Method for connecting electric vehicle battery internal and external tanks, and structure thereof

A technology of electric vehicle battery and connection method, applied in connection, structural parts, electric power device, etc., can solve the problems of difficult processing, burning of connecting components, unfavorable standardization and installation, etc., to enhance safety and reliability, facilitate assembly and The effect of dismantling and avoiding the influence of communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

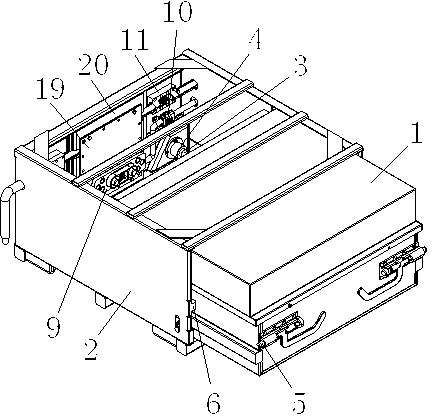

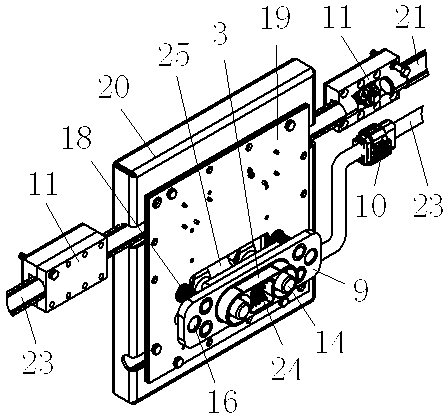

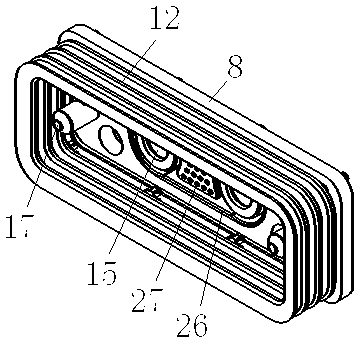

[0026] A method for connecting the inner and outer boxes of electric vehicle batteries, such as figure 1 shown. In this method, the battery inner box 1 is inserted into the battery outer box 2 in a drawer-type structure, and the fast replacement and positioning of the battery inner box 1 are realized through the fixing method that the lock tongue 5 is inserted into the lock hole 6; The elastic limiting seat 3 exerts a pre-thrust force on the battery inner box 1 to slow down the impact force generated by vehicle acceleration or braking; The minimum limit position between them prevents the electrical connectors installed between the battery outer box 2 and the battery inner box 1 from being crushed. The electrical connector includes a socket assembly 9 installed on the inside of the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com