Injection molding process of foamed multicolor material

A process and foaming agent technology, applied in the field of injection molding of foamed multi-color materials, can solve the problems of preform deformation, cumbersome procedures, and slow down the injection molding process, so as to speed up the injection molding process, optimize the injection molding quality, and reduce heat. Dissipated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

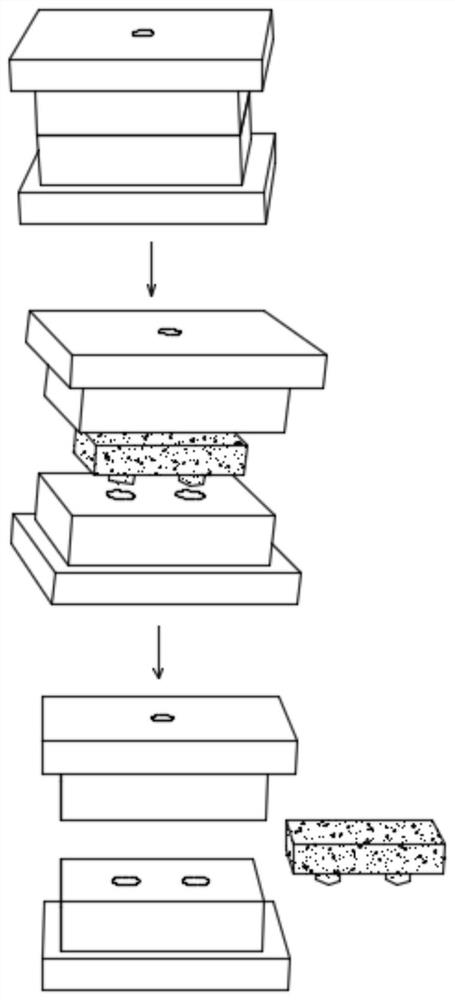

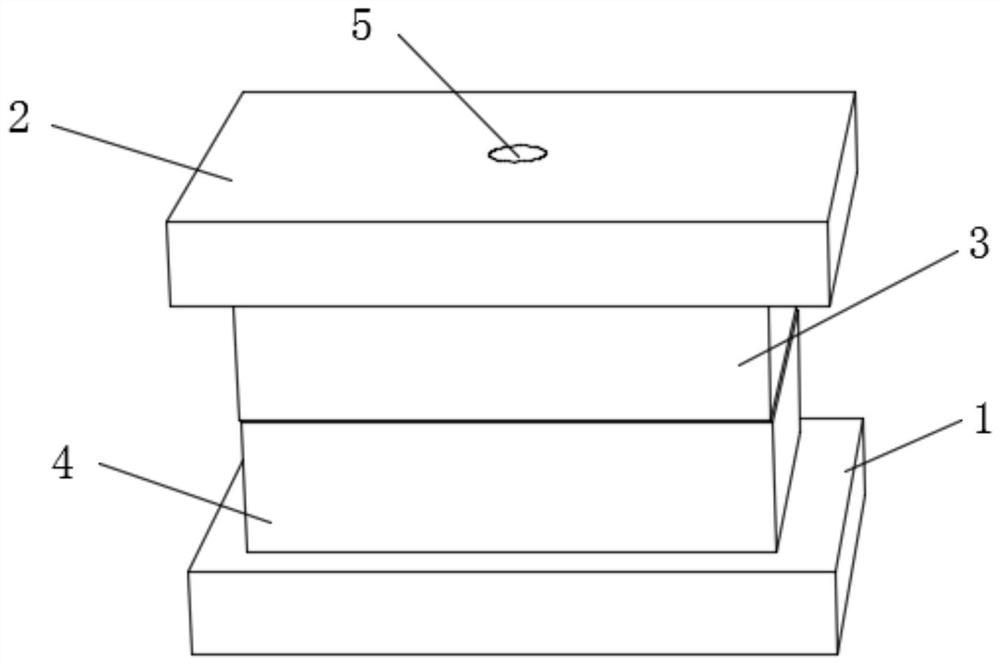

[0050] see figure 1 , an injection molding process of a foamed multi-color material, comprising the following steps:

[0051] Step 1. The polymer melt and the foaming agent are mixed, and the microcellular foaming injection molding machine mixes the foaming agent evenly into the polymer melt, and maintains a high-pressure environment; at the same time, after the special-shaped mold is closed and sealed, it is filled with high pressure

[0052] gas;

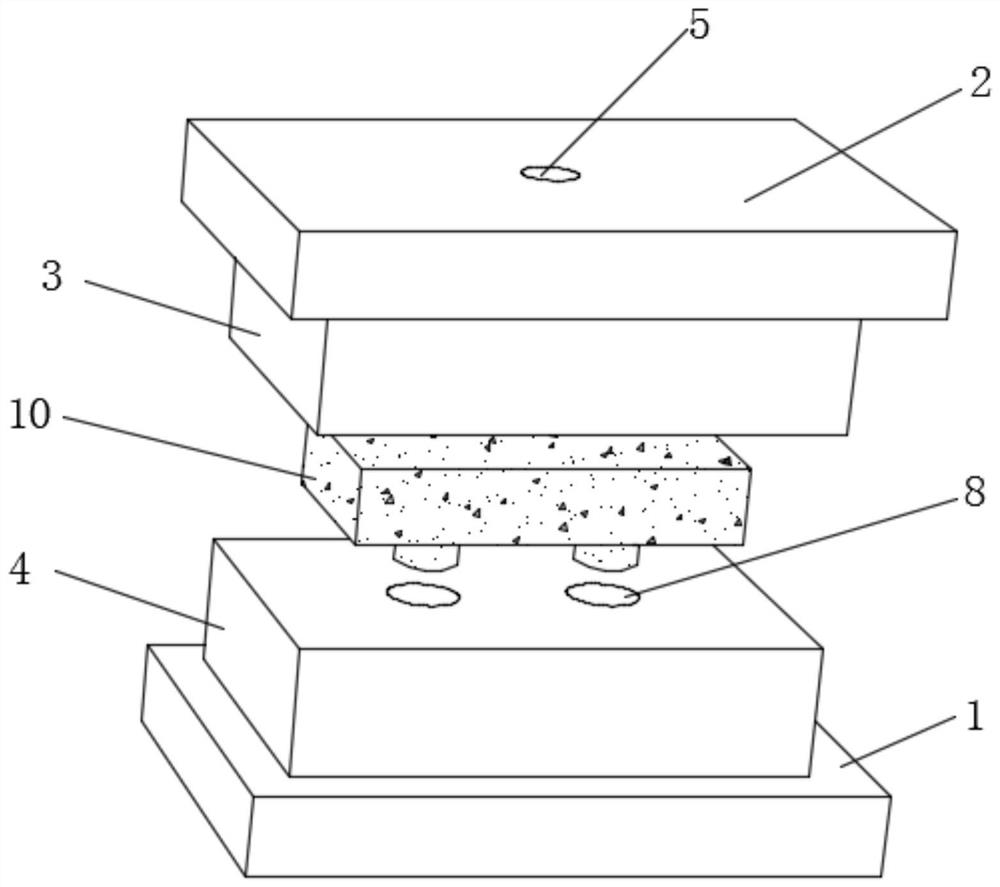

[0053] Step 2, forming the preform, injecting the mixed system of polymer melt and foaming agent into the special-shaped mold, and cooling under pressure to obtain the preform 6;

[0054] Step 3, heating and foaming to soften the preform 6 and start foaming; the polymer melt foams and expands;

[0055] Step 4. Cooling. After the foaming and expansion is completed, the mold is cooled to room temperature, and finally the mold is opened to obtain the final product 10 .

[0056] This scheme omits the original billet transfer step, ...

Embodiment 2

[0064] see figure 1 , an injection molding process of a foamed multi-color material, comprising the following steps:

[0065] Step 1. The polymer melt and the foaming agent are mixed, and the microcellular foaming injection molding machine mixes the foaming agent evenly into the polymer melt, and maintains a high-pressure environment; at the same time, after the special-shaped mold is closed and sealed, it is filled with high pressure

[0066] gas;

[0067] Step 2, forming the preform, injecting the mixed system of polymer melt and foaming agent into the special-shaped mold, and cooling under pressure to obtain the preform 6;

[0068] Step 3, heating and foaming to soften the preform 6 and start foaming; the polymer melt foams and expands;

[0069] Step 4. Cooling. After the foaming and expansion is completed, the mold is cooled to room temperature, and finally the mold is opened to obtain the final product 10 .

[0070] This scheme omits the original billet transfer step, ...

Embodiment 3

[0079] see figure 1 , an injection molding process of a foamed multi-color material, comprising the following steps:

[0080] Step 1. The polymer melt and the foaming agent are mixed, and the microcellular foaming injection molding machine mixes the foaming agent evenly into the polymer melt, and maintains a high-pressure environment; at the same time, after the special-shaped mold is closed and sealed, it is filled with high pressure

[0081] gas;

[0082] Step 2, forming the preform, injecting the mixed system of polymer melt and foaming agent into the special-shaped mold, and cooling under pressure to obtain the preform 6;

[0083] Step 3, heating and foaming to soften the preform 6 and start foaming; the polymer melt foams and expands;

[0084] Step 4. Cooling. After the foaming and expansion is completed, the mold is cooled to room temperature, and finally the mold is opened to obtain the final product 10 .

[0085] This scheme omits the original billet transfer step, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com