Ceramic optical fibre cold coupler

A ceramic and optical fiber technology, applied in the field of ceramic optical fiber cold splices, can solve the problems of inconvenient optical fiber docking, matching oil pollution, loss, etc., to achieve the effect of easy operation, reduce later failures, and improve assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

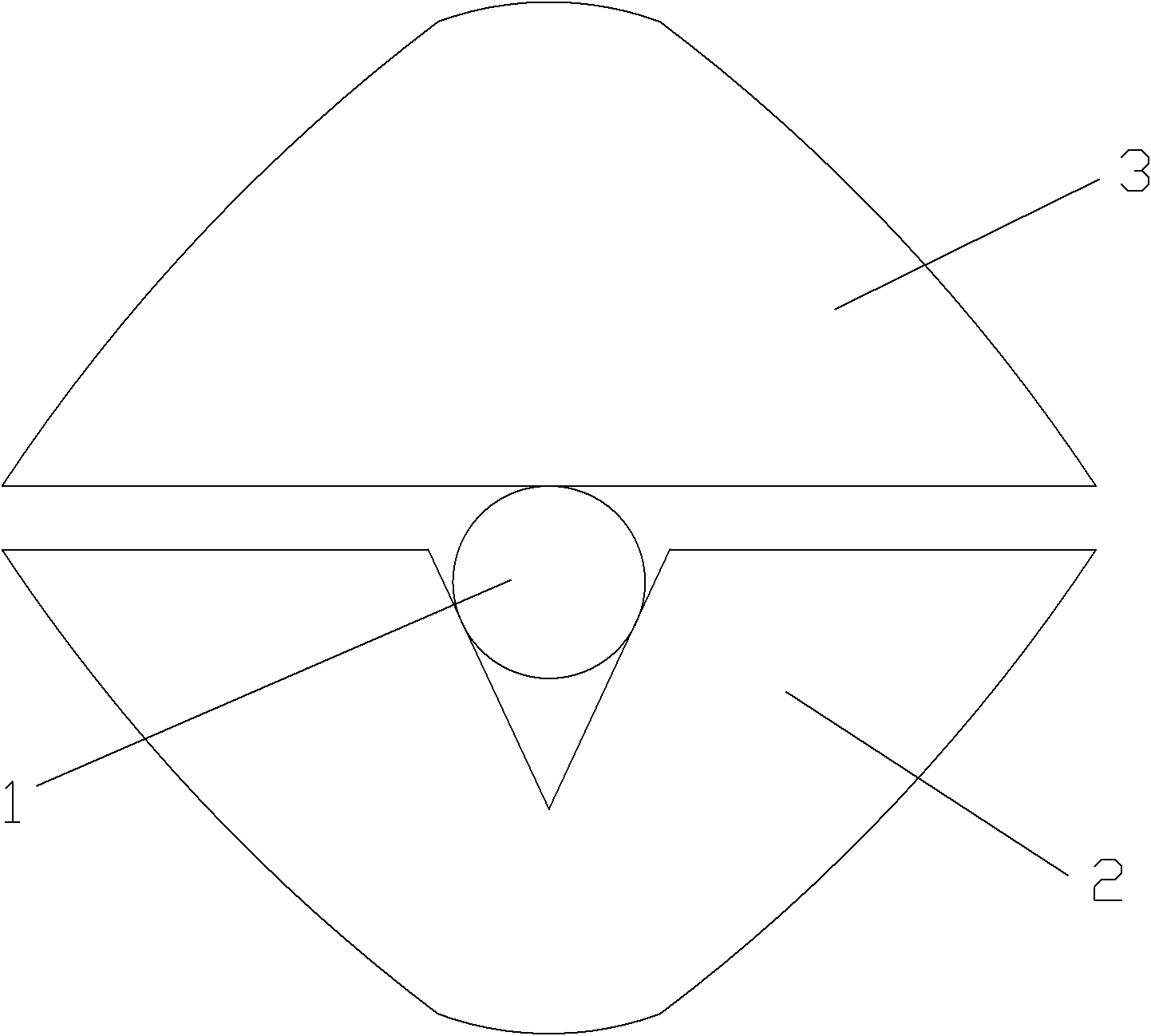

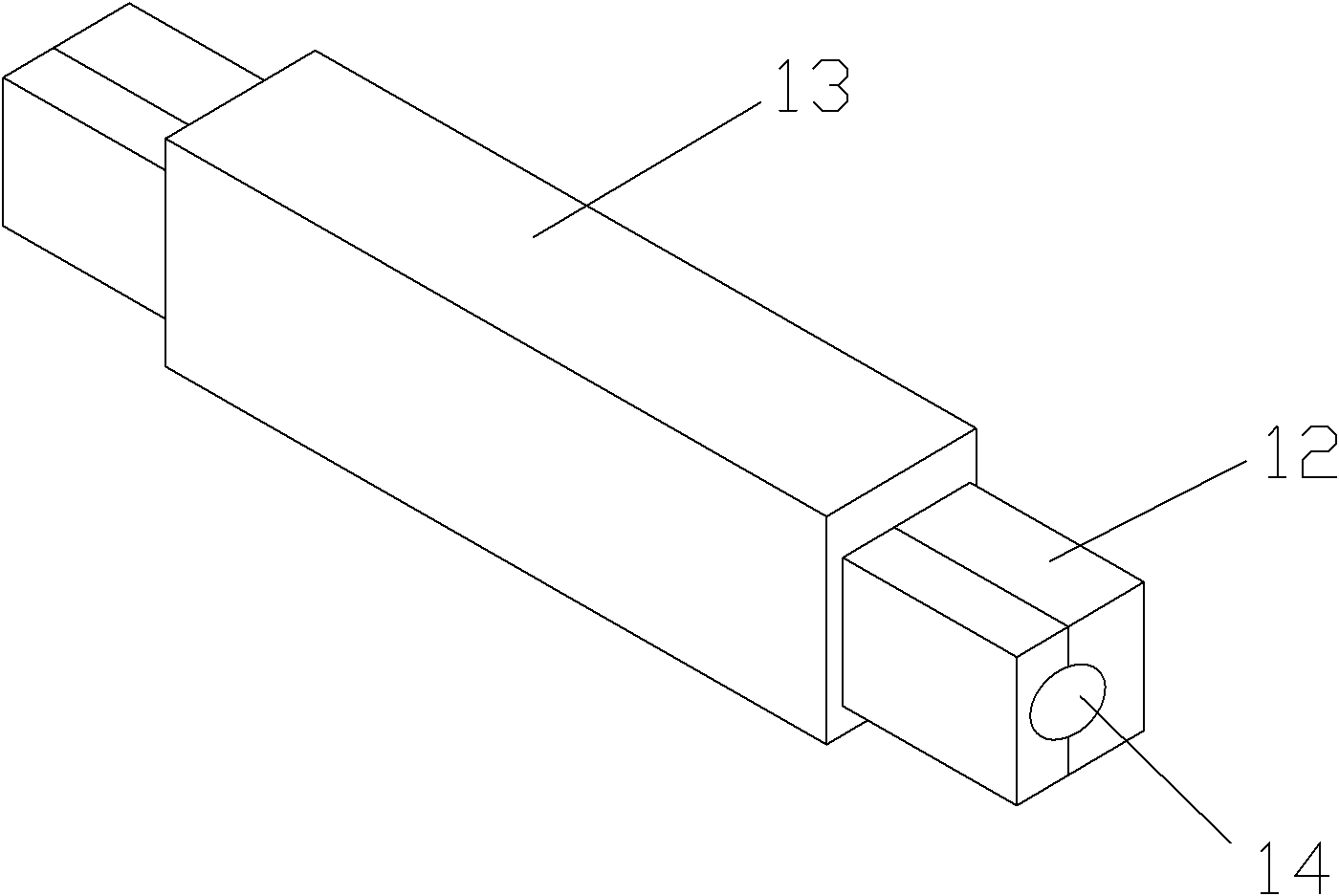

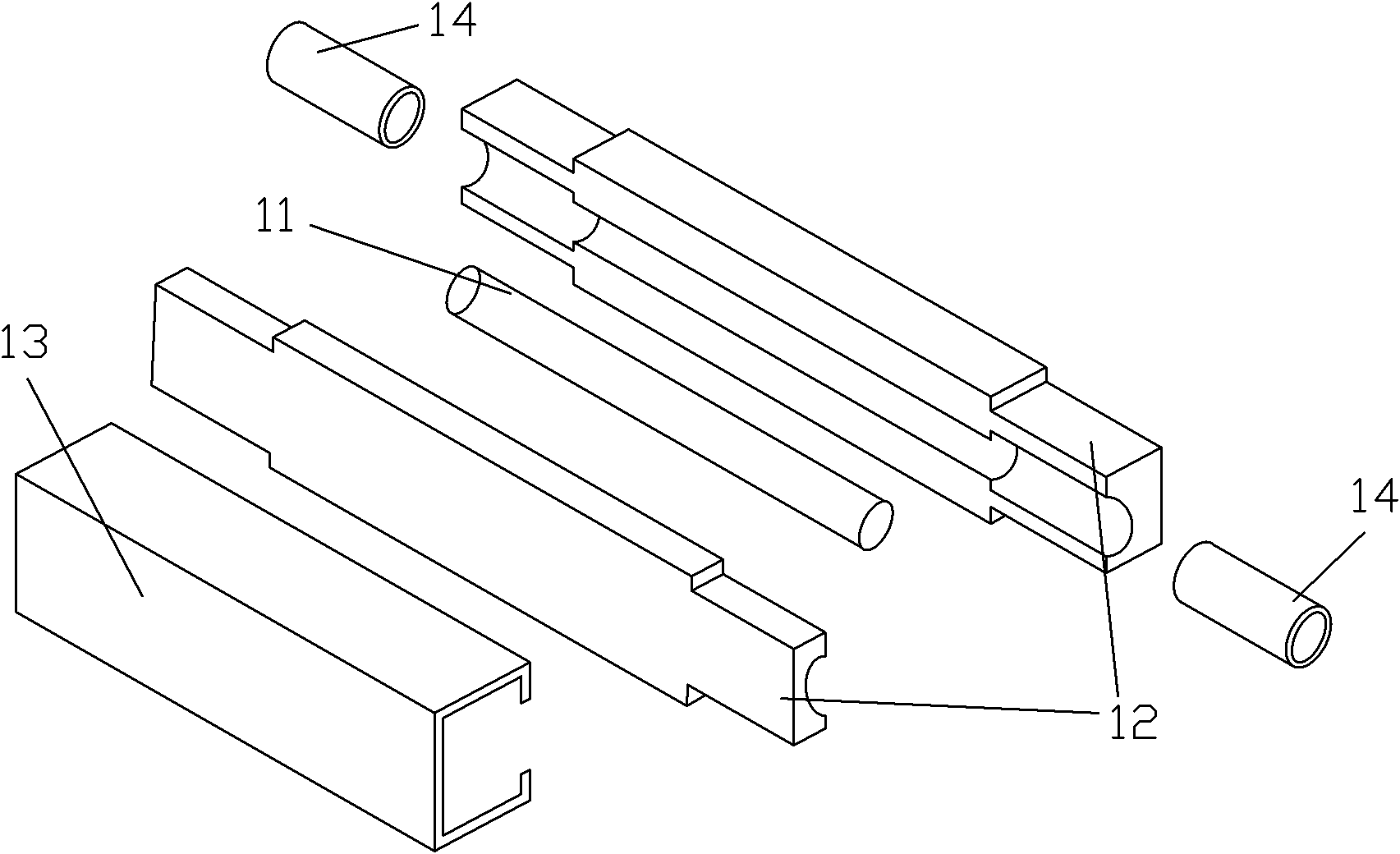

[0014] see figure 2 and image 3 As shown: the ceramic optical fiber cold joint of the present invention includes a ceramic hollow tube 11, a fixing seat 12 and a stainless steel sleeve 13, the fixing base 12 is connected by a Huff structure, the ceramic hollow tube 11 is located in the fixing base 12, and the stainless steel sleeve 13 is set on the outside of the fixed seat 12, and the shape of the inside of the stainless steel sleeve 12 matches the shape of the fixed seat. The ceramic hollow tube 11 is used to fix the optical fiber. After the optical fiber is processed, the ceramic hollow tube 11 is used to meet the docking of its end face. The optical fiber is wrapped in the ceramic hollow tube 11 to achieve low-loss transmission of optical signals. The material is not affected by any environment, so the optical fiber will not be squeezed due to environmental changes inside the ceramic ferrule, so that the optical fiber can achieve a good connection. Moreover, the cerami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com