Adsorption device and adsorption method

An adsorption device and adsorber technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of large-scale and fast-paced production requirements, high time ratio of slag discharge, The reduction of equipment processing capacity and other problems can achieve the effect of enhancing multi-tasking versatility, high efficiency of slurry filtration, and smooth flow of slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

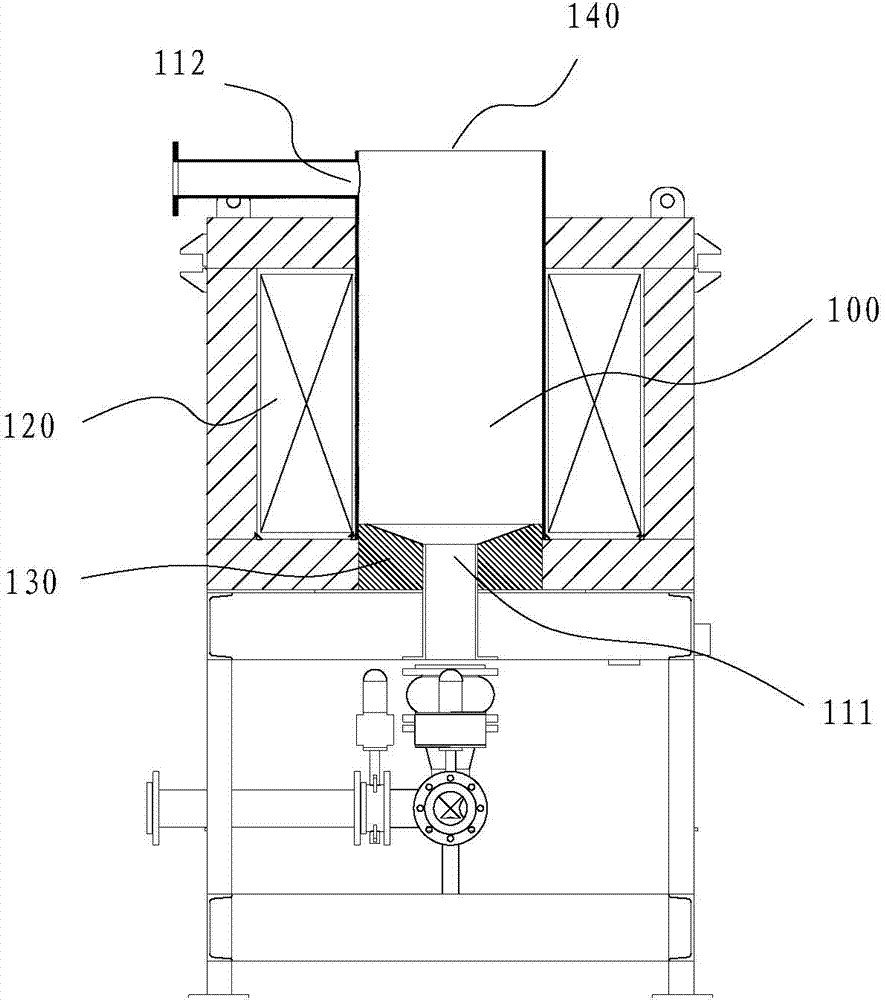

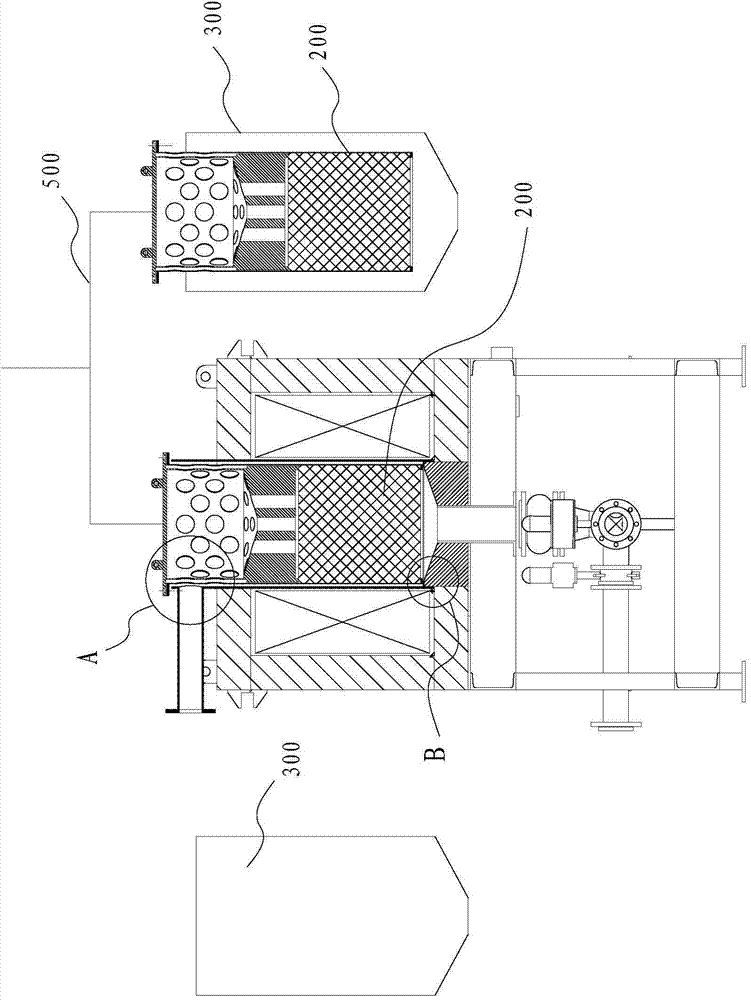

[0044] The adsorption device includes: an adsorption chamber 100 , an adsorber 200 , a cleaning station 300 and a switching device 500 .

[0045] The adsorption chamber 100 is an upright cylindrical cavity.

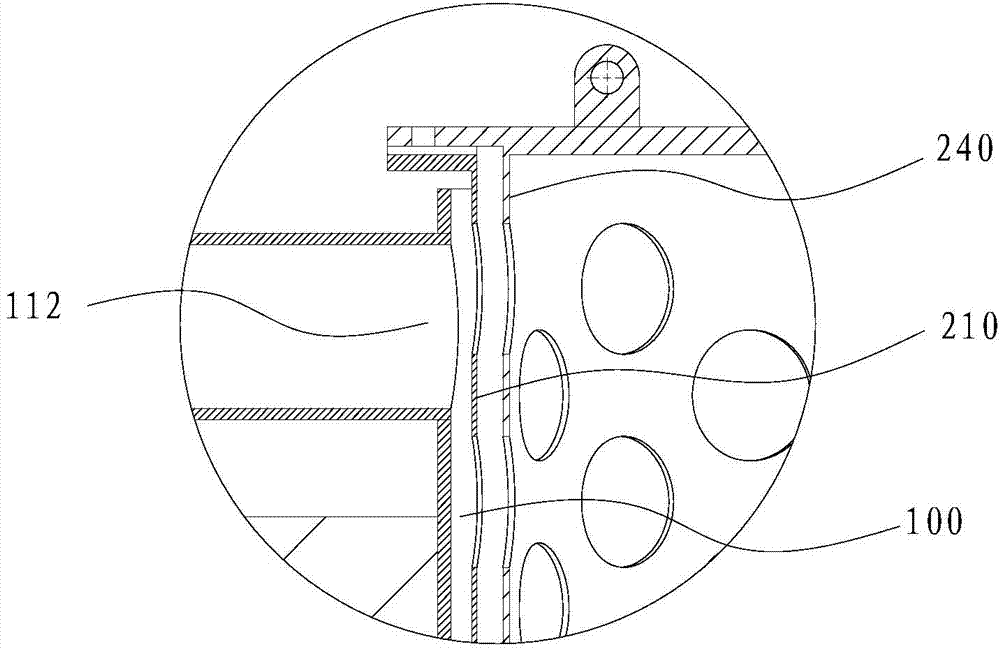

[0046] The bottom surface of the lower part of the adsorption chamber 100 is provided with a first liquid inlet 111, and the first liquid inlet 111 is connected with a liquid inlet pipe for sending the original slurry into the adsorption chamber 100; the lower part of the adsorption chamber 100 is also provided with a first magnetic yoke 130 , the first magnetic yoke 130 is provided with a central through hole, the liquid inlet pipe passes through the central through hole of the first magnetic yoke 130 , and the first magnetic yoke 130 is welded and sealed with the side wall of the adsorption chamber 100 .

[0047]The side of the upper part of the adsorption chamber 100 is provided with a first liquid outlet 112 , and the first liquid outlet 112 is connected with a liquid...

Embodiment 2

[0071] The difference between embodiment two and embodiment one is:

[0072] Only one cleaning station 300 is provided, and the cleaning station 300 is arranged in parallel with the adsorption chamber 100 .

[0073] The switching device is provided with a lifting mechanism and a rotating mechanism, and the rotation center of the rotating mechanism is at the center of the line connecting the cleaning station 300 and the adsorption chamber 100 .

[0074] At the beginning, the first adsorber is adsorbed in the adsorption chamber, and the second adsorber is in the cleaning station; when the first adsorber is fully loaded, the first adsorber and the second adsorber are lifted at the same time, and the rotating mechanism is used to move the The first adsorber and the second adsorber are rotated 180 degrees so that the positions of the two are reversed. At this time, the first adsorber is aligned with the cleaning station and the second adsorber is aligned with the adsorption chamber...

Embodiment 3

[0076] The difference between embodiment three and embodiment one is:

[0077] The switching device is provided with a lifting mechanism and a rotating mechanism. The first cleaning station and the second cleaning station are located on both sides of the adsorption chamber 100. The first cleaning station, the second cleaning station, and the adsorption chamber are based on the rotation center of the rotating mechanism The centers are arranged in circles.

[0078] At the beginning, the first adsorber is adsorbed in the adsorption chamber, and the second adsorber is in the second cleaning station;

[0079] When the first adsorber is fully loaded, lift the first adsorber and the second adsorber at the same time, and use the rotating mechanism to rotate the first adsorber and the second adsorber several degrees so that the positions of the two are reversed. At this time, the first adsorber Align the first cleaning station, the second adsorber to the adsorption chamber, and use th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com