Vehicle-mounted aluminum alloy tank production process

A production process, aluminum alloy technology, applied in the field of vehicle-mounted aluminum alloy tank production process, can solve the problems of high production cost and low flaw detection pass rate of the old process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The vehicle-mounted aluminum alloy tank production process of the present invention comprises the following steps:

[0025] ①Cylinder plate processing:

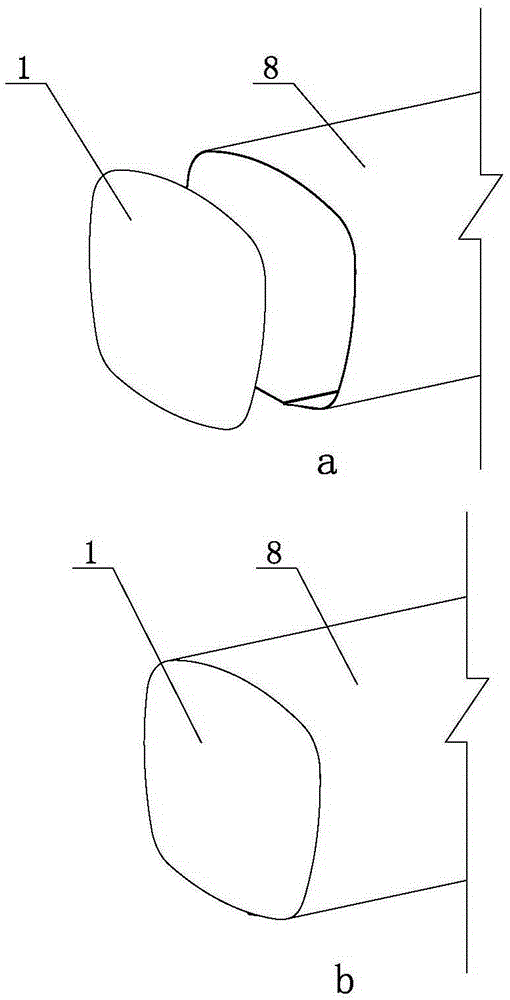

[0026] A Preparation of plates: Cut the plates into several plates of specified size and shape, which are used to make tanks; the plates cut out when making equal-diameter cylinders are only rectangular, and the plates of reduced-diameter cylinders are fan-shaped. Usually 5 pieces are cut, and 5 pieces of plates are assembled into a cylinder plate to make a cylinder. The specified size depends on the size of the tank body.

[0027] B. Edge alignment: Milling the edge of the plate cut out in step ①A to remove the oxide layer on the edge and ensure its straightness; hand-held edge milling machine can be used for edge milling, but the straightness is not easy to control. Therefore, edge milling The work can be done by an edge milling machine.

[0028] C panel welding: splicing all the plates after edge milling in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com