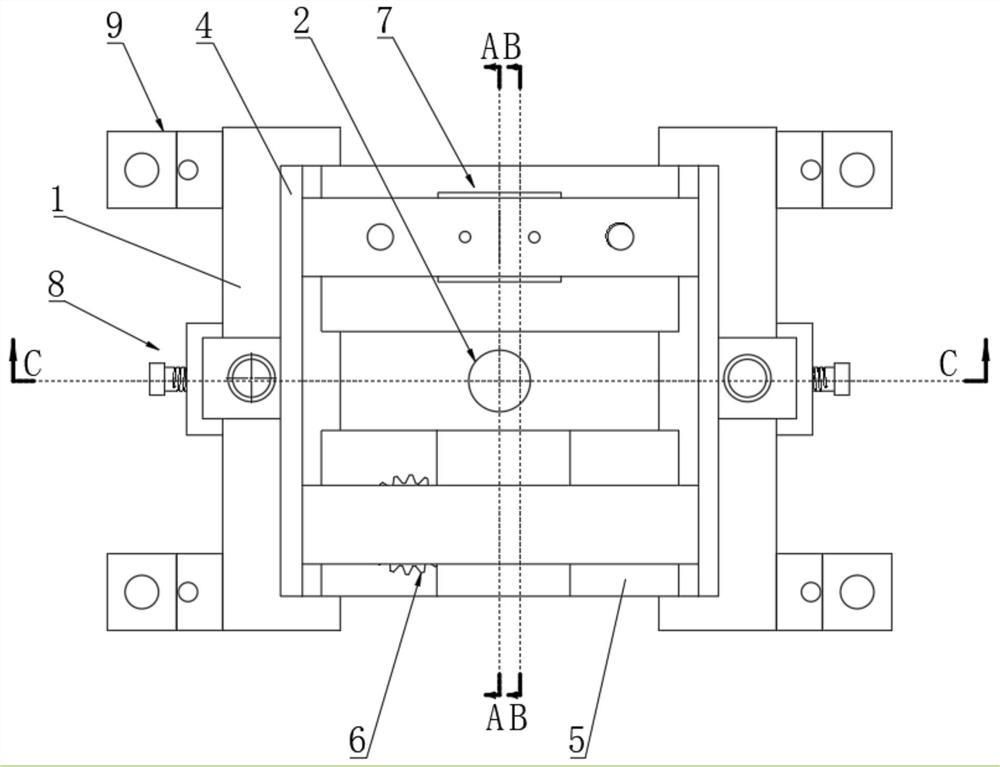

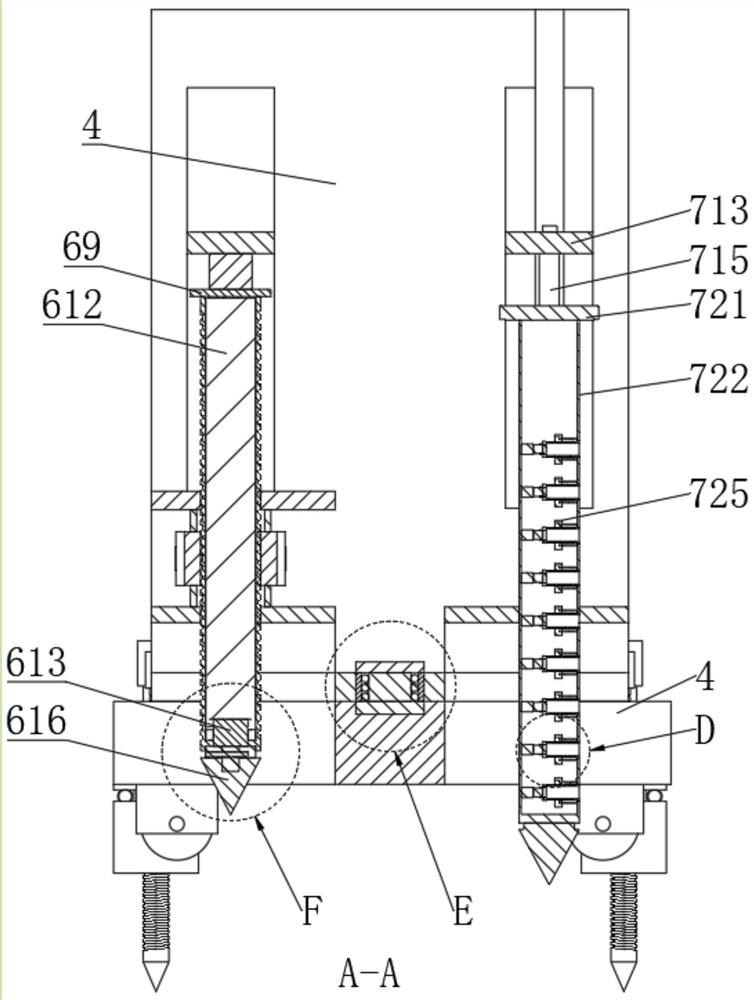

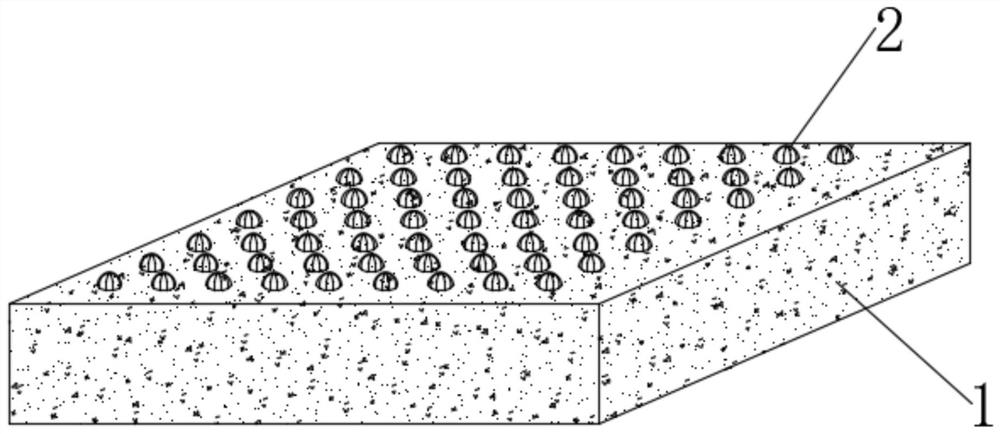

Intelligent plate cutting and welding equipment

InactiveCN113523570AThe same thicknessRealize Tailored WeldingMeasurement devicesWelding/cutting auxillary devicesButt jointPhysics

The invention relates to the technical field of plate tailor-welding, in particular to intelligent plate cutting and welding equipment. The equipment comprises a drum-type conveyor, a feeding manipulator, a cutting and welding device and an output platform; a first stacking table and a second stacking table are arranged on the two sides of the feeding manipulator respectively; the output direction of the output platform is perpendicular to the conveying direction of the drum-type conveyor; the cutting and welding device comprises a positioning and butt-joint assembly and a thickness detection assembly, the positioning and butt-joint assembly is used for performing tailor-welding on a plurality of plates after the plates are in tight butt joint, and the positioning and butt-joint assembly comprises a positioning and welding table, a traction mechanism, a cutting and welding manipulator and an auxiliary butt-joint mechanism. Through detection of the thicknesses of the plates by the thickness detection assembly, it is guaranteed that the thicknesses of the plates are consistent, and follow-up tailor-welding can be effectively carried out; tight butt joint of the multiple plates is achieved through the positioning and butt-joint assembly, tight butt joint of the plates is achieved, tailor-welding is facilitated, and the accuracy and quality of tailor-welding of the plates are guaranteed.

Owner:刘乐

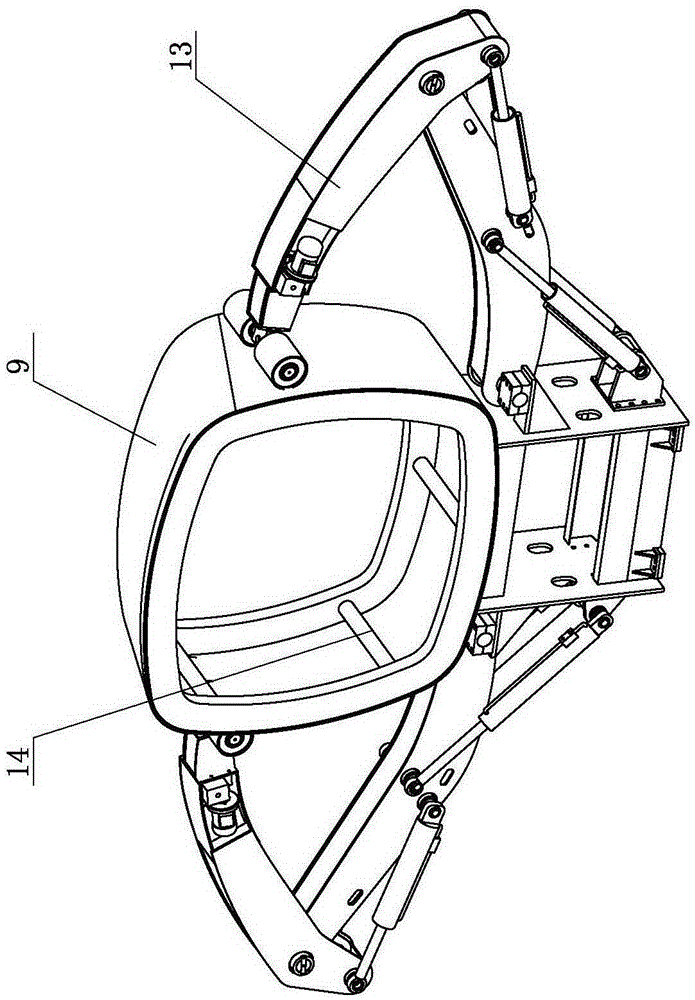

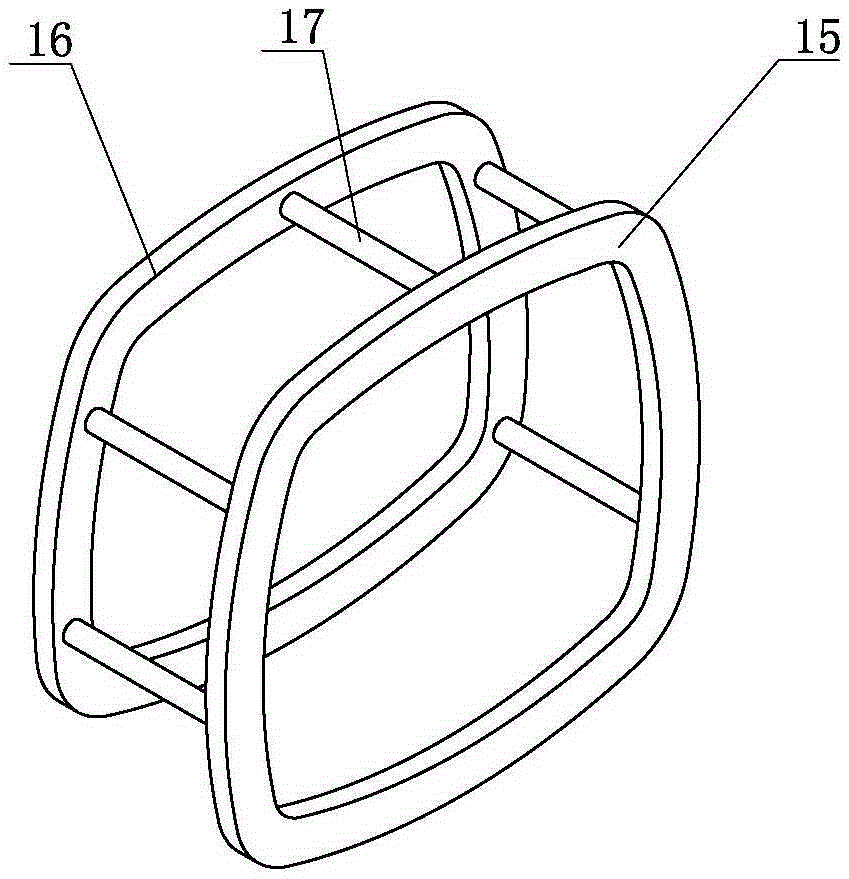

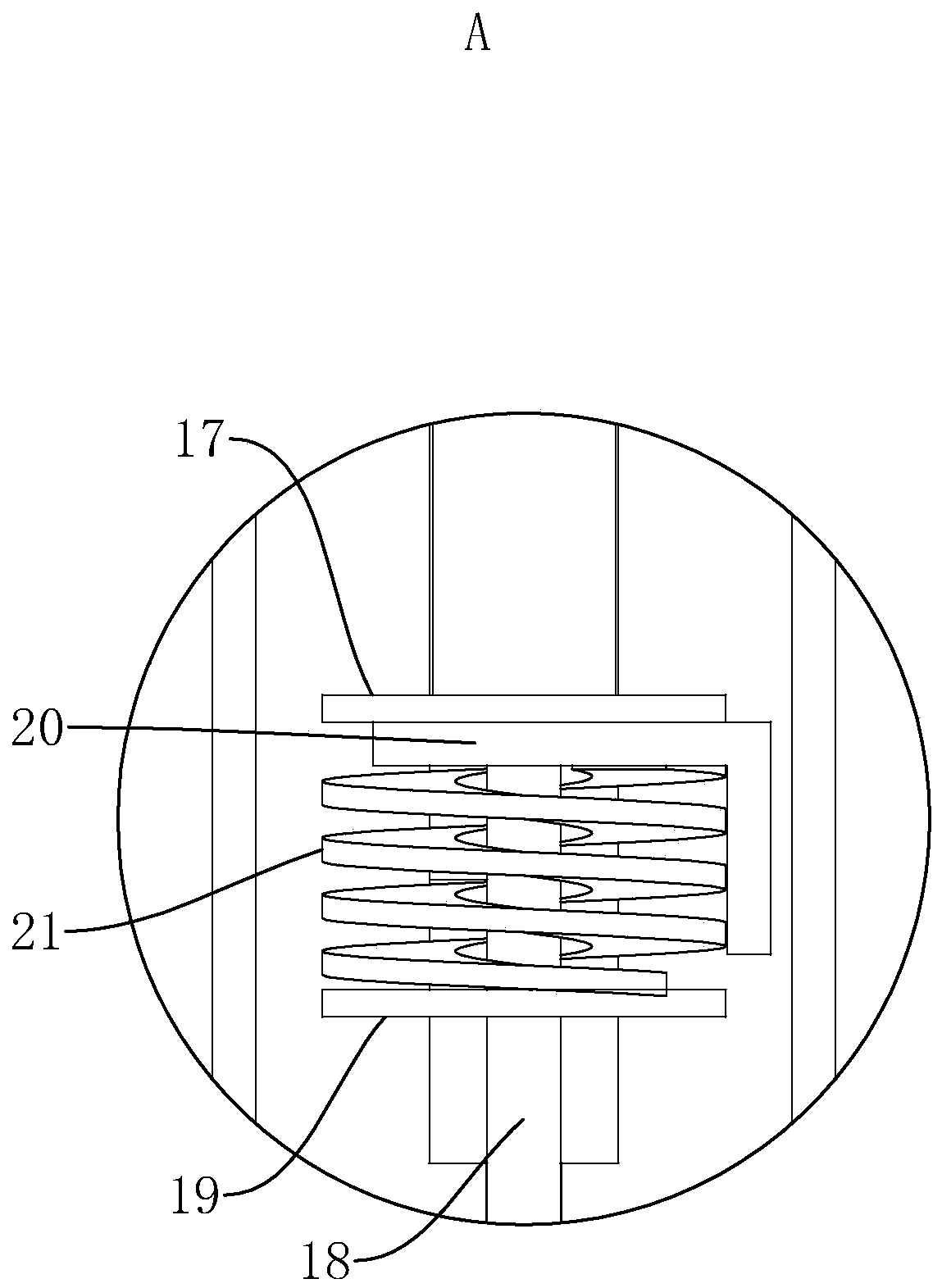

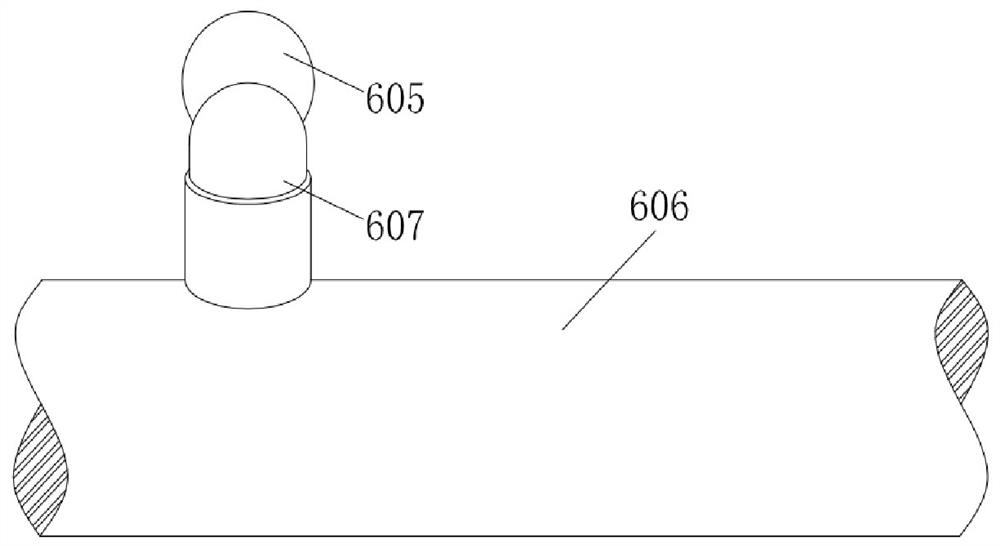

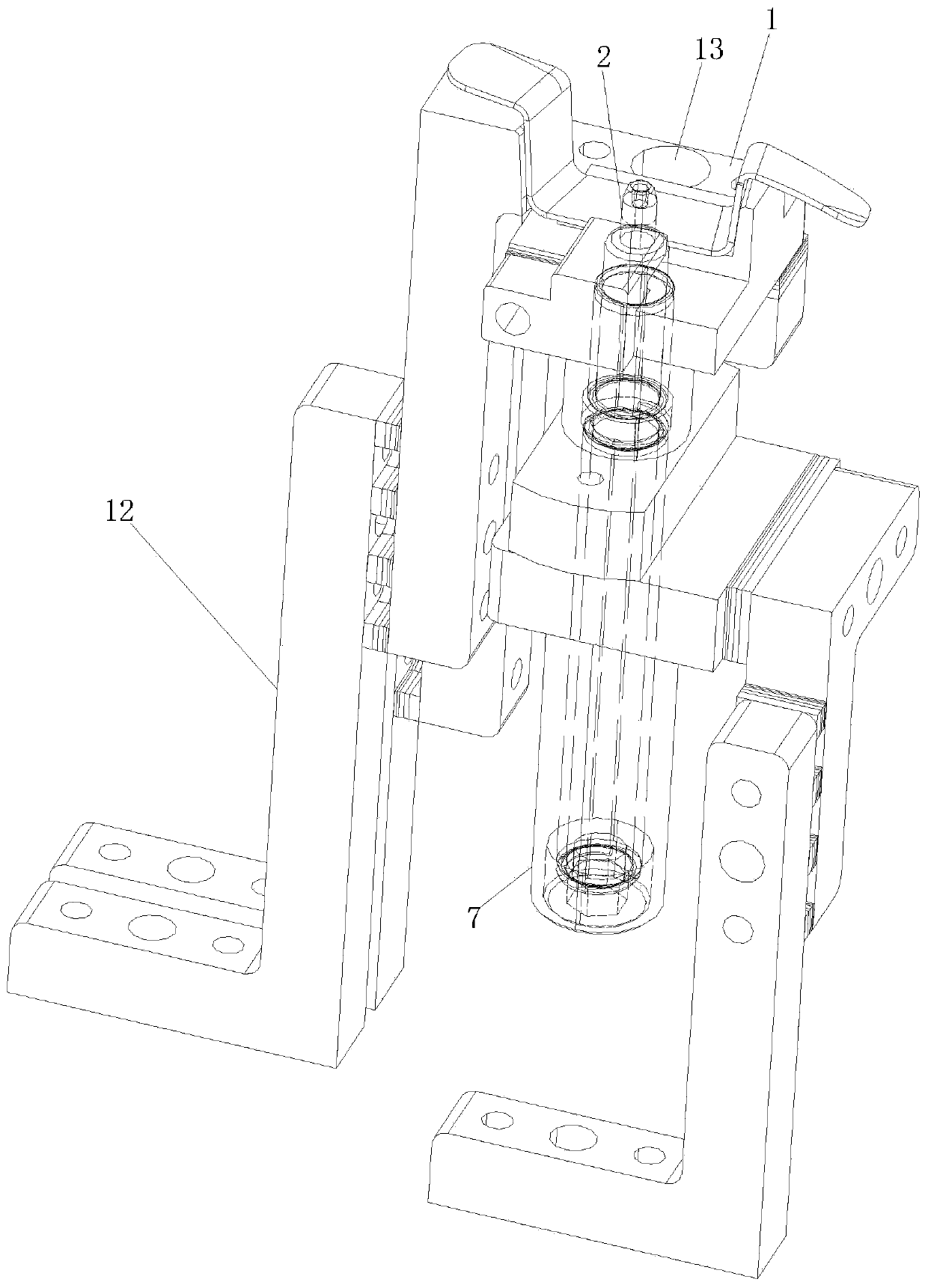

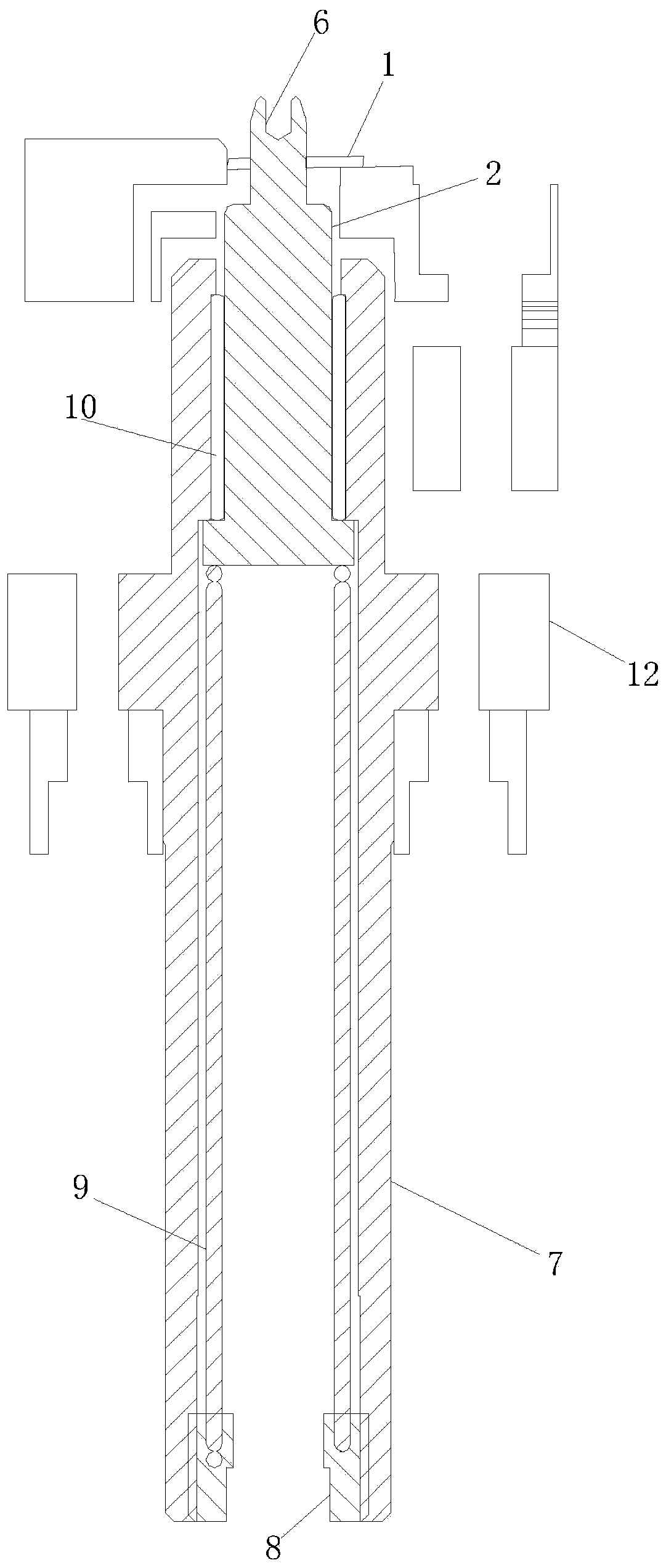

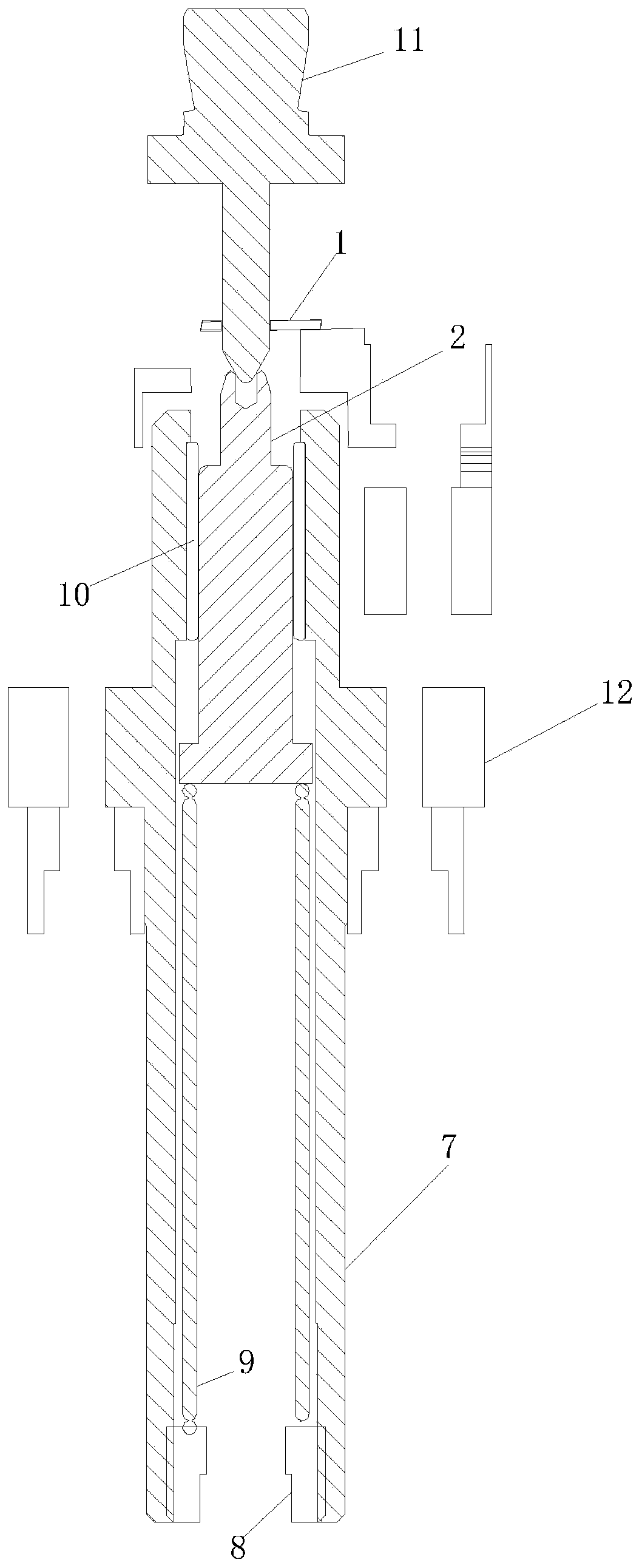

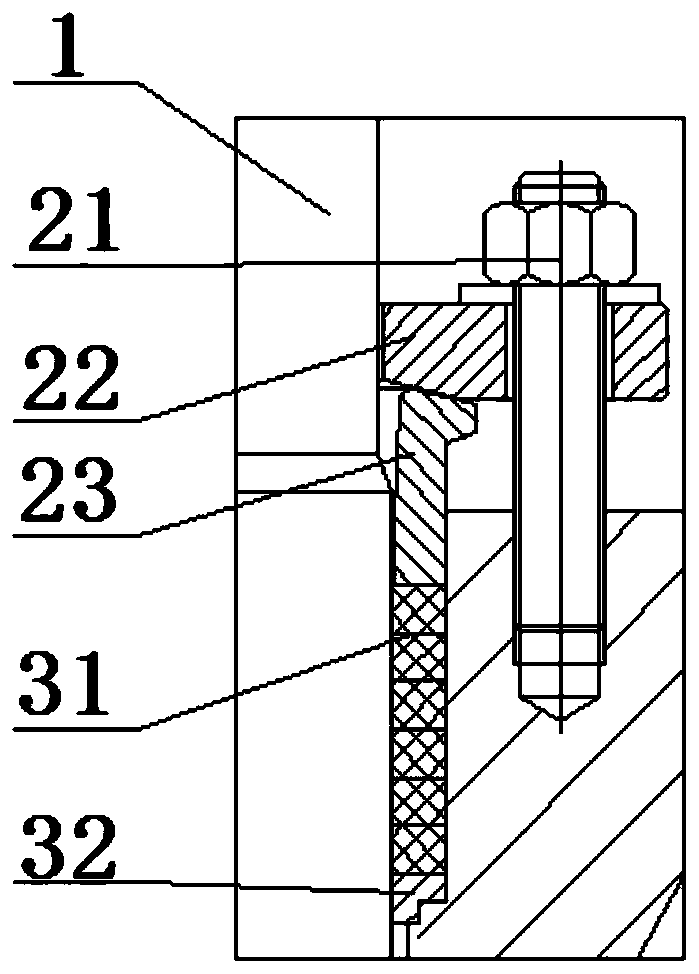

Spring positioning pin device applied to automatic welding line

InactiveCN110081058ASave power and control system costsGuaranteed positioning accuracyGripping headsWelding/cutting auxillary devicesBiomedical engineeringWelding

The invention discloses a spring positioning pin device applied to an automatic welding line. The spring positioning pin device is used for positioning a sheet metal, and the structure is as follows,an adjusting bolt of the spring positioning pin device is installed at the tail part of a sleeve through threads in a screw rod inwards mode; the head of a clamp positioning pin is exposed out of thetop end of the sleeve and is matched in the positioning hole of the sheet metal in the initial state, the tail part is provided with a stage, the clamp positioning pin can retract into the inner cavity of the sleeve and is separated from the positioning hole; one end of the spring is connected to the end of the screw rod, and the other end of the spring is always pressed against the bottom end surface of the stage of the clamp positioning pin; the guide sleeve is arranged between the sleeve and the clamp positioning pin, guide is provided for the axial movement of the clamp positioning pin, and the axial limit of the clamp positioning pin is achieved through the bottom end surface; and a blind hole which is axially arranged is formed in the center of the head of the clamp positioning pin,and the front end of the tail end guide part of a gripper positioning pin can be inserted into the blind hole. According to the spring positioning pin device, the cost is reduced and the positioning precision is improved on the premise that the positioning hole is shared by a gripper and a clamp.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

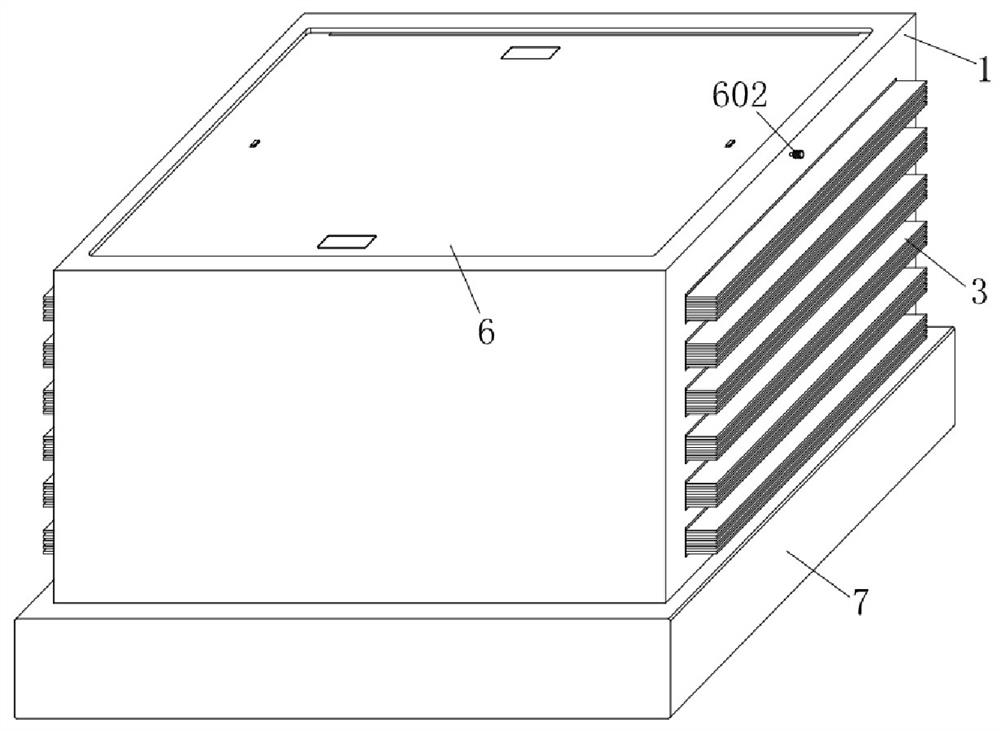

Geological mineral exploration device for layered storage of ore beds with different depths

The invention discloses a geological mineral exploration device for layered storage of ore beds with different depths, and relates to the technical field of mineral exploration devices. The device includes a base, the base is connected with a rotating shaft assembly, the side wall of the rotating shaft assembly is rotationally connected with a conversion plate, the two opposite sides of the conversion plate are both fixedly connected with supporting plates, two oppositely-arranged U-shaped frames are arranged between the two supporting plates, the U-shaped frames are fixedly connected with the conversion plate, one U-shaped frame is connected with a drilling assembly, and the other U-shaped frame is connected with a sampling assembly. The drilling assembly and the sampling assembly are oppositely arranged, the sampling assembly comprises a lifting mechanism and a sampling mechanism, the side walls, away from each other, of the two supporting plates are connected with locking assemblies, and the base is connected with a positioning assembly; therefore, transverse sampling can be carried out on different ore beds of an exploration hole, extracted samples can be independently stored, the sample extraction precision is effectively improved, meanwhile, repeated sampling of workers in different times and groups is avoided, waste of manpower resources is reduced, and the sampling efficiency is improved.

Owner:秦光平

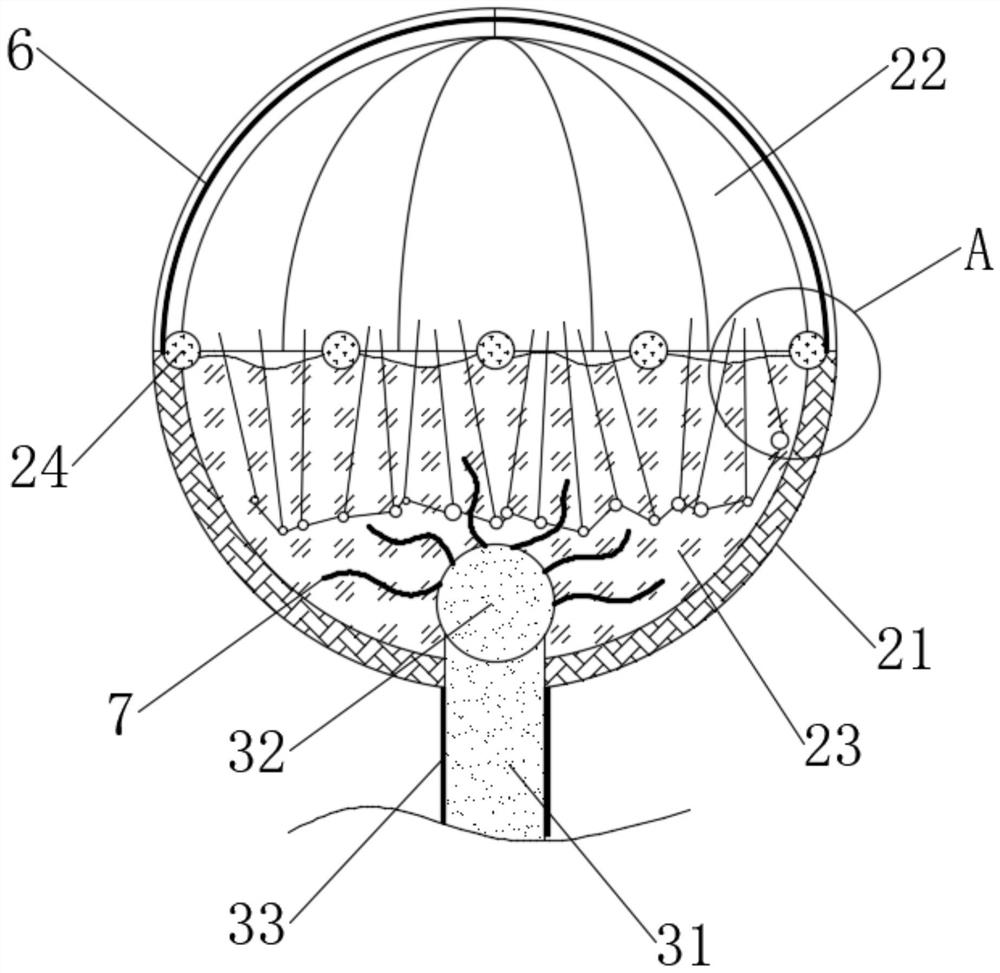

Foam concrete roof insulation board capable of detecting internal humidity and manufacturing method thereof

PendingCN111734056AImprove internal moistureFacilitated DiffusionRoof covering insulationsFoam concretePetal

The invention discloses a foam concrete roof insulation board capable of detecting internal humidity and a manufacturing method thereof and belongs to the technical field of construction. A humidity sensing framework can be introduced into a foam concrete insulation board body. Once water enters the foam concrete insulation board body, the humidity sensing framework can sense humidity quickly andconduct water to a humidity display and damp removal ball. After a water accumulating sponge ball in the humidity display and damp removal ball is diffused autonomously, a display propelling expansionball absorbs moisture to expand, so that a humidity display petal blooms by imitating a flower petal, so that on the one hand, a user can be prompted that the foam concrete insulation board body is affected with damp internally and on the other hand, water diffusion and release of water in the water accumulating sponge ball can be accelerated and an evaporation-assisting water absorbing fluff canbe driven to transfer water outward for efficient evaporation to improve the damp affecting condition in the foam concrete insulation board body based on high frequency jittering by means of a disintegration automatic ball specially arranged in the water accumulating sponge ball as the disintegration automatic ball is disintegrated quickly after encountering with water.

Owner:支琴芳

Explosion-proof fuse and method for manufacturing same

InactiveCN102496536AWill not blast and splashAvoid Soldering ProcessFuse device manufacturePlastic materialsEngineering

The invention discloses an explosion-proof fuse and a method for manufacturing the same. The explosion-proof fuse comprises a shell, a tube, a fuse wire and pins, wherein clamping holes are formed in two ends of the shell; the fuse wire is arranged in the tube; the pins are respectively connected to two ends of the fuse wire and fixedly clamped in the clamping holes; an opening is formed in the sidewall of the shell; and the tube is clamped in the shell. The pins and the fuse wire are combined in a resistance welding or laser welding mode and arranged in the shell which is made of a plastic material, and the fuse wire is arranged in the tube, so that a soldering process is eliminated, the explosion-proof fuse meets a requirement of environment friendliness, and is high in production efficiency and stable in performance, and the tube cannot be burst and spattered when a circuit is short-circuited. By adoption of the method for manufacturing the explosion-proof fuse, the fuse wire and the pins are directly lapped, so that welding middle processes are eliminated, the flow is simple, and the cost is reduced.

Owner:DONGGUAN BETTER ELECTRONICS TECH

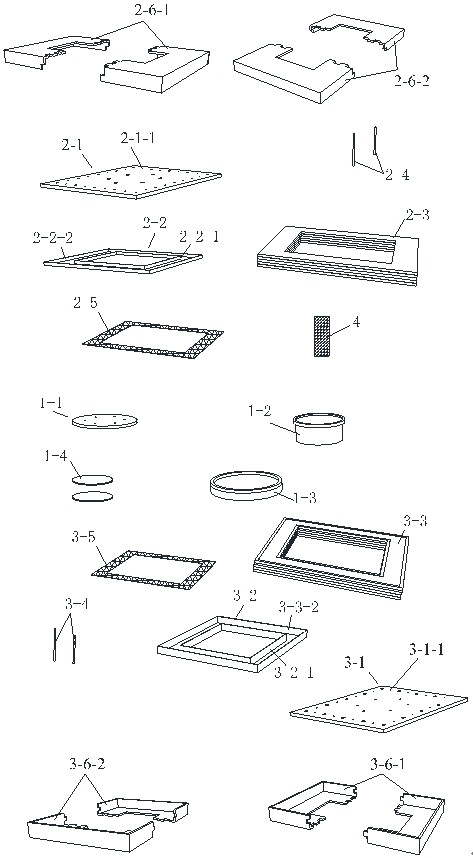

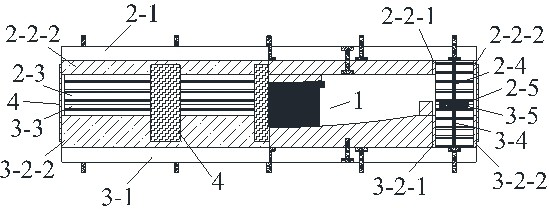

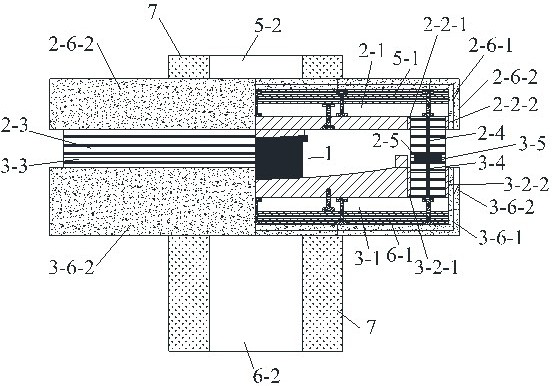

Function achieving method for prefabricated assembly type fireproof friction pendulum bearing

PendingCN111809740AImprove applicabilitySimple designBridge structural detailsProtective buildings/sheltersClassical mechanicsEngineering

The invention relates to a function achieving method for a prefabricated assembly type fireproof friction pendulum bearing. A factory prefabrication method for the bearing comprises the steps that a friction pendulum bearing cover plate is fixed below an upper protection device; a friction pendulum bearing chute is fixed above a lower protection device; and a plurality of side fixed plates are fixed along the peripheries of an upper outer fence and a lower outer fence. A site assembly method for the bearing comprises the steps that a prefabricated assembly type fireproof friction pendulum bearing structure prefabricated in a factory is transported to a use site, a lower cover plate and a lower main body structure are fixed, and an upper main body structure and an upper cover plate are fixed; the multiple side fixed plates arranged on the peripheries of the upper outer fence and the lower outer fence are disassembled; two lower fireproof inner sleeves are inserted together in an abutting mode, two lower fireproof outer sleeves are inserted together in an abutting mode, two upper fireproof inner sleeves are inserted together in an abutting mode, and two upper fireproof outer sleevesare inserted together in an abutting mode. The function achieving method for the integrated prefabricated assembly type fireproof friction pendulum bearing can achieve both shock insulation and fire proof function needs for friction pendulum bearings of different carrying capacities, structures and specifications.

Owner:应急管理部天津消防研究所 +1

Thermocouple protection sleeve convenient for temperature measurement

PendingCN113607294AConvenient temperature measurementLow thermal conductivityThermometer detailsThermometers using electric/magnetic elementsThermocouple deviceMagnetic insulation

The invention discloses a thermocouple protection sleeve convenient for temperature measurement, which comprises a protection sleeve main body and a wiring part heat insulation plug, wherein the overall structure of the protection sleeve main body is a hemispherical circular tube structure with a closed end part, the protection sleeve main body comprises a metal base material layer, a protective layer arranged on the inner edge surface of the metal base material layer and a cladding layer processed by laser cladding on the outer edge surface of the metal base material layer, the cladding layer is coated on the outer edge surface of the side, which faces the closed end, of the protection sleeve main body, the side, which is away from the hemispherical closed end, of the protection sleeve body is in butt joint with the wiring part heat insulation plug, a plurality of sets of heat insulation guide rings for supporting a thermocouple magnetic insulation tube are installed in the protective layer, and a set of hemispherical heat conduction end is installed on the side, which faces the hemispherical closed end, of the protective layer. The thermocouple protection sleeve convenient for temperature measurement is reasonable in structure, the magnetic insulation tube can be easily mounted and dismounted in the protection sleeve, line position heat insulation and protection of the magnetic insulation tube are facilitated, and the thermocouple protection sleeve is recommended to be widely used.

Owner:安徽宏康特种金属材料有限公司

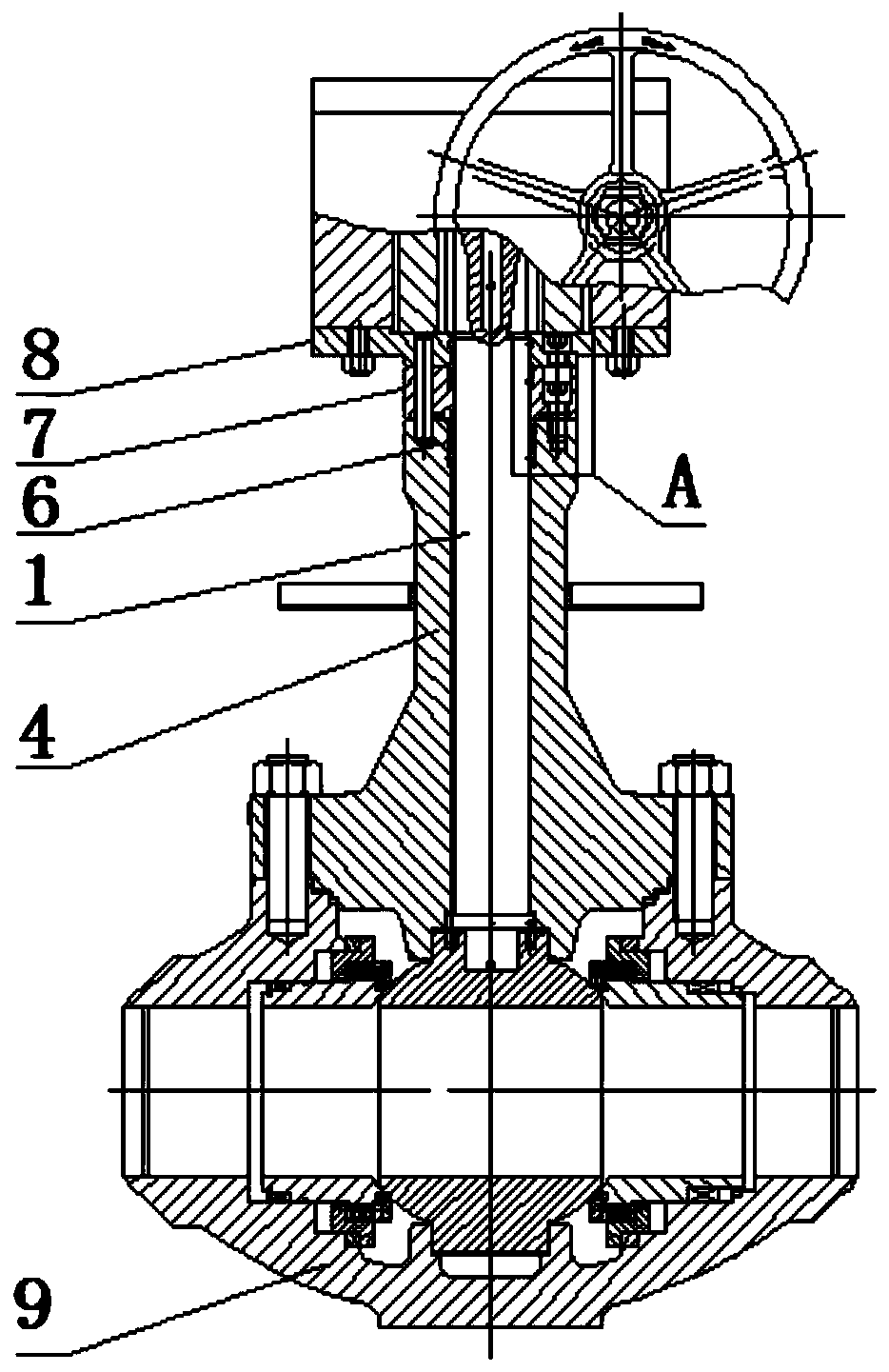

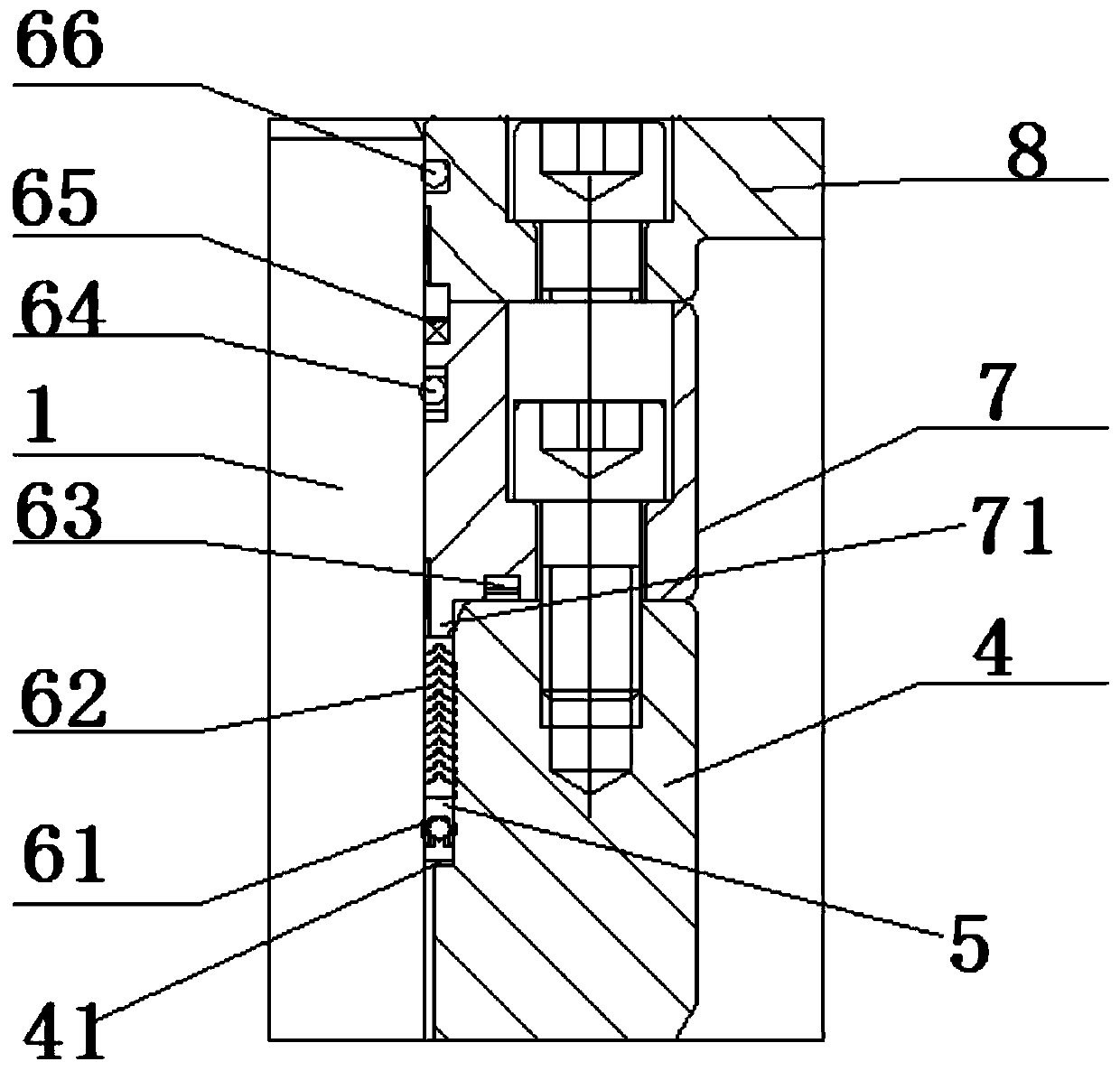

Valve rod sealing structure and valve

PendingCN111255945ASimple structureCompact structureSpindle sealingsPlug valvesLinear motionFriction torque

The invention provides a valve rod sealing structure and a valve. The valve rod sealing structure comprises a valve rod, a valve cover and a spring ring, wherein the valve comprises the valve rod sealing structure; the valve cover sleeves the valve rod; a first annular groove is formed in the inner wall surface of the valve cover; a filler groove is formed between the outer wall of the valve rod and the inner wall of the valve cover; and the spring ring sleeves the valve rod, and is positioned in the filler groove. The valve rod sealing structure with the structure is applied to the valve without needing to arrange a pressing plate and a pressing sleeve, is simple in structure, saves the space, and is compact in structure; the spring ring is deformed by medium force, and the inner side andthe outer side are correspondingly bonded on the valve rod and the valve cover to realize sealing between the valve rod and the valve cover; when the valve rod sealing structure is mounted, pretightening force is not needed to be applied to fillers; when the valve rod performs a rotating motion or a linear motion, the friction torque of the valve rod is low, so that the torque of the valve duringopening and closing is reduced, and the opening and closing power consumption of the valve is reduced; the medium force is high, so that the spring ring is high in stress deformation, and the sealingof the spring ring is more reliable; and the valve rod sealing structure can be used on various valves.

Owner:NEWAY VALVE SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com