Preparation method for platinum membrane catalytic plate based on passive hydrogen and oxygen recombiner

A technology of platinum film catalytic plate and recombiner, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve potential safety hazards and preparation of recombiner catalytic plates Solve the problems of complex process and high cost, and achieve the effect of eliminating potential safety hazards, better preparation effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

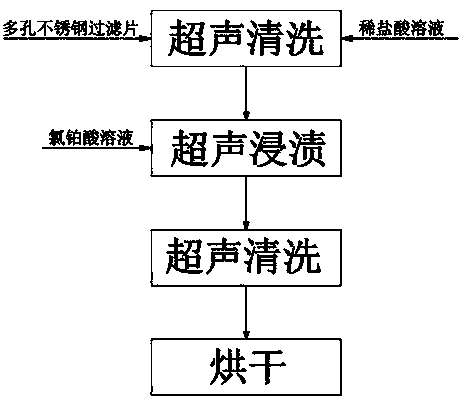

[0048] Such as figure 1 As shown, the present invention uses the porous stainless steel filter as the base material, Pt as the catalytic active component, and adopts ultrasonic cleaning and ultrasonic impregnation process to process the porous stainless steel filter to make a catalytic plate, and its product structure is that the surface of the porous stainless filter is uniform Plated with a dense Pt film with a thickness of not less than 50nm, the preparation process of the catalytic plate of the present invention comprises the following steps:

[0049] (1) At room temperature, place the porous stainless steel filter in an ultrasonic cleaning tank with dilute hydrochloric acid solution for ultrasonic cleaning;

[0050] (2) Take out the porous stainless steel filter and place it in the chloroplatinic acid solution for ultrasonic impregnation;

[0051] (3) Take out the porous stainless steel filter and place it in ultrapure water for ultrasonic cleaning;

[0052] (4) Take ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com