Sealing device for cleaning chamber of lifting hook type shot blasting machine

A technology of sealing device and shot blasting machine, which is applied in the direction of engine sealing, used abrasive treatment device, mechanical equipment, etc., can solve the problems of low sealing effect, reduced sealing efficiency, weak resistance to shot sand splash and impact strength, etc. , to achieve the effect of good practicability, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

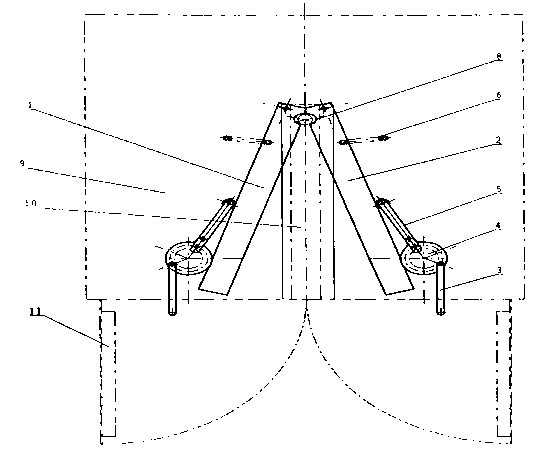

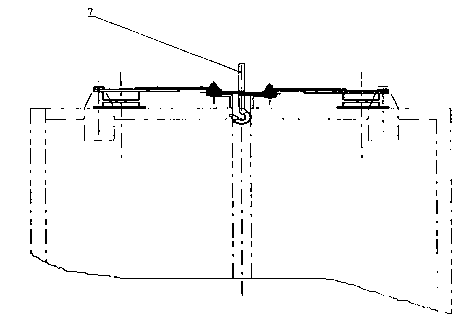

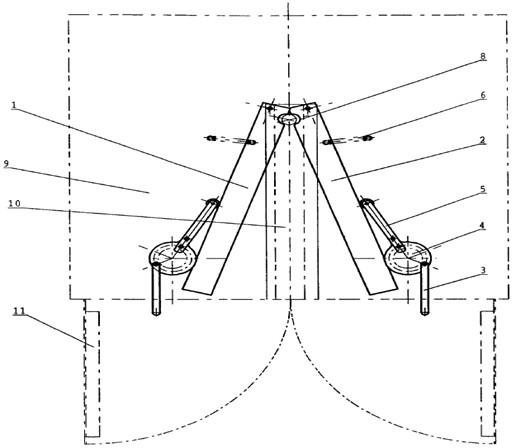

[0015] See figure 1 with figure 2 As shown, the invention is described below by taking the application of the invention in the notch on the top of the cleaning chamber of the hook type shot blasting machine as an example:

[0016] A sealing device for the cleaning room of the hook type shot blasting machine, the hard blocking block 1 and the hard blocking block 2, the two hard blocking blocks can be made of wood, plastic or metal, with hard blocking One end of the block 1 is provided with a rotating shaft, and the hard plugging block 2 is provided with a rotating shaft on the same side end. The driving mechanism of the two hard plugging modules includes a connecting rod rotating mechanism and a return elastic body. There are two connecting rod slewing mechanisms, corresponding to the hard blocking block 1 and the hard blocking block 2. Each connecting rod slewing mechanism includes a linear push rod 3, a eccentric rotating mechanism, and the eccentric rotating mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com