Technological process of making wing type centrifugal vane whell

A manufacturing process, centrifugal impeller technology, applied in non-variable pumps, pump elements, components of pumping devices for elastic fluids, etc., can solve the problems of reduced space, large investment, and increased difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: it comprises following processing step

[0024] A. Manufacture of Airfoil Blades

[0025] a. Outsourcing processing of hollow aluminum profiles with non-equal wall thickness and wing section with longitudinal ribs, in which the ratio of the thicker curved surface wall thickness to the thinner plane wall thickness is greater than 2, and the ratio of the longitudinal rib wall thickness to the thinner wall thickness is greater than 3 ;

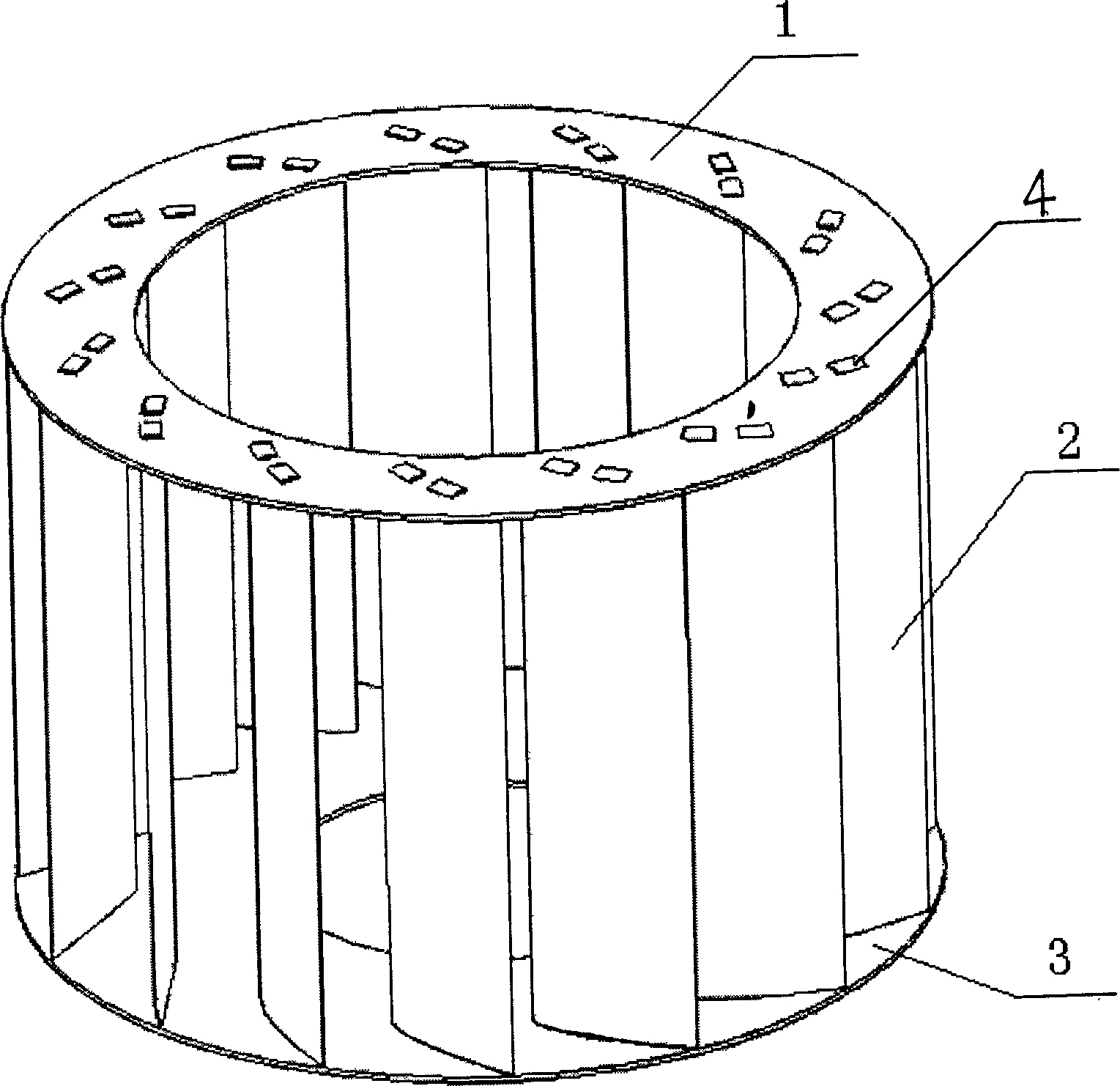

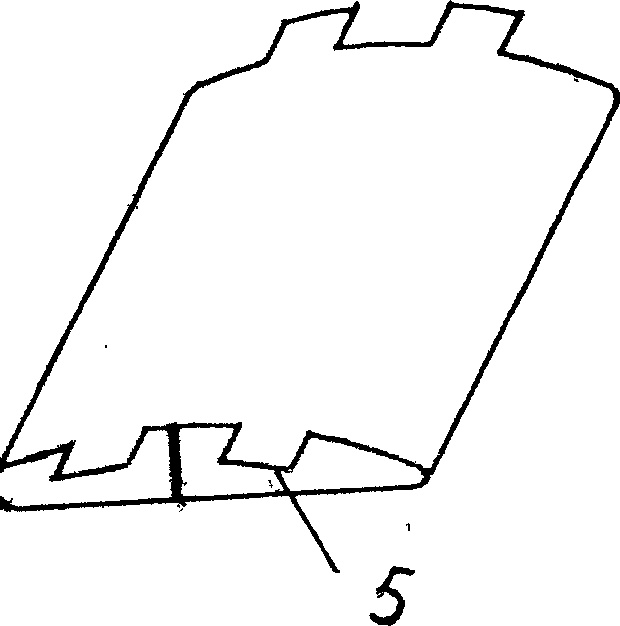

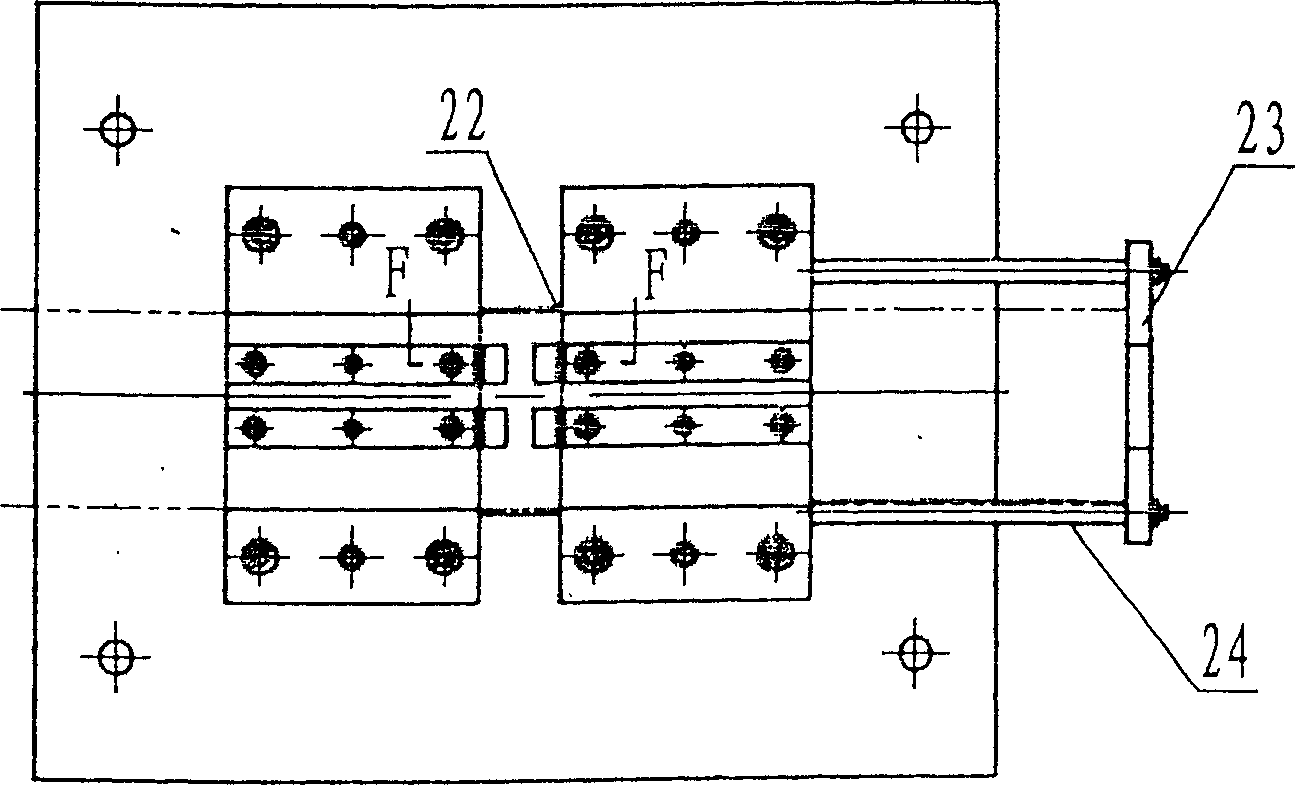

[0026] b. If figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the protrusion of the blade end on the joint surface of the punched blade end and the straight front disk 1, the straight rear disk 3 or the blade end and the arc or tapered front disk 1 and the straight rear disk 3 Platform 5, the mold should have the functions of shearing and indentation, wherein when punching the boss 5 of the blade end on the joint surface of the blade end and the arc-shaped or conical front disk 1, and the straight rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com