Quick joint for liquid pipeline

A liquid pipeline, fast technology, applied in the direction of pipe/pipe joint/pipe fitting, threaded connection, sleeve/socket connection, etc., can solve the problems of relative inclination of joint 1 and female joint 2, poor sealing of liquid pipeline quick joint, etc. To save time, improve installation efficiency and improve sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

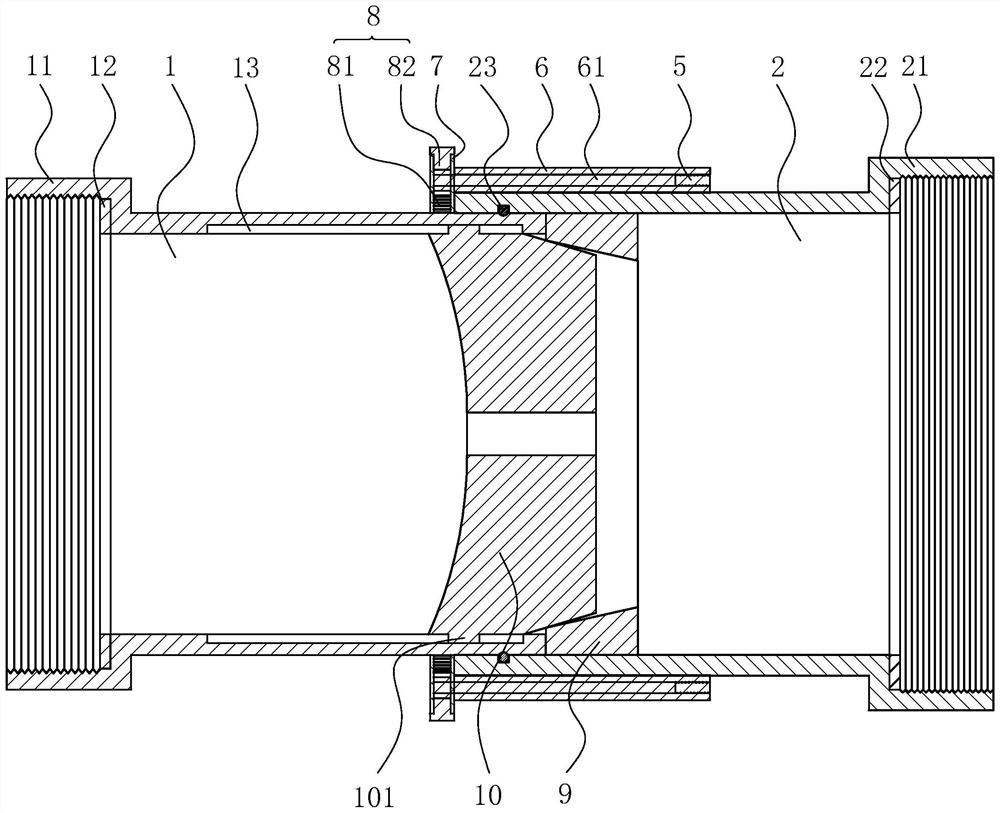

[0035] The following is attached Figure 2-3 The application is described in further detail.

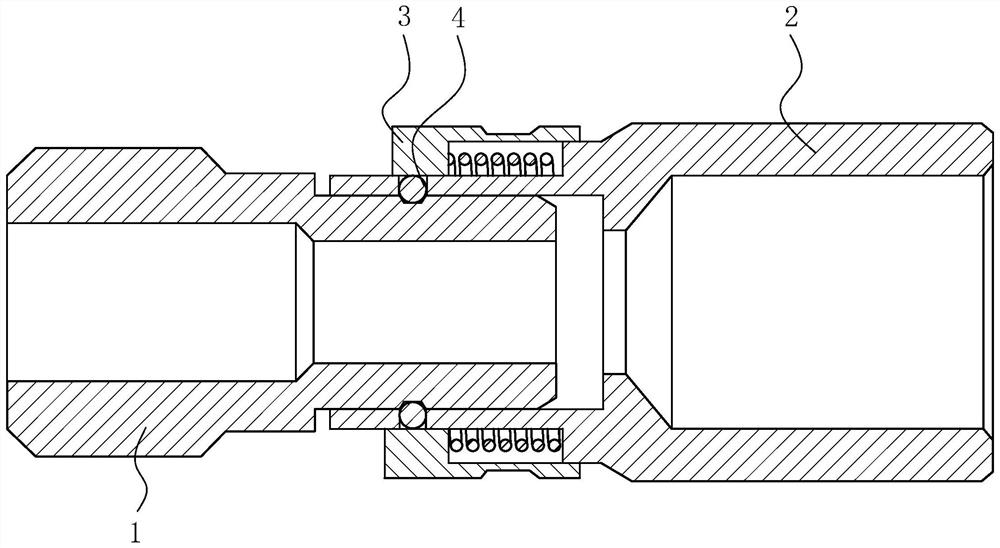

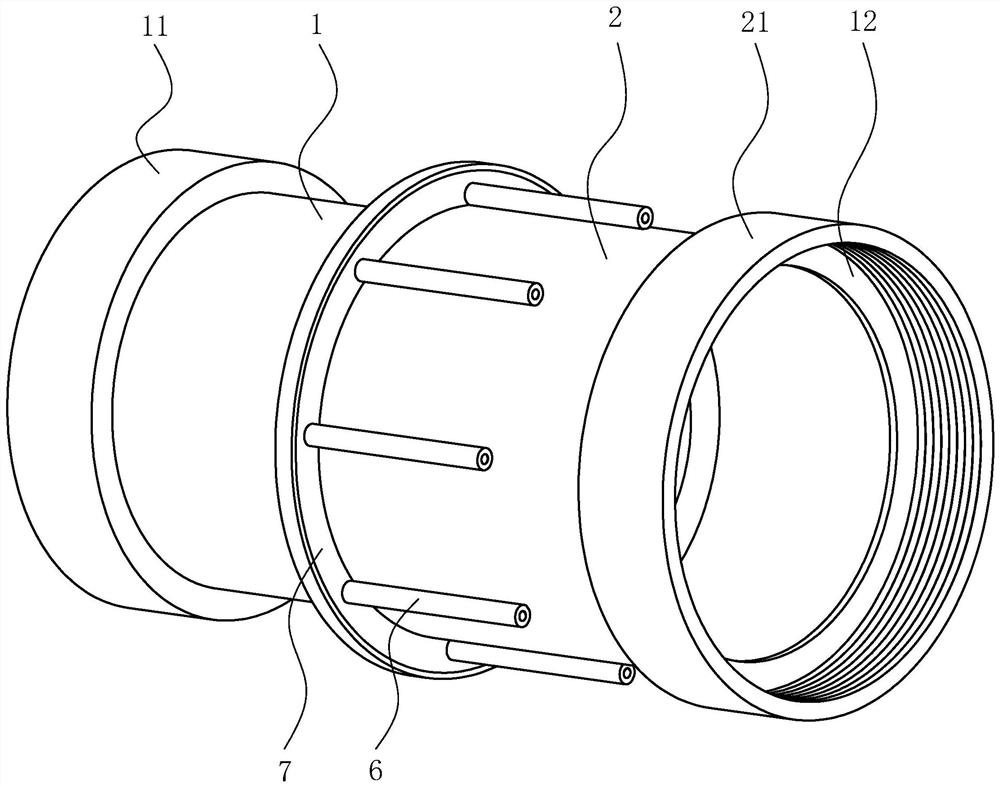

[0036] The embodiment of the present application discloses a liquid pipeline quick connector, which is used to be installed between adjacent ends of two liquid pipelines. refer to figure 2 , the liquid pipeline quick connector includes a male connector 1 and a female connector 2, the male connector 1 is parallel to the female connector 2, the male connector 1 and the female connector 2 are both round tubes, and one end of the male connector 1 is detachably fixedly connected to one end of the female connector 2 Inside, the two ends of the male joint 1 and the female joint 2 that are far away from each other are respectively detachably and sealingly connected to the adjacent ends of the two liquid pipes. During use, first install the adjacent ends of the two liquid pipes on the male joint 1 and the female joint 2 respectively, then insert the male joint 1 into the female joint 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com