Double column vertical lathe

A vertical lathe and column technology, applied in the field of lathes, can solve problems such as high requirements for the column screw, large contrast between rising and falling loads, and influence on the service life of the machine tool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

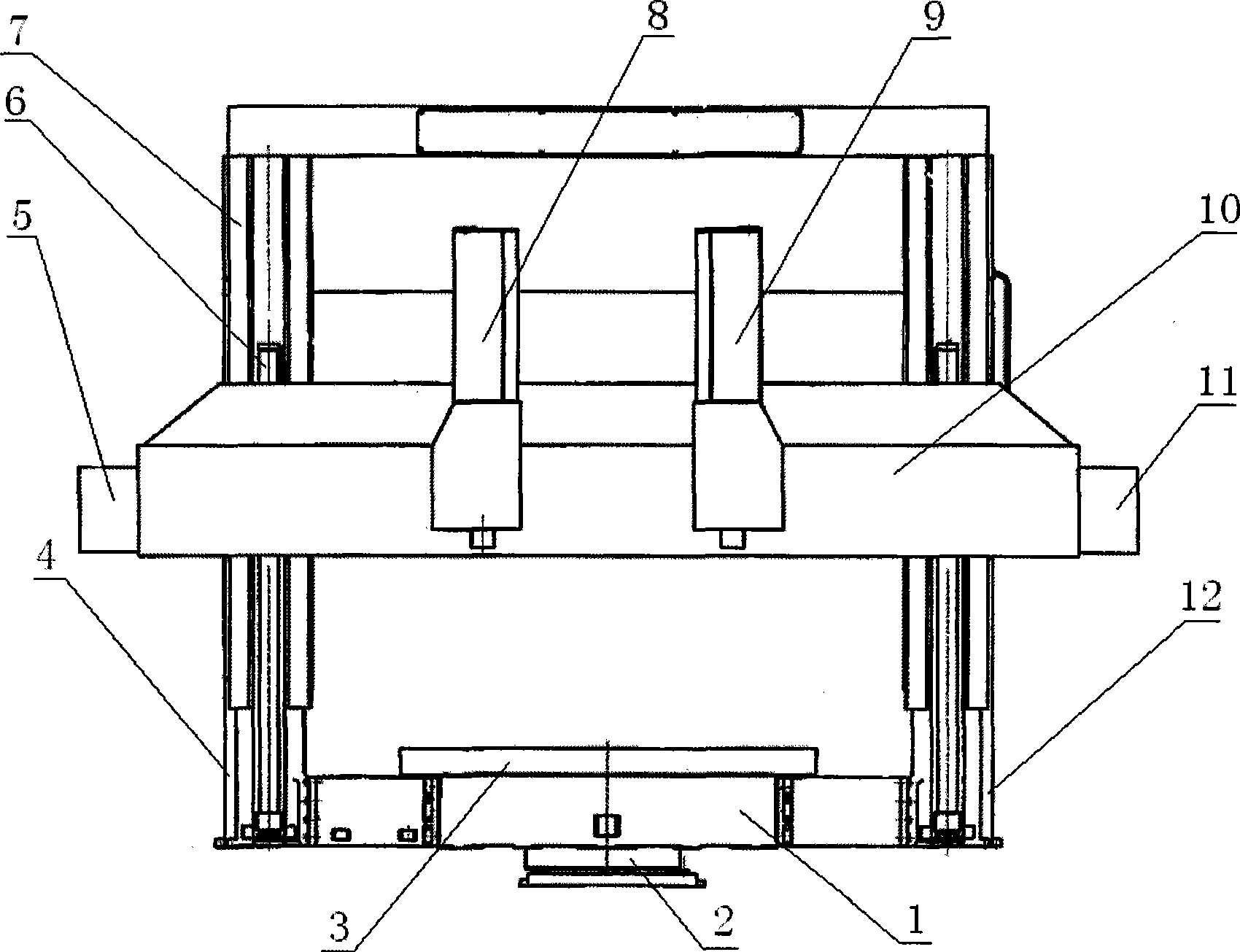

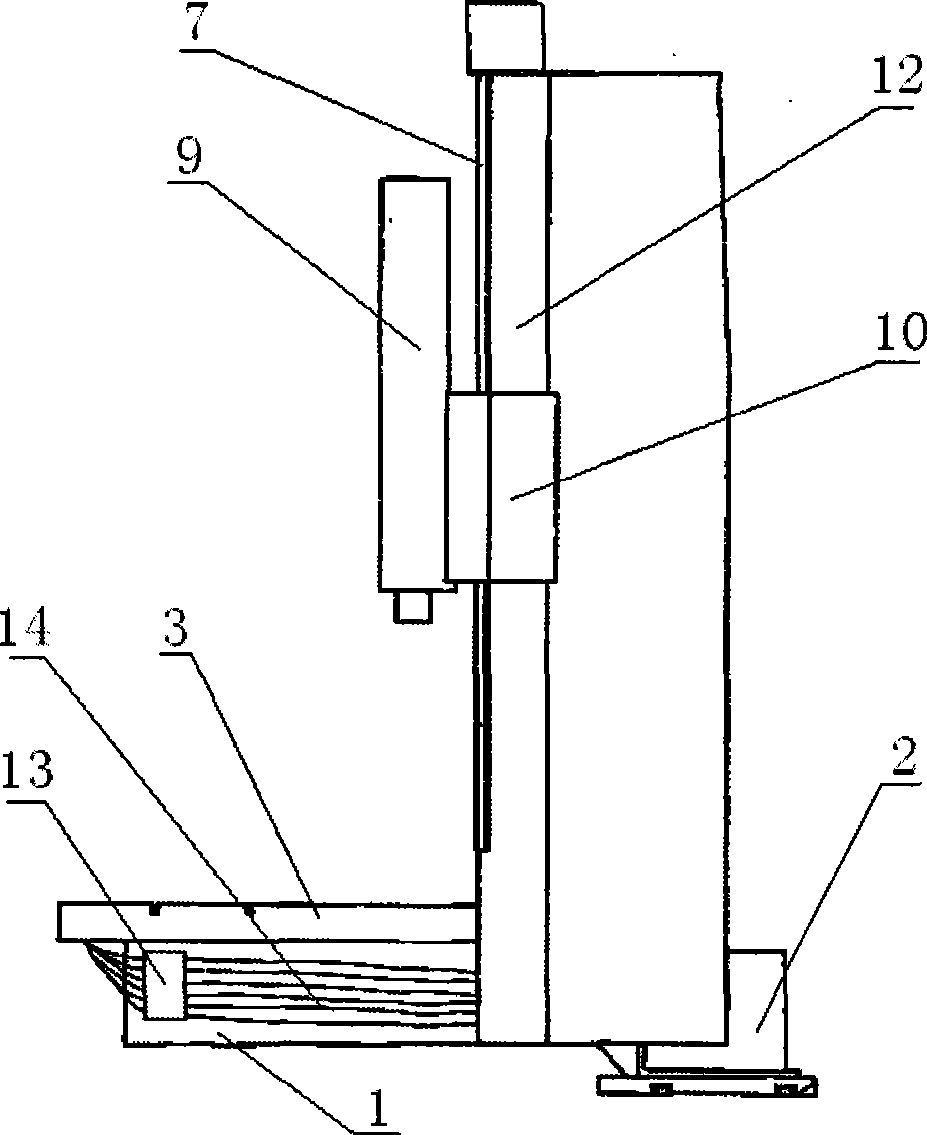

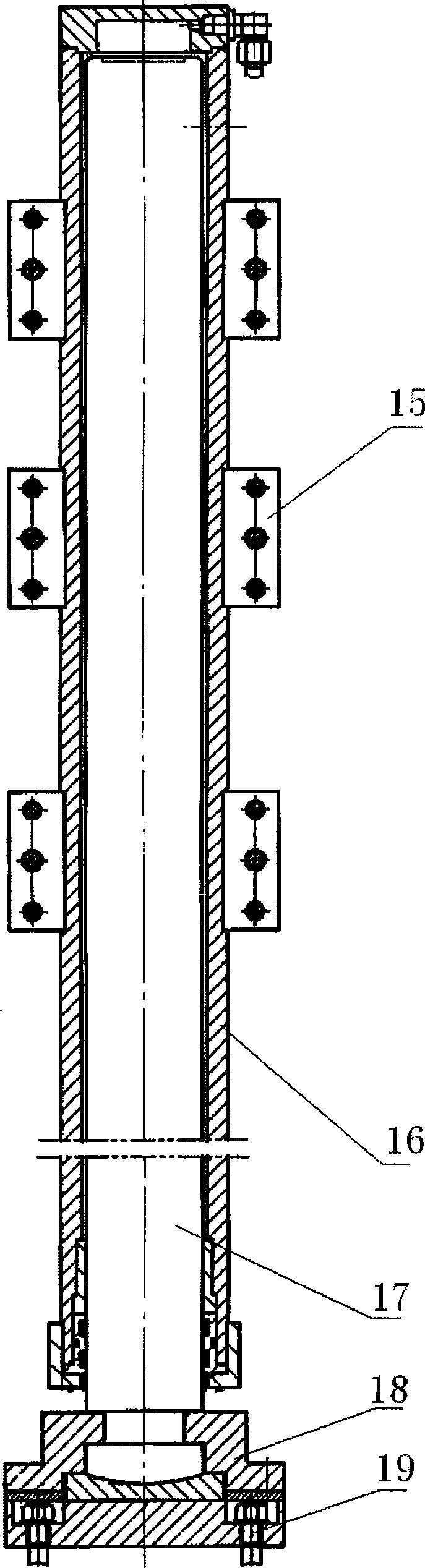

[0022] Such as figure 1 , figure 2 , image 3 As shown, a double-column vertical lathe includes a left column 4, a right column 12, a beam 10, a left vertical tool rest 8, a left feed box 5, a right vertical tool rest 9, a right feed box 11, and a rotary table Device, crossbeam hydraulic balance cylinder device and control system, the left vertical knife rest 8 and the right vertical knife rest 9 grams reciprocate horizontally along the crossbeam guide rail, and the crossbeam 10 can reciprocate up and down along the left column 4 guide rail and the right column 12 guide rail The crossbeam hydraulic balance cylinder device comprises a crossbeam hydraulic balance cylinder 6 respectively positioned at the middle of the left column 4 and the right column 12, and each crossbeam hydraulic balance cylinder 6 includes a balance cylinder base 18 fixed to the ground by anchor bolts 19, a cylinder liner 16 and Piston 17 in the cylinder liner 16, the upper end of the cylinder liner 16 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com