Motion control device, motion control method, mask stage system and photoetching machine

A motion control device and motion module technology, applied in the field of lithography, can solve problems affecting the accuracy of a mask stage system and a lithography machine, and achieve the effects of reducing interference and improving motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a mask table system, which is applied to a motion control device and a photolithography machine in the mask table system.

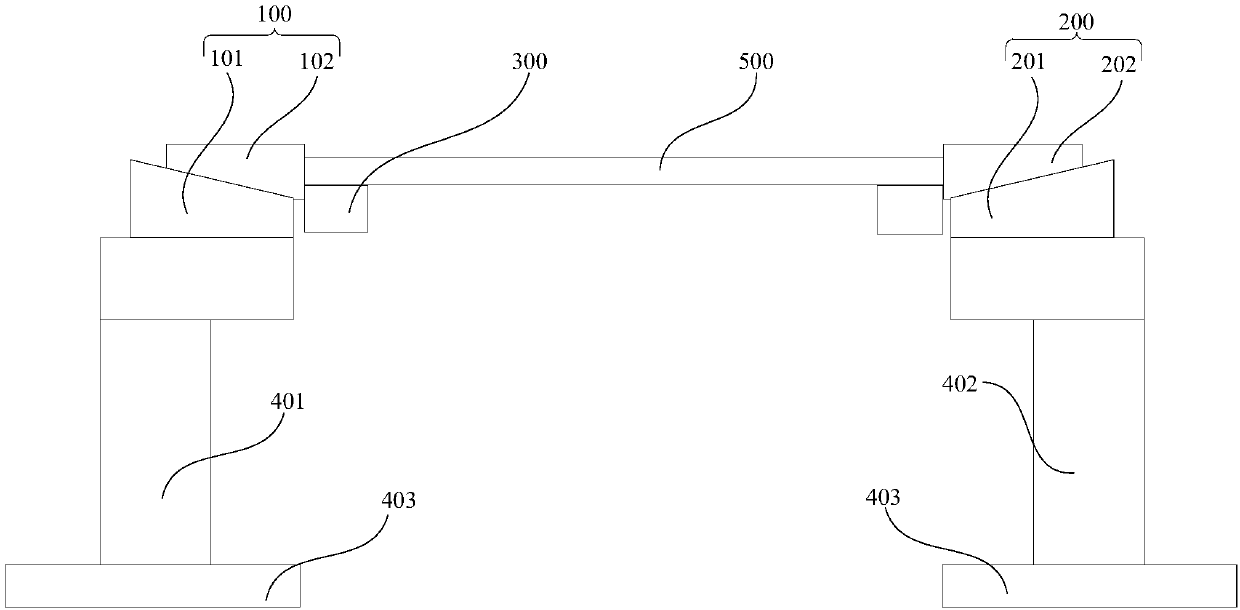

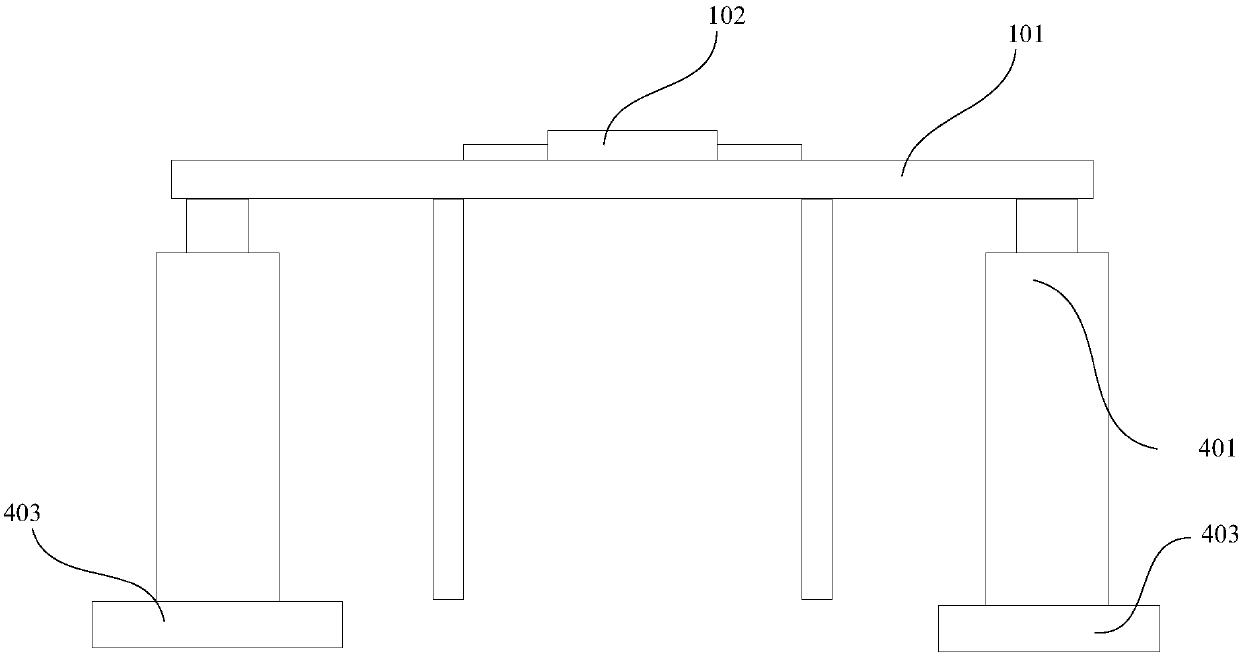

[0081] refer to Figure 4 and Figure 5 , Figure 4 is the front view of the mask stage system in Embodiment 1 of the present invention, Figure 5 It is a left view of the mask table system in Embodiment 1 of the present invention, the mask table system includes a first coarse motion module 810, a second coarse motion module 820, a mask table installation frame, a mask table 840, a motion control device, a position detection device, a first acceleration sensor and a second acceleration sensor.

[0082] The mask stage installation frame includes a first installation frame 831 and a second installation frame 832 . The first installation frame 831 and the second installation frame 832 are respectively set on the foundation 834 .

[0083] The first coarse motion module 810 and the second coarse motion module 820 are respec...

Embodiment 2

[0110] This embodiment provides a mask stage system. refer to Figure 7 , Figure 7 It is a front view of the mask table system in Embodiment 2 of the present invention. The difference between this embodiment and Embodiment 1 is that in this embodiment, the mask table system may further include a shock absorber 890 . In this embodiment, the coarse movement module is not directly arranged on the mask stage installation frame, but the shock absorber 890 is arranged on the mask stage installation frame, and the coarse movement module is arranged on The shock absorber 890 is on. The vibration transmitted from the foundation 834 passes through the mounting frame of the mask table, passes through the shock absorber 890 , and then transmits to the first coarse motion module 810 and the second coarse motion module 820 . Vibration transmitted to the mask table 840 by the lithography machine can be effectively reduced by providing a shock absorber 890 between the mask table mounting ...

Embodiment 3

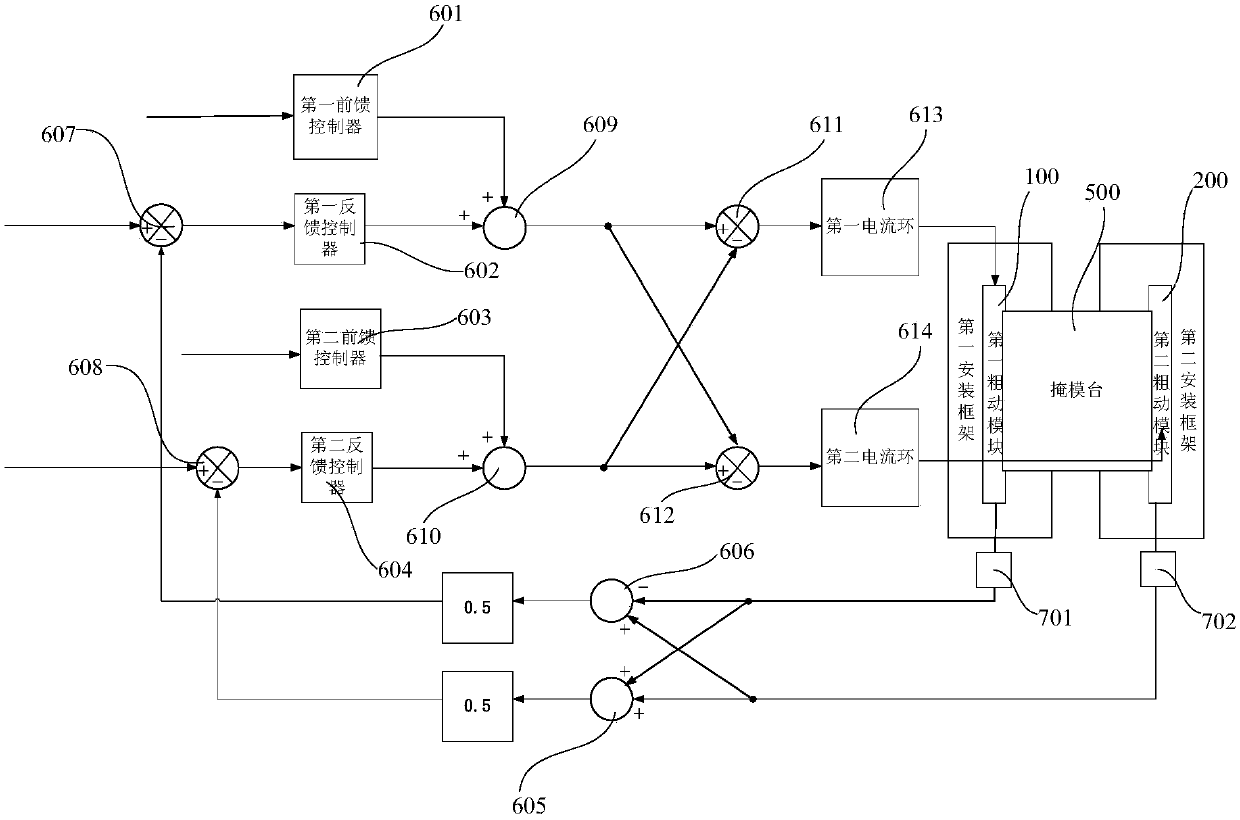

[0120] This embodiment provides a motion control method of the motion control device in the mask table system in the above embodiments. Before the motion control device works, it sends the motion track signal, the motion track acceleration signal of the first coarse motion module 810 and the motion track acceleration signal of the second coarse motion module 820 to the motion control device, and sends the first position information and the second The second position information is sent to the motion control device, and the acceleration information of the first installation frame 831 and the second installation frame 832 is sent to the motion control device.

[0121] The motion control method includes the steps of:

[0122] Step S10, the first position feedback unit converts the first position information and motion track signal into first drive information; the second position feedback unit converts the second position information and motion track signal into second drive info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com