Method for preparing 3D printing resistor and adjusting resistance value

A 3D printing and adjustment method technology, which is applied in the direction of resistor manufacturing, resistors, and fine-tuning resistors, etc., can solve the problems of uncontrollable resistor thickness differences, inconsistent resistors, and multiple pastes, so as to reduce the risk of falling off and reduce materials. Wasteful, easy-to-integrate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

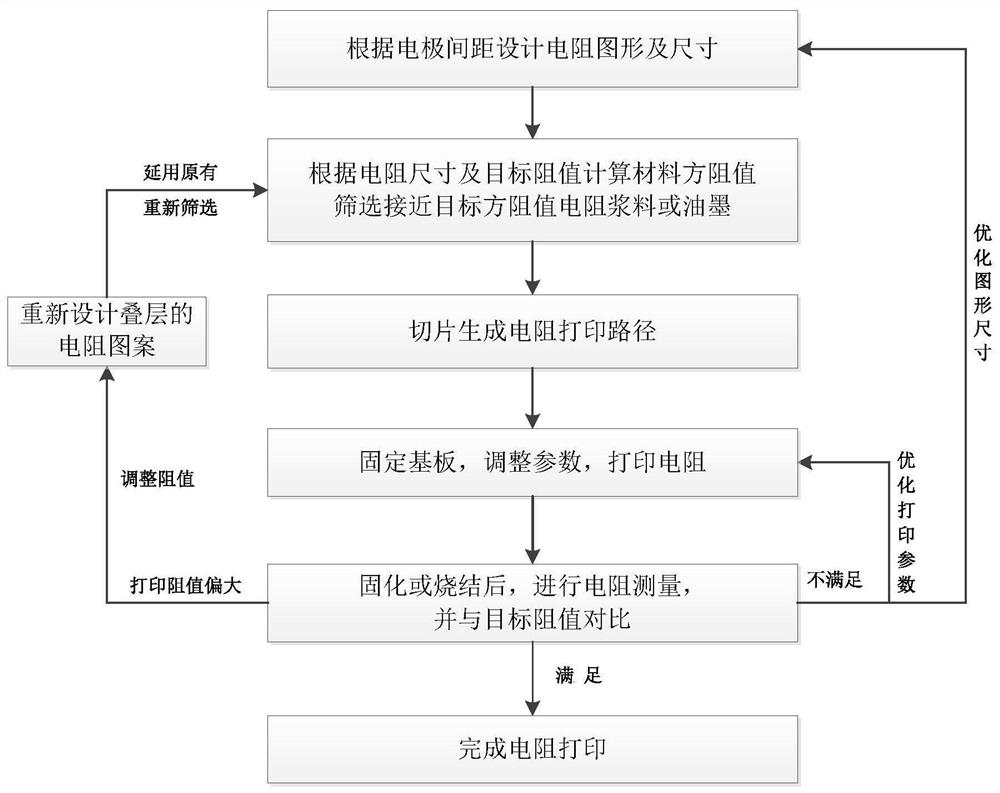

Method used

Image

Examples

Embodiment example 1

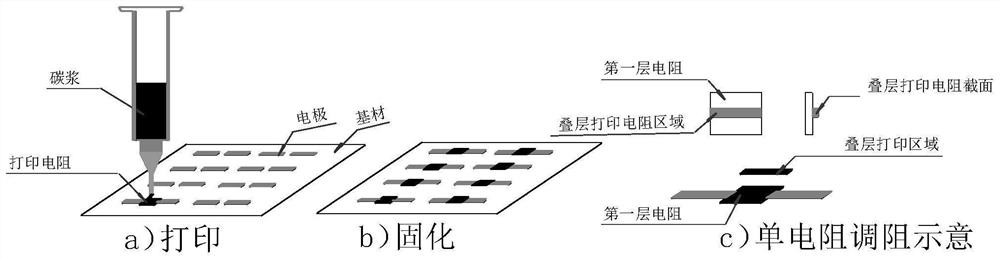

[0038] The target resistance value is: 160Ω±10%, the electrode spacing is: 0.3mm, the base material is PET; the design square resistance size is: 1.6mm×1.6mm, the thickness: subject to the actual printing thickness (20~50μm), the printed resistance The slurry is: carbon slurry (Xi'an Ruite 3D Technology Co., Ltd.), viscosity: (4~5)×10 4 Cp, square resistance: 1KΩ / □, curing temperature 160℃@0.5h. Equipment: Dual micro-pen direct writing 3D printer (Model: JD200Pro, Xi'an Ruite 3D Technology Co., Ltd.)

[0039] The printing parameters are: needle diameter: 0.24mm, printing air pressure: 0.38Mpa, layer height 0.1mm, printing speed 100mm / min

[0040] Printing resistance result: The resistance value actually tested by a multimeter is 250Ω±10%, the specific data is shown in Table 1, and the appearance is shown in Figure 4 a).

[0041] The design size of the resistance adjustment pattern: 1.6mm×0.4mm, the height from the substrate layer: 0.15mm, other printing parameters and the ...

Embodiment example 2

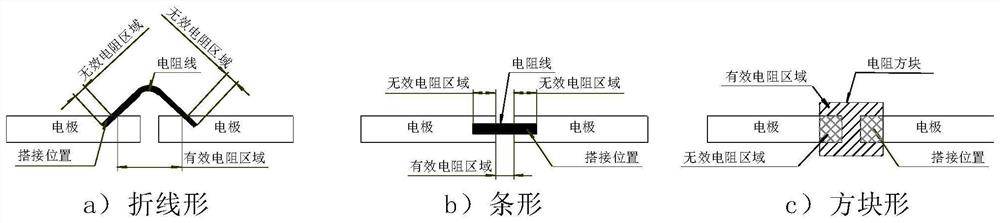

[0044] Different resistance between fixed electrodes can be achieved by designing different graphics, such as designed bar, square, round, S-shaped, etc. The electrode spacing is 4mm, the electrode size is 2*2mm, the selected resistance slurry is graphene slurry, the viscosity is 3~6*10 4 , the square resistance is 25Ω@20μm, the curing temperature is: 150℃@30min, and the base material is PI film. Equipment: Dual micro-pen direct writing 3D printer (Model: JD200Pro, Xi'an Ruite 3D Technology Co., Ltd.)

[0045] Printing parameters: the diameter of the printing needle is 0.16mm, the air pressure is 0.2Mpa, the layer height is 0.1mm, and the printing speed is 400mm / min.

[0046] The printing resistance and graphics of different design graphics are shown in Table 2.

[0047] Table 1 Printed resistance and resistance value change after stacking

[0048]

[0049] Table 2 Print the resistors of different design graphics

[0050]

[0051] The present invention uses an oven, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com