Patents

Literature

37results about How to "Avoid soldering process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

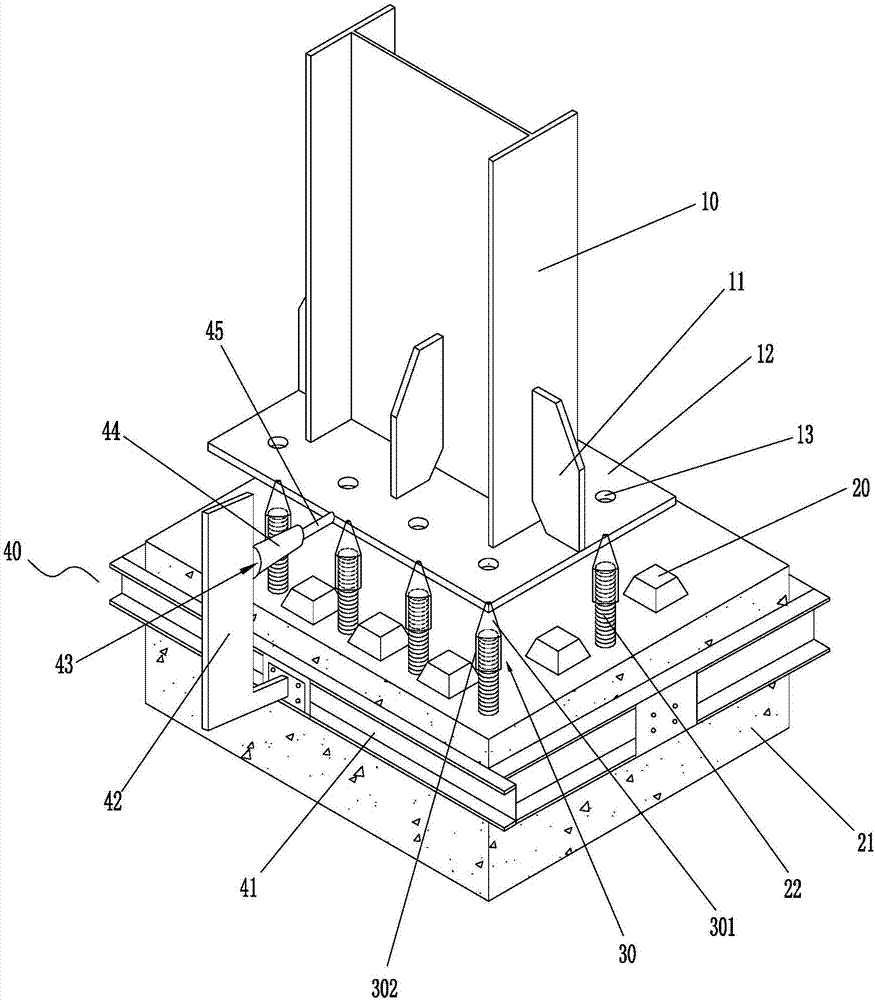

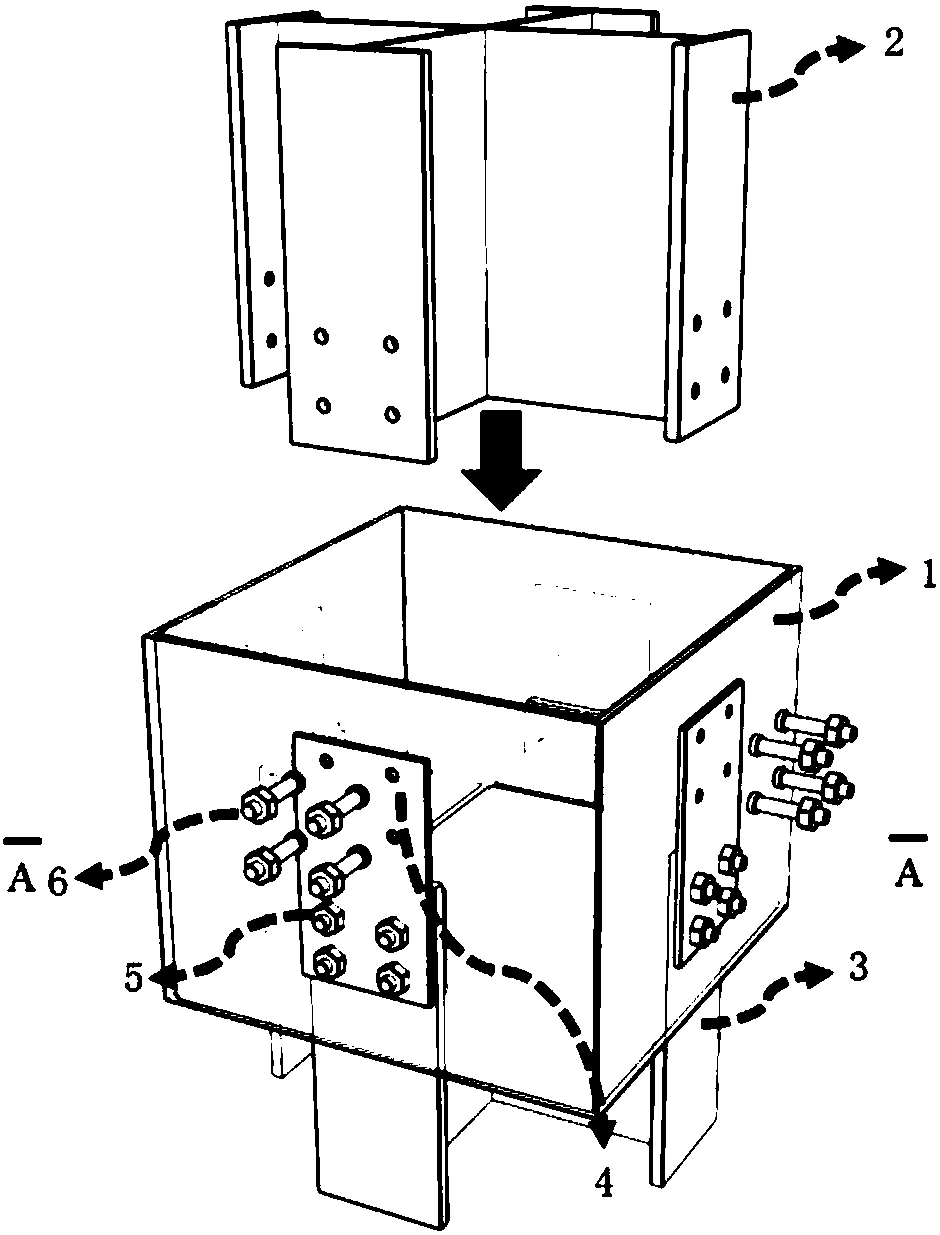

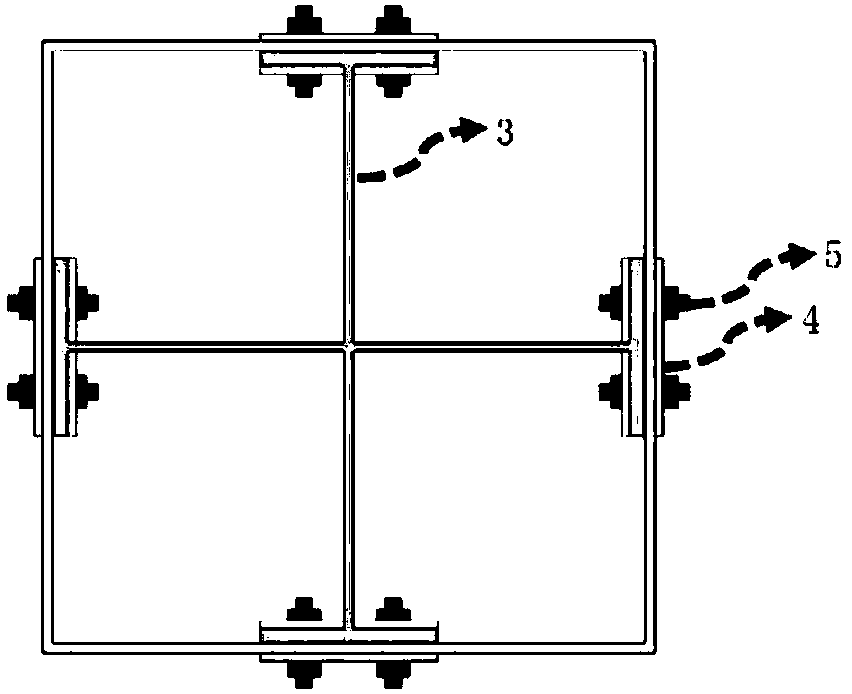

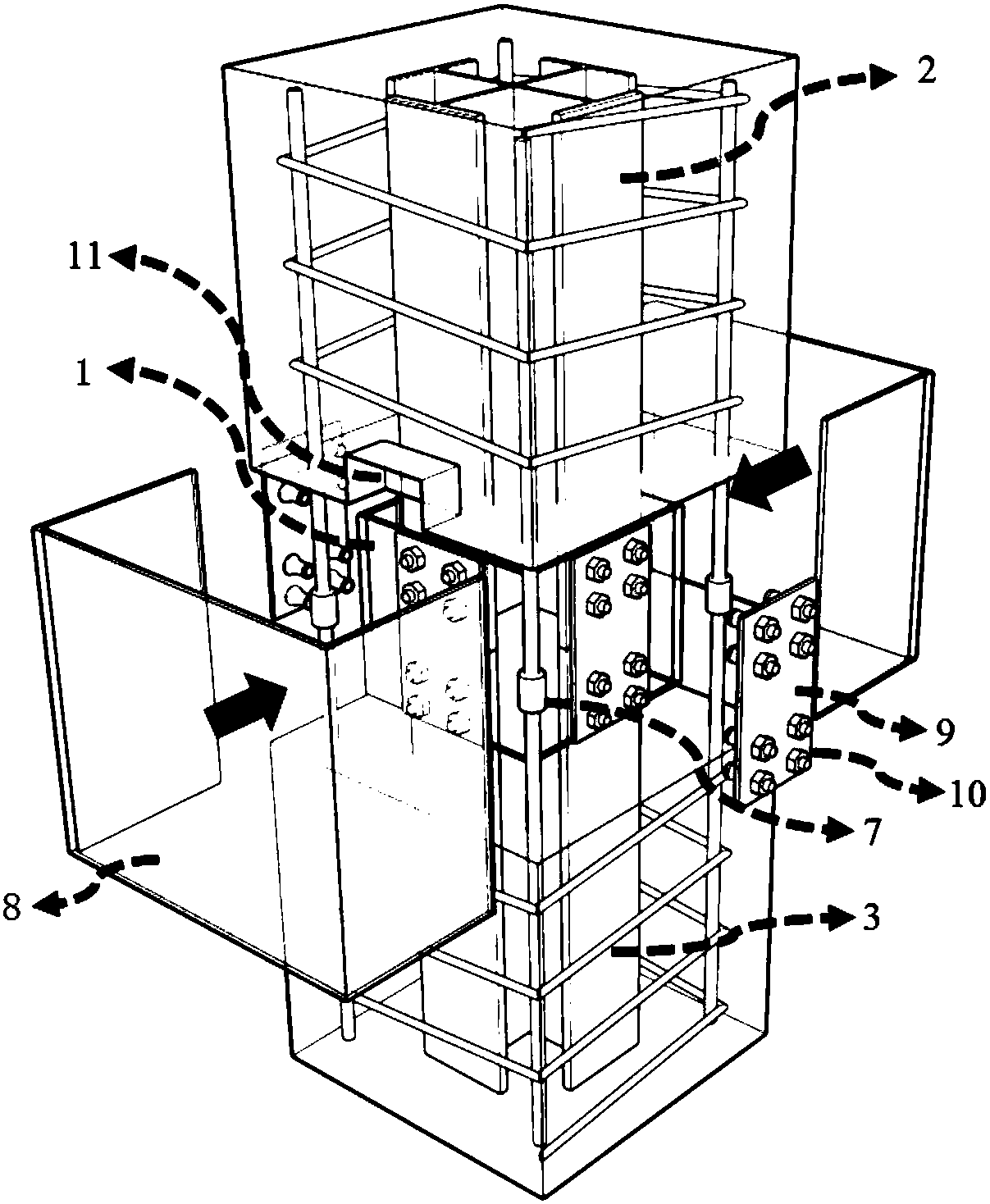

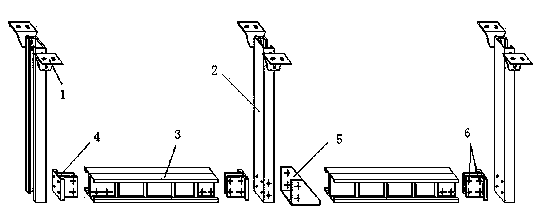

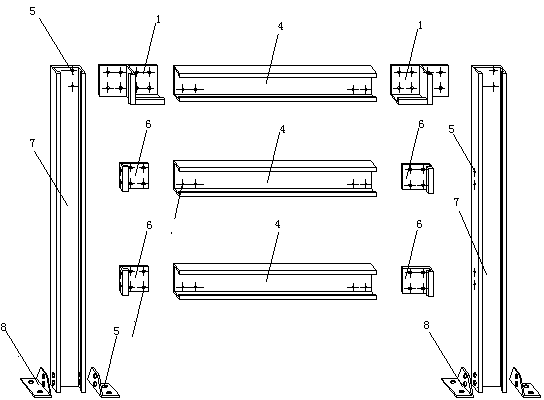

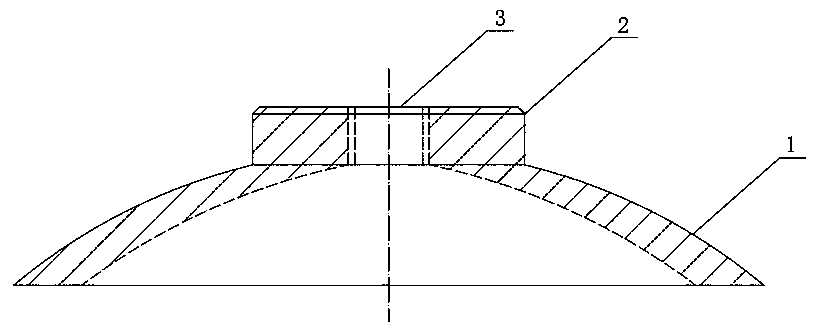

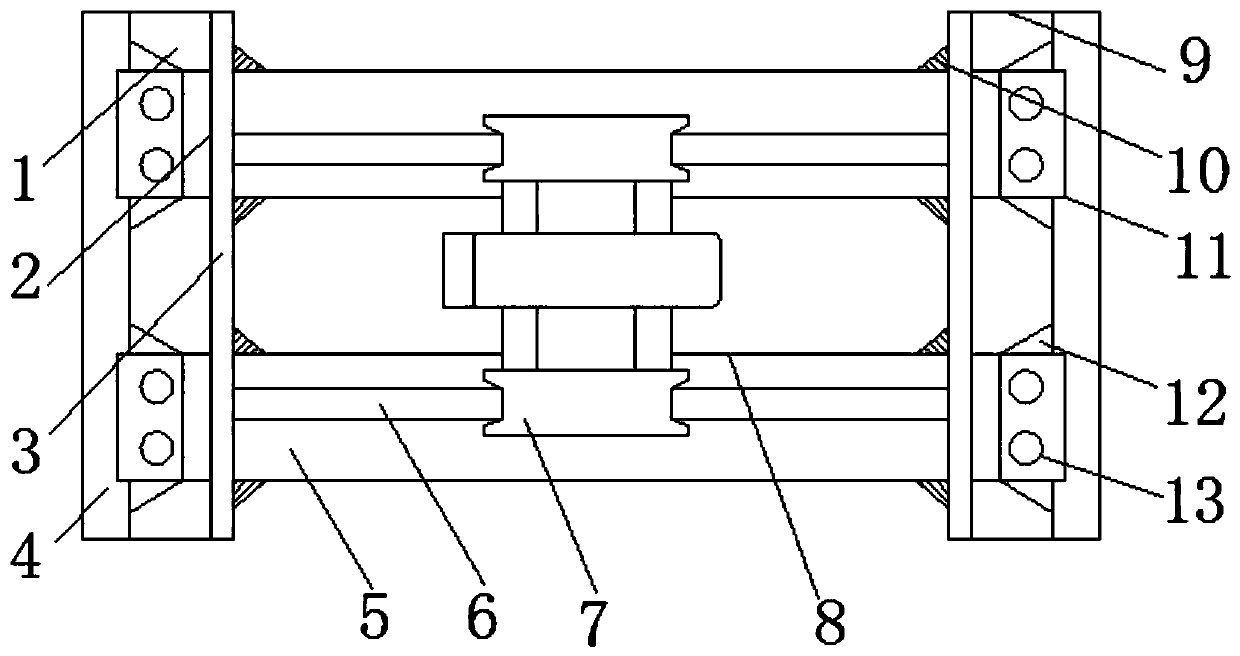

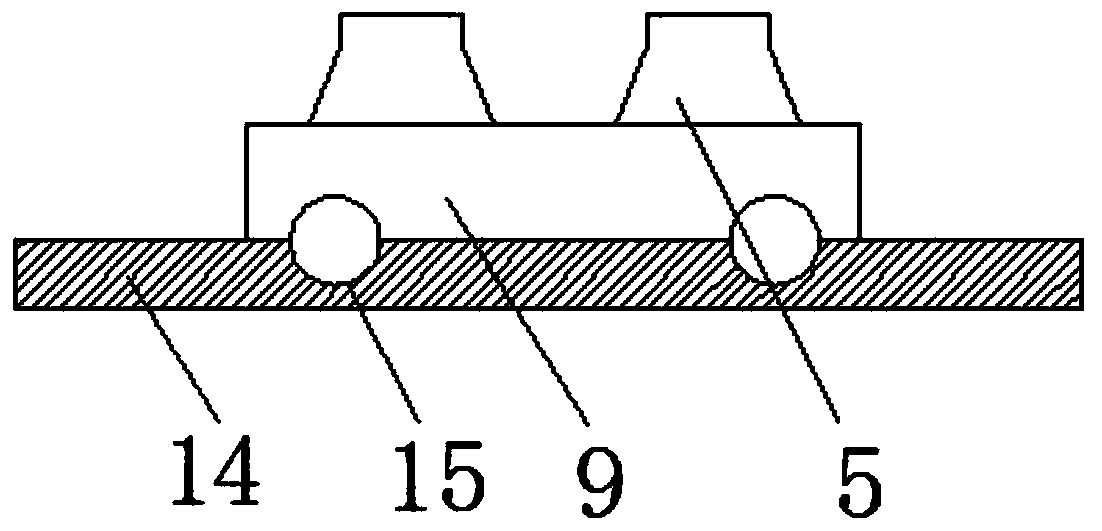

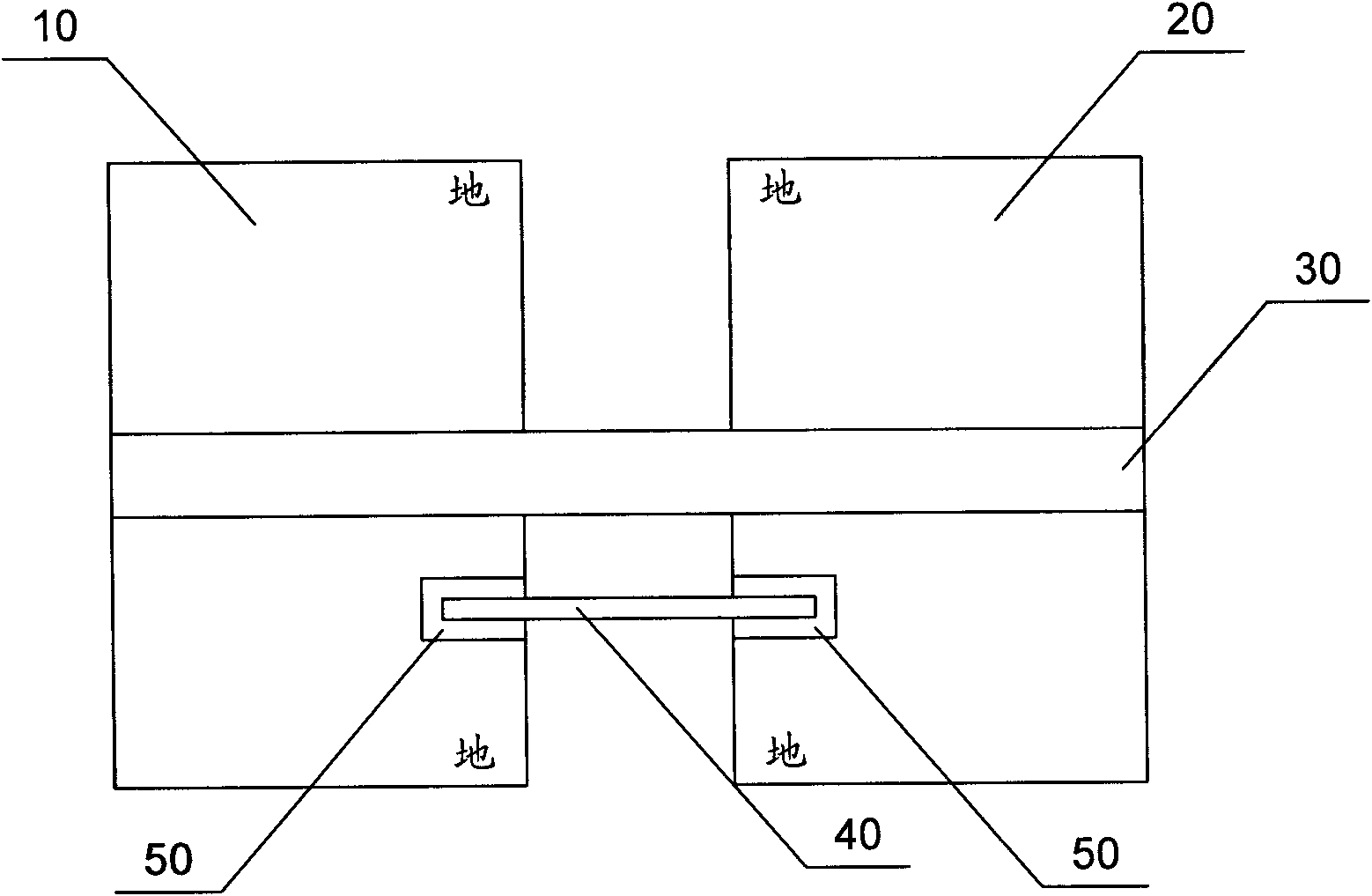

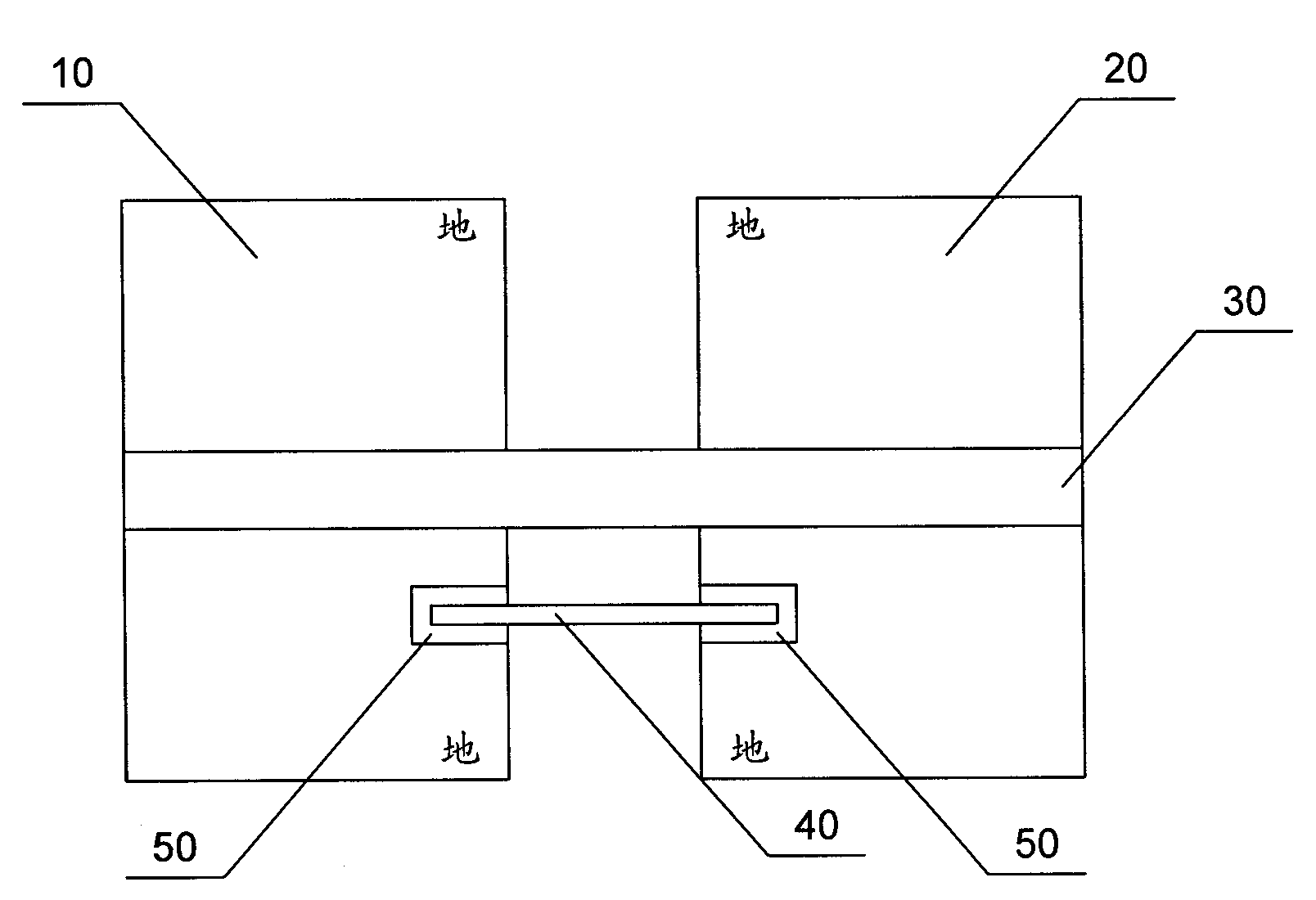

Method for mounting steel-structure module in place

InactiveCN107327023AAccurate placementPrevent reamingFoundation engineeringBuilding material handlingComputer moduleEngineering

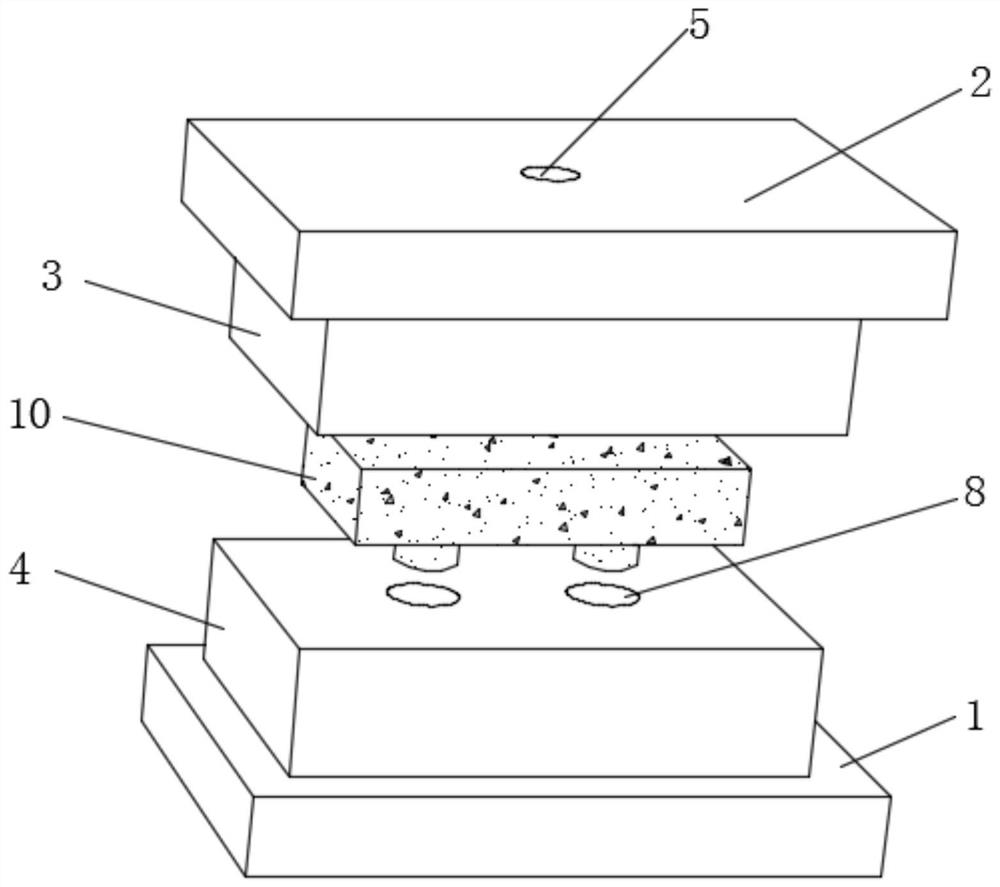

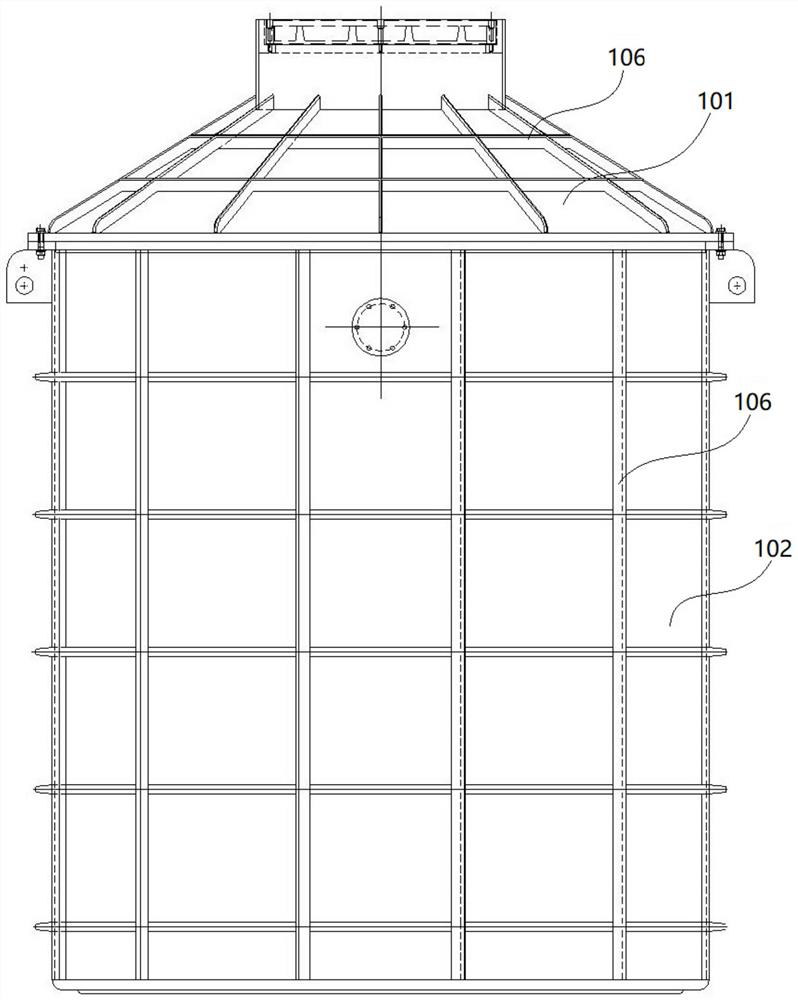

The invention provides a method for mounting a steel-structure module in place. The method for mounting the steel-structure module in place comprises the steps that foundation bolts are mounted in place; a concrete foundation is poured; steel column base mortar lumps are arranged on the foundation; guiding devices and a horizontal jacking deviation correction device used for leveling a base are manufactured, and the guiding devices are arranged at the tops of the foundation bolts in a sleeving mode; bolt holes are formed in the base; steel columns are welded on the base; the steel columns and a steel-structure beam are assembled into a steel-structure frame in a prefabrication factory, technological pipelines are mounted in the frame, and thus the steel-structure module is formed; the steel-structure module is transported to a mounting position through a transport vehicle; and the relative positions between the bolt holes and the foundation bolts are checked, the module is lowered slowly through a transport vehicle hydraulic system, whether upper openings of the guiding devices are within the ranges of the bolt holes or not is checked in real time, and the guiding devices are dismounted after the steel-structure module is mounted in place accurately. By adoption of the method for mounting the steel-structure module in place, chambering of the bolt holes in the steel column base on a field can be avoided, and thus the construction quality is ensured; and slight horizontal movement can be achieved through the guiding devices, the self weight of the module and the horizontal jacking deviation correction device, and thus the purpose of mounting the module in place rapidly and accurately is achieved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

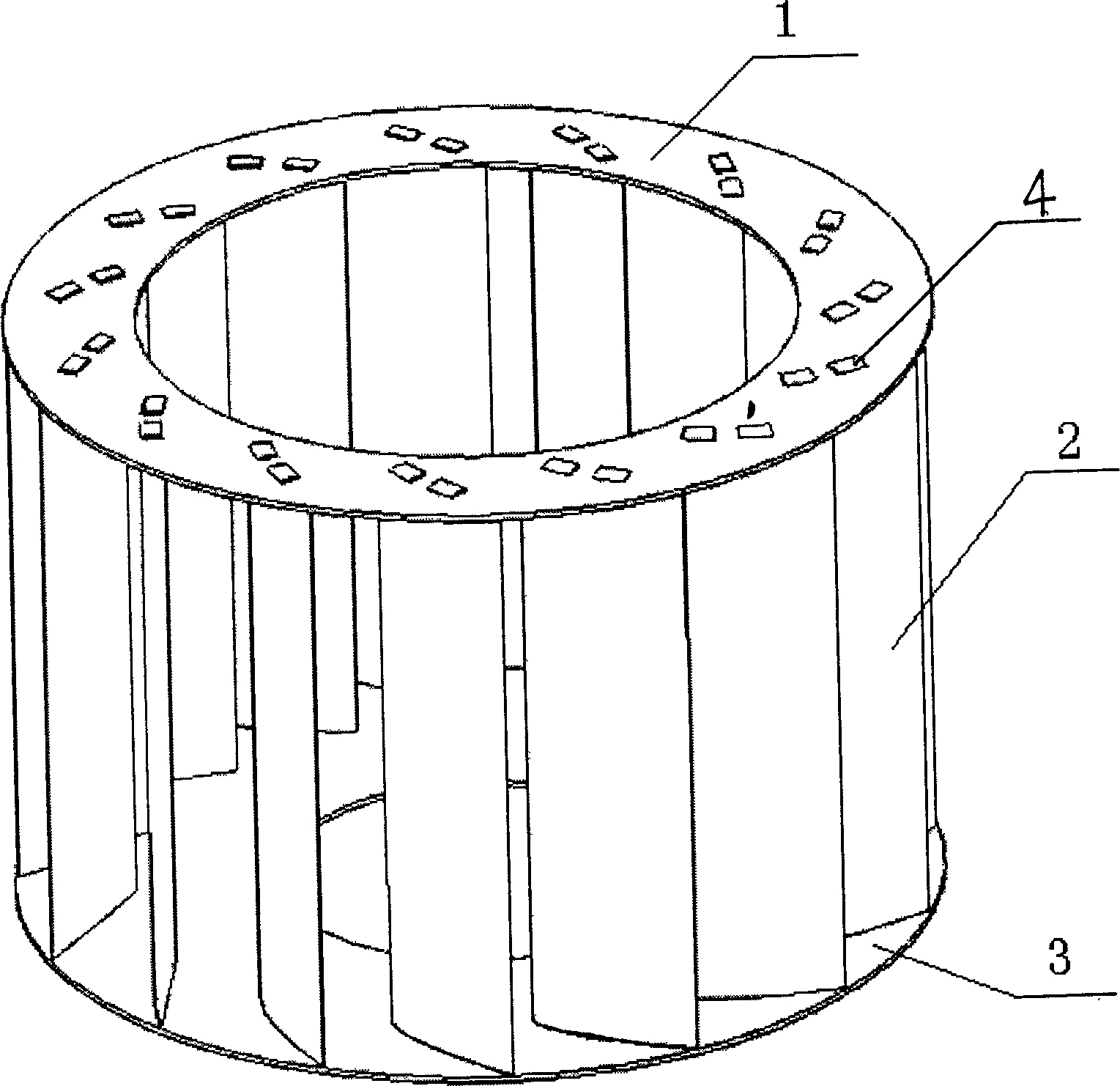

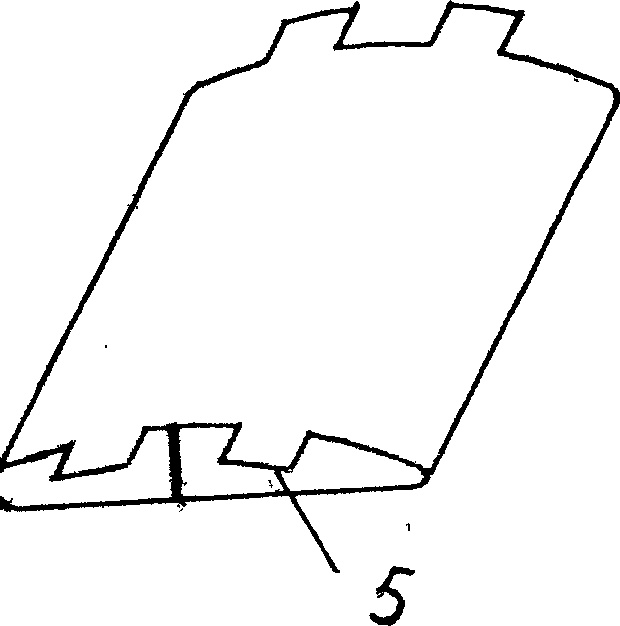

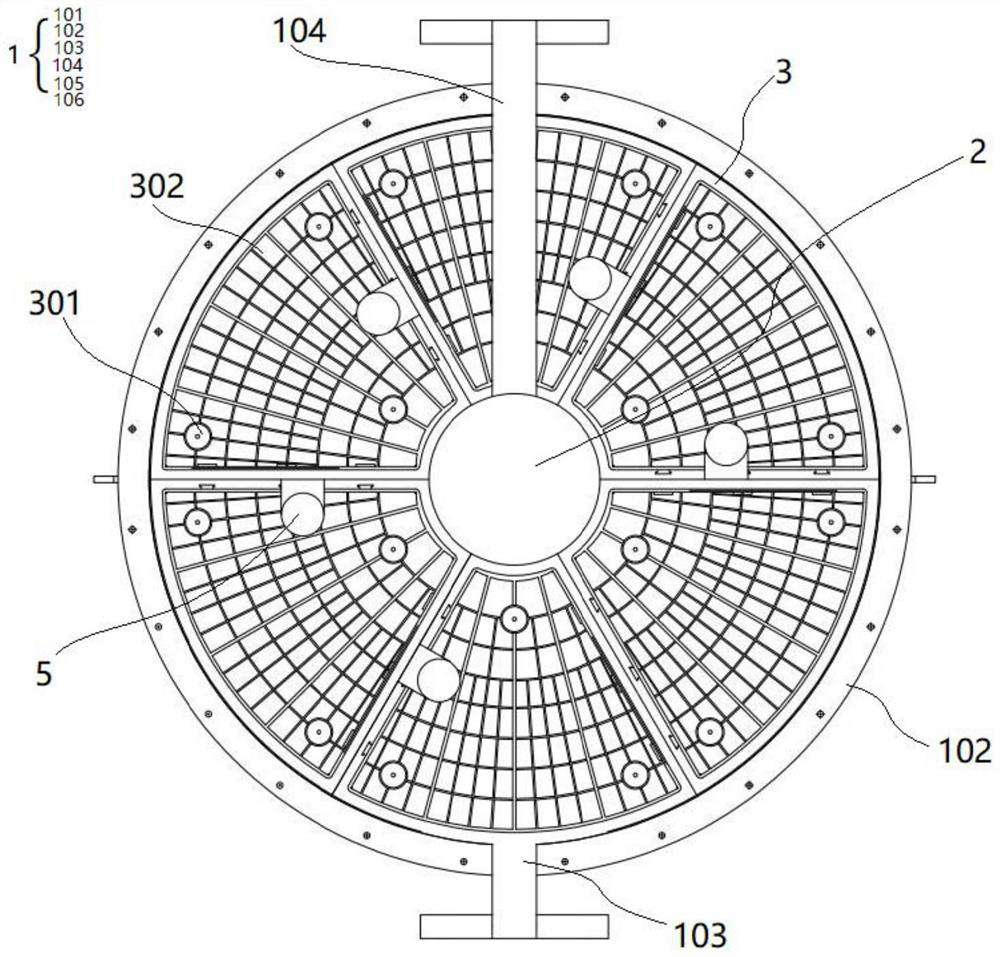

Technological process of making wing type centrifugal vane whell

The technological process of making wing type centrifugal vane wheel includes the steps of: making the profile with single layer of boss and planar, arc or conic surface in ribbed hollow aluminum section bar with unequal wall thickness and wing, forming slots on the flat front and back disc and arc or conic front disc, inserting, bending and connecting to form vane wheel. The technological process has no welding and no limitation in vane number, and the produced vane wheel has high efficiency, low noise, small size and low cost.

Owner:SHANDONG UNIV

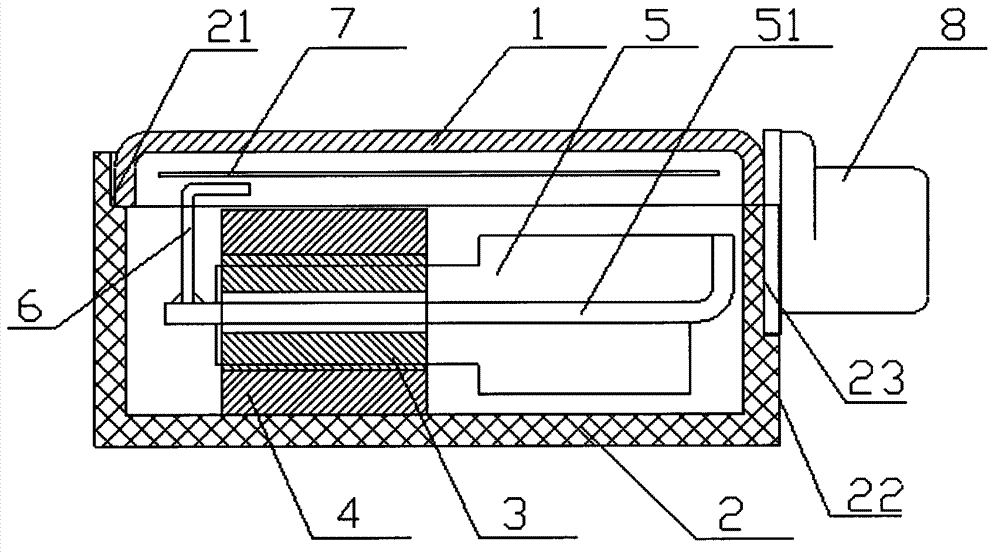

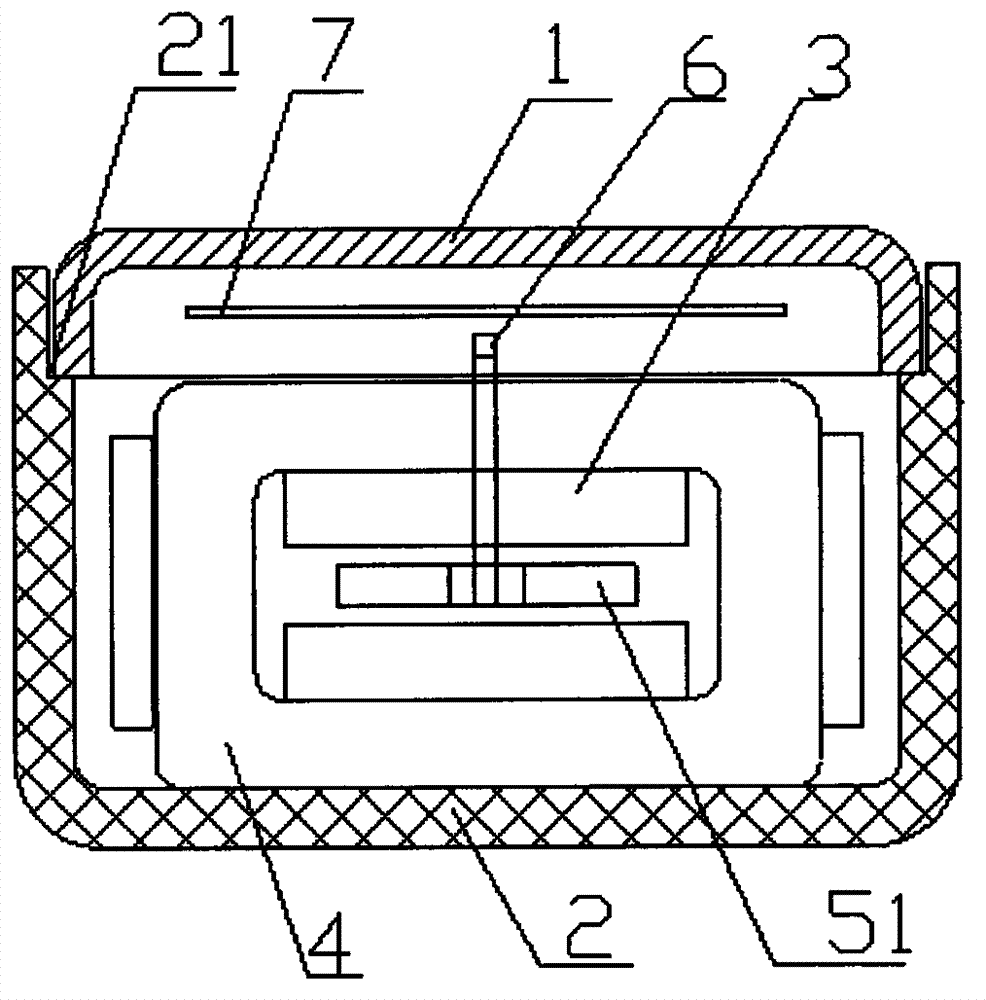

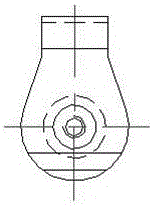

Moving iron unit for loudspeaker

InactiveCN102833656ALow costReduced docking accuracyElectrical transducersVibrating membranePlastic injection molding

The invention provides a moving iron unit for a loudspeaker. The moving iron unit comprises a shielding housing, a balance armature, a magnet, an electromagnetic coil, a vibrating membrane, a lead, and a voice guide pipe, wherein the balance armature, the magnet, the electromagnetic coil, the vibrating membrane, the lead and the voice guide pipe are placed in the shielding housing; and the moving iron unit is characterized in that the shielding housing is divided into an upper housing and a lower housing which are connected in a manner of embedding. According to the moving iron unit for the loudspeaker, the upper housing and the lower housing are abutted by embedding, so that the precision in abutting of the upper housing and the lower housing is reduced, and the working efficiency is improved. The upper housing and the lower housing are made of plastic and can be manufactured in an injection molding way. Compared with the metal materials, when plastic injection molding is carried out to manufacture the upper housing and the lower housing, the cost is lowered, and the processing technology is simple. The welding process can be avoided due to the use of the plastic housings.

Owner:何朝阳

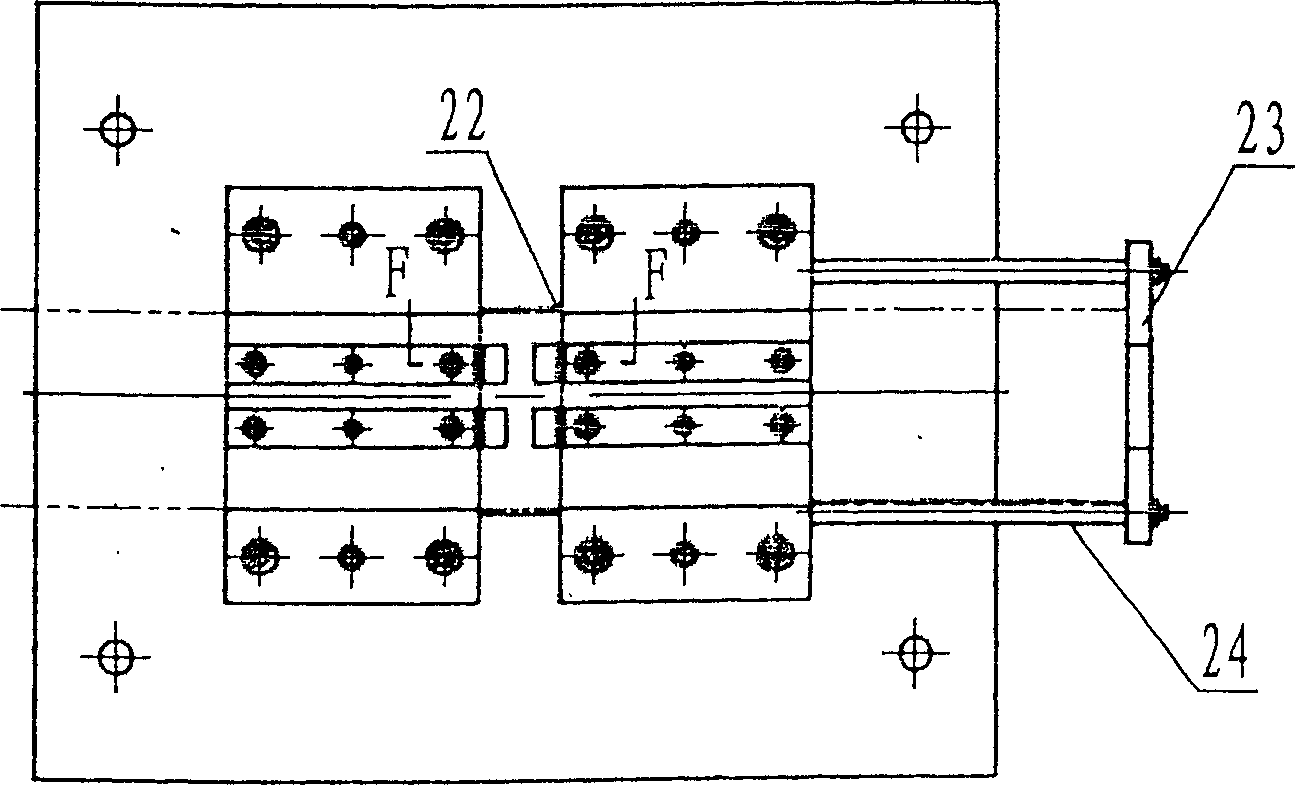

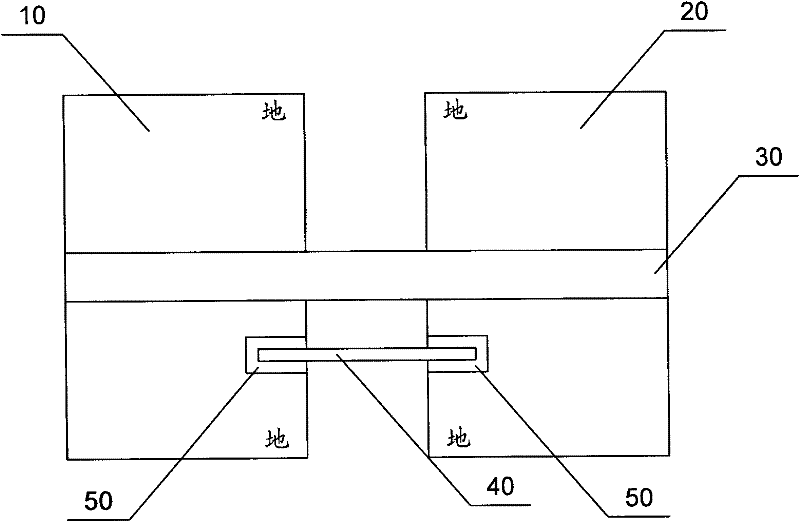

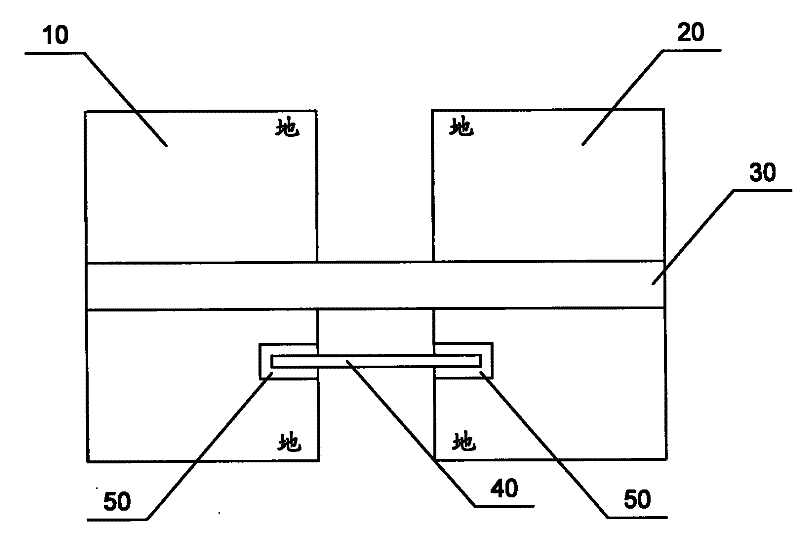

Prefabricated reinforced concrete column connection structure and method

ActiveCN108252424AEasy constructionUse fewer boltsBuilding constructionsReinforced concrete columnPerformance engineering

The invention relates to a prefabricated reinforced concrete column connection structure and method. The idea of equivalent cast-in-place is adopted, based on mechanical optimization analysis, a method connecting to the middle of a column is proposed, shape steel in the column is connected by a shape steel sleeve instead of welding and bolt connection commonly used in engineering, and the construction is simplified; rebars in the column are connected by a mechanical sleeve instead of a grouting sleeve often used in the assembled reinforced concrete structure, and the cost is reduced; the connection part is covered with a steel plate tube and no stirrups are arranged, and the construction is simplified; a hole is reserved in a prefabricated reinforced concrete column at the upper part of the connection part; and after installation of the steel plate tube is completed, high-performance engineering cement-based composite materials (ECC) can be poured to further ensure the integral strength and deformation capacity of the connection part. The prefabricated reinforced concrete column connection structure has high assembly property, the assembly mode is basically a bolt connection with convenient construction, on-site welding and large-area concrete pouring operation are avoided, and the construction is convenient. At the same time, the prefabricated reinforced concrete column connection structure and method is based on the idea of equivalent cast-in-place, and the strength and deformation capability of the connection part can be effectively guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

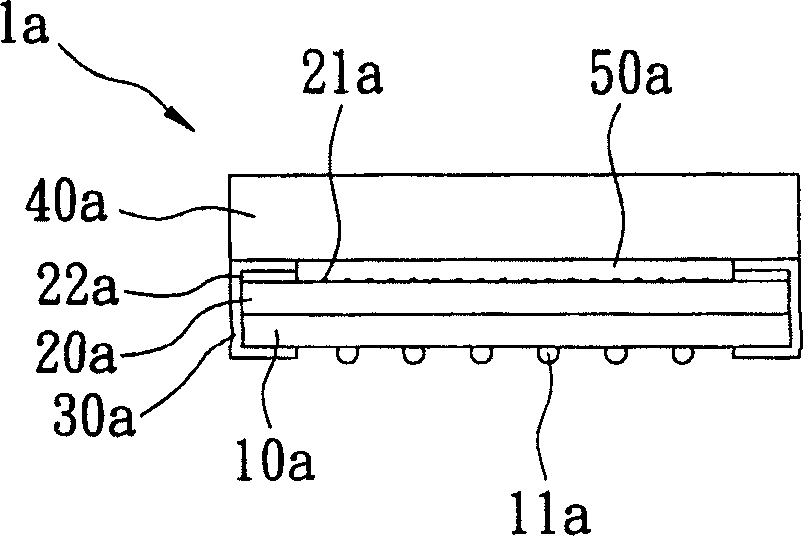

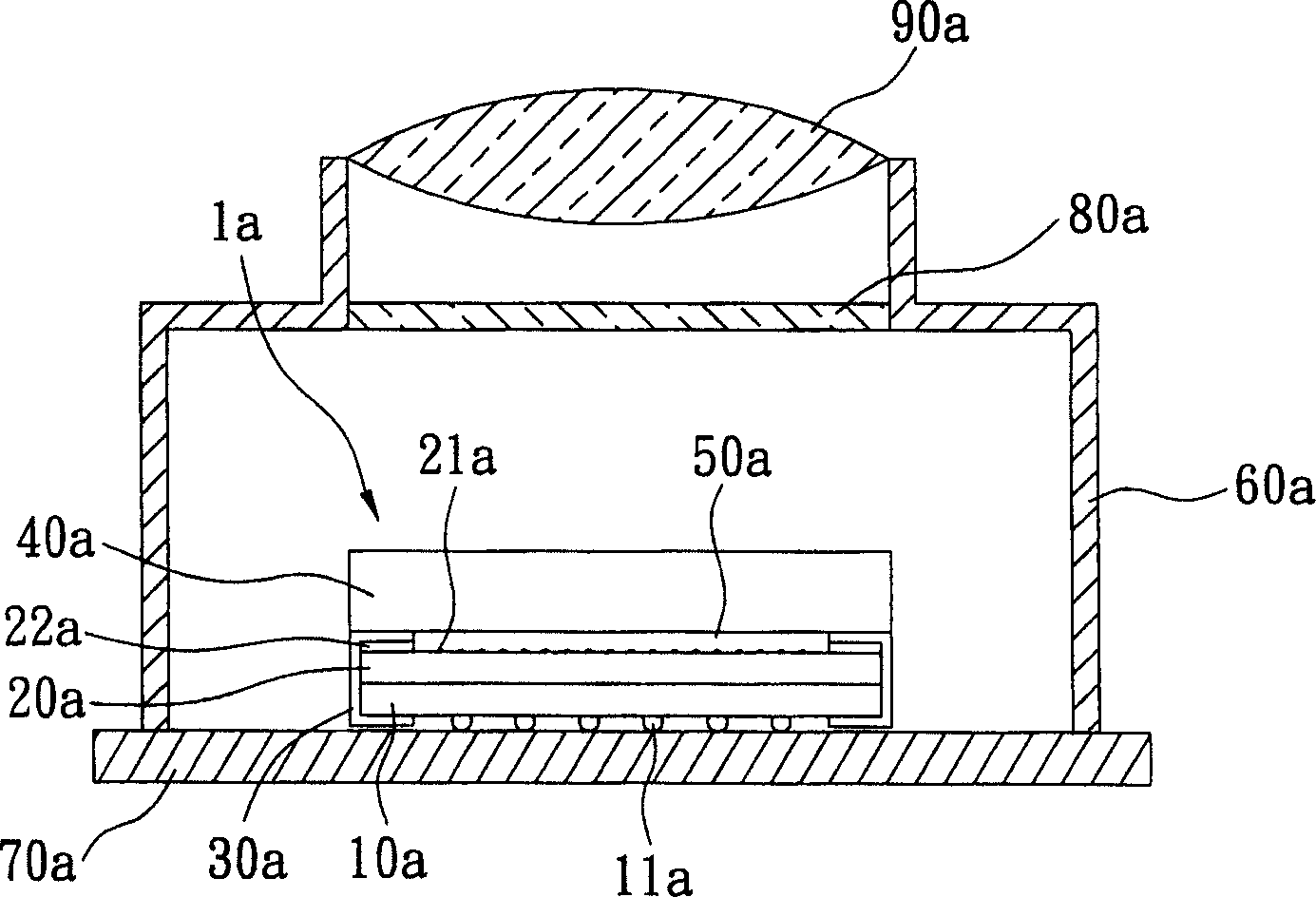

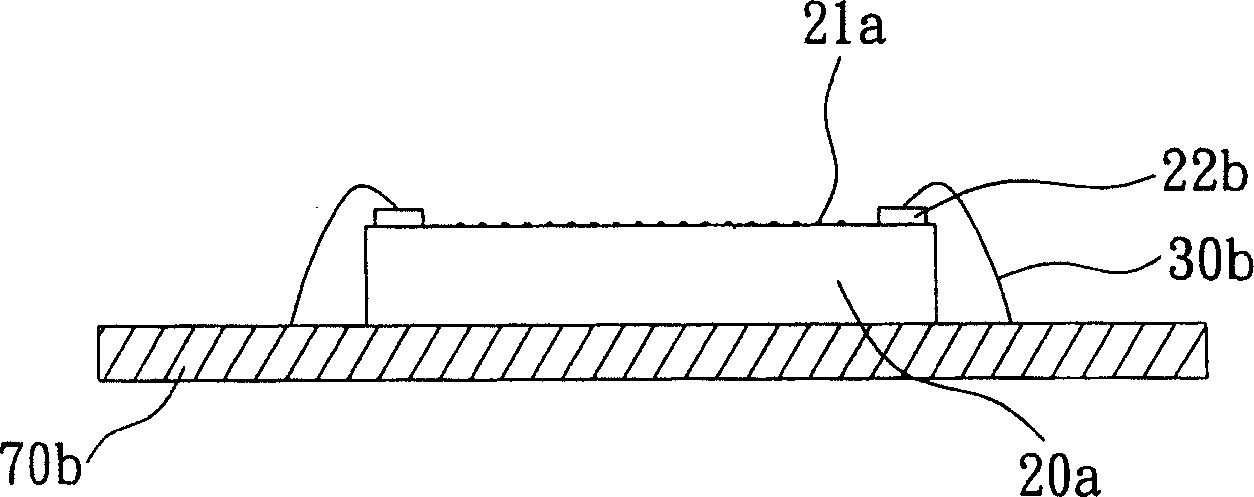

Method and equipment for fabricating structure of compound crystal

InactiveCN1761042ASimple processLow costSemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

The method improves capability of technique for packing tranditional photoelectric chip for example chip of optical sensor. Photoelectric chip is bonded on prearranged position of transparent base plate (such as glass base plate), where there is circuit layout. A joining pad connects the photoelectric chip to the transparent base plate at the prearranged place. After an existed sealed hollow interlayer is detected, then structure of each chip is cut to each simple piece, which is assembled to module according to specification. Being different to traditional encapsulation, the invention raises rate of good product, and saves material.

Owner:欣相光电股份有限公司

Assembling integrated support hanger and connecting pieces thereof

InactiveCN103438282AReduce processLow costPipe supportsMachine supportsEngineeringMechanical engineering

Owner:江苏奇佩建筑装配科技有限公司

Detachable supporting hanging frame

Owner:JIANGSU DALICHENG ELECTRICAL

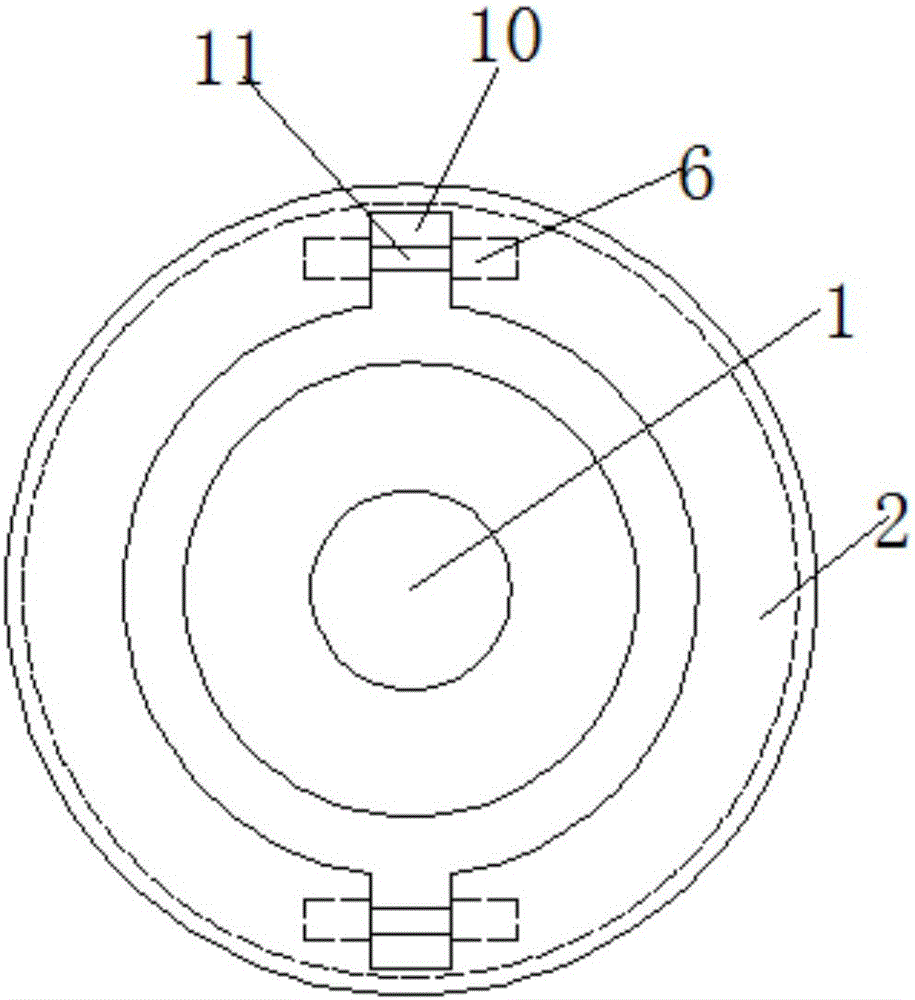

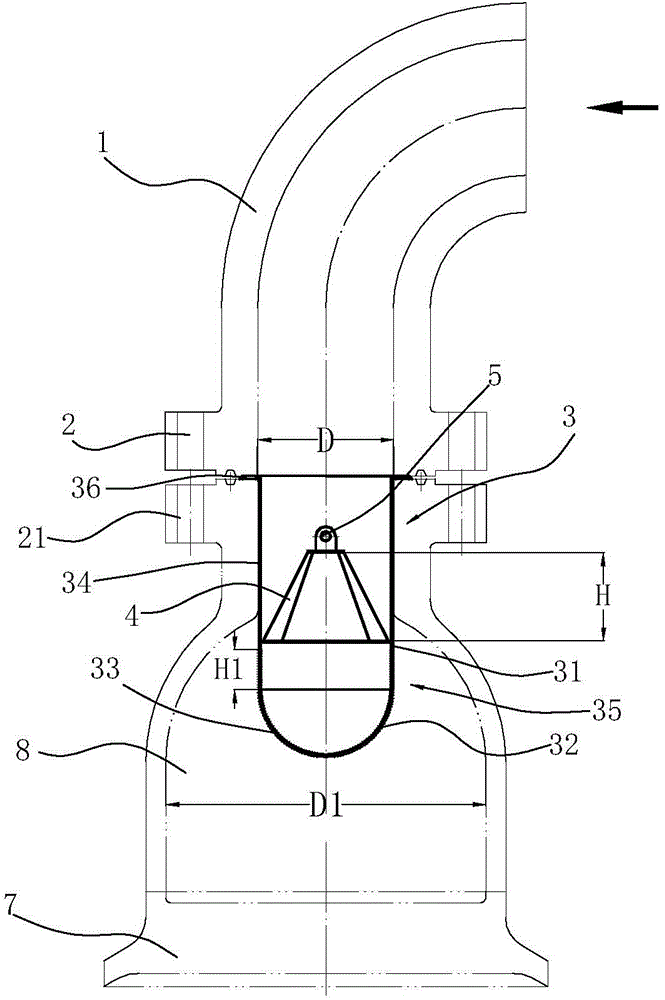

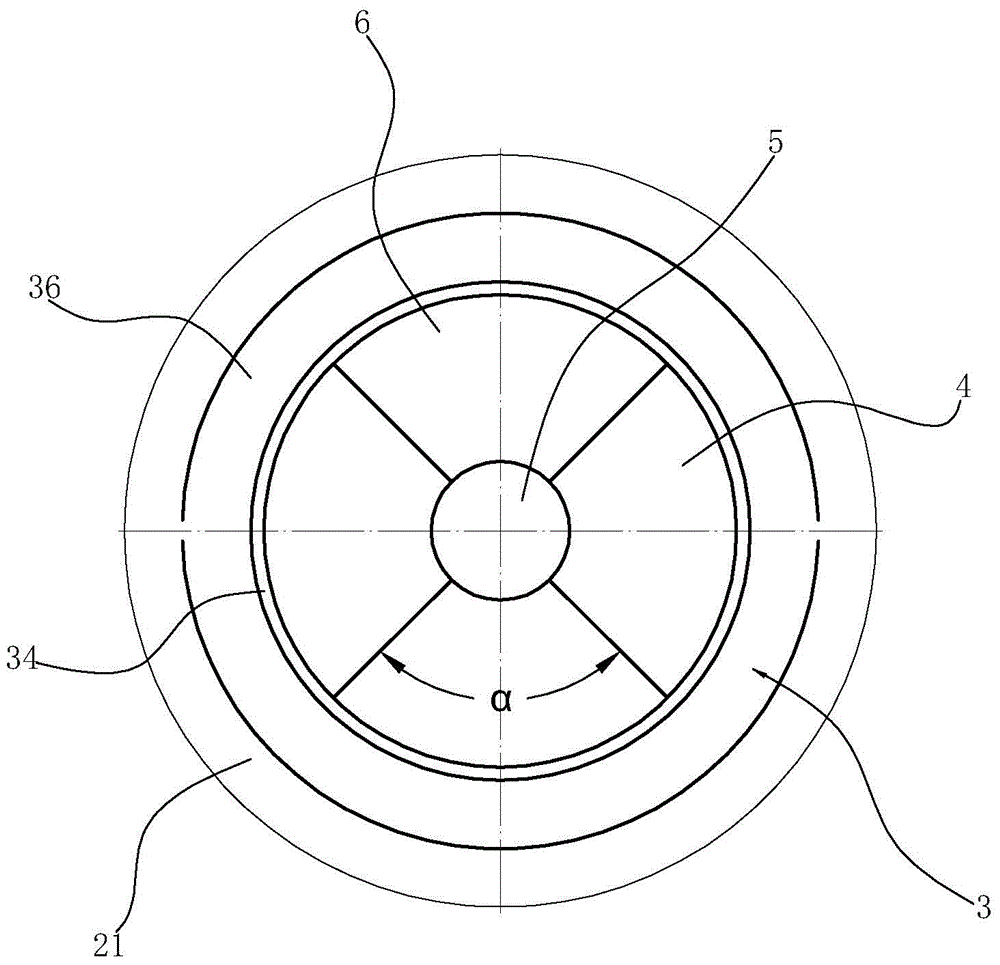

Fixing device for loop laying tube of loop laying head

InactiveCN105964726AGuaranteed weightGuaranteed to maintain the same weightEngineeringStructural engineering

The invention relates to a fixing device for a loop laying tube of a loop laying machine. The fixing device is characterized by comprising a loop laying head body, the loop laying tube, tube clamps and a fixing assembly, wherein the loop laying tube is arranged at the loop laying head body according to Archimedes spiral; the tube clamps are arranged on the loop laying tube and the loop laying head body; the fixing assembly is used for fixing the tube clamps and the loop laying head body and comprises fixing pins and bolts, the fixing pins are arranged in pin holes of the tube clamps and the loop laying head body, and the bolts are arranged in the fixing pins. The fixing device can prevent bump between the tube clamps of the loop laying head and a protection cover, protects the tube clamps of the loop laying head from wearing, guarantees stable dynamic balance of the loop laying head and reduces vibration of the loop laying head greatly.

Owner:JIANGSU YONGGANG GROUP CO LTD

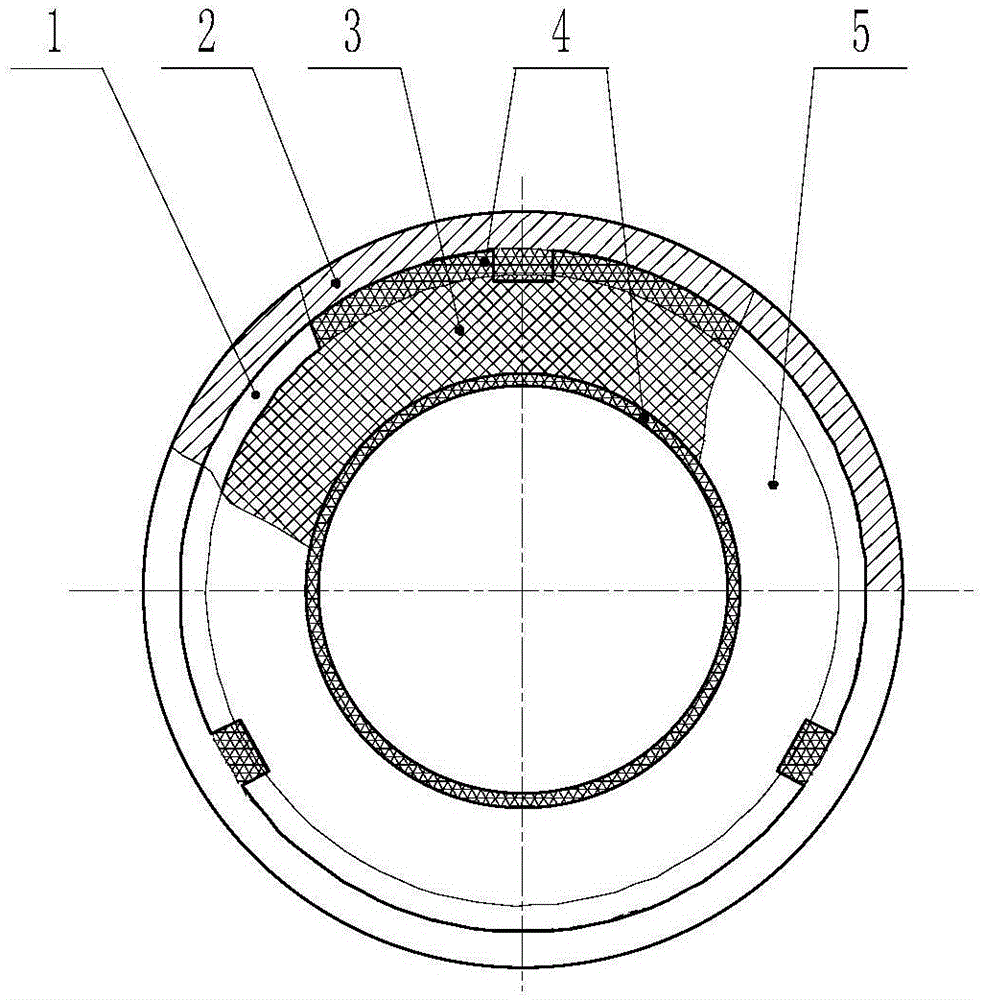

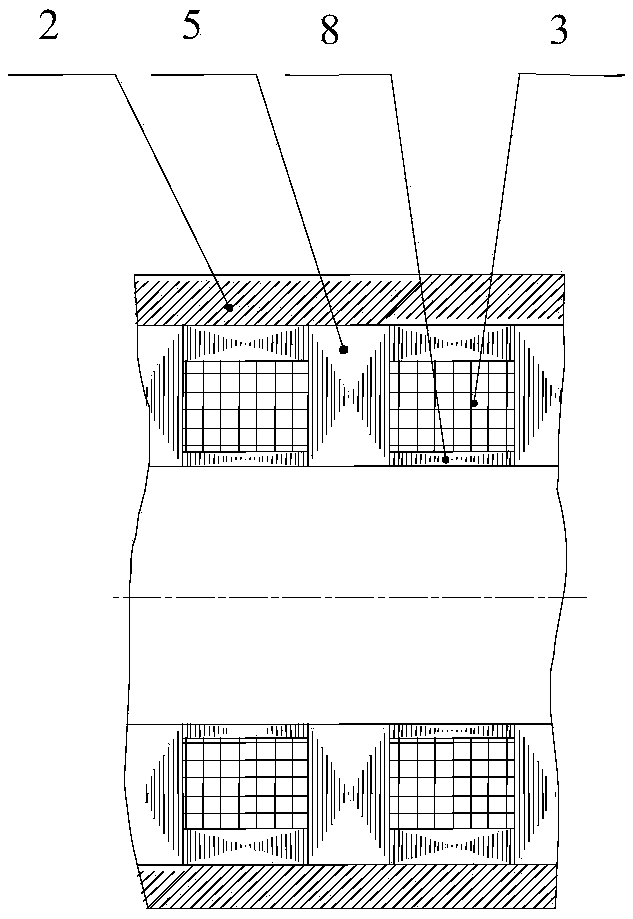

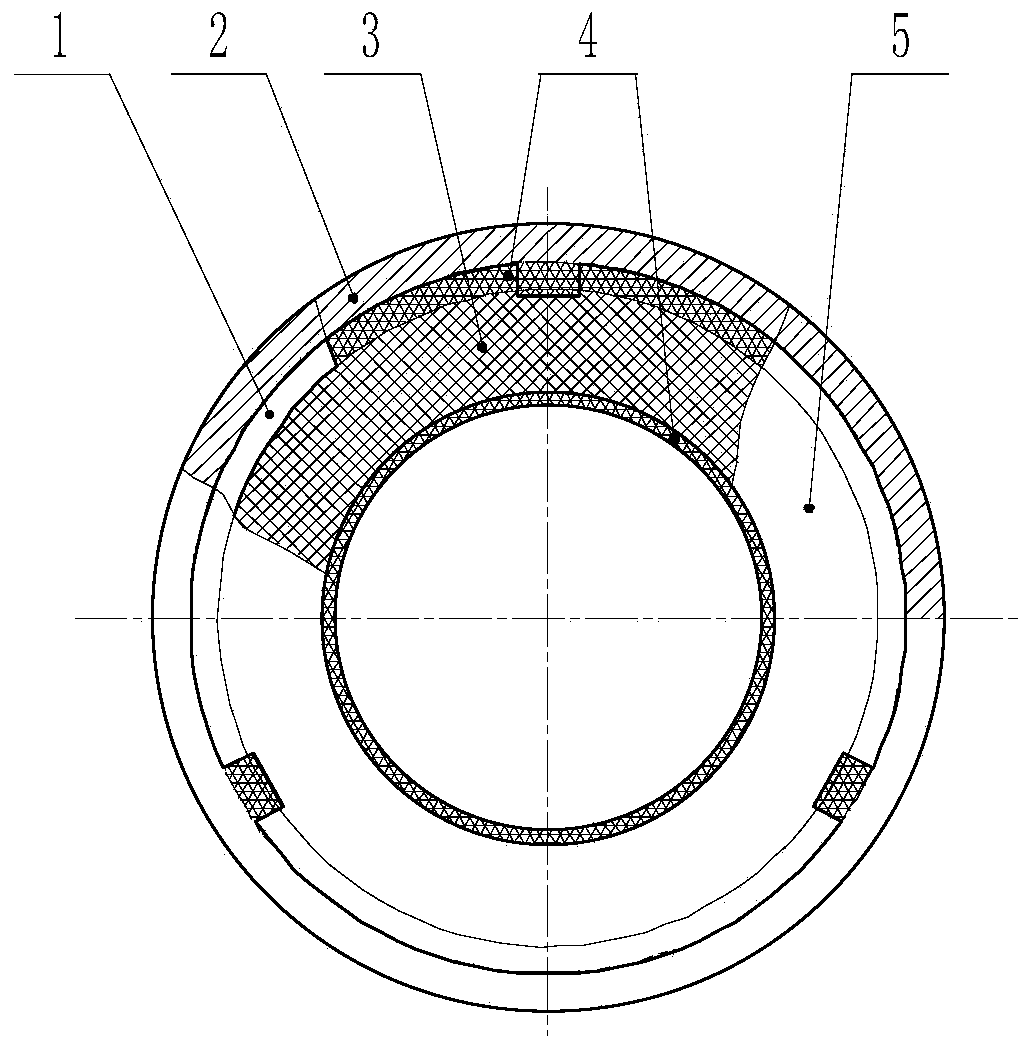

Permanent magnetic submersible linear motor and manufacturing method thereof

ActiveCN106571729AImprove securityImprove quality reliabilityManufacturing dynamo-electric machinesPropulsion systemsFilling materialsLinear motor

The invention provides a permanent magnetic submersible linear motor and a manufacturing method thereof. The permanent magnetic submersible linear motor comprises a mover, a stator and a casing which are sequentially arranged from inside to outside, and resin filling materials are embedded into a gap between the stator and the mover and a gap between the stator and the casing. According to the permanent magnetic submersible linear motor, the gap between the stator and the mover and the gap between the stator and the casing are embedded through the resin filling materials, fully mixing and stirring the filling materials and then embedding the filling materials into the motor stator with an embedding tire are only required in an embedding process, welding during connecting a stainless steel cylinder with a stator core can be avoided, improving safety and quality reliability of the motor is facilitated, moreover, the embedded materials after curing exist in a solid mode, so the motor needs no quite high sealingness, processing precision and dimension requirements of each part of the motor are relatively loose, dimension in the embedding process depends on the embedding tire, and precision is higher compared with the stainless steel cylinder.

Owner:PETROCHINA CO LTD +1

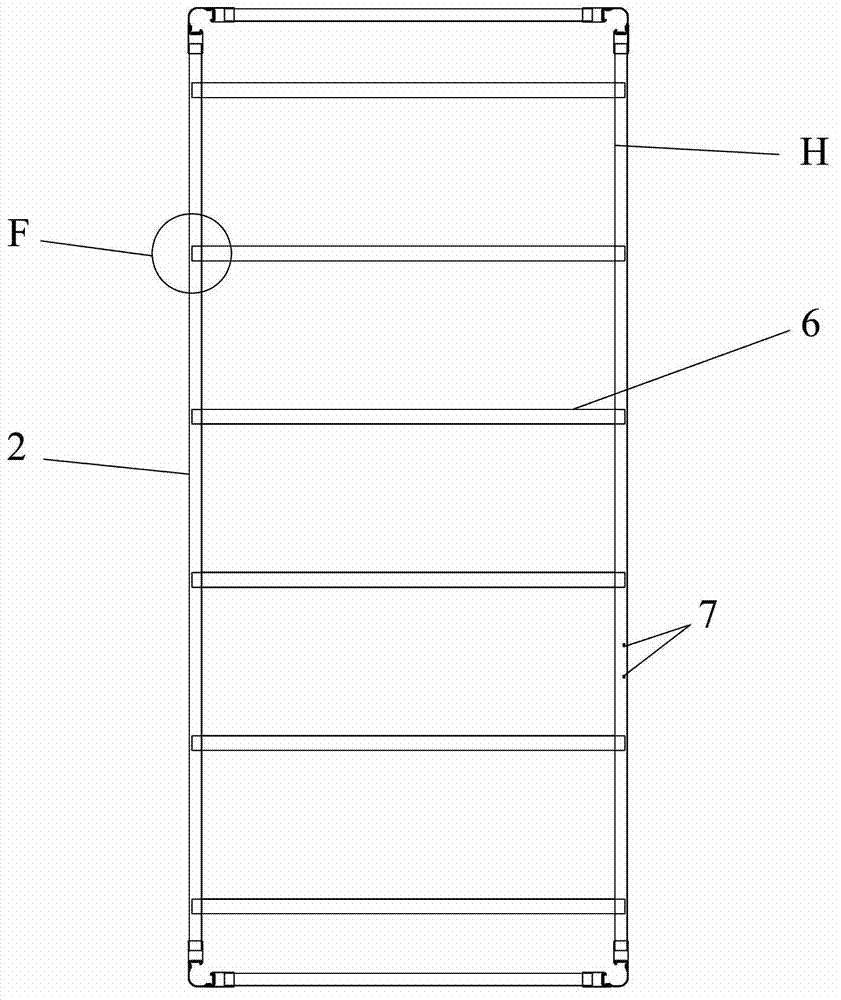

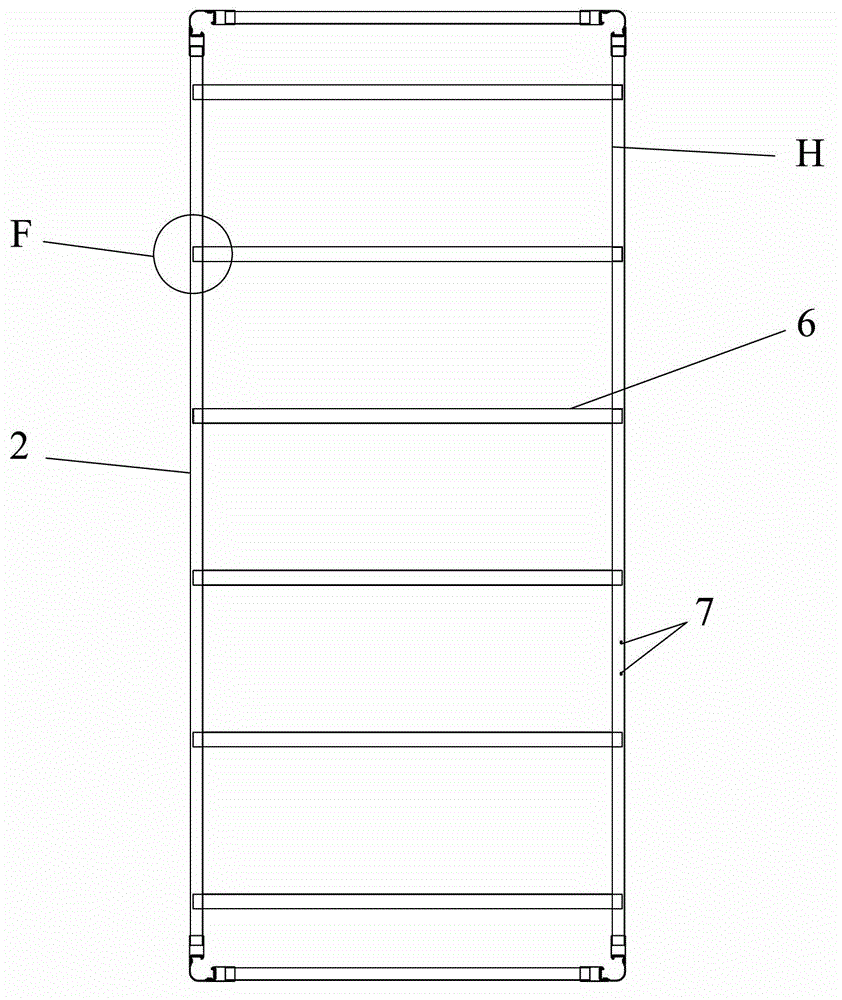

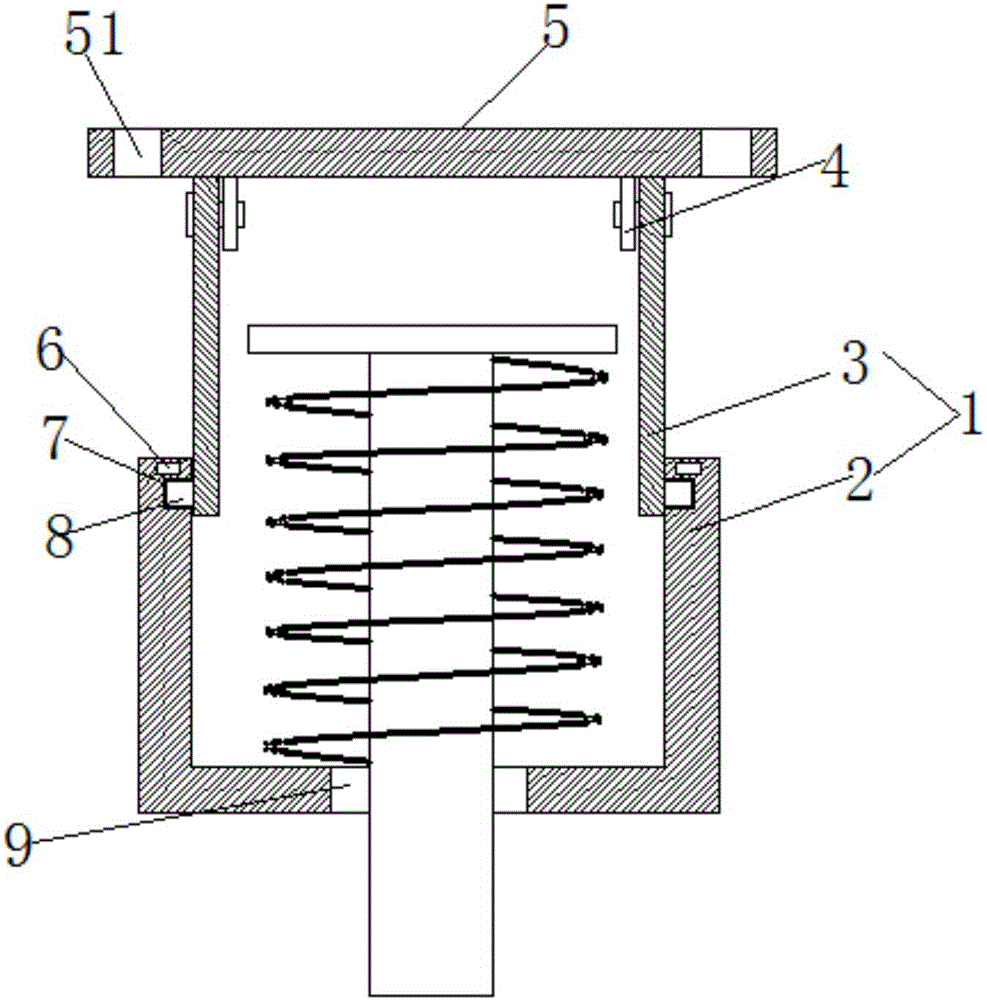

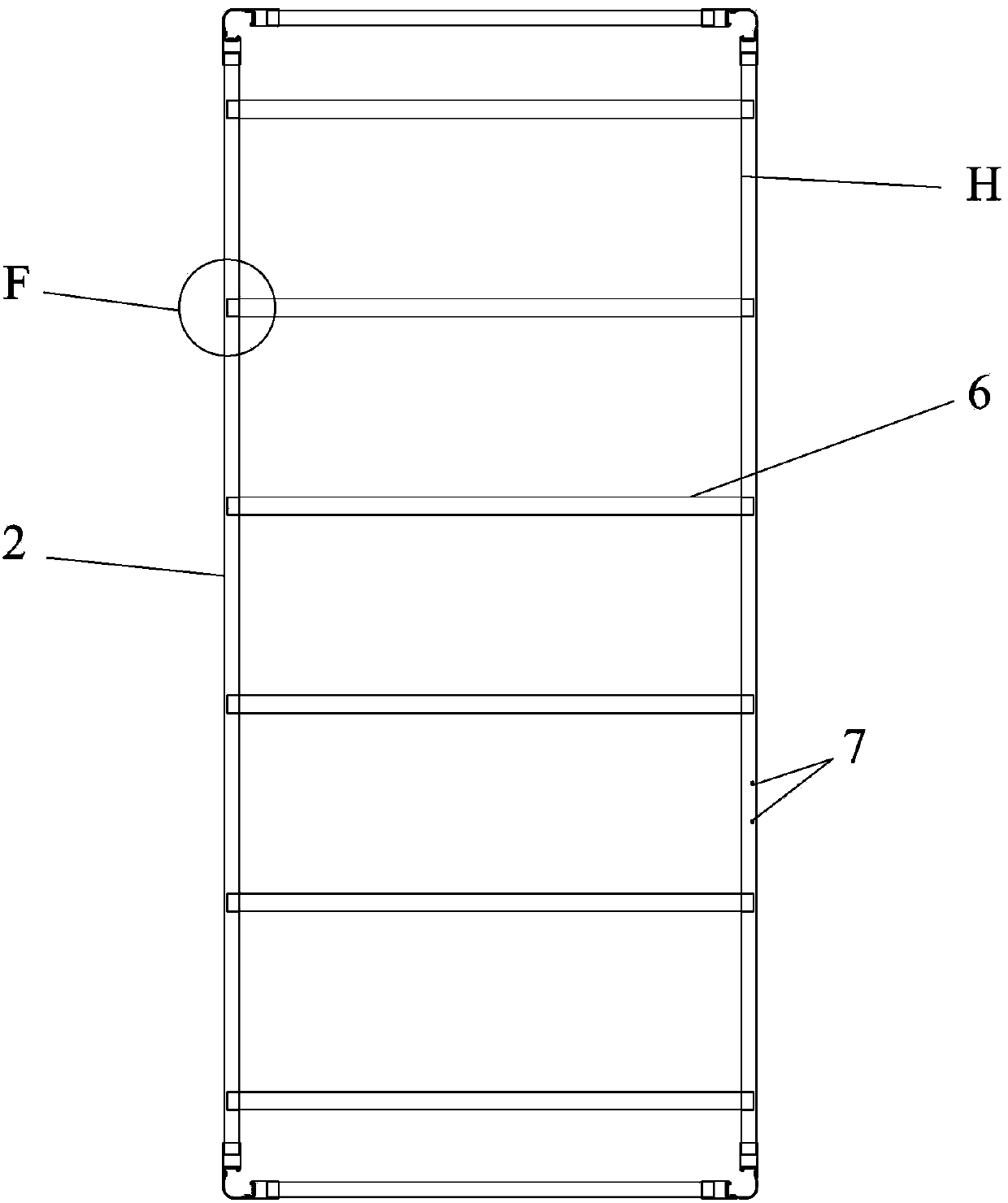

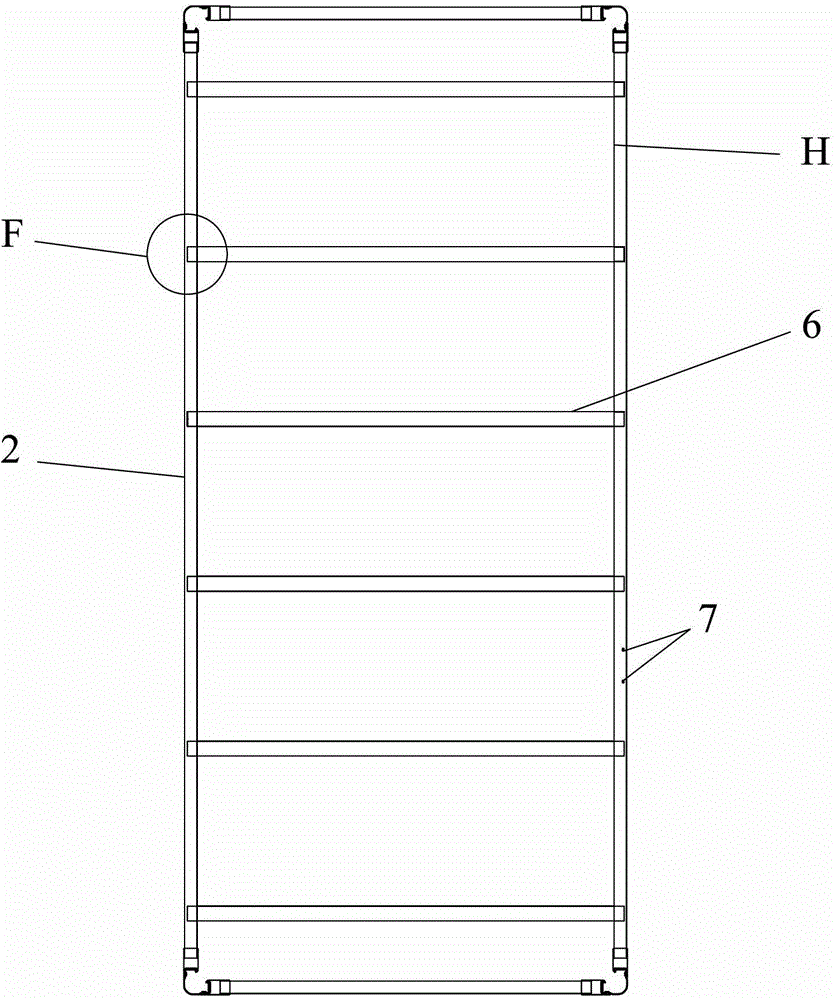

Plug structure for bed and plug structure-based bedding

InactiveCN102960978ASimple appearanceAvoid collision damageBedstandsFurniture joiningStamping processEnvironmentally friendly

The invention discloses a plug structure for bedding. The plug structure comprises a column 1 and a cross bar connected with the column, and the column and the cross bar are connected through a connector 8 which comprises a cylinder 21 and a clamped hook body 22, wherein the clamped hook body comprises a hook-shaped part hooked at the column and a straight-edge part clamped at one side of the column; a cylinder port at the other side of the cylinder is formed with an internally retracted outer edge; and the cross bar is connected at the outer edge. The invention further provides basic forms of single-layer beds or bunk beds and apartment beds based on the above connecting structure. The bedding provided by the invention is beautiful, simple, firm, durable, green, and environmentally friendly. By using a stamping process, a welding process is omitted and production cost is reduced; and by using a component connecting form such as inserting and combining, size is reduced and transportation and installation are facilitated.

Owner:徐华玉

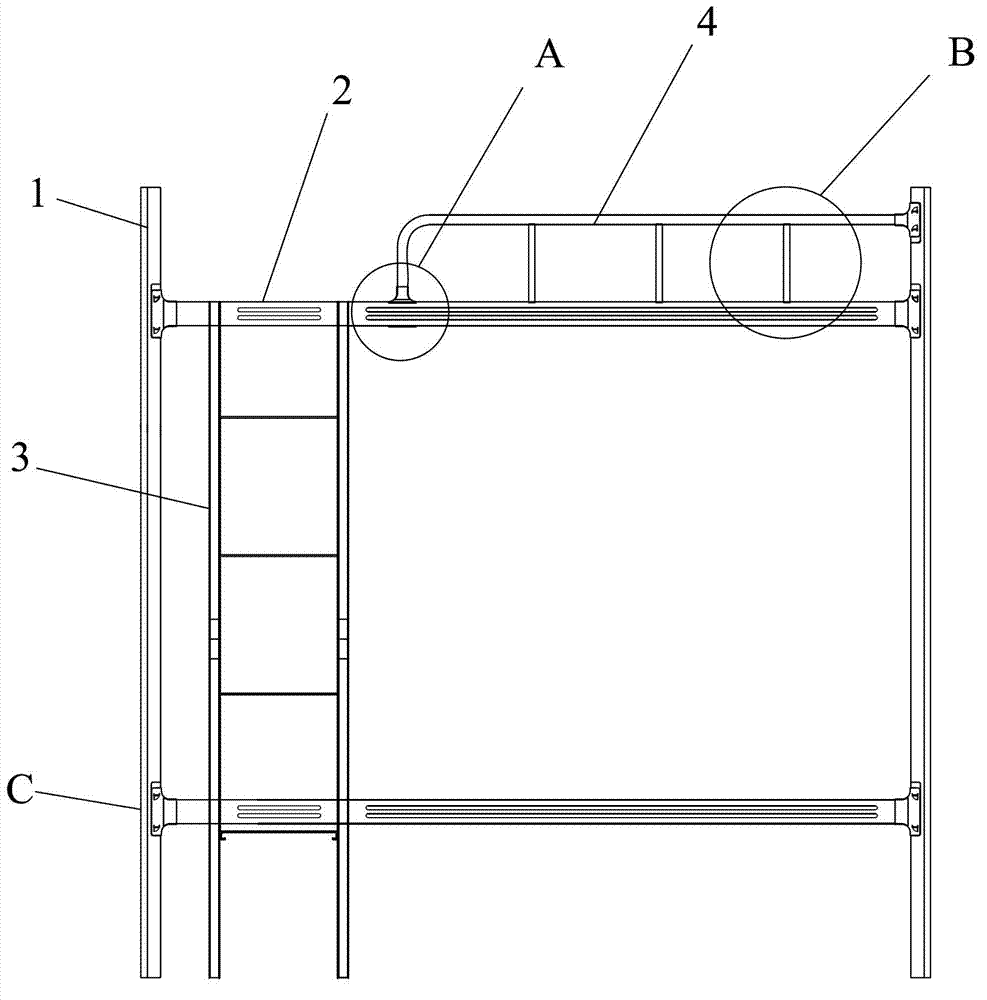

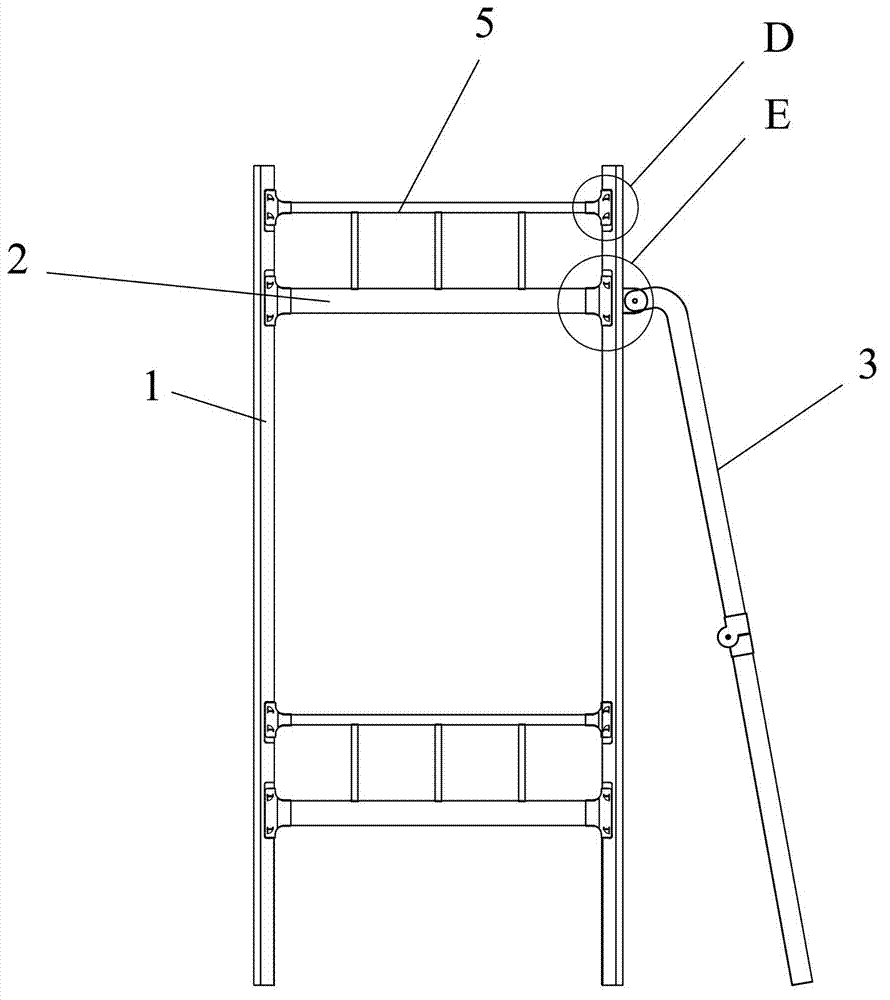

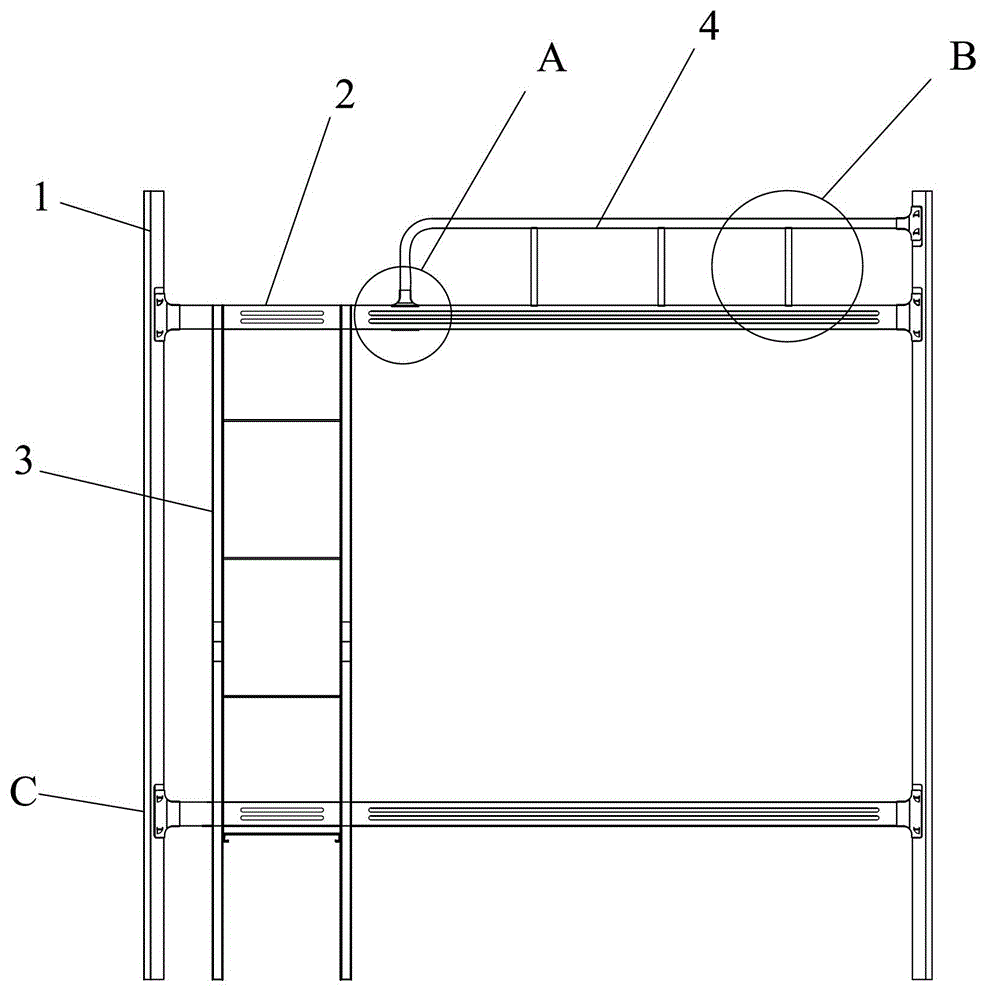

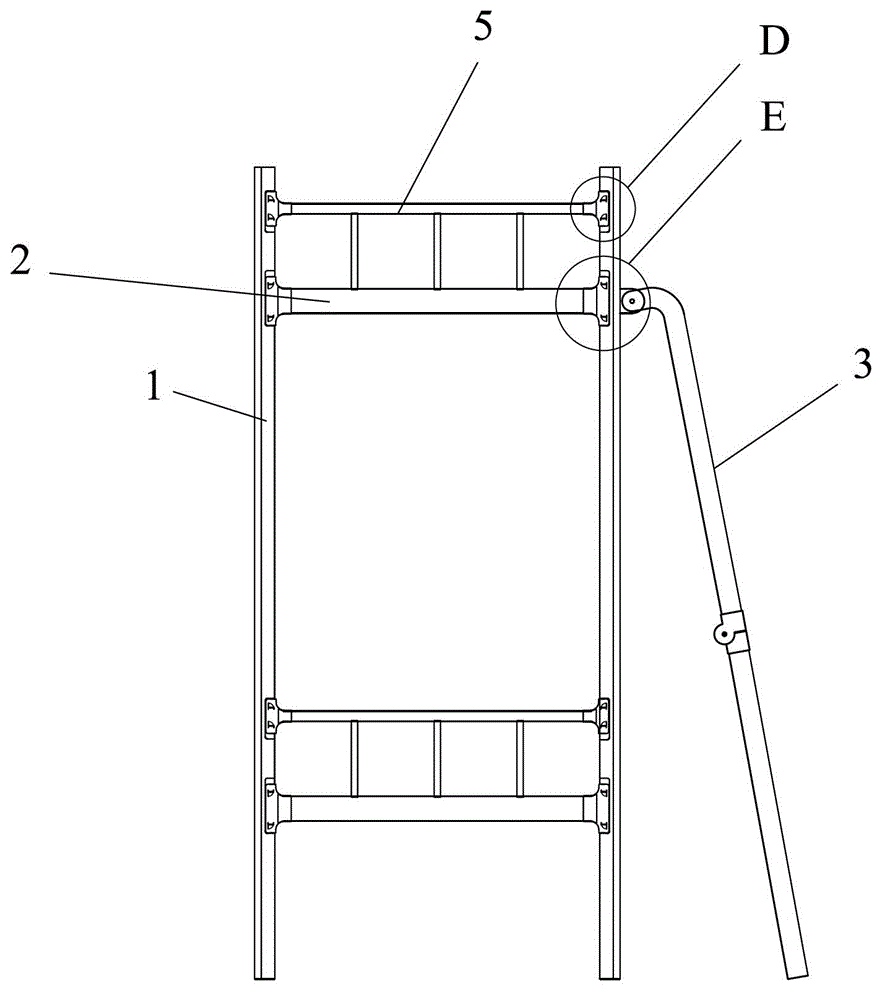

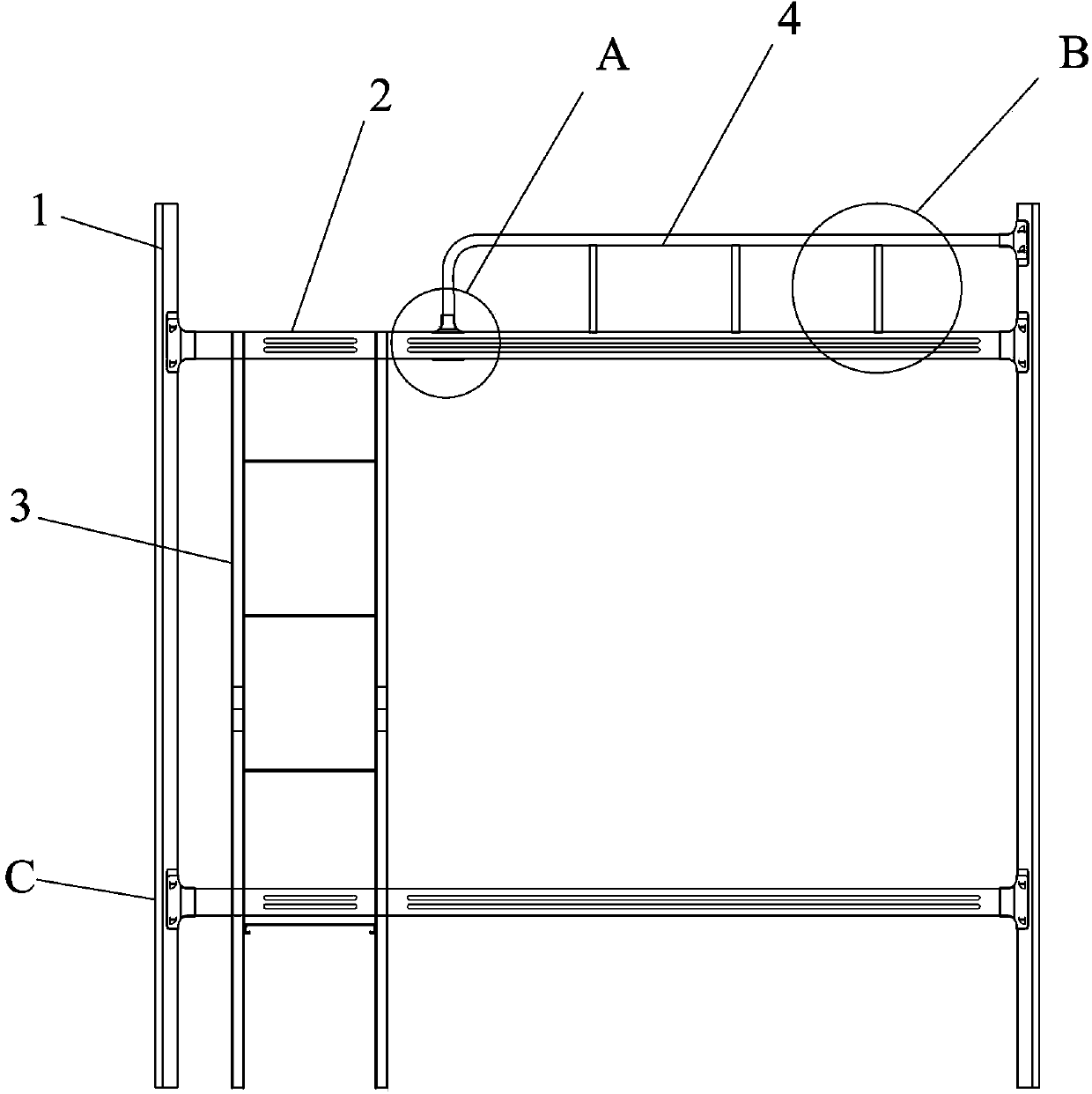

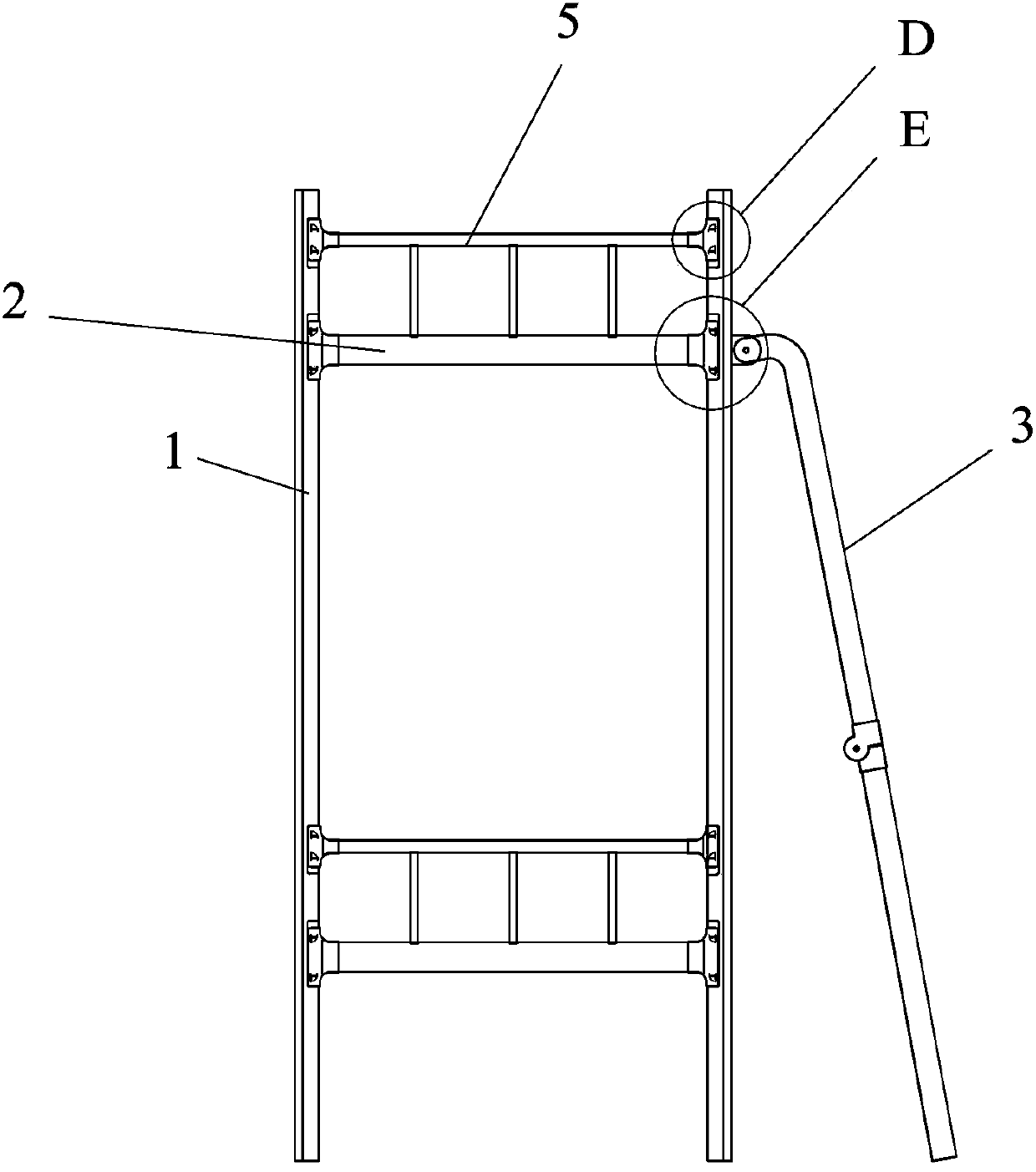

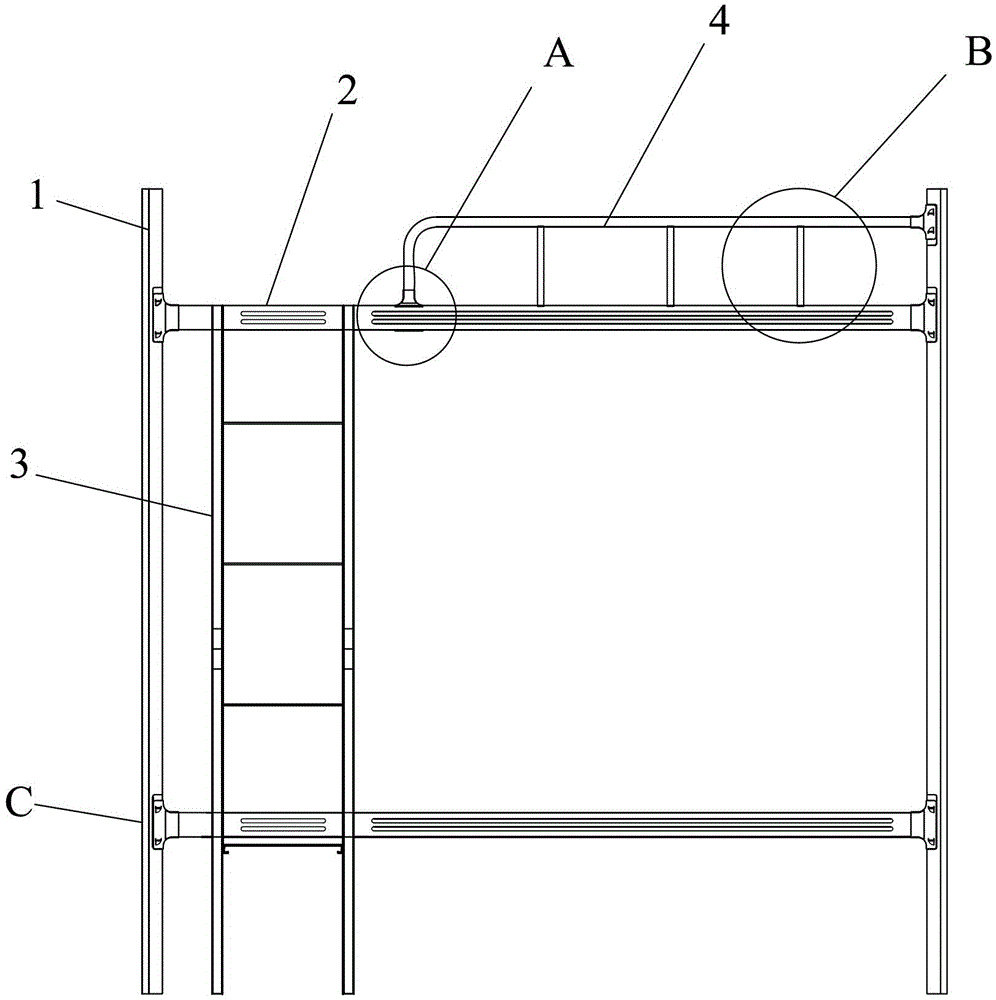

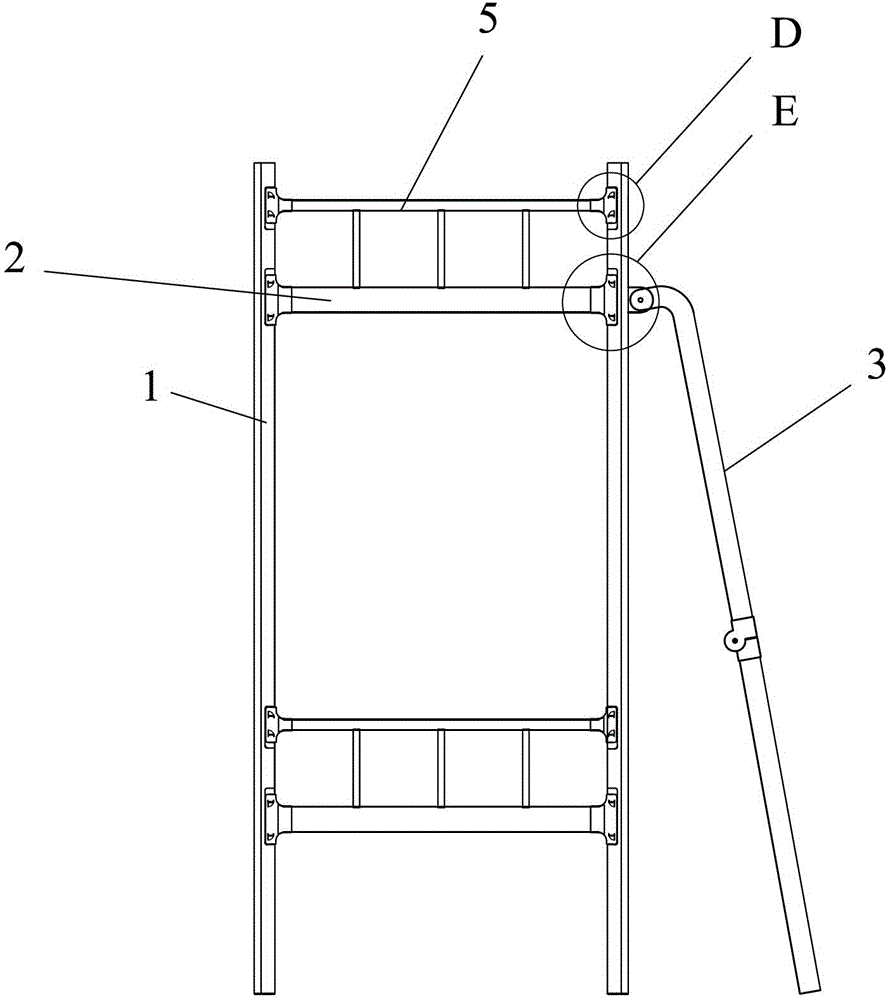

Double-decker bed based on plug-in type guardrail

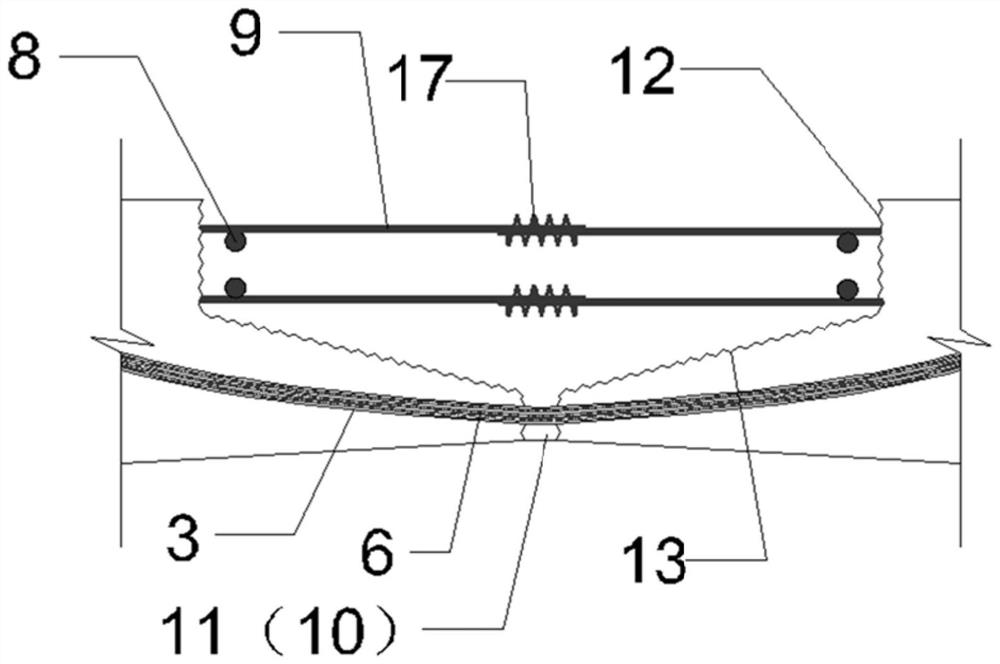

The invention discloses a double-decker bed based on a plug-in type guardrail. The double-decker bed comprises a vertical post (1) as well as an upper and a lower layer bed surrounded by beams, wherein the upper layer bed is provided with a ladder stand (3); one outer side in the length direction of the upper layer bed is provided with an upper layer bed guardrail; the upper layer bed guardrail comprises a vertical rod (12) and an outer handrail (4); the outer handrail comprises a horizontal straight rod part and an arc-shaped connection rod part; the external end of the horizontal straight rod part is connected to the vertical post (1) by a connecting piece (8); and the arc-shaped connection rod part is connected to the lower beam (2) by an intermediate unit (11). The bed disclosed by the invention has the following characteristics of beauty, simplicity, fastness, endurance and environment friendliness. With the adoption of a stamping technique, the welding process is omitted, so that the production cost is reduced; and with the adoption of an insertion and combination part connection mode, the volume is reduced, and the bed is convenient to transport and mount.

Owner:徐华玉

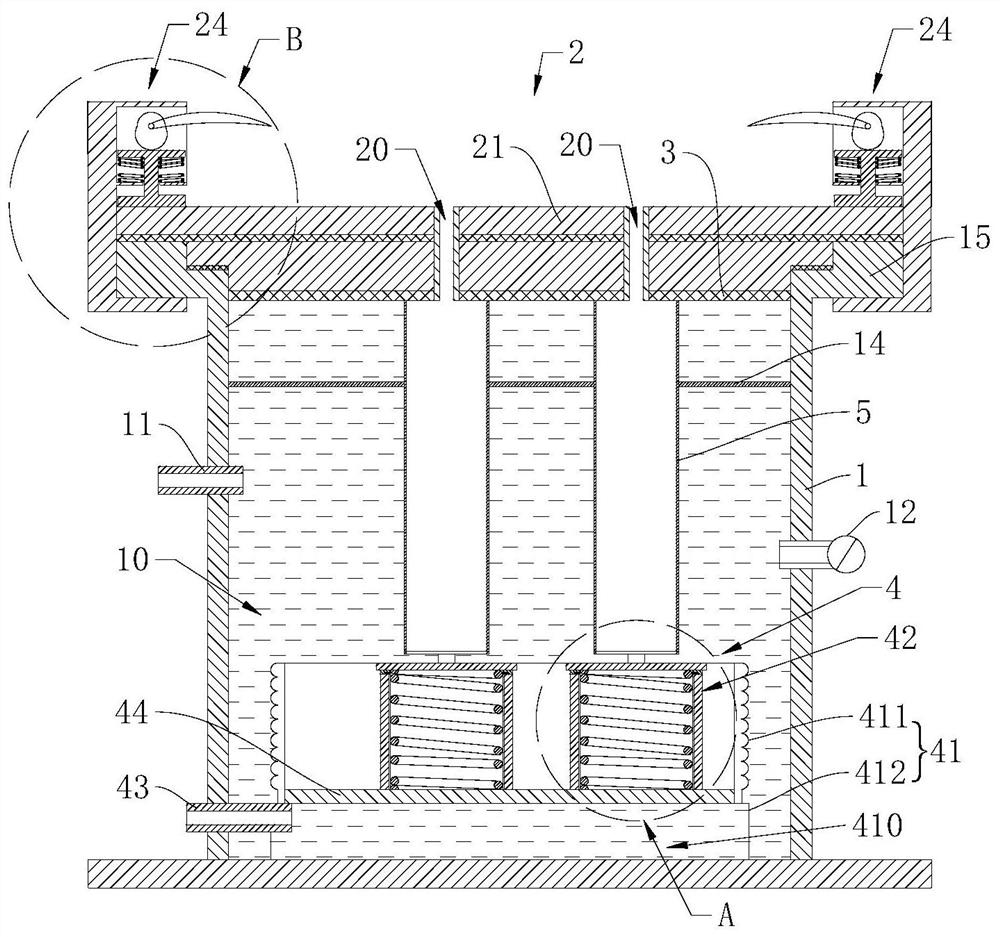

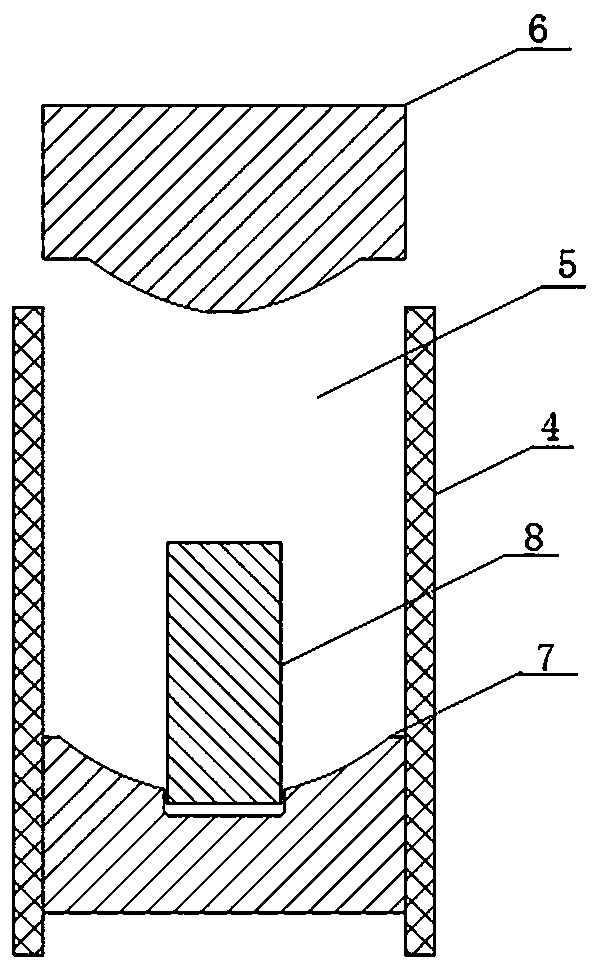

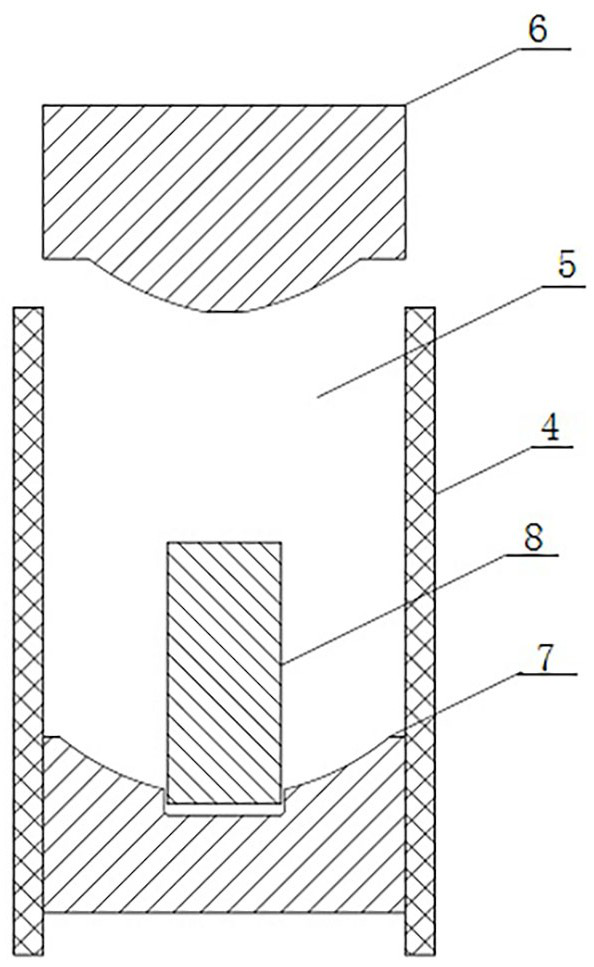

Device and method for detecting sealing pressure resistance of sounding pipe for cast-in-place pile

The invention provides a device for detecting the sealing pressure resistance of a sounding pipe for a cast-in-place pile and a method using the device. The device comprises a sealed container, an endcover assembly and a hydraulic lifting mechanism, wherein the sealed container is used for containing hydraulic oil, the end cover assembly is connected to an opening in the top end of the sealed container in a sealed mode, and an elastic gasket is arranged on the lower surface of the end cover assembly; the end cover assembly and the elastic gasket are further provided with ventilation openingsused for communicating with the interior of the sounding pipe; the hydraulic lifting mechanism is arranged in an inner cavity and positioned below the elastic gasket, and comprises an oil filling shell and a lifting table; the oil filling shell is provided with an oil filling cavity used for containing hydraulic oil, and the oil filling shell is further connected with an oil pipeline; and the lifting table or the oil filling shell is used for abutting against the end part of the sounding pipe. According to the device, when the hydraulic oil is continuously introduced into the oil filling cavity through the oil pipeline, the lifting table and the oil filling shell can be pushed to move upwards until the end part of the sounding pipe abuts against the elastic gasket in a sealed mode. Compared with the prior art, welding operation is not needed, the workload is reduced, and the detection efficiency is improved.

Owner:中交路桥科技有限公司

Support and hanger shell convenient to disassemble

The invention relates to the field of support and hanger shells, in particular to a support and hanger shell convenient to disassemble. The support and hanger shell convenient to disassemble comprises a support and hanger shell body. The support and hanger shell body is composed of an upper shell body and a lower shell body. A top plate is arranged at the top end of the upper shell body. Protruding blocks are arranged on the bottom surface of the top plate, and the tail ends of the protruding blocks extend into the upper shell body. Sliding blocks are arranged at the tail end of the upper shell body and slidably connected in sliding grooves of the lower shell body. Grooves are formed in the upper surface of the lower shell body and communicate with the sliding grooves. A through hole is formed in the bottom surface of the lower shell body. By adding the sliding blocks and the sliding grooves, the sliding blocks enter the sliding grooves through the grooves, and thus the upper shell body and the lower shell body can be fixedly connected; if the upper shell body and the lower shell body need to be separated, the sliding blocks only need to be separated from the sliding grooves and lifted out from the grooves; and in this way, the welding process is avoided, the cost is reduced, installing of the support and hanger shell is facilitated, and support and hanger internal maintenance is also facilitated.

Owner:江苏万威电气有限公司

Redistribution device structure of heat exchanger

ActiveCN104567518AExpand material selectionEasy to disassembleHeat exchanger casingsPlate heat exchangerMixing effect

The invention relates to a redistribution device structure of a heat exchanger. The structure is characterized by comprising a redistribution device arranged in a channel of the heat exchanger; the redistribution device comprises a connection sleeve accommodated in an inlet flange of the channel, the lower end of the connection sleeve is connected to a redistribution barrel, and the outer side wall of the connection sleeve is provided with a convex edge connected to the inlet flange; a plurality of baffles are arranged in the connection sleeve, first ends of the baffles are connected to the upper end edge of the redistribution barrel, second ends of the baffles are connected, and gaps are formed between adjacent baffles; the redistribution barrel is located in the inner cavity of the channel, and the wall of the redistribution barrel is provided with a plurality of discharge holes communicated with the inner cavity of the channel. The welding procedure is avoided, the integrity and anti-corrosion properties of the inner wall of the channel can be guaranteed, and the heat process of the channel is facilitated; meanwhile, the redistribution device can be detached and installed conveniently, by means of the secondary flow mixing of the baffles and redistribution barrel, the gas-liquid phase mixing effect is better, and the pressure drop is reduced.

Owner:ZHENHAI PETROCHEM JIANAN ENG

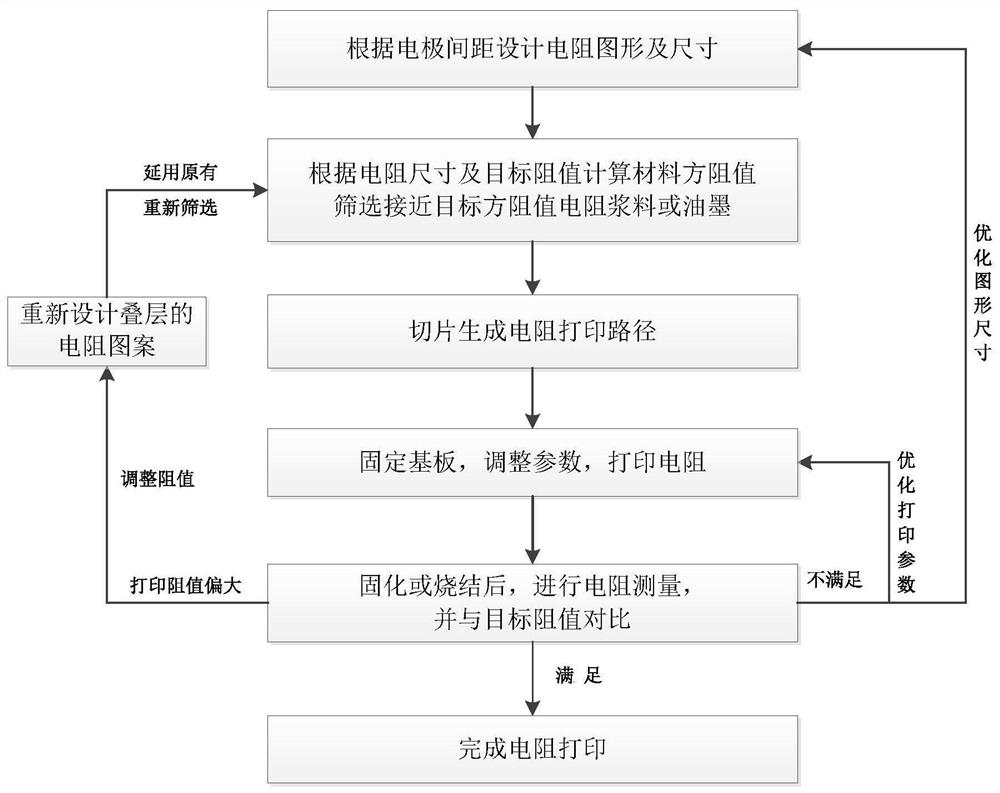

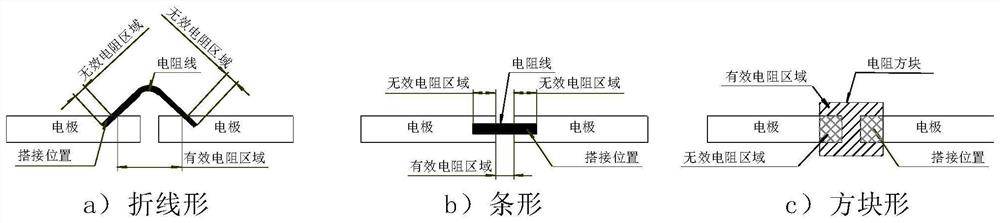

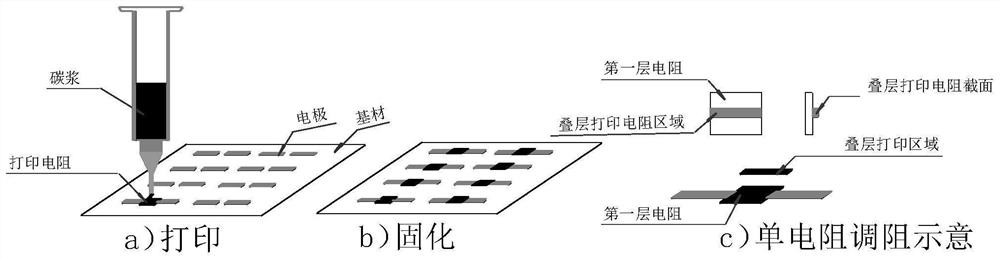

Method for preparing 3D printing resistor and adjusting resistance value

The invention discloses a method for preparing a 3D printing resistor and adjusting the resistance value. The method comprises the following steps of: firstly, preliminarily designing the graphic size of the printed resistor according to information including the distance between electrodes, the space size and the required target resistance value, secondly, calculating the sheet resistance value or the resistivity of a material needing to be printed, and screening printed resistor slurry or printing ink; generating a printing path file of the resistor; fixing the base material on a printer base table, adjusting printing parameters, and completing resistor printing; after the printed resistor is cured and sintered, testing the resistor, comparing with a target resistance value, and if the target resistance value design is met, finishing printing; and if not, adjusting the resistance value by adopting an optimized design pattern size or printing parameters, or adjusting the resistance value on the basis of the printed and cured resistor. According to the invention, screen plate manufacturing and material waste in a traditional silk-screen printing process can be avoided, in addition, the resistor pattern and the resistor thickness can be flexibly adjusted, and the problem that the thickness is difficult to accurately adjust in silk-screen printing is avoided.

Owner:西安瑞特三维科技有限公司

Plug structure for bed and plug structure-based bedding

InactiveCN102960978BAvoid collision damageGood lookingBedstandsFurniture joiningEngineeringStamping process

The invention discloses a plug structure for bedding. The plug structure comprises a column 1 and a cross bar connected with the column, and the column and the cross bar are connected through a connector 8 which comprises a cylinder 21 and a clamped hook body 22, wherein the clamped hook body comprises a hook-shaped part hooked at the column and a straight-edge part clamped at one side of the column; a cylinder port at the other side of the cylinder is formed with an internally retracted outer edge; and the cross bar is connected at the outer edge. The invention further provides basic forms of single-layer beds or bunk beds and apartment beds based on the above connecting structure. The bedding provided by the invention is beautiful, simple, firm, durable, green, and environmentally friendly. By using a stamping process, a welding process is omitted and production cost is reduced; and by using a component connecting form such as inserting and combining, size is reduced and transportation and installation are facilitated.

Owner:徐华玉

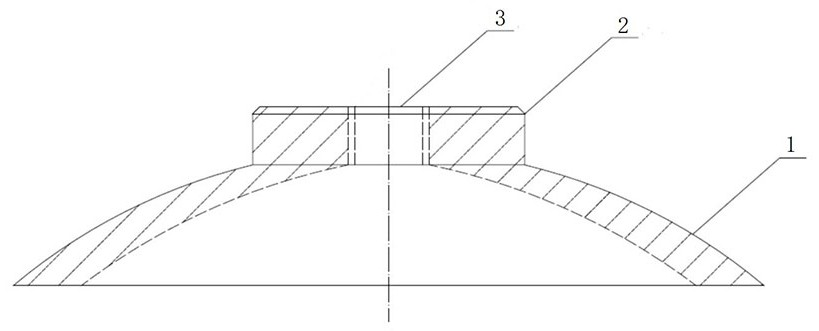

Liquefied petroleum gas bottle upper cover and product thereof

ActiveCN109366097ASimple structureStable structureVessel mounting detailsContainer filling methodsGas cylinderMetallic materials

The invention discloses a preparation process of a liquefied petroleum gas bottle upper cover and a product thereof. The preparation process of the liquefied petroleum gas bottle upper cover comprisesthe following steps of A, blank pretreatment, B, performing blank extrusion forming, and C, carrying out rough blank finishing treatment on the cover body. The liquefied petroleum gas bottle upper cover comprises a cover body and a valve seat, the cover body and the valve seat are made of an extrusion method, the cover body and the valve seat are integrally formed, a through hole is formed in thecenter of the valve seat, and threads are arranged on the through hole. The valve seat and the upper cover are integrally formed, so that the welding process of a traditional gas cylinder is avoided,the number and the length of the welding seam of the whole gas cylinder are reduced, and the using safety of the gas cylinder is improved; in the extrusion forming process of the cover body, the metal material and the inner wall of an extrusion cylinder do not slide relative to each other, the metal flowing in the extrusion process is uniform, and compared with a traditional stamping method, thesize precision of the part is high, and the structure is more compact; compared with the prior art, the manufacturing process is reduced, the production processing efficiency is improved, and the production cost is reduced.

Owner:KUNMING METALLURGY INST

bridge crane bridge

ActiveCN108128698BFirmly connectedHigh precisionLoad-engaging girdersRunwaysStructural engineeringSteel plates

The invention discloses a bridge crane loading bridge which comprises rectangular through holes, a main beam, end beams and a positioning plate. The rectangular through holes are formed in the two ends of first fixing steel plates, the first fixing steel plates are arranged on one sides of the end beams, the other sides of the end beams are provided with second fixing steel plates, the inner sidesof the second fixing steel plates are provided with limiting grooves corresponding to the rectangular through holes, a groove is formed between the inner walls of the second fixing steel plates and the first fixing steel plates, the main beam is connected between the end beams, and the two ends of the main beam penetrate through the rectangular through holes and the groove to be connected with the limiting grooves. By means of the first fixing steel plates and the second fixing steel plates, the first fixing steel plates, the second fixing steel plates and the end beams are of an integrally-formed U-shaped structure, the two ends of the main beam penetrate through the rectangular through holes to be connected with the limiting grooves in the inner sides of the second fixing steel plates,the two ends of the main beam are fixed to the positioning plate through fastening screws, the main beam can be connected with the end beams conveniently, tedious welding working procedures are avoided, the whole bridge accuracy is improved, and disassembly and assembly are convenient and fast.

Owner:合肥市春华起重机械有限公司

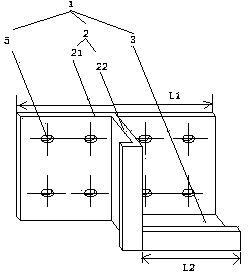

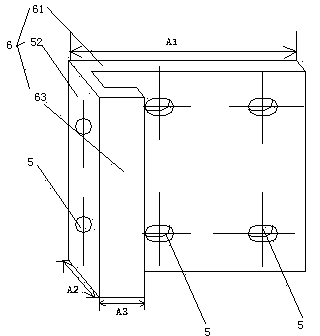

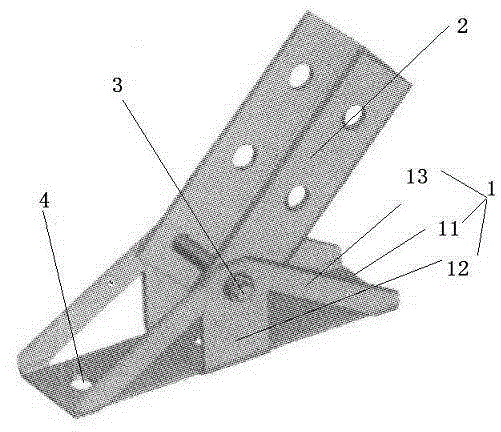

Corner connecting piece special for solar photovoltaic support

InactiveCN104092429AReduce processLow costPhotovoltaic supportsPhotovoltaic energy generationArchitectural engineeringPhotovoltaics

The invention discloses a corner connecting piece special for a solar photovoltaic support. The corner connecting piece comprises a base and a stand column. The base is an integral part and comprises a base plate and parallel lateral plates arranged on the two sides of the base plate respectively, the lateral plates are perpendicular to the base plate, and the lateral plates are isosceles-triangle-shaped parts. The stand column is a groove-shaped part and located between the two lateral plates, one end of the stand column is connected with the base through a bolt to form a whole, and the bolt penetrates through the top ends of the two lateral plates and the two sides of the stand column to enable the stand column and the base to be connected into the whole. Supporting plates are arranged on the two lateral plates respectively and located on the center line of the base plate, one end of each supporting plate is connected with the base plate, and the other end of each supporting plate is connected with the top end of the corresponding lateral plate. The corner connecting piece is convenient to use, and adjustment at any angel ranging from 0 degree to 180 degrees can be achieved.

Owner:JIANGSU DALICHENG ELECTRICAL

Permanent magnet submersible linear motor and manufacturing method thereof

ActiveCN106571729BImprove securityImprove quality reliabilityManufacturing dynamo-electric machinesPropulsion systemsElectric machineLinear motor

The invention provides a permanent magnetic submersible linear motor and a manufacturing method thereof. The permanent magnetic submersible linear motor comprises a mover, a stator and a casing which are sequentially arranged from inside to outside, and resin filling materials are embedded into a gap between the stator and the mover and a gap between the stator and the casing. According to the permanent magnetic submersible linear motor, the gap between the stator and the mover and the gap between the stator and the casing are embedded through the resin filling materials, fully mixing and stirring the filling materials and then embedding the filling materials into the motor stator with an embedding tire are only required in an embedding process, welding during connecting a stainless steel cylinder with a stator core can be avoided, improving safety and quality reliability of the motor is facilitated, moreover, the embedded materials after curing exist in a solid mode, so the motor needs no quite high sealingness, processing precision and dimension requirements of each part of the motor are relatively loose, dimension in the embedding process depends on the embedding tire, and precision is higher compared with the stainless steel cylinder.

Owner:PETROCHINA CO LTD +1

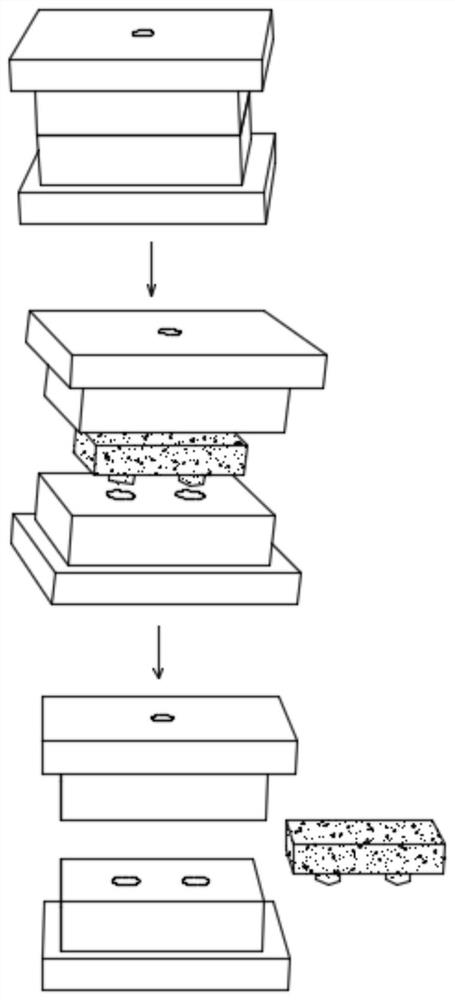

Injection molding process of foamed multicolor material

InactiveCN113146918AAvoid the influence of external uncertain factorsSpeed up the injection molding processPolymer scienceFoaming agent

The invention discloses an injection molding process of a foamed multicolor material, and belongs to the field of injection molding process. The injection molding process of the foaming multicolor material comprises the following steps: mixing of a polymer melt and a foaming agent: uniformly mixing the foaming agent with the polymer melt through a microcellular foaming injection molding machine, and keeping a high-pressure environment; forming of a preformed blank: injecting the mixed system of the polymer melt and the foaming agent into a special-shaped mold, and performing pressure maintaining and cooling to obtain the preformed blank; heating and foaming: starting foaming after softening the preformed blank; foaming and expanding the polymer melt; and cooling: after foaming and expansion, starting to cool the mold to room temperature, and finally, opening the mold to take a part to obtain a final finished product. According to the scheme, the original step of transferring the preformed blank is omitted, heating and foaming treatment is directly carried out after the preformed blank is formed, the preformed blank does not make contact with the outside before foaming, the influence of external uncertain factors is avoided, by deleting the working procedures, the injection molding process is accelerated, and the injection molding quality can be optimized.

Owner:银川网曌科技有限公司

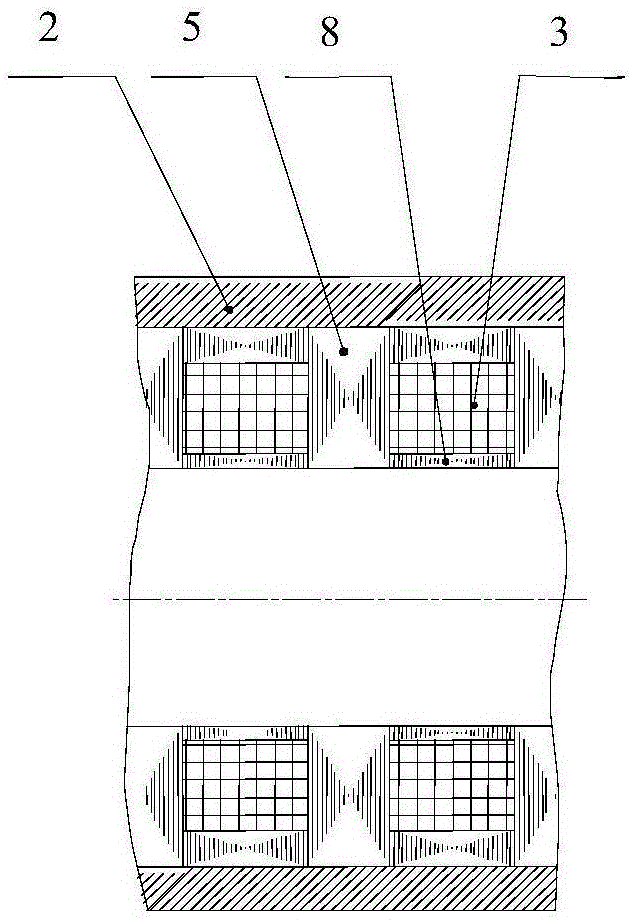

Circuit board interconnecting device

ActiveCN101877934BAvoid soldering processImprove consistencyMagnetic/electric field screeningPrinted circuit detailsHemt circuitsMechanical engineering

The invention provides a circuit board interconnecting device which comprises a signal wire, wherein the signal wire is connected with circuit board modules on different printed circuit boards, a shielding device used for signal reflux is arranged adjacent to the signal wire, and the shielding device is crimped on the circuit module on the printed circuit board through a separating rib. Accordingto the technical scheme, the shielding devices crimped on the circuit boards on different printed circuit boards are directly connected with the separating ribs on the first circuit module and the second circuit module, so the embodiment of the invention realizes the interconnection of the signal reflux, avoids the welding procedure, improves the consistency of the assembly, and reduces the cost.

Owner:HUAWEI TECH CO LTD

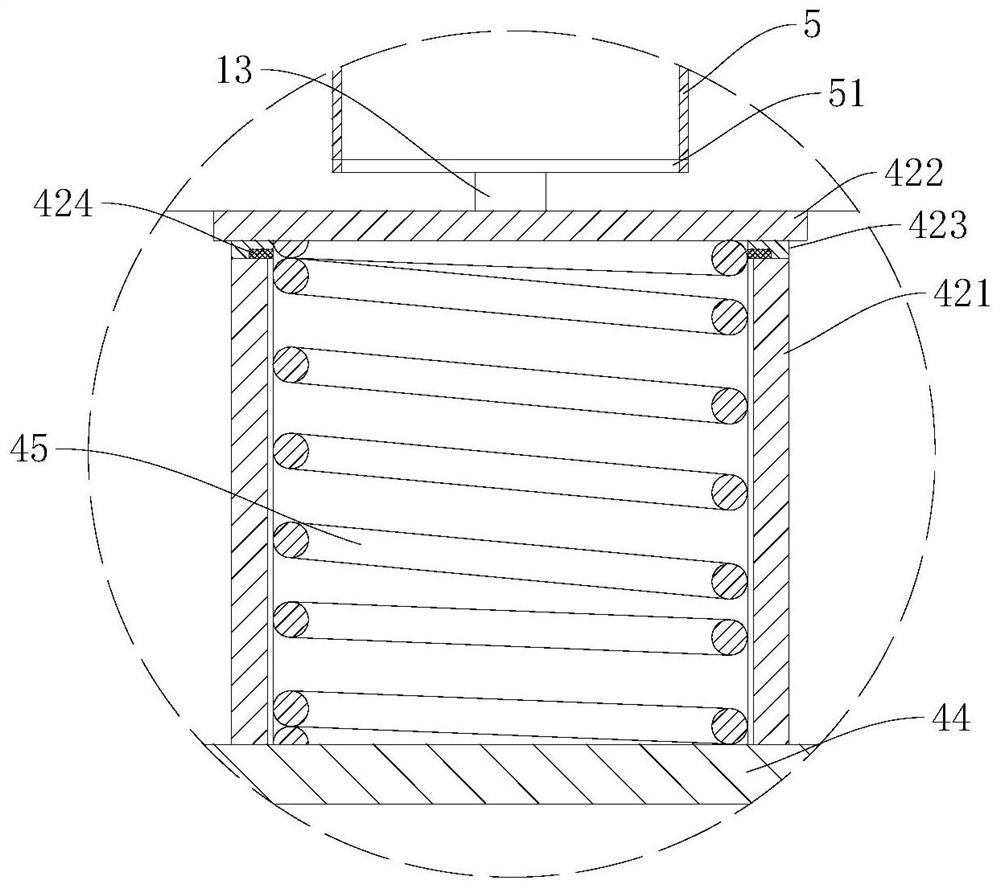

Distributed sewage equipment assembling method

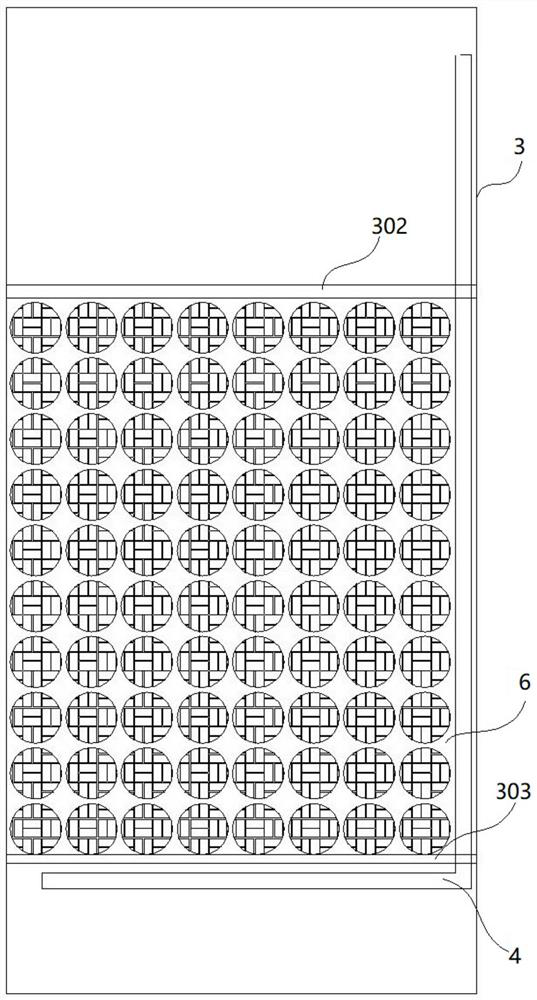

InactiveCN112919621AEmission complianceReduce processBiological treatment apparatusSustainable biological treatmentSewageSewage treatment

The invention relates to the technical field of sewage treatment, and particularly discloses a distributed sewage equipment assembling method, and distributed sewage equipment comprises a tank body, a water outlet cylinder and grid cylinders; the water outlet cylinder is arranged in the middle of the tank body; the plurality ofgrid cylinders are spliced and mounted between the water outlet cylinder and the tank body; thegrid cylinder comprises supporting legs, an upper grid, a lower grid and a cylinder body, the supporting legs are installed in the cylinder body, and the upper grid and the lower grid are installed on the supporting legs in parallel at intervals; a packing layer, an aeration pipe and a water guide pipe are respectively arranged on each grid cylinder; the packing layer is arranged between the upper grid and the lower grid; one end of the aeration pipe is arranged at the bottom of the grid cylinder; and one end of the water guide pipe is arranged at the bottom of the latticed cylinder, and the other end of the water guide pipe is arranged at the top of the adjacent latticed cylinder. The modular assembly mode is adopted, various requirements can be met, the production efficiency can be improved, and meanwhile follow-up replacement and maintenance are facilitated.

Owner:GUANGZHOU RESOURCE ENVIRONMENTAL PROTECTION TECH CO LTD +1

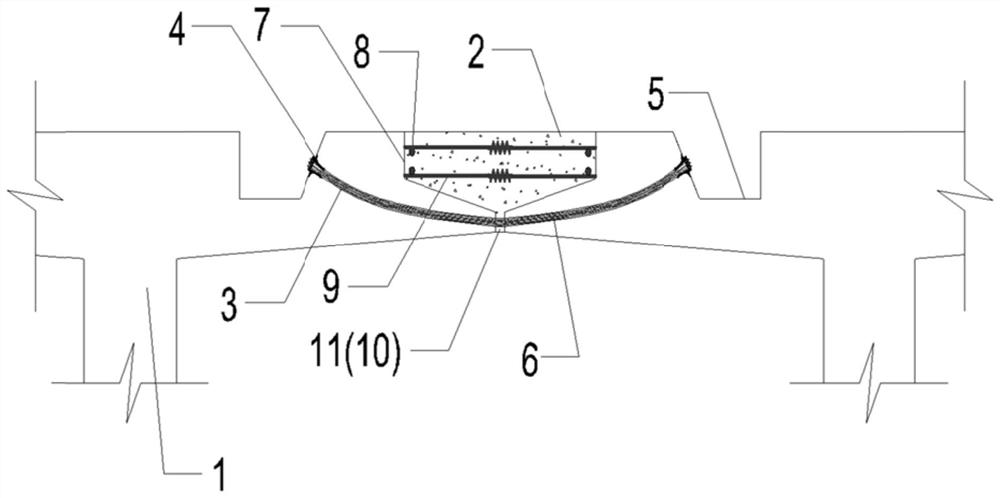

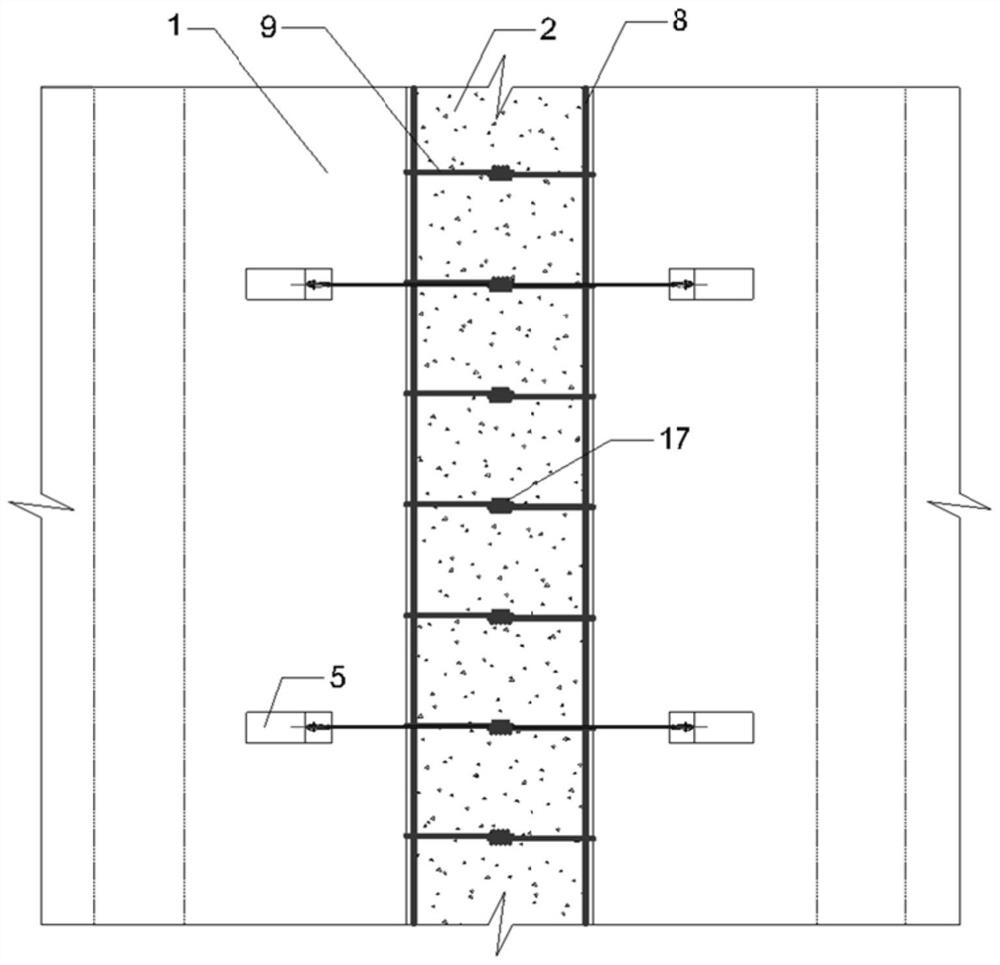

Bridge deck rabbet wet joint connecting structure and construction method thereof

PendingCN114293462AImprove performanceImprove mechanical propertiesBridge structural detailsBridge erection/assemblyConcrete beamsPre stress

The invention discloses a bridge deck rabbet wet joint connecting structure and a construction method thereof, two adjacent prefabricated concrete beams are connected through a reserved UHPC wet joint, and ultra-high performance concrete is poured in the UHPC wet joint; a prestressed duct is reserved in a flange plate of the prefabricated concrete beam, a prestressed steel strand is arranged in the prestressed duct, and clamping piece anchorage devices are embedded in the two sides of the prestressed duct. The method has the characteristics of easiness in industrialized production, small field pouring amount, high construction speed, high wet joint quality, small influence on construction field traffic and surrounding environment and the like.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES +1

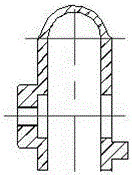

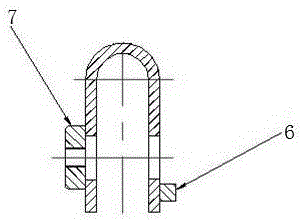

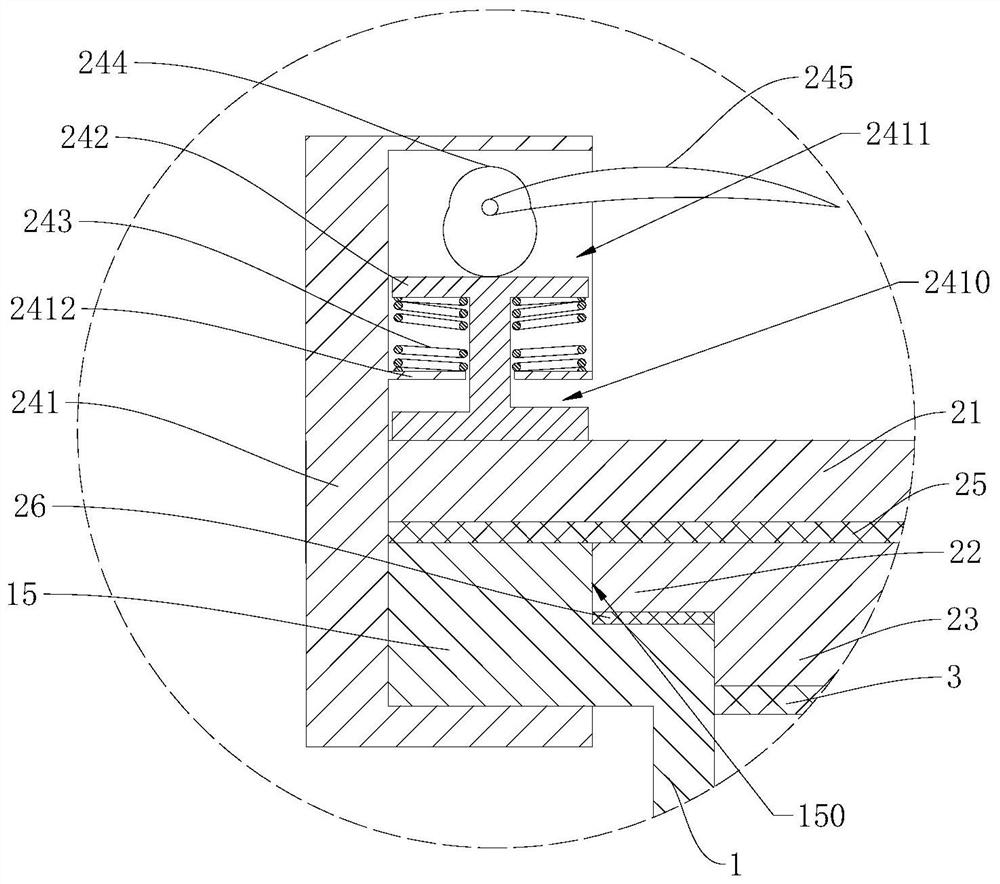

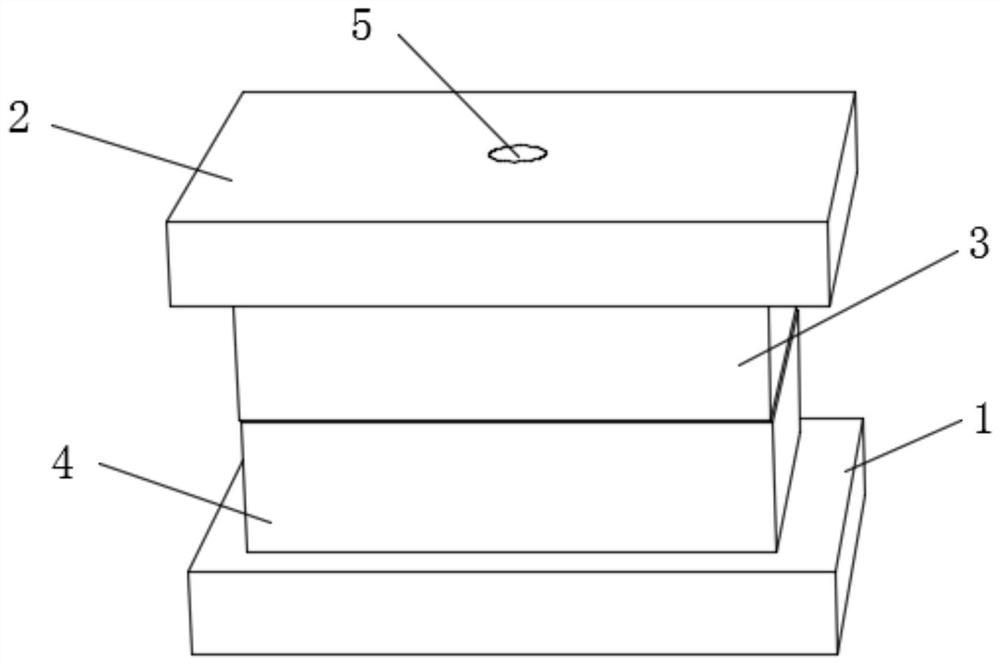

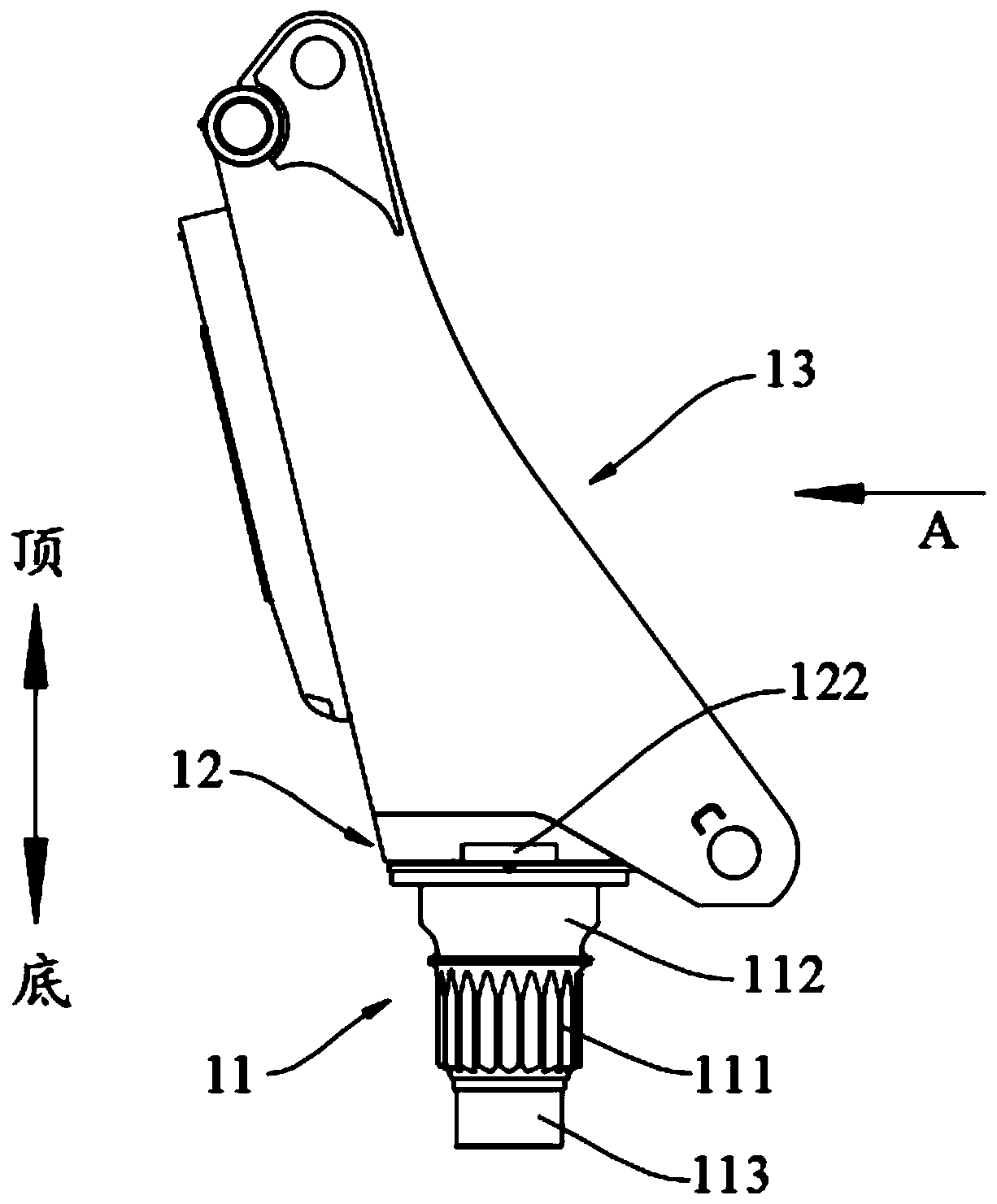

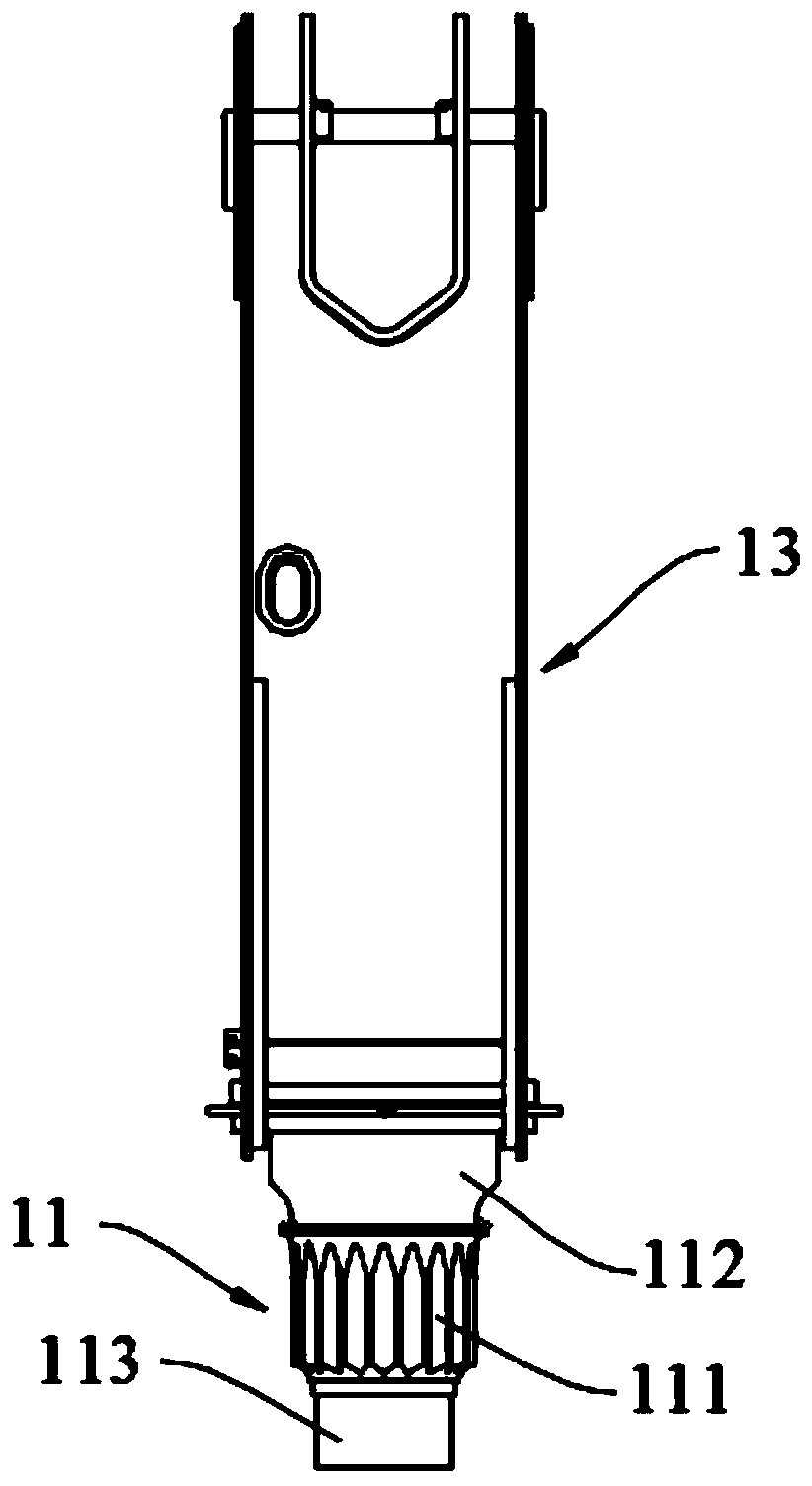

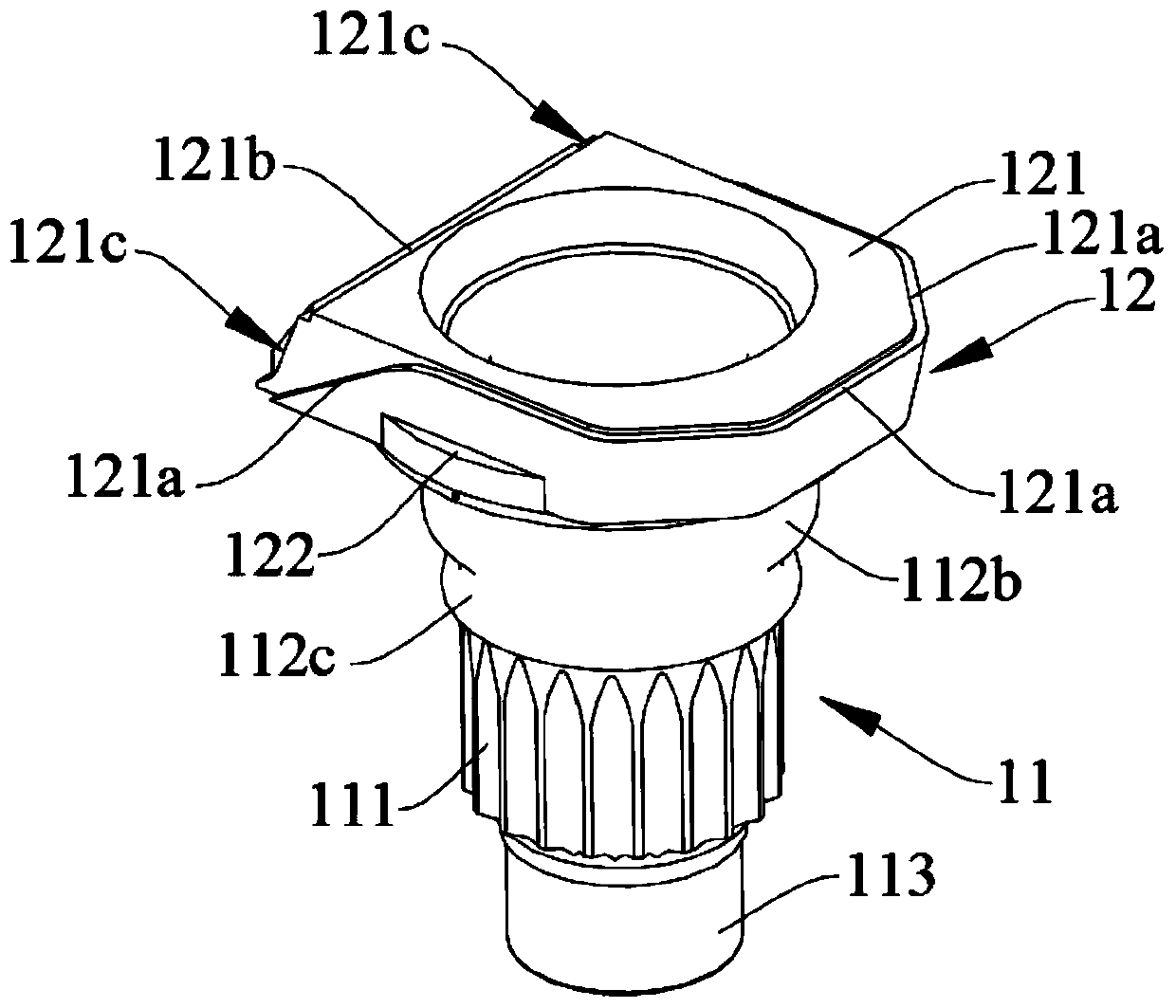

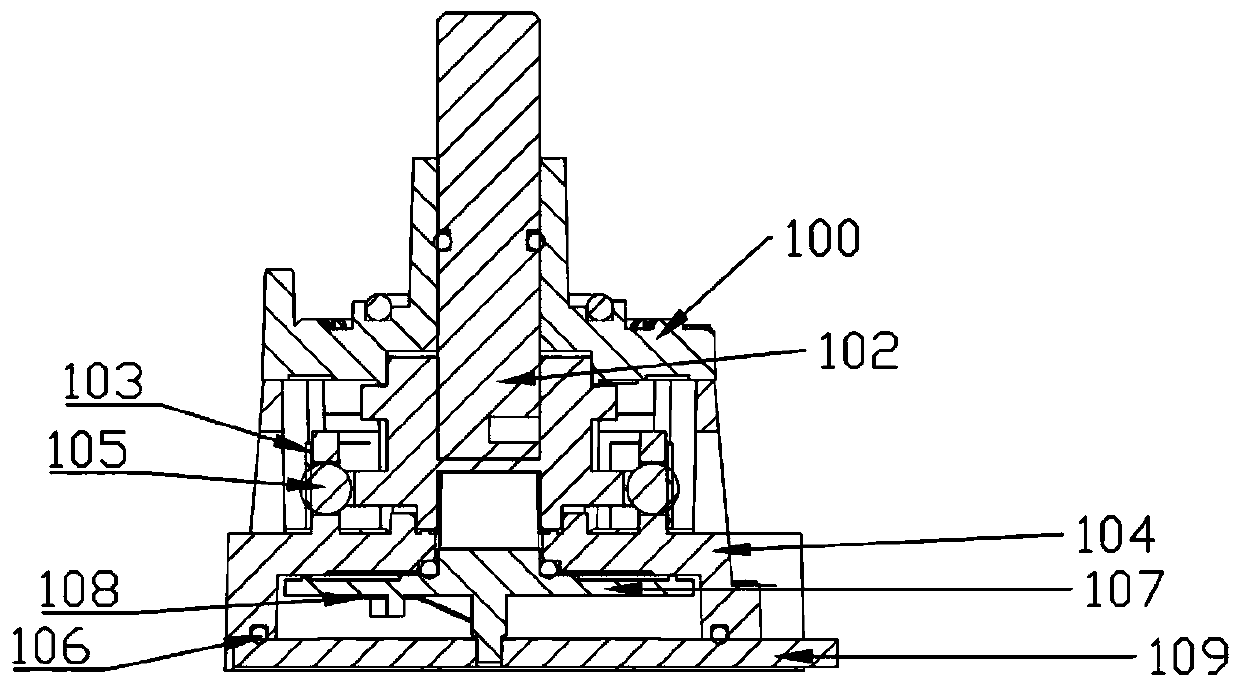

Gyration device and lorry-mounted crane

PendingCN111153334AAvoid soldering processEasy to processCranesStructural engineeringMechanical engineering

The invention provides a gyration device and a lorry-mounted crane. The gyration device comprises a gear shaft, a base and a gyration stand column, wherein the base and the gear shaft are of an integral casting structure; the gyration stand column is welded to the base; and the gear shaft is used for driving the gyration stand column to rotate. In the gyration device, the gear shaft and the base are an integral-forming integral casting, a welding working procedure between the gear shaft and the base is avoided, processing is convenient, and stability is good when the integral casting drives the gyration stand column to rotate.

Owner:HUNAN SHUANGDA ELECTROMECHANICAL CO LTD

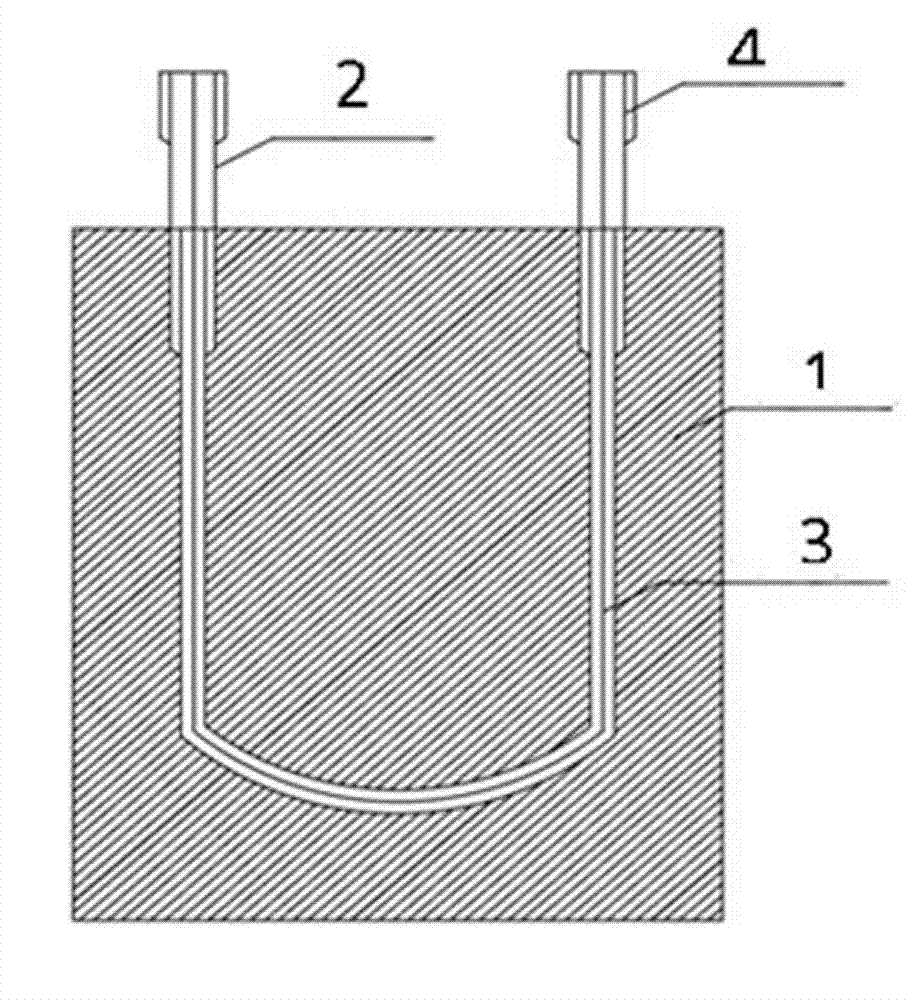

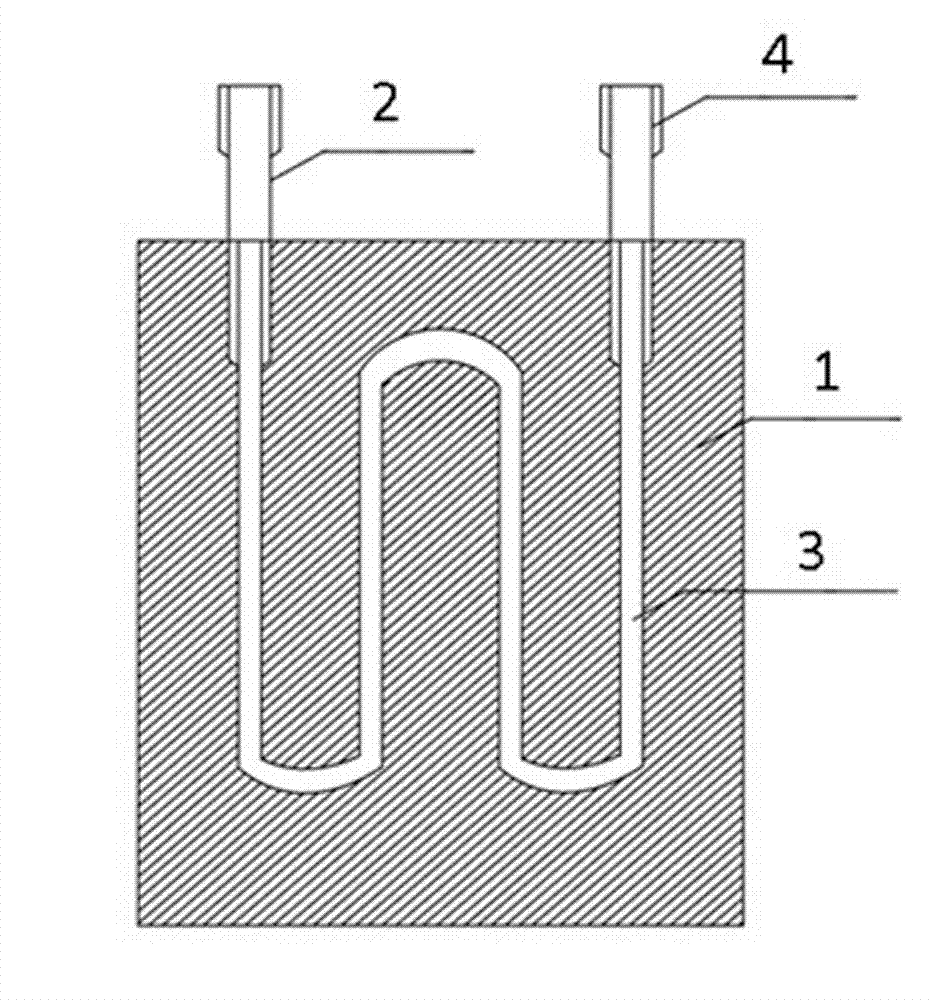

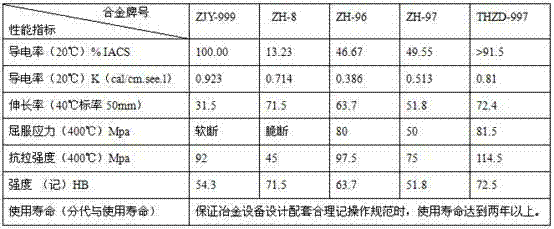

Conductive copper water jacket and casting process thereof

InactiveCN102865744AImprove heat transfer efficiencyExtended service lifeFoundry mouldsFurnace cooling arrangementsYttriumWater pipe

The invention provides a conductive copper water jacket which is used on a metallurgical furnace or a high temperature furnace. The conductive copper water jacket comprises a copper base body, a cooling water channel, a water inlet pipe and a water outlet pipe, wherein the cooling water channel is arranged inside the copper base body; the water inlet pipe and the water outlet pipe are communicated with the cooling water channel; and the cooling water channel, the water inlet pipe, the water outlet pipe and the copper base body are of an integrated overall structure. The procedure of welding the water inlet pipe, the water outlet pipe, the cooling water channel and the copper base body is avoided; the problem of welding leakage is prevented; the cooling water channel is shaped at a time; the cooling water is directly contacted with the copper base body; the cooling effect is improved; the service life of the water jacket is prolonged; as the copper base body is doped with phosphorus, magnesium, arsenic and yttrium, the density of the copper base body is increased effectively, the copper crystallization is finned, and the electric conductivity and the heat-conducting property of the copper are increased.

Owner:WUWEI HUICHENG IND TRADE

Circuit board interconnecting device

ActiveCN101877934AAvoid soldering processImprove consistencyPrinted circuit detailsMagnetic/electric field screeningInterconnectionPrinted circuit board

The invention provides a circuit board interconnecting device which comprises a signal wire, wherein the signal wire is connected with circuit board modules on different printed circuit boards, a shielding device used for signal reflux is arranged adjacent to the signal wire, and the shielding device is crimped on the circuit module on the printed circuit board through a separating rib. According to the technical scheme, the shielding devices crimped on the circuit boards on different printed circuit boards are directly connected with the separating ribs on the first circuit module and the second circuit module, so the embodiment of the invention realizes the interconnection of the signal reflux, avoids the welding procedure, improves the consistency of the assembly, and reduces the cost.

Owner:HUAWEI TECH CO LTD

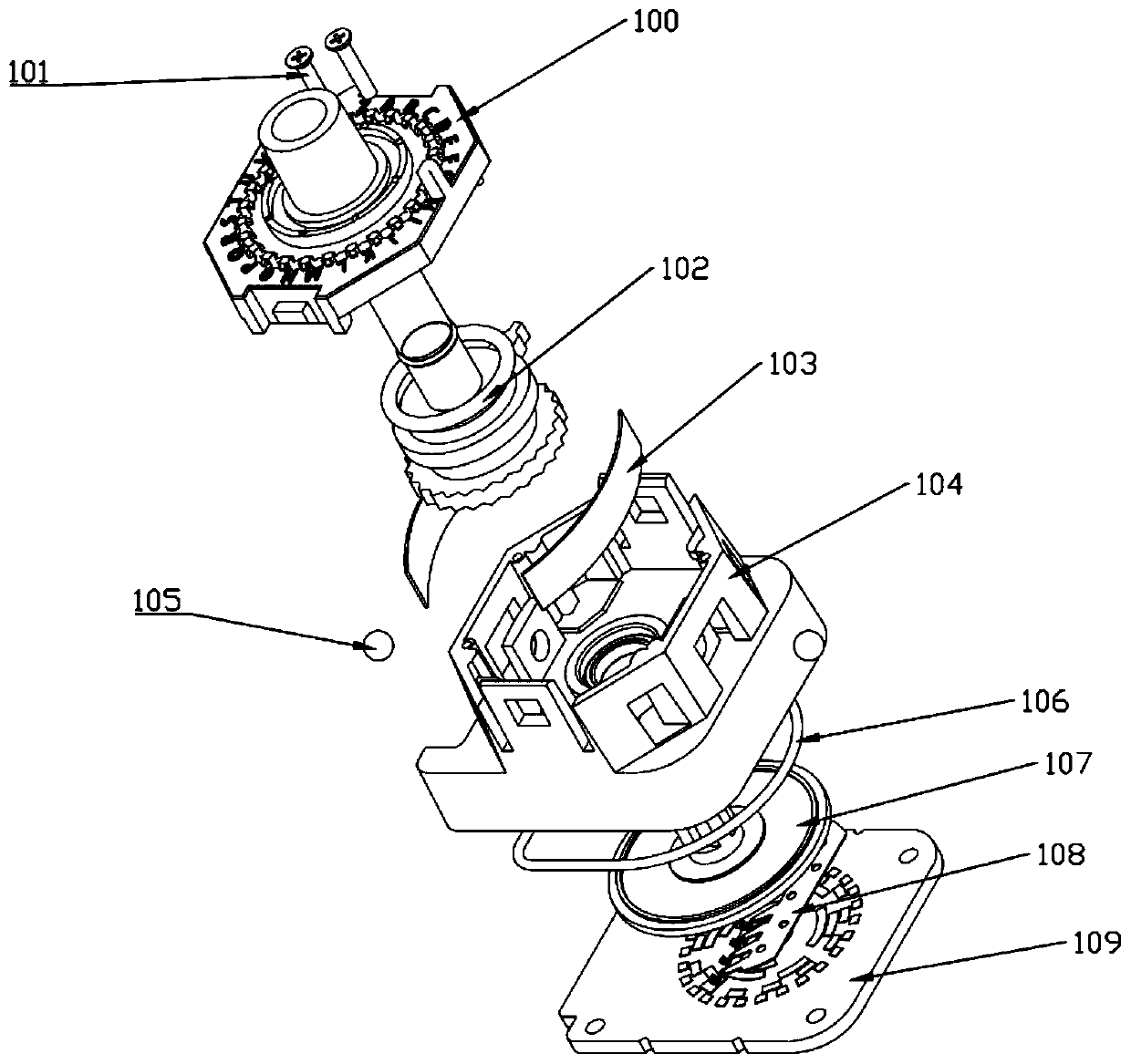

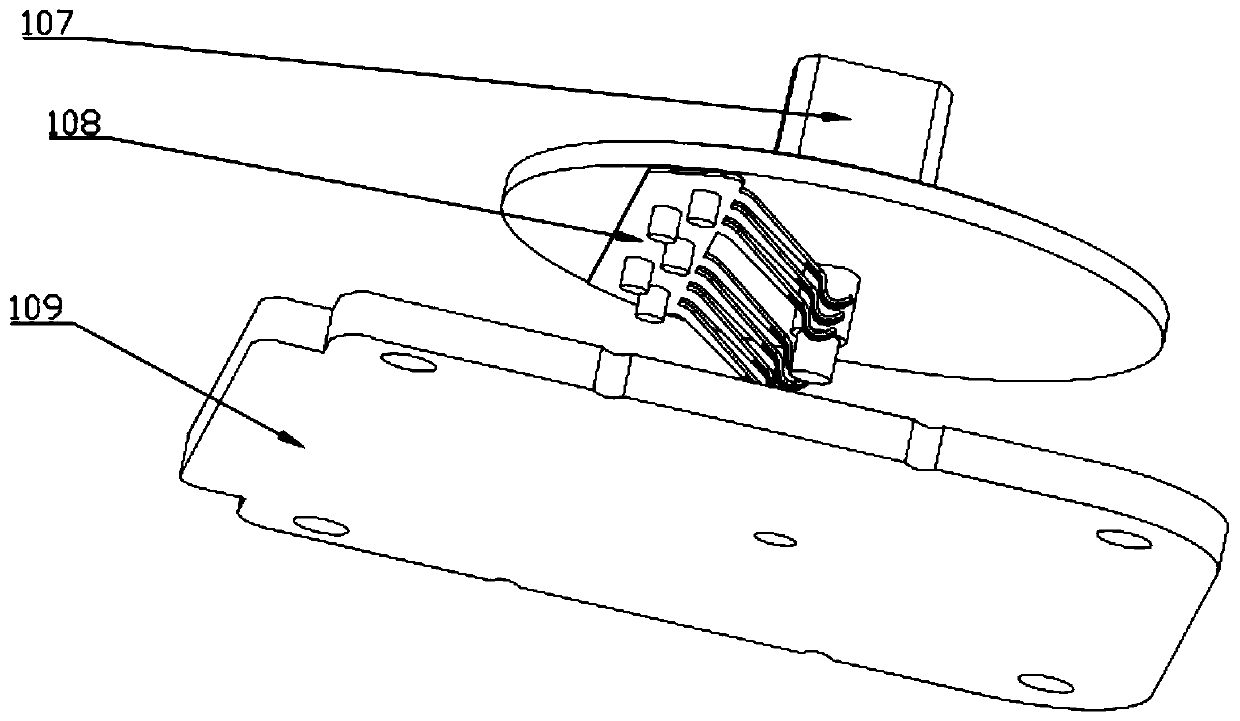

Binary band switch

A binary band switch comprises the following parts of a housing, a code disc assembly mounted on the bottom of the housing, an upper cover mounted on the upper portion of the housing, a gear assemblyextending through the upper cover and partially extending into the housing, a ball mounting hole disposed on the side of the housing, a detent ball disposed in the ball mounting hole and cooperating with the gear assembly for gear rotation, a detent shrapnel mounted in the housing and used for providing elastic force when selecting gears, and a shrapnel assembly disposed above the code disc assembly, wherein the lower part of the gear assembly is coupled to the shrapnel assembly and configured to drive the shrapnel assembly to frictionally rotate on the code disc assembly. In the binary band switch, the code disc assembly is located downwardly in a fixed structure and the shrapnel assembly is located upwardly as a rotating mechanism, which avoids the welding shrapnel process; and the shrapnel piece adopts an integrated shrapnel, which avoids the error of artificial assembly and improves the product consistency.

Owner:广州市诺帝恩技术有限公司

Double-decker bed based on plug-in type guardrail

The invention discloses a double-decker bed based on a plug-in type guardrail. The double-decker bed comprises a vertical post (1) as well as an upper and a lower layer bed surrounded by beams, wherein the upper layer bed is provided with a ladder stand (3); one outer side in the length direction of the upper layer bed is provided with an upper layer bed guardrail; the upper layer bed guardrail comprises a vertical rod (12) and an outer handrail (4); the outer handrail comprises a horizontal straight rod part and an arc-shaped connection rod part; the external end of the horizontal straight rod part is connected to the vertical post (1) by a connecting piece (8); and the arc-shaped connection rod part is connected to the lower beam (2) by an intermediate unit (11). The bed disclosed by the invention has the following characteristics of beauty, simplicity, fastness, endurance and environment friendliness. With the adoption of a stamping technique, the welding process is omitted, so that the production cost is reduced; and with the adoption of an insertion and combination part connection mode, the volume is reduced, and the bed is convenient to transport and mount.

Owner:徐华玉

A kind of preparation technology and product of liquefied petroleum gas bottle top cover

ActiveCN109366097BSimple structureStable structureVessel mounting detailsContainer filling methodsGas cylinderMetallic materials

The invention discloses a preparation process and a product of the upper cover of a liquefied petroleum gas bottle. The preparation process of the upper cover of the liquefied petroleum gas bottle includes A, blank pretreatment, B, blank extrusion molding and C, cover body rough blank trimming treatment. The upper cover of the liquefied petroleum gas cylinder includes a cover body and a valve seat, the cover body and the valve seat are made by extrusion, the cover body and the valve seat are integrally formed, and a through hole is provided in the center of the valve seat Threads are provided on the through holes. In the present invention, the valve seat and the upper cover are arranged in an integrated structure, which avoids the welding process of the traditional gas cylinder, reduces the number and length of the welding seams of the whole gas cylinder, and improves the use safety of the gas cylinder; , because there is no relative sliding between the metal material and the inner wall of the extrusion cylinder, the metal flow is uniform during the extrusion process. Compared with the traditional stamping method, the parts prepared by the traditional stamping method have higher dimensional accuracy and a tighter structure; compared with the existing technology, the manufacturing process is reduced, and the production is improved. Improve processing efficiency and reduce production costs.

Owner:KUNMING METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com