Dry-process connecting assembly type partition wallboard

A partition wall panel and assembly technology, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of poor installation quality and non-compact contact of partition wall panels, and achieve good installation quality, compact contact and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The application will be described in further detail below in conjunction with the accompanying drawings.

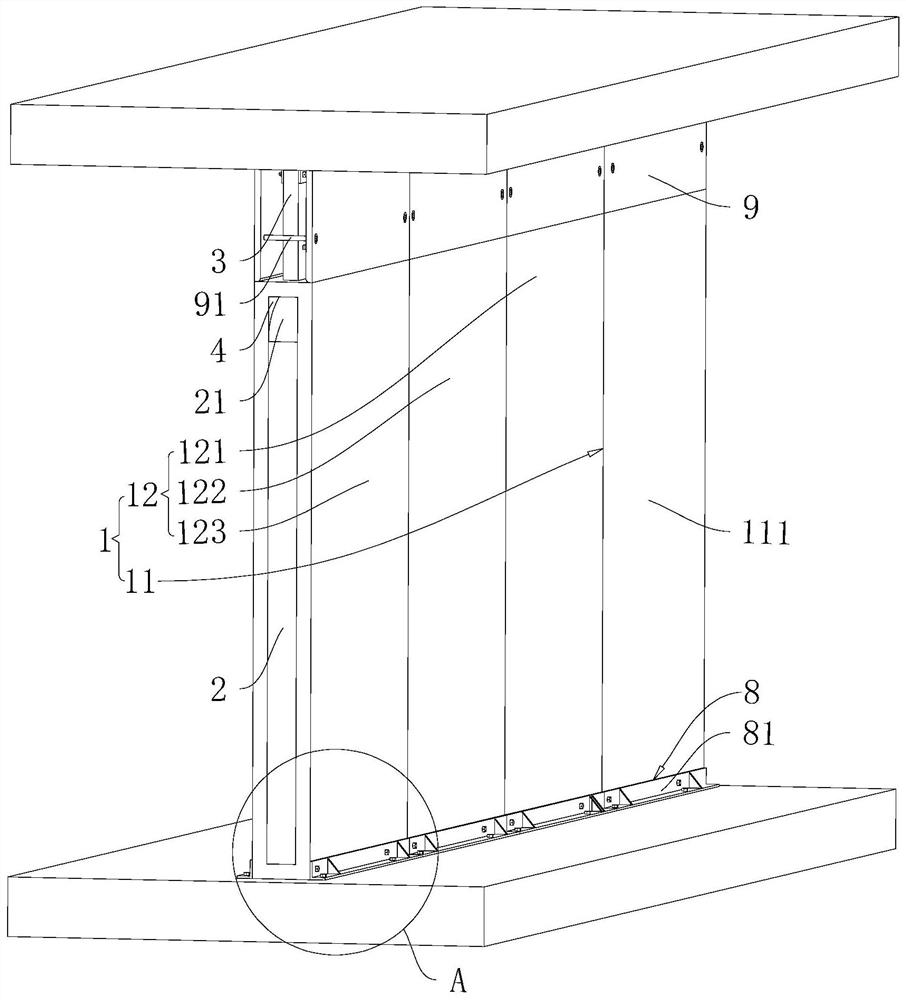

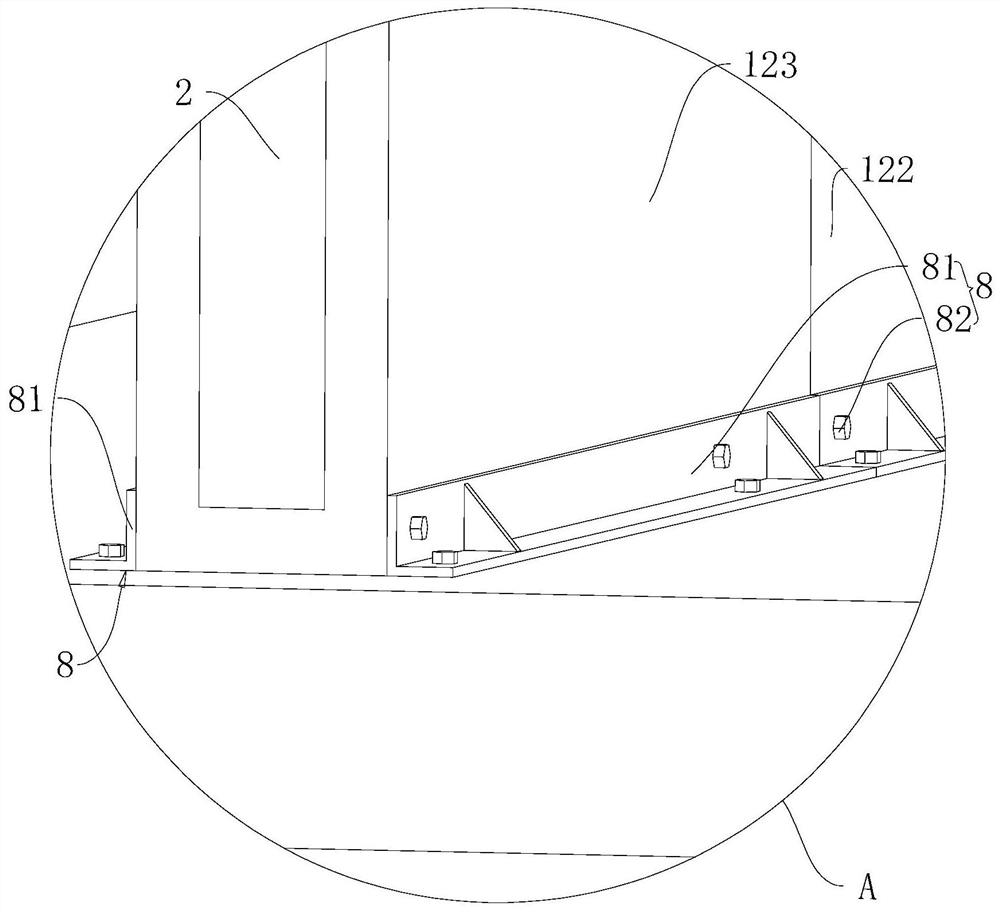

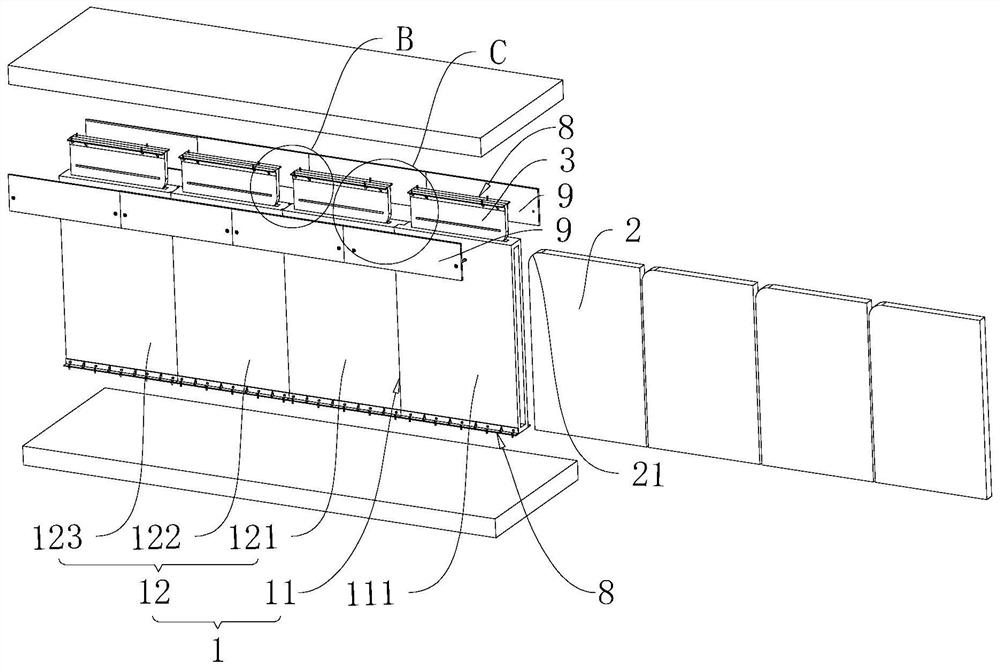

[0040] refer to figure 1 and figure 2, is a dry-connected assembled partition panel disclosed in the present application, comprising a total partition panel frame 1 and a support plate 2 pierced in the total partition panel frame 1, the total partition panel frame 1 and the support panel 2 Sliding fit, when the partition board is installed, the support plate 2 is inserted into the total partition board frame 1. The top of the total partition panel frame 1 is provided with a chute 4, the chute 4 runs through the top of the total partition panel frame 1 and extends vertically downward, the chute 4 is pierced with a sliding plate 3, and the sliding plate 3 and the chute 4 Slip fit. When the partition board needs to be installed between the floor top board and the floor bottom board, first insert the support board 2 into the overall partition board frame 1, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com