Liquefied petroleum gas bottle upper cover and product thereof

A technology of petroleum gas cylinders and preparation technology, which is applied in the direction of mechanical equipment, container discharge methods, container structure installation devices, etc., which can solve the problems of gas leakage, explosion, etc., achieve uniform metal flow, reduce production costs, and improve use safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

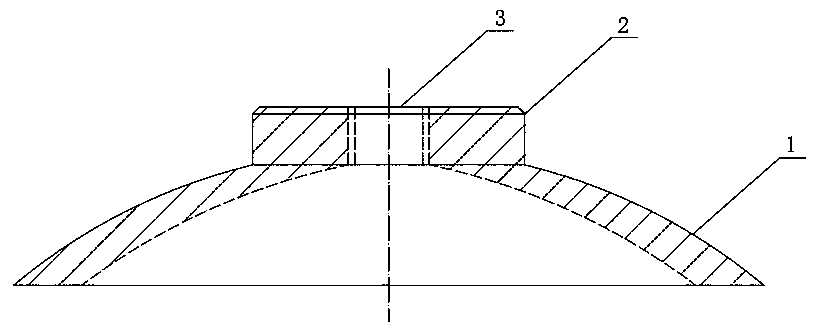

[0031] Example 1: 1) According to the size of the cover body 1, the aluminum alloy round bar ingot is cut into the billet 8 of the required thickness in advance, and the billet 8 is placed in a heating furnace with a temperature of 280~450°C and heated for 30~ 40min;

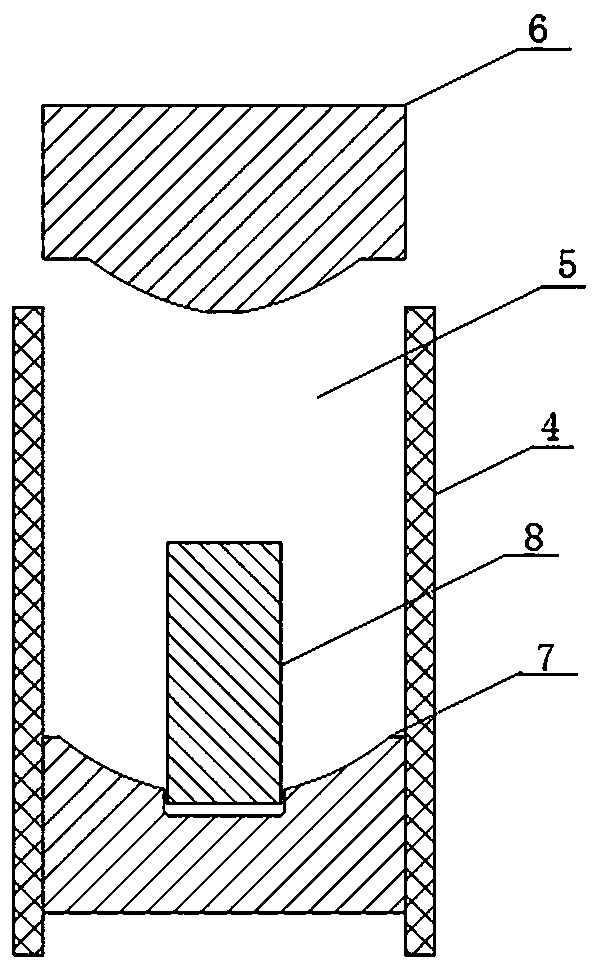

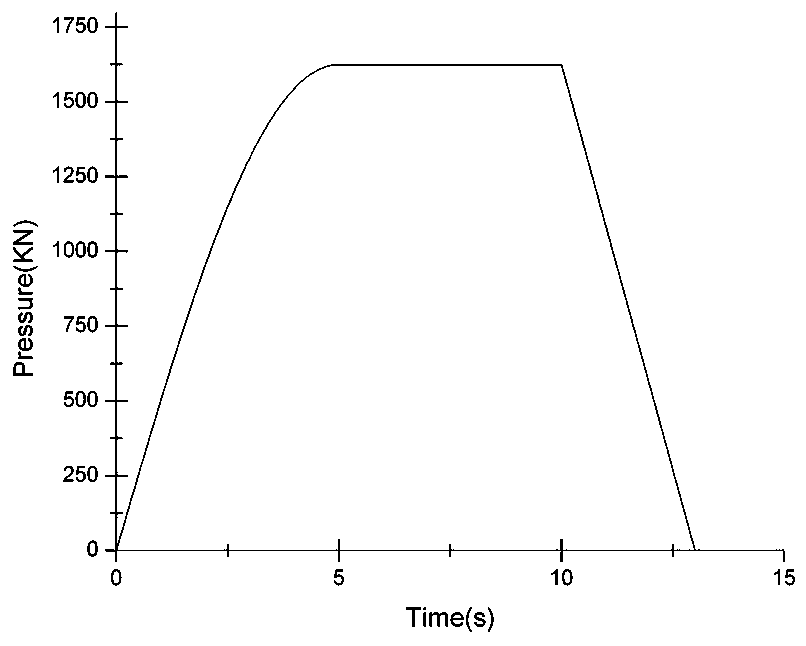

[0032] 2) Apply lubricant to the heated billet 8, the cavity 5 of the extrusion die 4 and the lower pressure head 7 respectively, and place the billet 8 in the cavity 5 of the extrusion die 4, and the height of the cavity 5 A positive number h must be greater than the height of the cover body 1 at least 80~140mm, start the upper pressing head 6 of the press to press the billet 8 downward at a speed of 3mm / s and a pressure of 1500KN, and the upper pressing head 6 presses the billet downward The pressure change time curve of 8 is attached image 3 As shown, make the blank 8 contact with the lower ram 7 and fill the cavity 5, then adjust the upper ram 6 to continue pressing down the blank 8 at a speed of 1mm / s and...

Embodiment 2

[0035] Embodiment 2: 1) According to the size of the cover body 1, the aluminum alloy round bar ingot is cut into the billet 8 of the required thickness in advance, and the billet 8 is put into a heating furnace with a temperature of 280~450°C and heated for 30~ 40min;

[0036] 2) Apply lubricant to the heated billet 8, the cavity 5 of the extrusion die 4 and the lower pressure head 7 respectively, and place the billet 8 in the cavity 5 of the extrusion die 4, and the height of the cavity 5 If it is a positive number, h must be greater than the height of the cover body 1 by at least 80~140mm. Start the upper pressing head 6 of the press to press the billet 8 downward at a speed of 4mm / s and a pressure of 1562.5KN, and the upper pressing head 6 will press downward. The pressure change time curve of billet 8 is as attached image 3 As shown, make the billet 8 contact with the lower ram 7 and fill the cavity 5, then adjust the upper ram 6 to continue pressing down the billet 8 a...

Embodiment 3

[0039] Example 3: 1) According to the size of the cover body 1, the aluminum alloy round bar ingot is cut into a billet 8 of required thickness in advance, and the billet 8 is placed in a heating furnace with a temperature of 280~450°C for heating for 30~ 40min;

[0040] 2) Apply lubricant to the heated billet 8, the cavity 5 of the extrusion die 4 and the lower pressure head 7 respectively, and place the billet 8 in the cavity 5 of the extrusion die 4, and the height of the cavity 5 If it is a positive number, h must be greater than the height of the cover body 1 by at least 80~140mm, start the upper pressing head 6 of the press to press down the billet 8 at a speed of 5mm / s and a pressure of 1625KN, and the upper pressing head 6 presses down the billet The pressure change time curve of 8 is attached image 3 As shown, make the blank 8 contact with the lower ram 7 and fill the cavity 5, then adjust the upper ram 6 to continue pressing down the blank 8 at a speed of 3mm / s and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com