Binary band switch

A band switch and binary technology, applied in the field of numerical control equipment, can solve problems such as high requirements for the consistency of shrapnel welding, misjudgment of the numerical control system, and waveform disorder, so as to avoid the shrapnel welding process, avoid combined installation, and improve consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

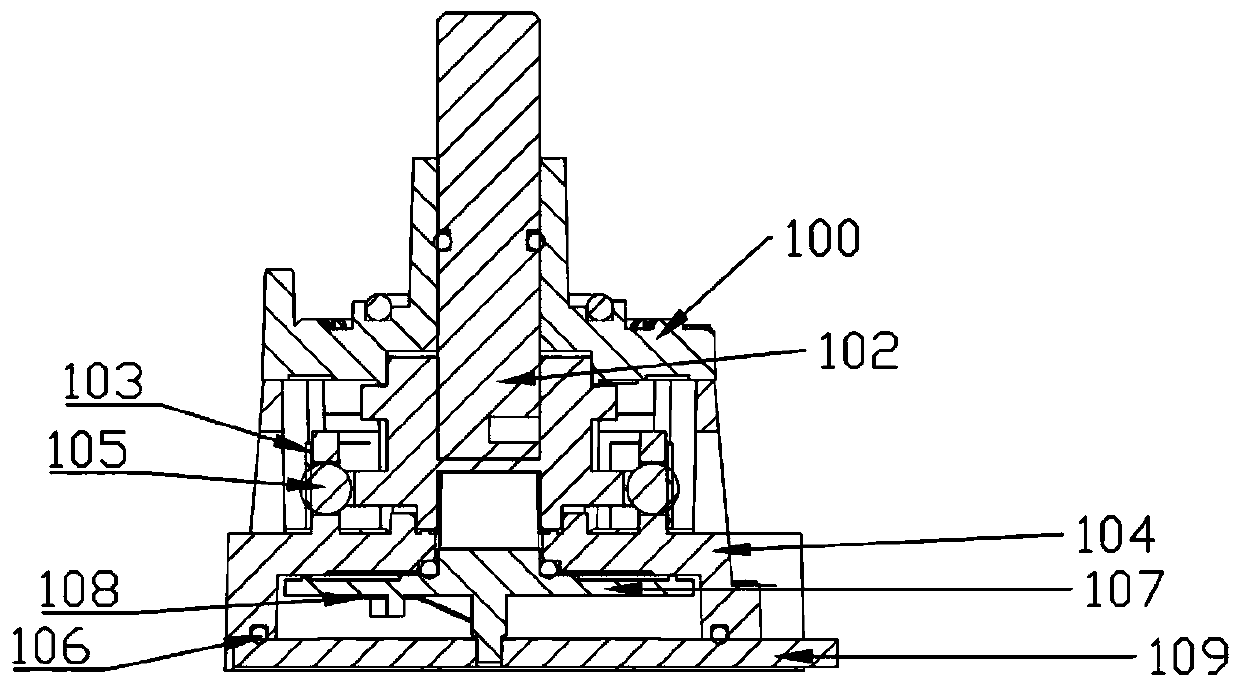

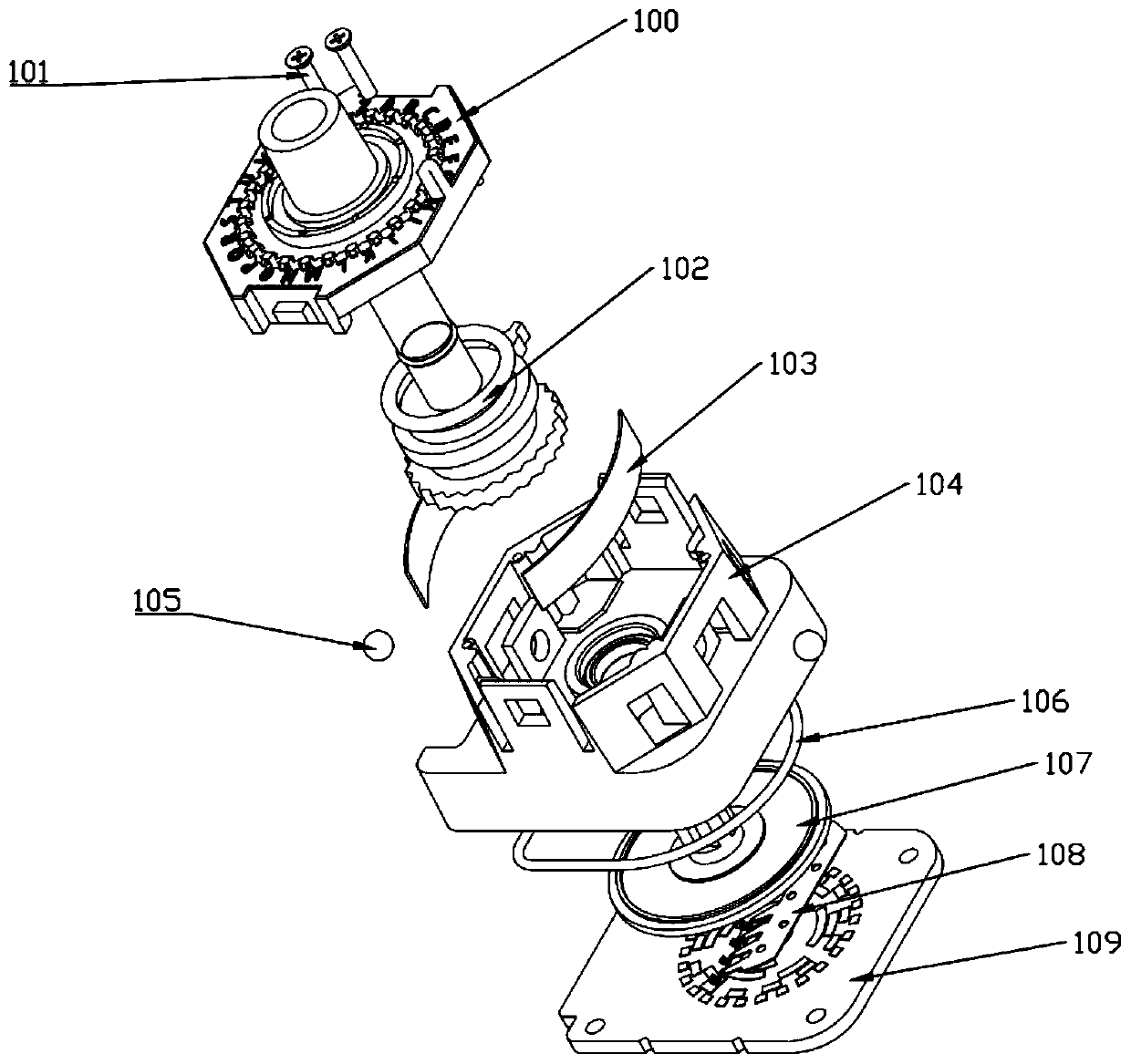

[0029] Such as Figure 1 to Figure 4 As shown, this embodiment provides a binary band switch. It should be noted that the serial numbers such as "first", "second" and "third" in this embodiment are only used to distinguish similar components and cannot be understood Specific limitations on the scope of protection in pairs. In addition, directional terms such as "bottom", "top", and "side edge" in the present embodiment are described based on the drawings.

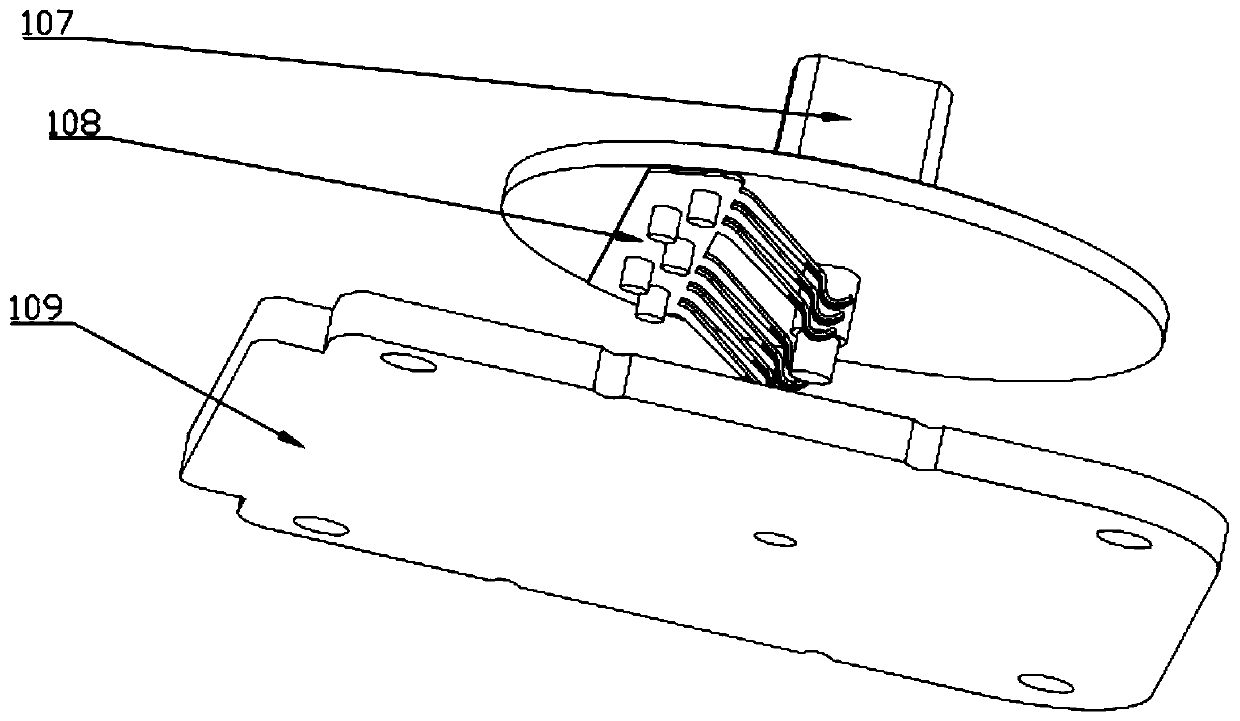

[0030] The binary band switch includes a housing 104, a code wheel assembly installed at the bottom of the housing 104, an upper cover 100 installed on the upper part of the housing 104, a gear assembly 102 that passes through the upper cover 100 and partially extends into the housing 104, and is arranged on the housing. The ball mounting hole on the side of 104, the snapping ball 105 arranged in the ball mounting hole, the snapping shrapnel 103 installed in the housing 104, and the shrapnel assembly arranged above the cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com