Valve rod sealing structure and valve

A technology of sealing structure and valve stem, which is applied to shaft seals, valve details, valve devices, etc., can solve the problems of easy failure and leakage of the valve stem sealing structure, large power consumption required for valve action, etc., and achieves simple structure and compact valve structure. , The effect of valve sealing performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

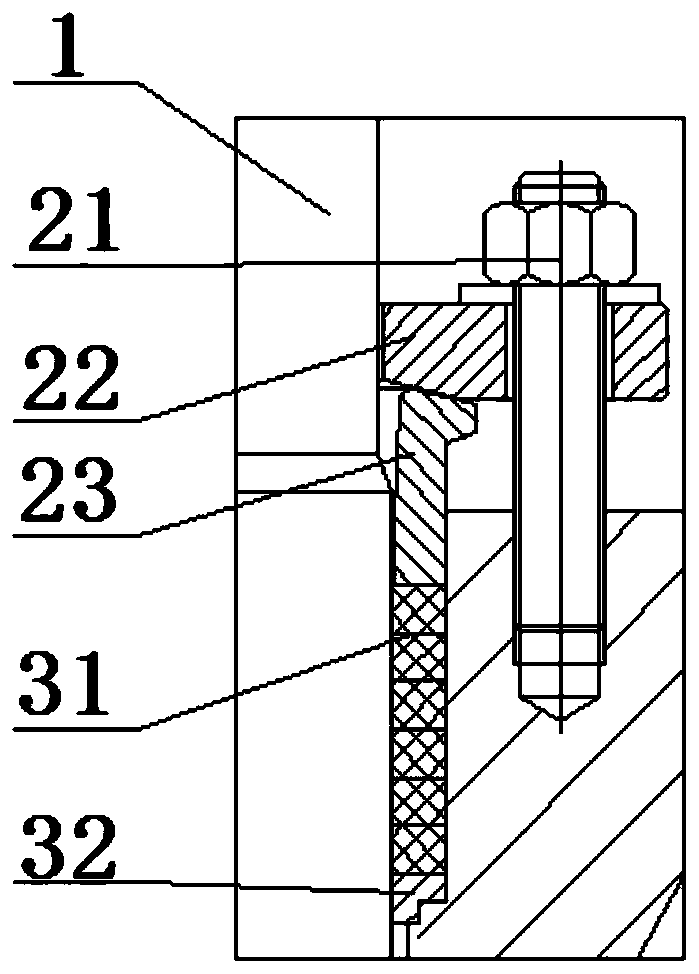

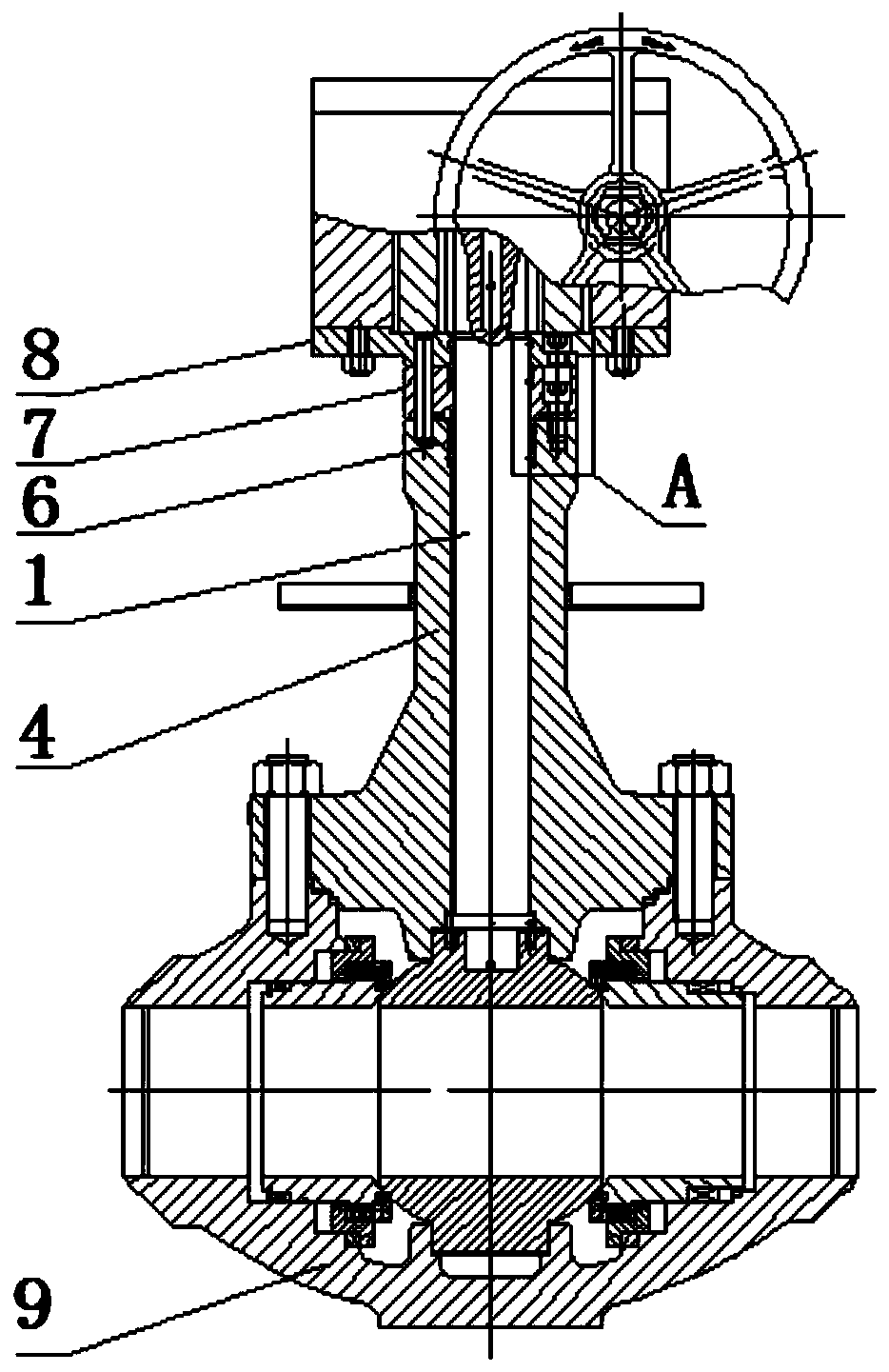

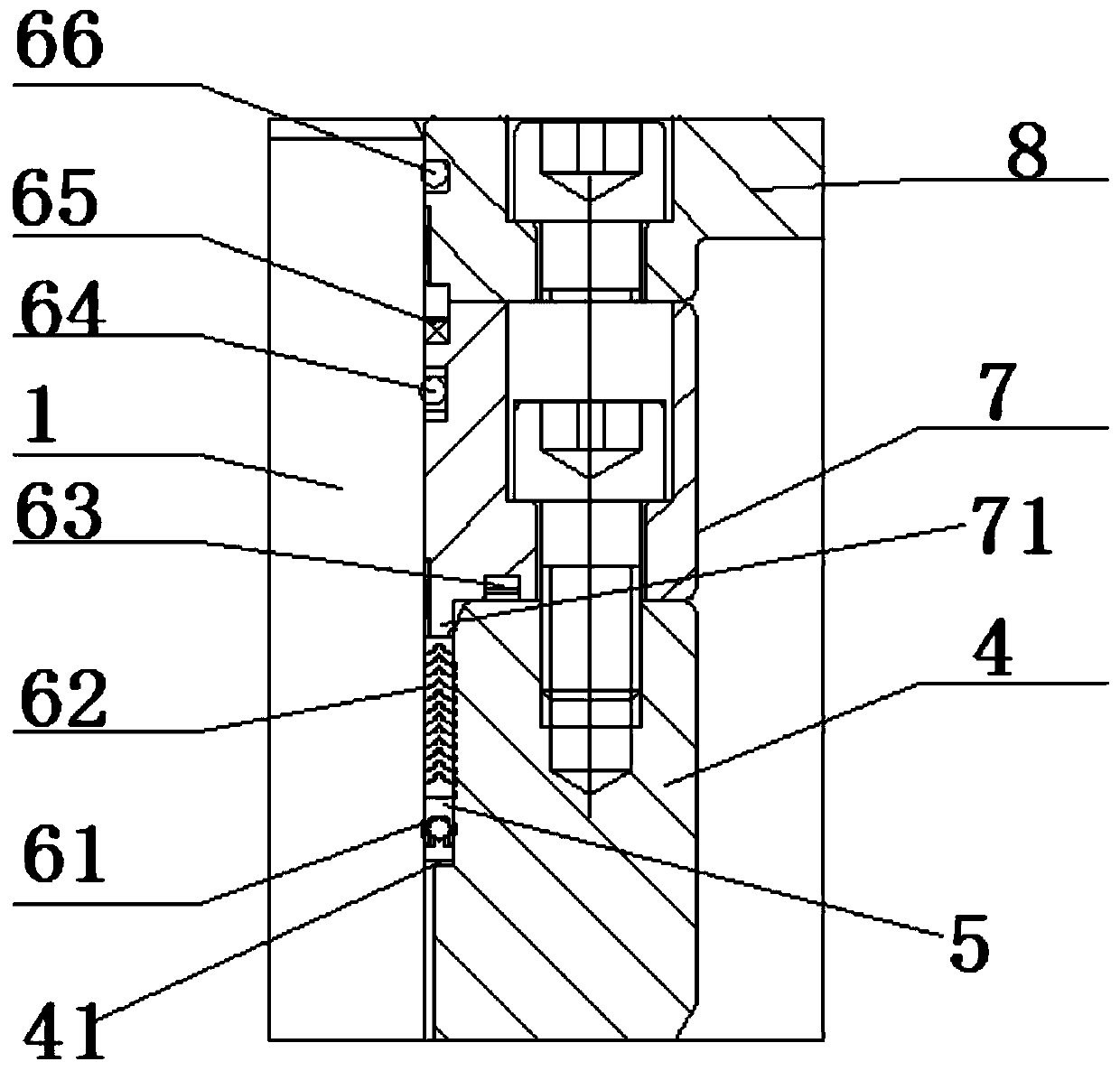

[0033] This embodiment provides a valve stem sealing structure, such as figure 2 As shown, it includes a valve stem 1 , a valve cover 4 and a pan-seal ring 61 .

[0034] Among them, the valve cover 4 is set outside the valve stem 1; the inner wall of the valve cover 4 has a first annular groove 41, and a packing groove 5 is provided between the outer wall of the valve stem 1 and the inner wall of the valve cover 4; the first annular groove 41 It is surrounded with the valve stem 1 to form a stuffing groove 5;

[0035] The valve stem sealing structure of this structure is applied to the valve without setting the pressure plate 22 and the pressure sleeve 23. The structure is simple and saves space, making the valve structure compact; the medium circulating in the valve body generates a medium force, and the medium force acts from bottom to top For the Variseal ring 61, the Varioseal ring 61 is deformed by force, and its inner and outer sides are respectively attached to the va...

Embodiment 2

[0054] This embodiment provides a ball valve, such as figure 2 As shown, it includes the valve body 9 and the valve stem sealing structure in Embodiment 1.

[0055] There is no need to set the pressure plate 22 and the pressure sleeve 23 in the ball valve, the structure is simple, the space is saved, and the valve structure is compact; when the valve is installed, there is no need to apply pretightening force to the packing first, and the friction torque of the valve stem 1 is small when the valve is opened and closed, and the power consumption is small; The greater the medium pressure, the better the valve sealing performance.

[0056] As a modification, the valve stem sealing structure in Embodiment 1 can also be applied to other sealing structures, such as gate valves or butterfly valves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com