Redistribution device structure of heat exchanger

A redistributor and heat exchanger technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of expanding material selection, reducing pressure drop, and facilitating disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

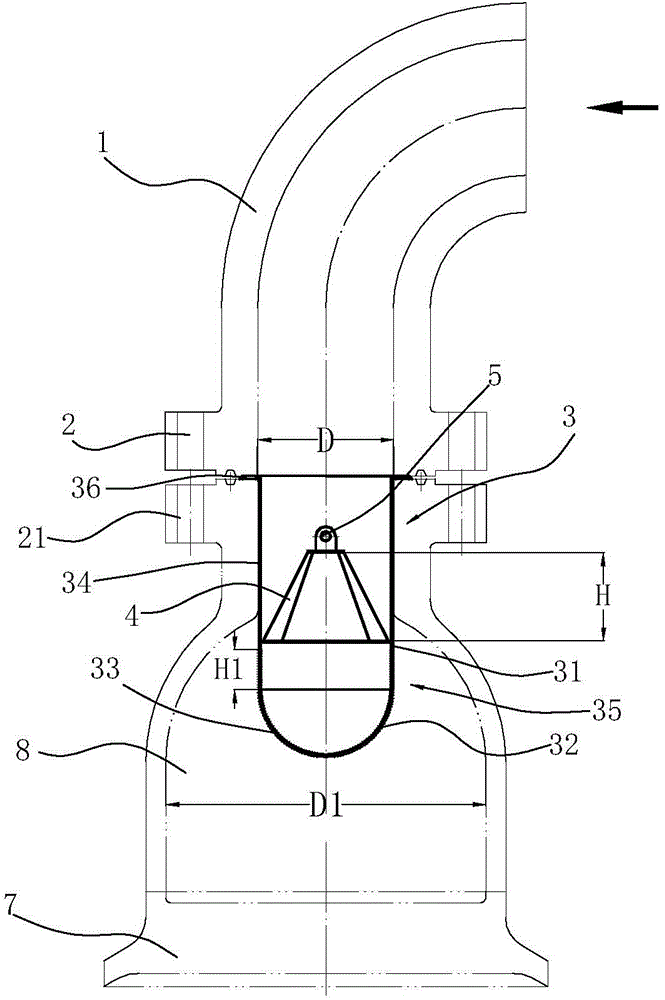

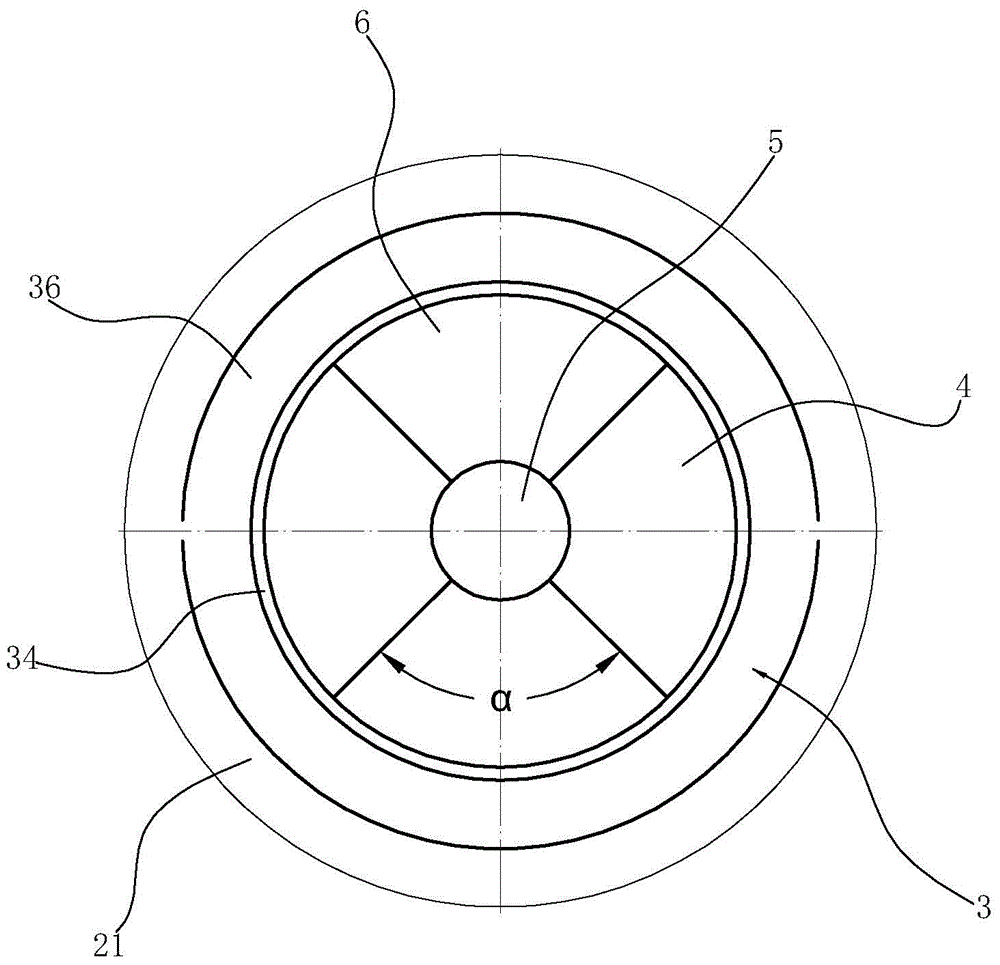

[0018] like figure 1 and figure 2 As shown, the redistributor structure for the heat exchanger is arranged in the tube box 8 of the heat exchanger, and the inlet flange 21 of the tube box 8 is detachably connected to the fluid delivery pipeline. The fluid delivery pipeline in this embodiment is connected to the pipe box through an elbow 1, and a connecting flange 2 connected to the inlet flange 1 is provided on the elbow 1. The inlet flange and the connecting flange in this embodiment are octagonal pads flange.

[0019] The redistributor 3 is arranged in the pipe box, and it includes a connecting sleeve 34 accommodated in the inlet flange 21, the lower end of the connecting sleeve 34 is connected with a redistribution bucket 35, and the upper end of the connecting sleeve 34 is connected with a The flange 36 is interposed between the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com