A kind of preparation technology and product of liquefied petroleum gas bottle top cover

A preparation process and technology of petroleum gas cylinders, applied in the field of production and manufacturing of liquefied petroleum gas cylinders, can solve problems such as explosion and gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

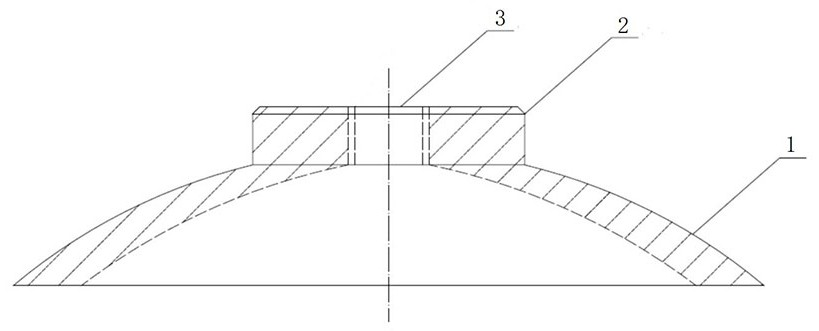

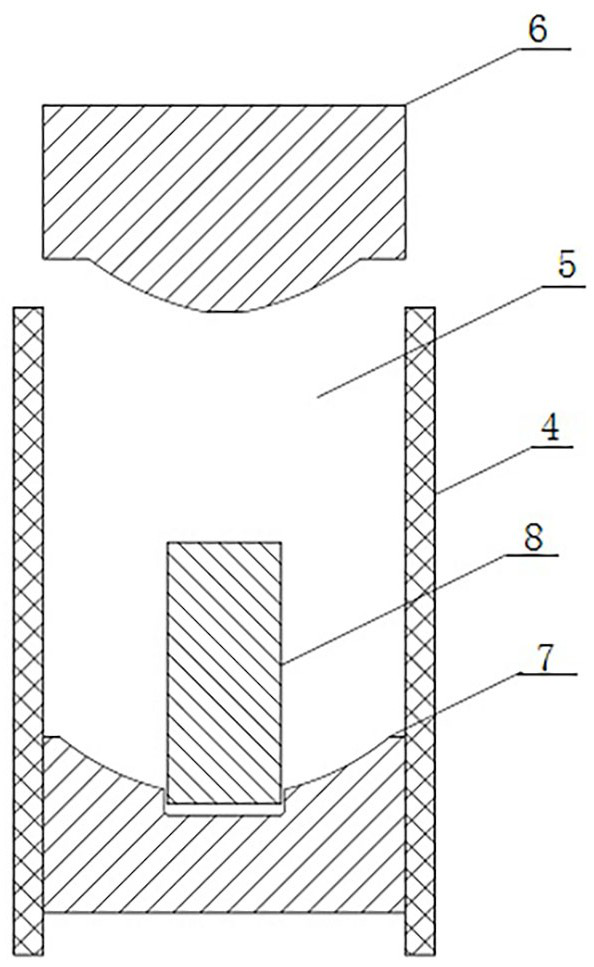

[0031] Example 1: 1) According to the size of the cover body 1, the aluminum alloy round bar ingot is cut into the billet 8 of the required thickness in advance, and the billet 8 is placed in a heating furnace with a temperature of 280~450°C and heated for 30~ 40min;

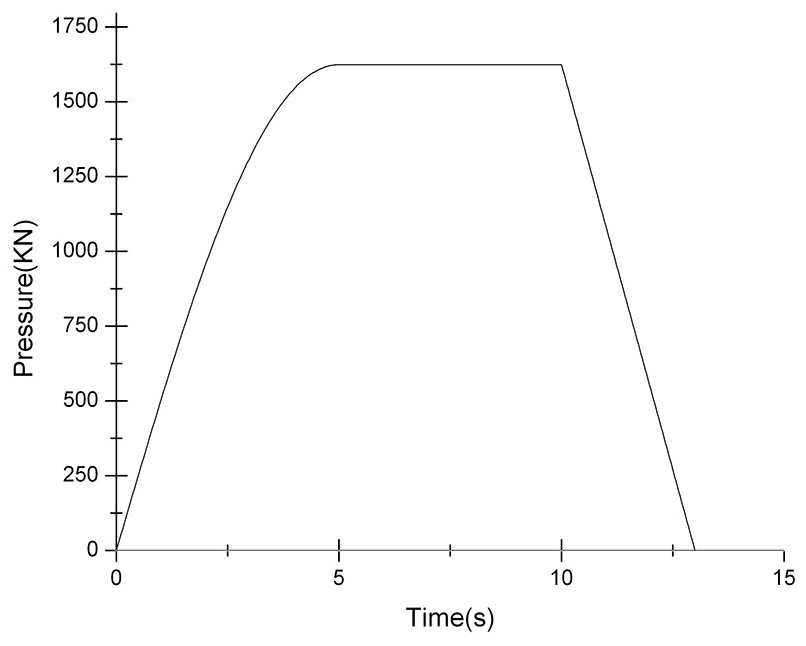

[0032] 2) Apply lubricant to the heated billet 8, the cavity 5 of the extrusion die 4 and the lower pressure head 7 respectively, and place the billet 8 in the cavity 5 of the extrusion die 4, and the height of the cavity 5 A positive number h must be greater than the height of the cover body 1 at least 80~140mm, start the upper pressing head 6 of the press to press the billet 8 downward at a speed of 3mm / s and a pressure of 1500KN, and the upper pressing head 6 presses the billet downward The pressure change time curve of 8 is attached image 3 As shown, make the blank 8 contact with the lower ram 7 and fill the cavity 5, then adjust the upper ram 6 to continue pressing down the blank 8 at a speed of 1mm / s and...

Embodiment 2

[0035] Embodiment 2: 1) According to the size of the cover body 1, the aluminum alloy round bar ingot is cut into the billet 8 of the required thickness in advance, and the billet 8 is put into a heating furnace with a temperature of 280~450°C and heated for 30~ 40min;

[0036] 2) Apply lubricant to the heated billet 8, the cavity 5 of the extrusion die 4 and the lower pressure head 7 respectively, and place the billet 8 in the cavity 5 of the extrusion die 4, and the height of the cavity 5 If it is a positive number, h must be greater than the height of the cover body 1 by at least 80~140mm. Start the upper pressing head 6 of the press to press the billet 8 downward at a speed of 4mm / s and a pressure of 1562.5KN, and the upper pressing head 6 will press downward. The pressure change time curve of billet 8 is as attached image 3 As shown, make the billet 8 contact with the lower ram 7 and fill the cavity 5, then adjust the upper ram 6 to continue pressing down the billet 8 a...

Embodiment 3

[0039] Example 3: 1) According to the size of the cover body 1, the aluminum alloy round bar ingot is cut into a billet 8 of required thickness in advance, and the billet 8 is placed in a heating furnace with a temperature of 280~450°C for heating for 30~ 40min;

[0040] 2) Apply lubricant to the heated billet 8, the cavity 5 of the extrusion die 4 and the lower pressure head 7 respectively, and place the billet 8 in the cavity 5 of the extrusion die 4, and the height of the cavity 5 If it is a positive number, h must be greater than the height of the cover body 1 by at least 80~140mm, start the upper pressing head 6 of the press to press down the billet 8 at a speed of 5mm / s and a pressure of 1625KN, and the upper pressing head 6 presses down the billet The pressure change time curve of 8 is attached image 3 As shown, make the blank 8 contact with the lower ram 7 and fill the cavity 5, then adjust the upper ram 6 to continue pressing down the blank 8 at a speed of 3mm / s and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com