Fitting member

A technology of parts and engaging parts, which is applied to vehicle parts, elastic suspensions, cantilevers mounted on pivots, etc., can solve the problems of dimensional tolerances, clutter, and the inability of the engaging surfaces to fit closely, and achieve a simple structure, Reliable and close contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

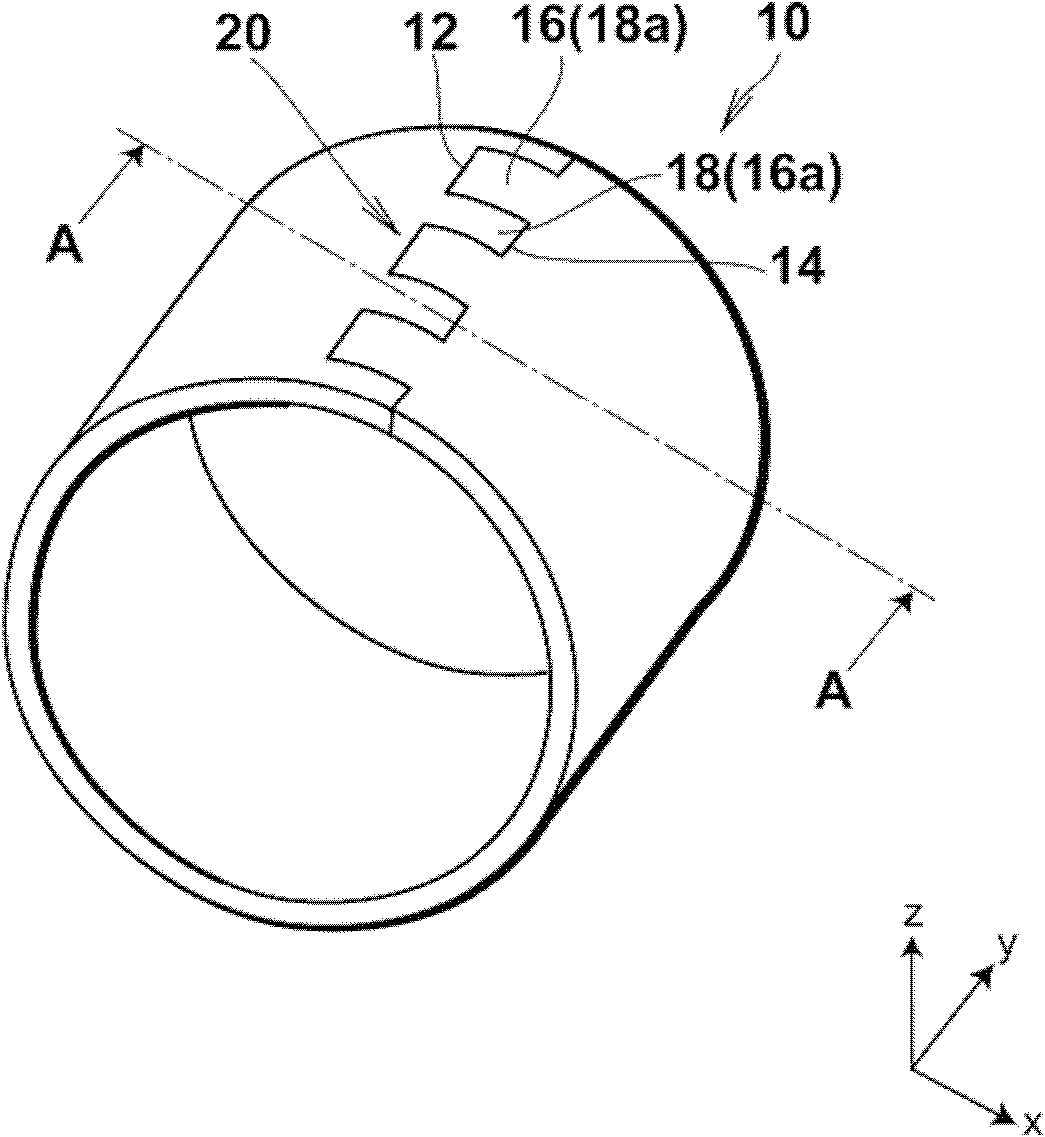

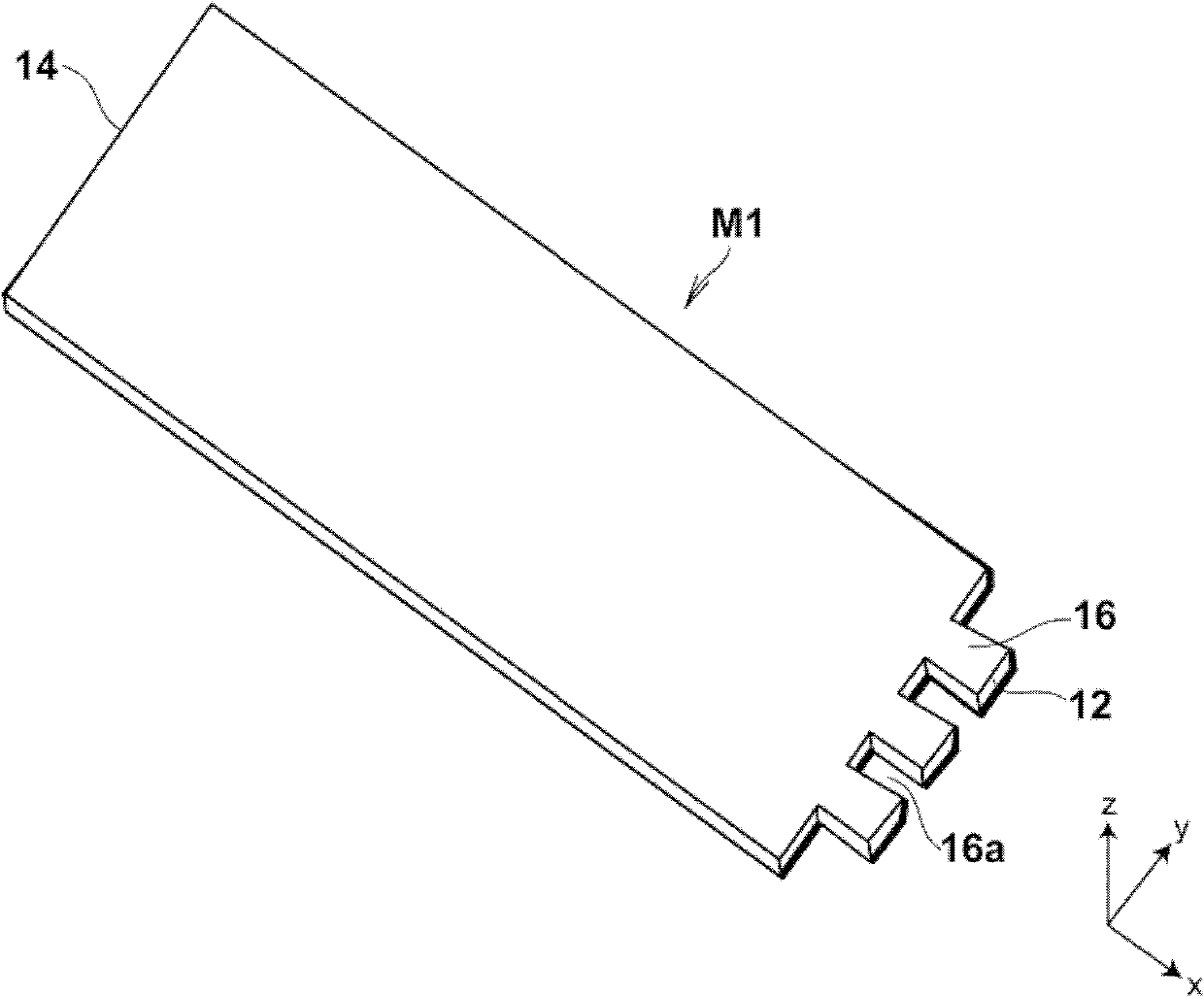

[0040] First, refer to figure 1 - Fig. 5 The collar of the first embodiment of the present invention will be described in detail.

[0041] figure 1 It is a perspective view of the collar of this embodiment.

[0042] Such as figure 1As shown, a cylindrical collar 10 made of metal such as iron or aluminum having a central axis in a direction parallel to the y-axis has one end 12 and the other end opposite to each other in the circumferential direction. 14. Here, when the collar 10 is a cylindrical member, it may have a square cylindrical shape other than a cylindrical one, and the cross-sectional shape cut in the x-z plane may be asymmetrical.

[0043] More specifically, one end portion 12 of the collar 10 has a plurality of protrusions 16 aligned in the axial direction, and recesses 16 a are formed correspondingly between the protrusions 16 . Here, when the protrusions 16 located at both ends in the axial direction have remaining portions adjacent to the outer side in the ...

no. 2 Embodiment approach

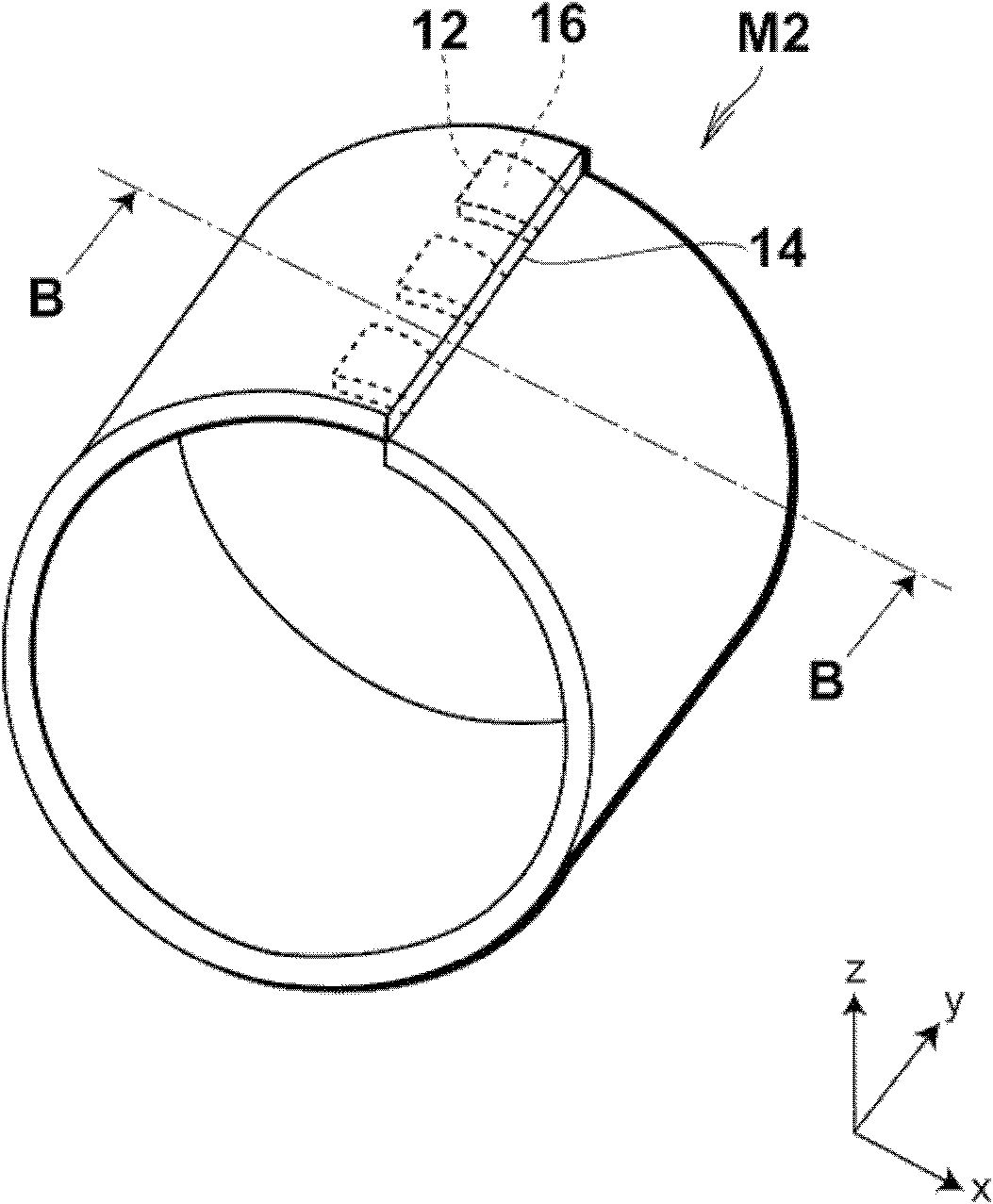

[0065] Next, refer to Figure 6 - Fig. 9 The collar of the second embodiment of the present invention will be described in detail.

[0066] Figure 6 It is a perspective view of the collar of this embodiment.

[0067]The main difference between the collar 100 of this embodiment and the first embodiment is that the structure of the fitting structure 120 is different, and the rest of the structure is the same. Therefore, in this embodiment, description will be made focusing on this difference, the same reference numerals will be attached to the same configuration, and the description will be simplified or omitted as appropriate.

[0068] Specifically, as Figure 6 As shown, the collar 100 has end portions opposite to each other in the circumferential direction, that is, one end portion 112 and the other end portion 114, and the one end portion 112 and the other end portion 114 are in contact with each other. 116. An engaging piece 118 made of metal such as iron or aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com