Novel vertical type lifting transverse magnetic furnace

A vertical and horizontal magnetic technology, applied in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of no air pressure, water pressure detection and alarm, vertical horizontal magnetic furnace without cooling air duct, unable to adjust the current size, etc. Achieving the effects of enhanced safety, improved production efficiency and product quality, and extensive usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

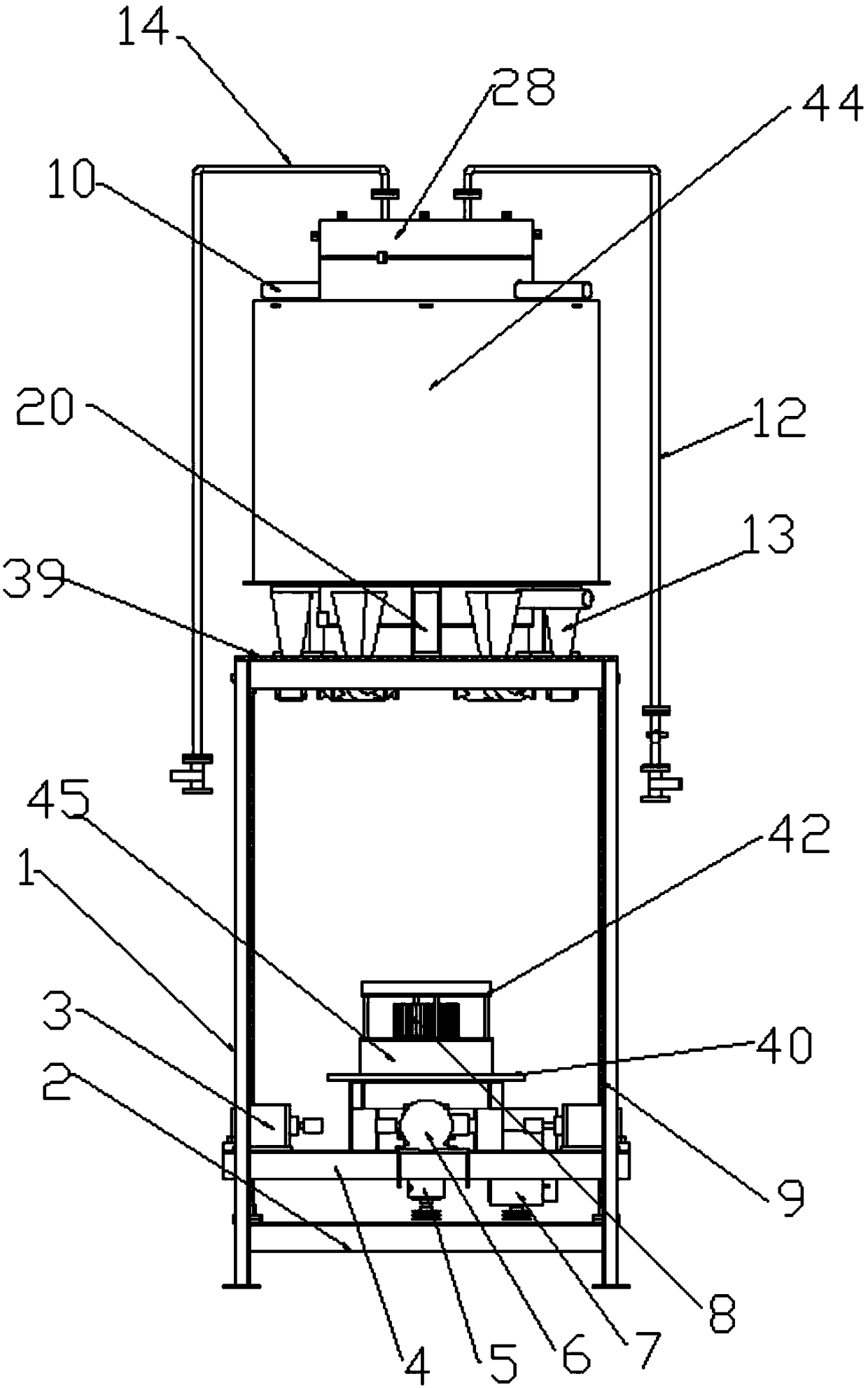

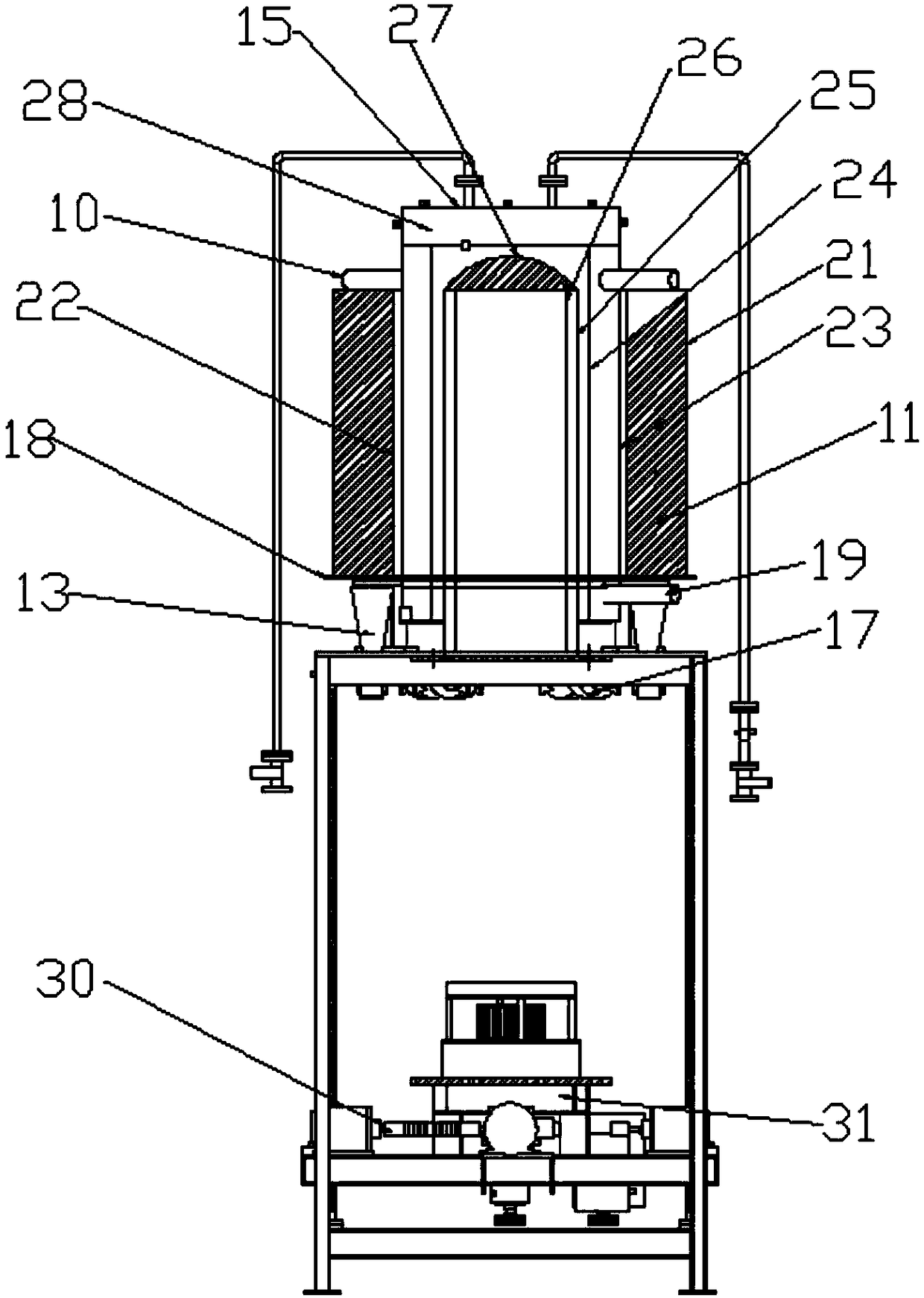

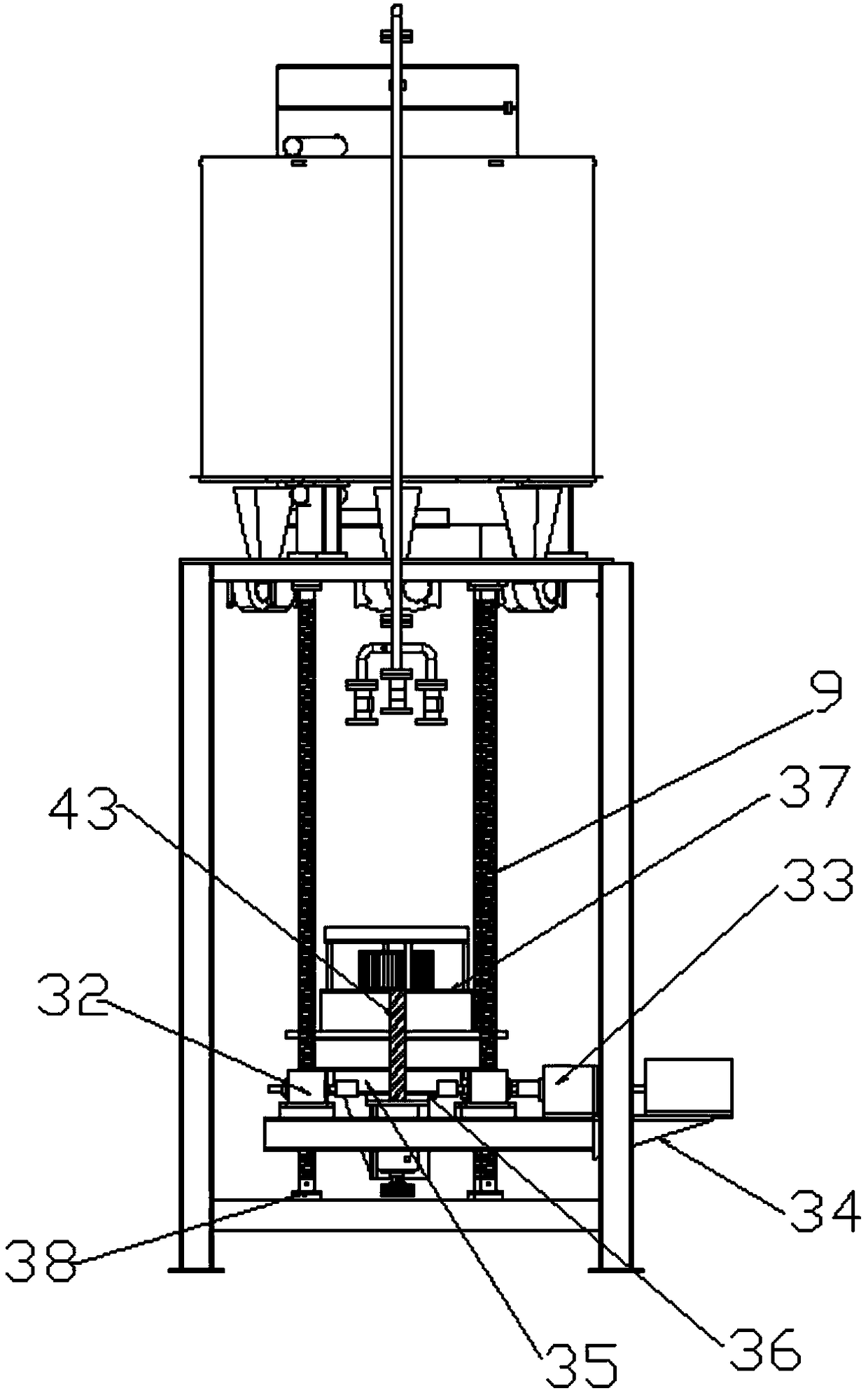

[0049] refer to Figure 1 to Figure 7 A kind of novel vertical lifting transverse magnetic furnace shown, comprises frame 1, furnace body 44, heating device, magnetizing device, lifting device and control cabinet, the top of described frame 1 is provided with a frame plate 39, Body of heater 44 is installed on the frame plate 39, and described heating device and magnetizing device are installed in body of heater 44, and described heating device is heating ceramic sheet (not shown), and magnetizing device is coil 11, and described lifting The device is installed on the frame 1, and the elevating device cooperates with the furnace body 44. The lower end of the frame 1 is provided with a support frame 2, and the support frame 2 is provided with four screw mandrels 9, and the two screw mandrels 9 Each end is provided with a screw mandrel fixing seat 38, and the upper and lower ends of the screw mandrel 9 are fixed on the support frame 2 and the frame 1 by the screw mandrel fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com