Mortar-free building block for eliminating energy and reducing shock

A technology without mortar and blocks, applied to building components, walls, buildings, etc., can solve the problems of long production cycle, increase the difficulty of manufacturing process, increase positioning error, etc., to improve the quality of internal structure, save raw material consumption, eliminate chain spies effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

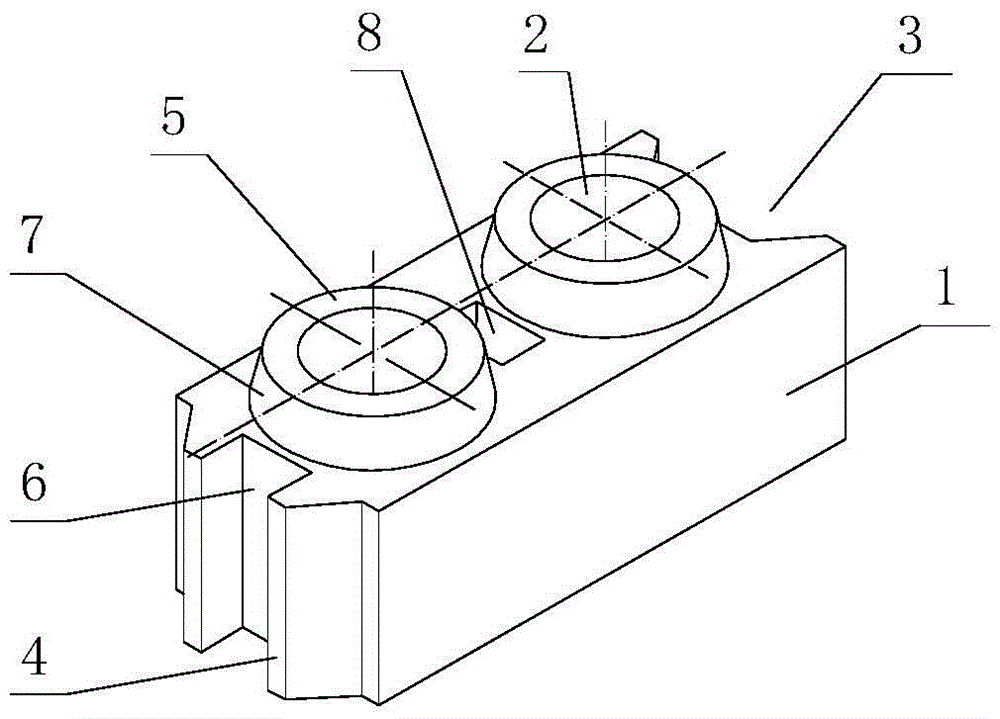

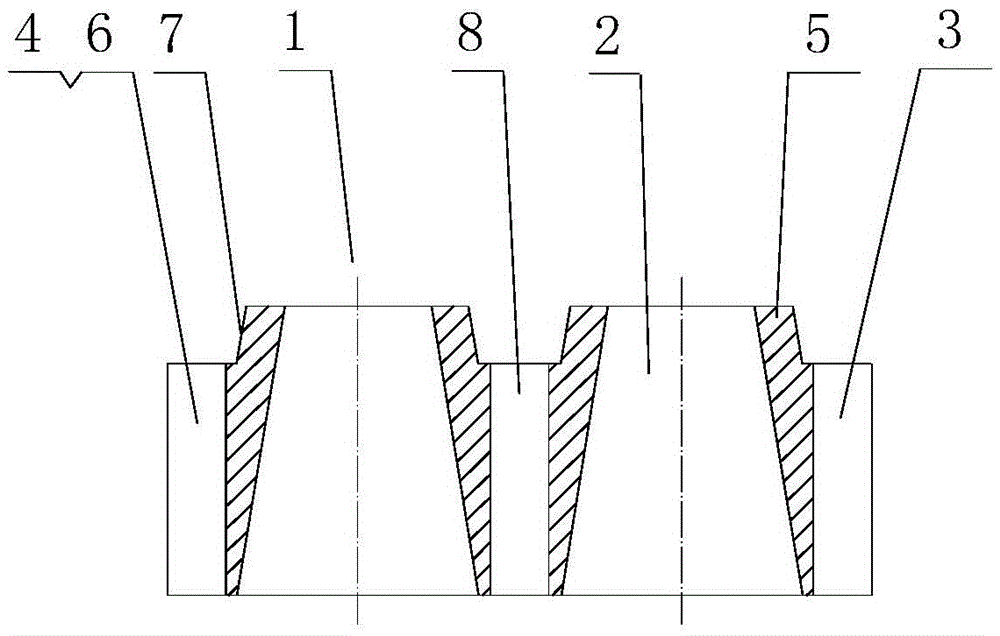

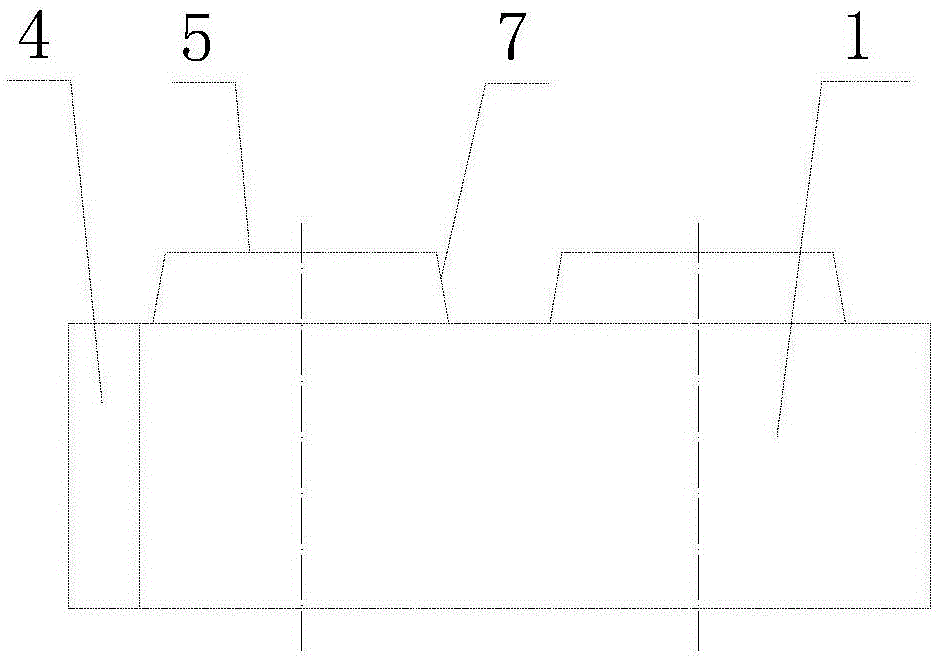

[0049]Combined with the accompanying drawings, a working condition and principle of a mortar-free block based on energy dissipation and shock absorption: it includes more than three basic features: ① The block body 1 is composed of at least two conical cavities 2 arranged in parallel; ② The bottom of the block body 1 is flat, the top of the block body 1 is a boss 5 and a hollow conical truncated 7 in the center; ③ One end of the block body 1 is a protrusion 4, and the other end is a cavity 3; or both The side ends are all protrusions 4; or both sides are concave cavities 3; ④The bosses 5 and the conical frustum 7 are matched and connected to form a hollow nodular conical lumen 9 throughout the body.

[0050] Referring to the drawings, the block body 1 is provided with a central hollow conical cavity 2, at least two conical cavities 2 are arranged in parallel, between the conical cavities 2 is a rectangular cavity 8, and a pipeline 10 is arranged in the rectangular cavity 8. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com