Aspheric surface measuring apparatus

A measuring device and aspheric technology, which are applied to measuring devices, optical devices, geometric characteristics/aberration measurement, etc., can solve the problems of inconvenient measurement of aspheric surfaces, difficulty in ensuring micro-motion accuracy, and inability to obtain motion accuracy. , to achieve the effect of improving measurement accuracy, preventing sudden changes in temperature and humidity, and high motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

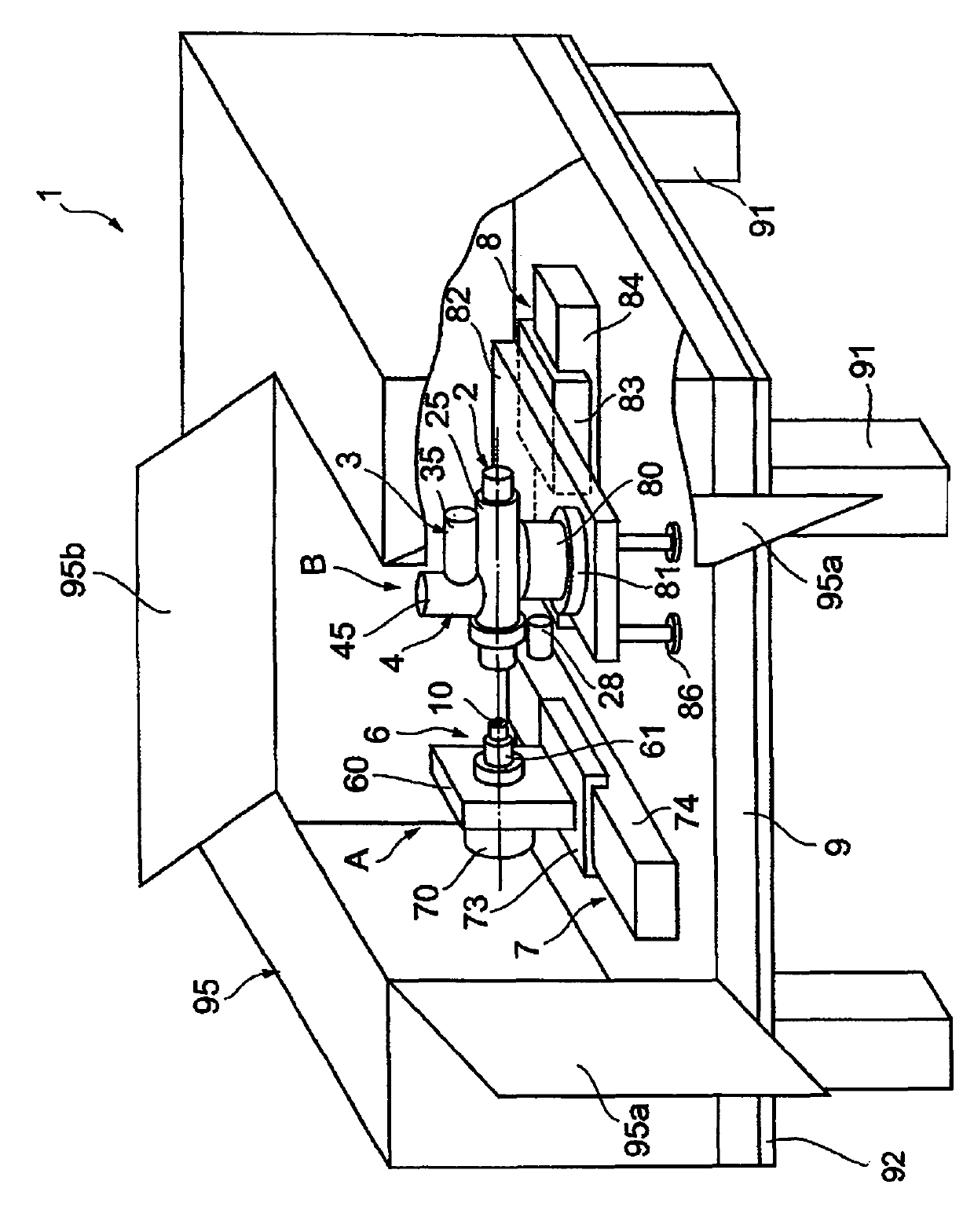

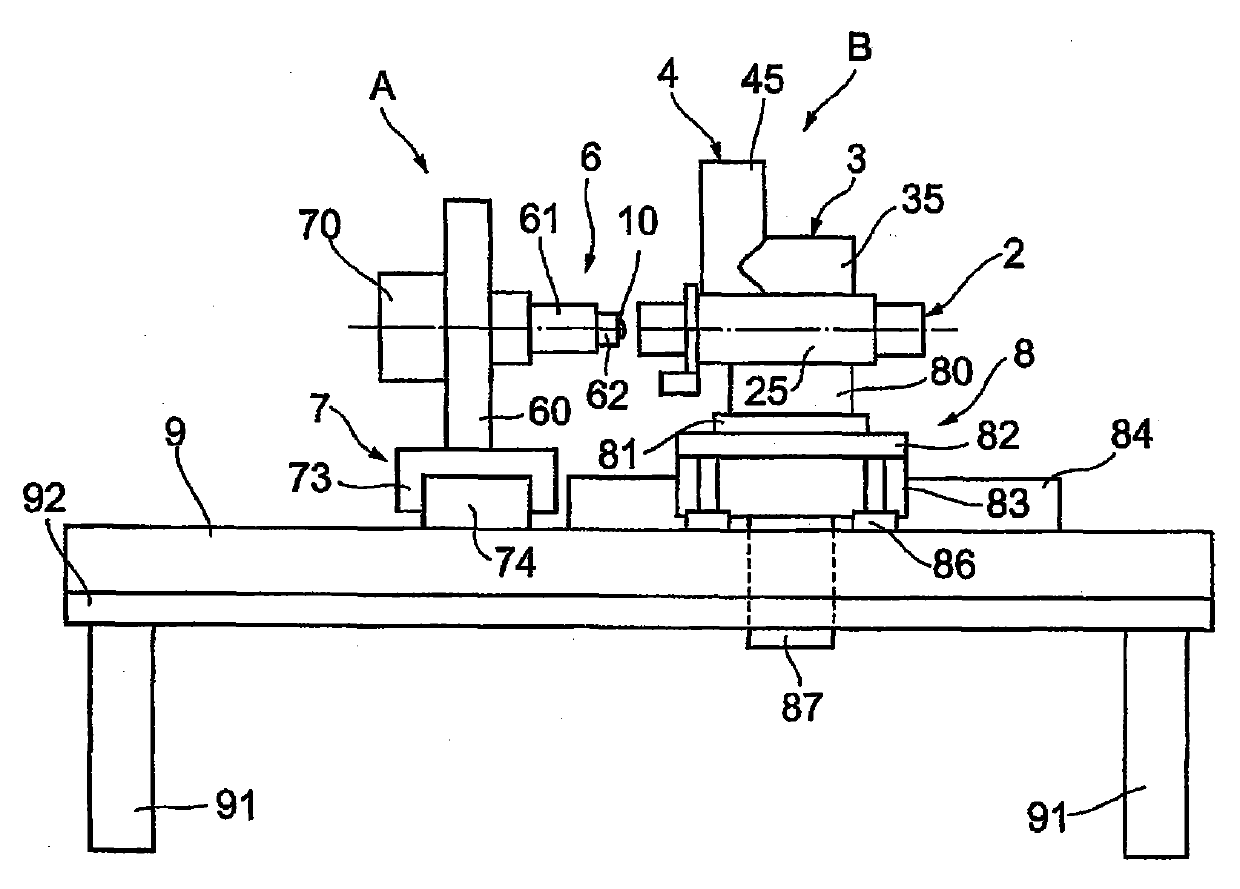

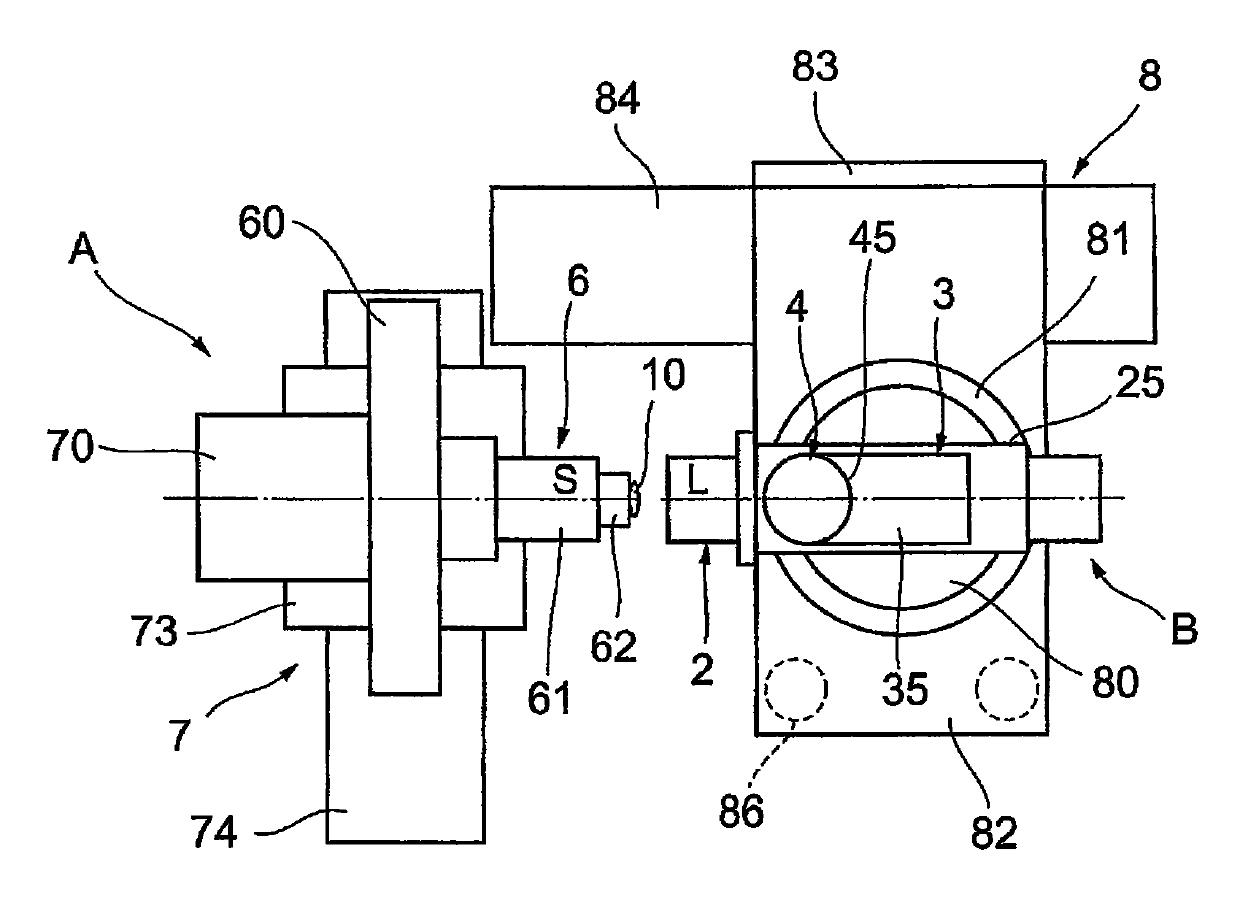

[0038] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. noticed Figure 5 The schematic diagram of the structure is to show the precise shape and structure; when appropriate, according to Figure 1-4 Make changes to the dimensions of the components and the distances between the components as illustrated in .

[0039] Should Figure 1-5 The aspheric surface measuring device 1 of this embodiment shown in , measures and analyzes a rotationally symmetric aspheric surface 10a of a sample (aspheric lens) 10 (see Figure 5 )shape. The aspheric measuring device 1 comprises an interference optical system 2, a first imaging system 3, a second imaging system 4, a measurement analysis system 5 (see Figure 5 ) and sample stage 6. In the interference optical system 2, a measurement beam is applied to the aspheric test surface 10a to combine a beam reflected from the aspheric test surface 10a (hereinafter may be referred to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com