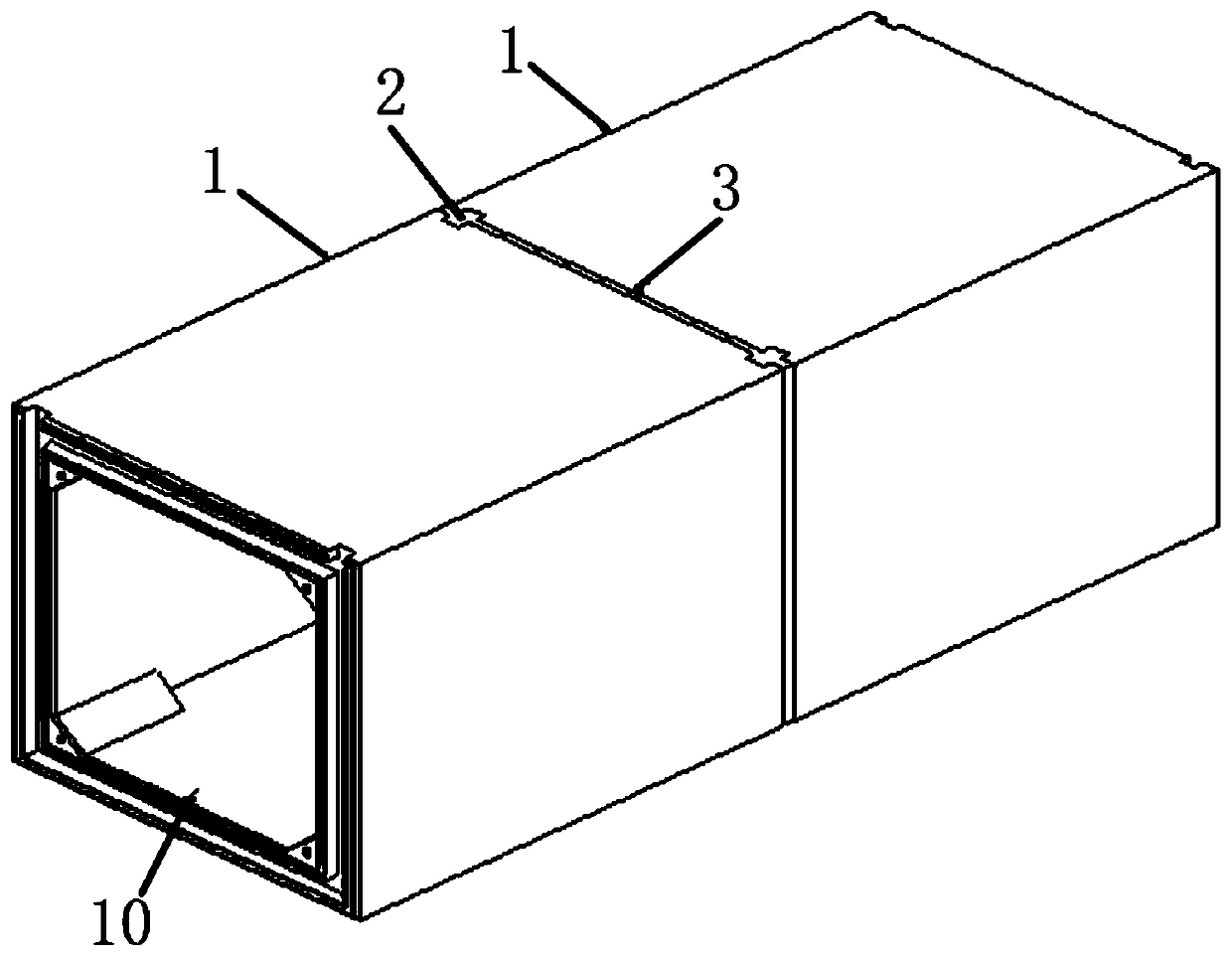

Prefabricated comprehensive pipe gallery joint waterproof connecting structure

A technology for connecting structures and integrated pipe galleries, which is applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as inability to replace, complex underground environment, and easy deformation of waterstops, so as to improve the waterproof effect, The effect of reducing joint deformation and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

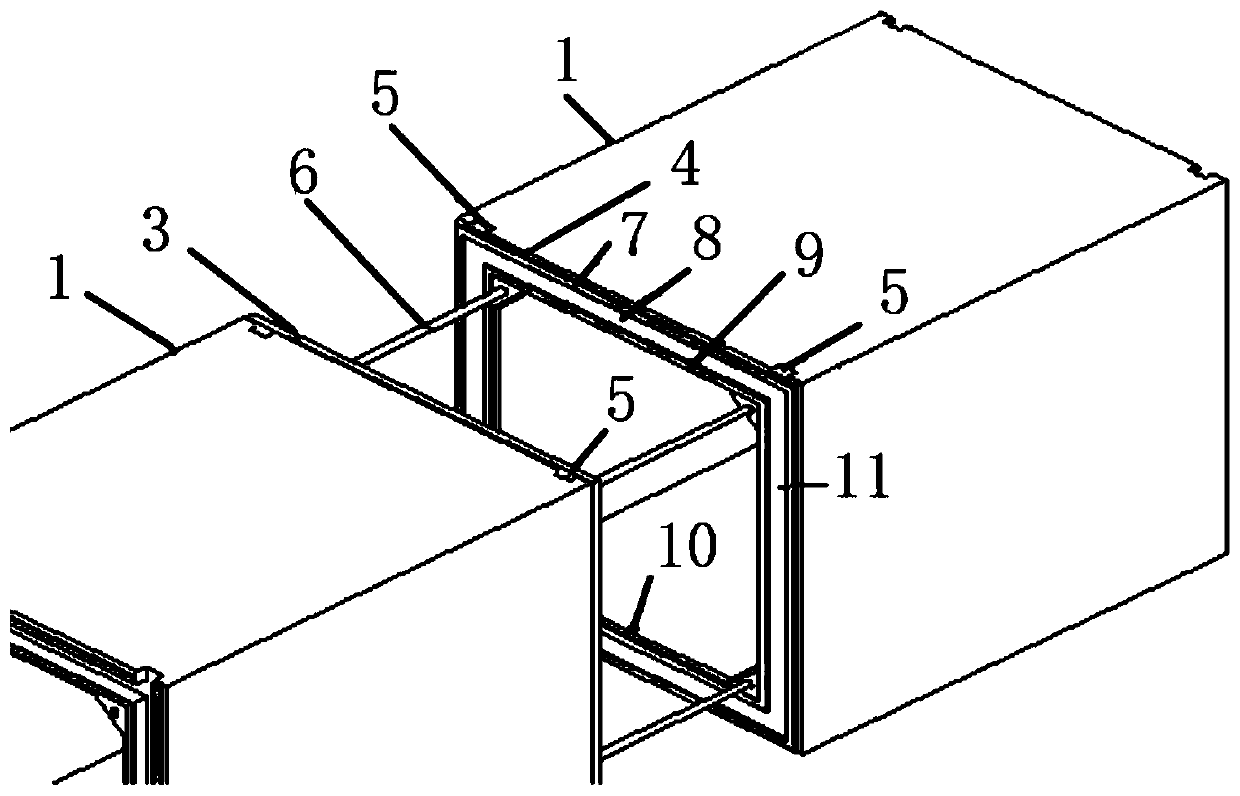

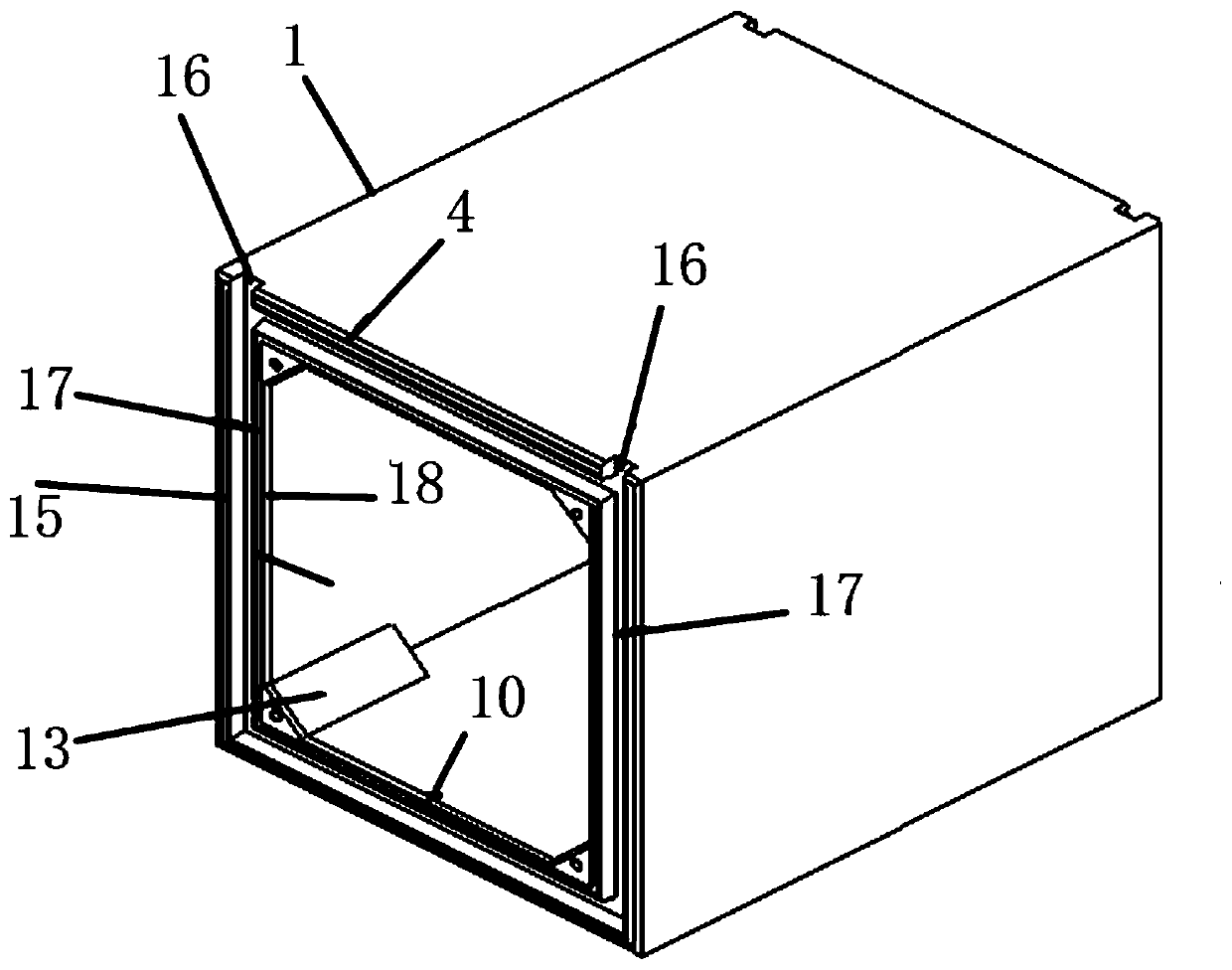

[0034] When the grouting cavity 21 is filled with concrete 11 to form a sealed grouting 8: before the two-section pipe gallery is connected and installed, the end faces of the joints are cleaned, and the external sealing strip grooves 15 on both ends are pasted to expand and stop water when exposed to water Article 7, the inner sealing strip groove 12 is pasted with the water-expanding water-stop strip 9, and then the pipe gallery is butted to ensure that the waterproof strips on the end faces of the two pipe galleries correspond to each other and the inner and outer surfaces of the pipe gallery at the joint are smooth. After the adjustment is completed, put the prestressed tendon in the prestressed tension anchor and fix it with prestressed tension. After the joint is fixed, pump micro-expansion waterproof concrete into the grouting hole 10 below the inner side of the joint, and observe the upper exhaust port 14. When concrete emerges from the upper two exhaust outlets, seal t...

Embodiment 2

[0037] When the inflatable rubber ring 19 is installed in the grouting cavity 21: before the butt joint installation of the two pipe galleries, clean the end faces of the joints, paste the outer water-expandable water-swelling water-stop strips 7 in the outer sealing strip grooves 15 on both ends, and the inner sealing strip grooves In 12, paste the internal water-expanding water-stop strip 9 and fix the inflatable rubber ring 19 in the grouting groove 17 at one end, fix the inflation port of the inflatable rubber ring 19 in the grouting hole 10 below the joint, and then place the The pipe gallery is butted to ensure that the water-swelling water-stop strips on the end faces of the two pipe galleries correspond to each other and the inner and outer surfaces of the pipe gallery at the joint are smooth. The prestressed tension is fixed, and after the joint is fixed, pump air, powder waterproof material or micro-expansion waterproof concrete into the inflatable rubber ring 19 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com