Plug structure for bed and plug structure-based bedding

A plug-in structure and bed technology, which is applied in the direction of furniture connection, connection components, household appliances, etc., can solve the problems of inconvenient transportation and large engineering volume, and achieve the effects of low labor cost, elimination of hazards, and low transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

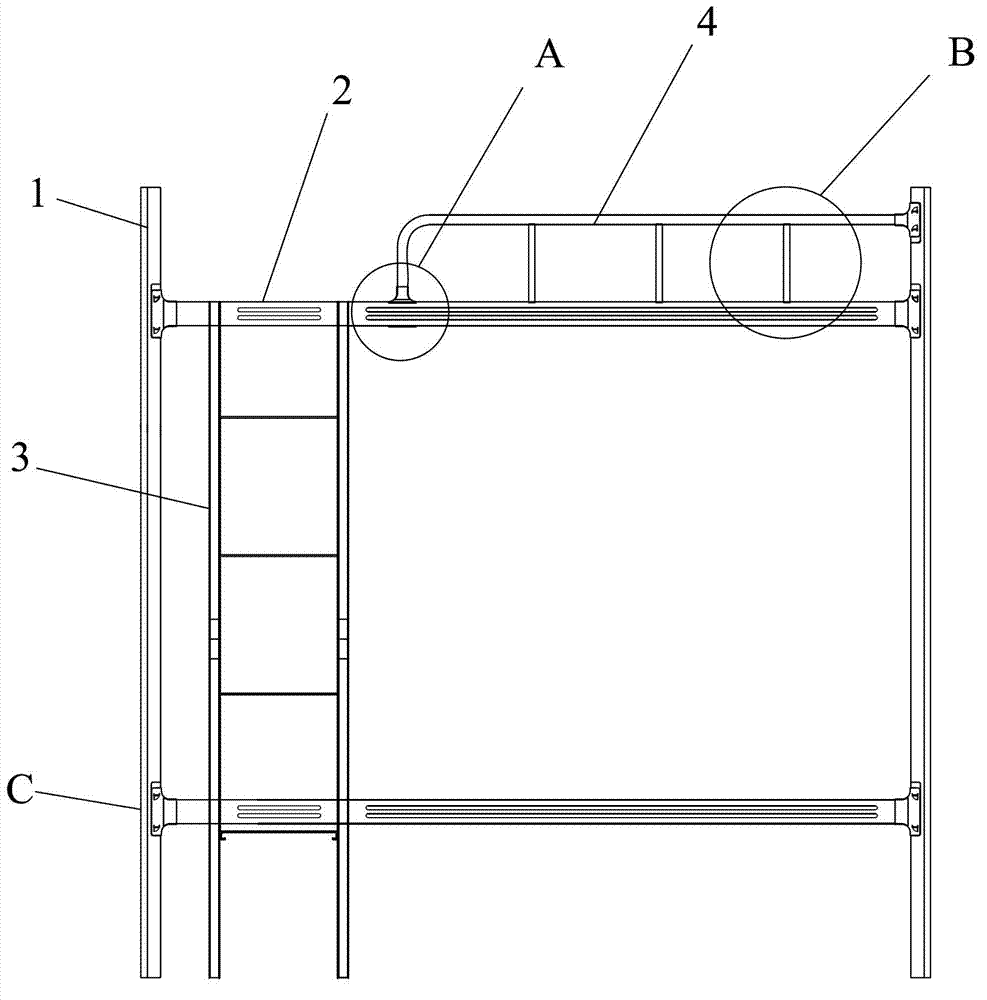

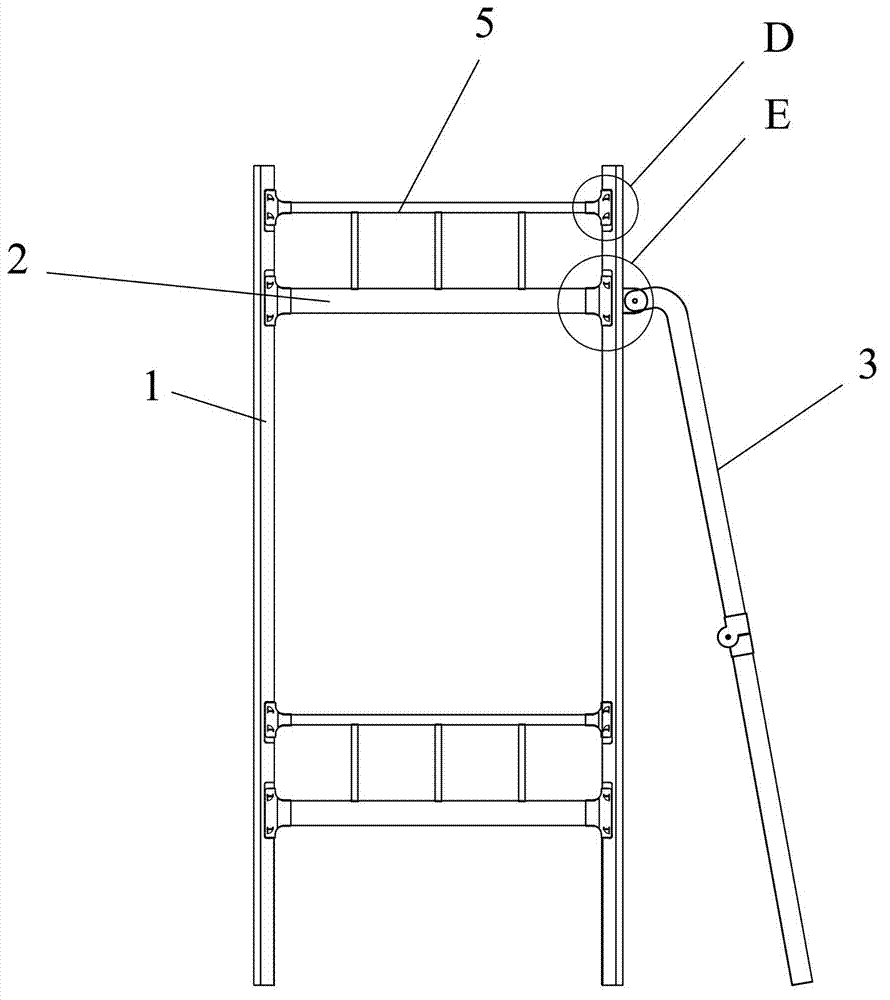

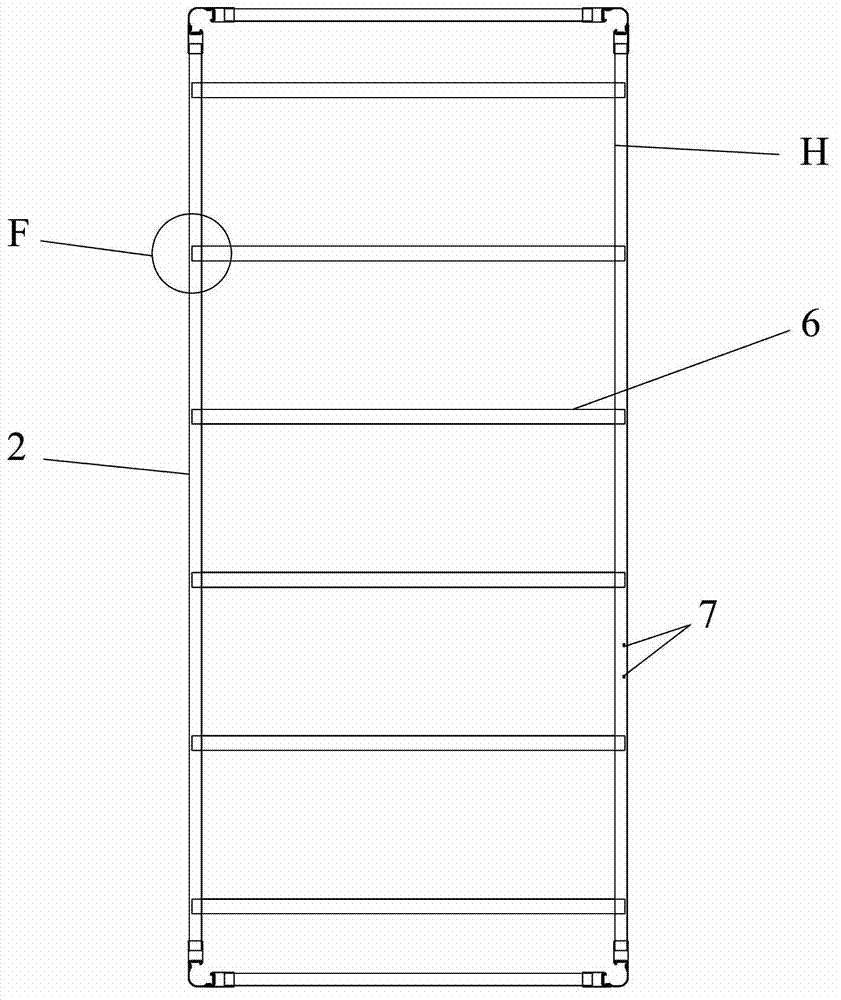

[0051] like Image 6 and 7 , combined with Figure 1-3 The shown bunk bed illustrates the plug-in structure of the present invention for the bed, including a column 1 supporting the bed body, and a cross bar connected to the column 1 . Cross bar among the figure is to form the surrounding cross beam 2 of bed; This cross bar also can be the horizontal bar 5 ( figure 2 shown) or the outer railing 4 ( figure 1 shown).

[0052] like Image 6 and 7 As shown, the cross-section of the column 1 is a "C"-shaped structure, the middle part is a circular arc transition, the two sides are at right angles, and each side is formed with a right-angle fold, and a bend 23 is formed at the end. .

[0053] The column 1 and the cross bar are connected by a connecting piece 8; the connecting piece 8 includes a cylinder body 21 and a snap-in hook body 22 blocked at the mouth of the cylinder body 21; the snap-in hook body 22 includes The hook-shaped portion hooked to the crimp 23 of the colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com