Function achieving method for prefabricated assembly type fireproof friction pendulum bearing

A friction pendulum support and prefabricated assembly technology, which is applied in the direction of fire prevention, earthquake resistance, protective buildings/shelters, etc., can solve the problems of low reliability, lack of shock-isolation friction pendulum support, and failure to meet the requirements of friction pendulum support before leaving the factory. Issues such as temporary fixes are required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

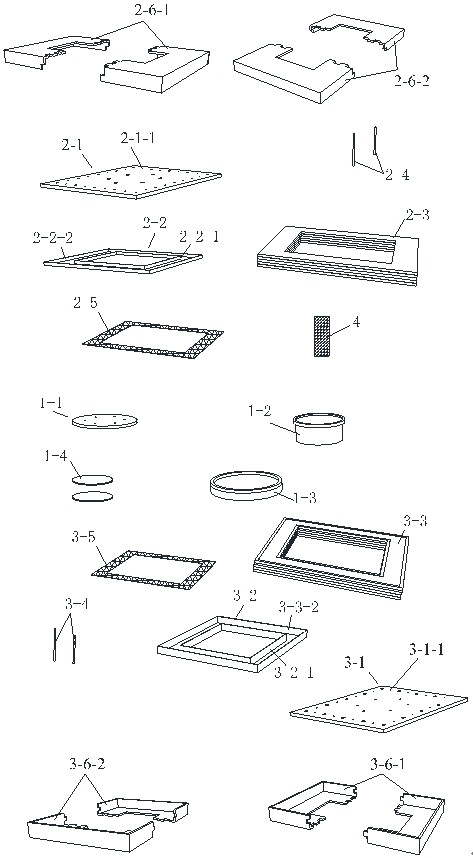

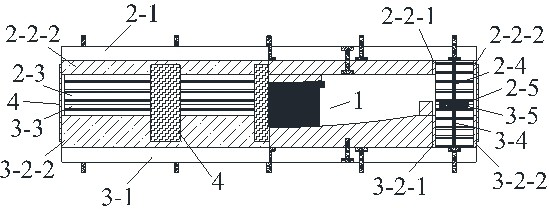

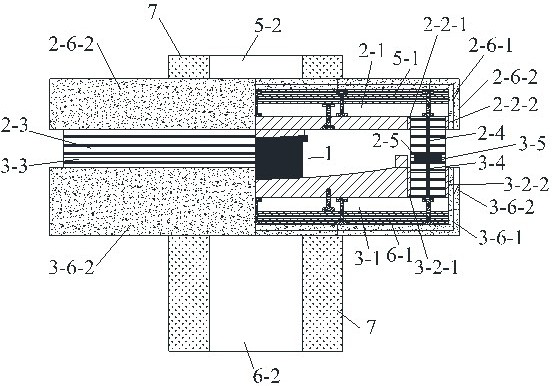

[0073] Such as Figure 1 to Figure 15 As shown, a method for realizing the function of a prefabricated fireproof friction pendulum support, the fireproof friction pendulum support includes a friction pendulum support 1, an upper main body structure 5, and a lower main body structure 6;

[0074] The friction pendulum support 1 is composed of a cover plate 1-1, a slider 1-2, a chute 1-3, and a polytetrafluoroethylene sliding pad 1-4. The center of the bottom surface of the cover plate 1-1 is a raised column, and the raised column The end face of the chute is a convex arc surface Ⅰ1-1-1, the inner surface of the chute 1-3 is a concave arc surface Ⅰ1-3-1, the slider 1-2 is a cylinder, and the upper end of the slider 1-2 is a concave arc surface Ⅱ1-2 -1, the lower end of the slider 1-2 is a convex arc surface II1-2-2, the convex arc surface I1-1-1 of the cover plate 1-1 has the same curvature as the concave arc surface II1-2-1 of the slider 1-2, The concave arc surface Ⅰ1-3-1 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com