PCB detection method and device and computer readable storage medium

A technology of PCB board and detection method, which is applied in the directions of calculation, optical test defect/defect, image analysis, etc., can solve the problem of low efficiency of PCB back drilling, improve test efficiency and accuracy, improve accuracy, avoid inefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

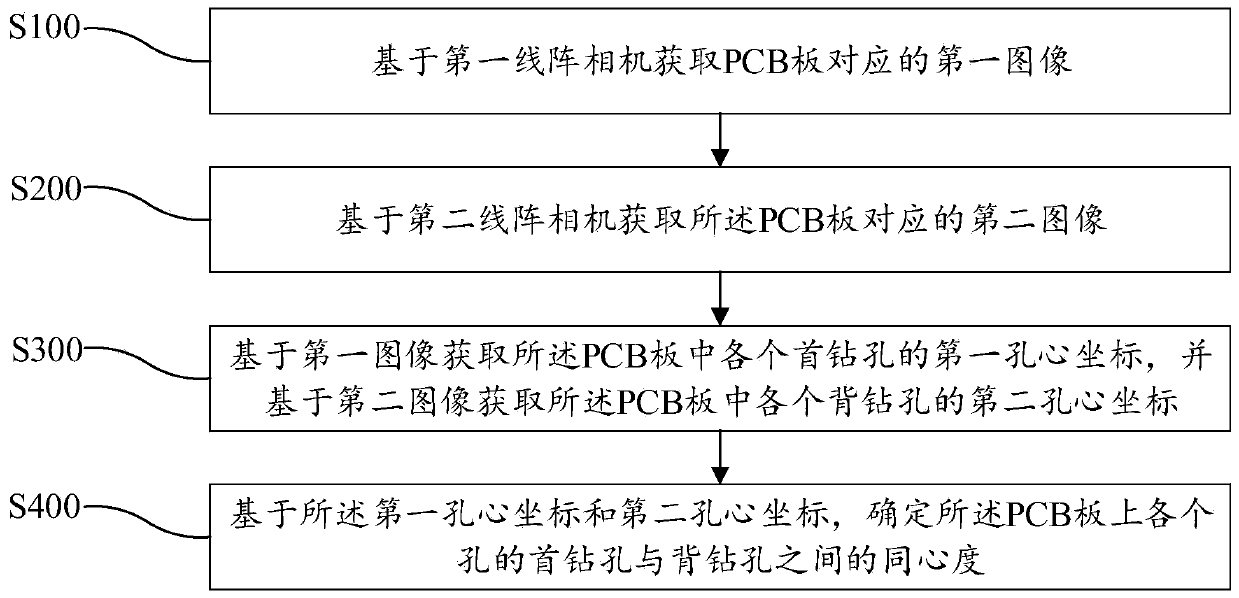

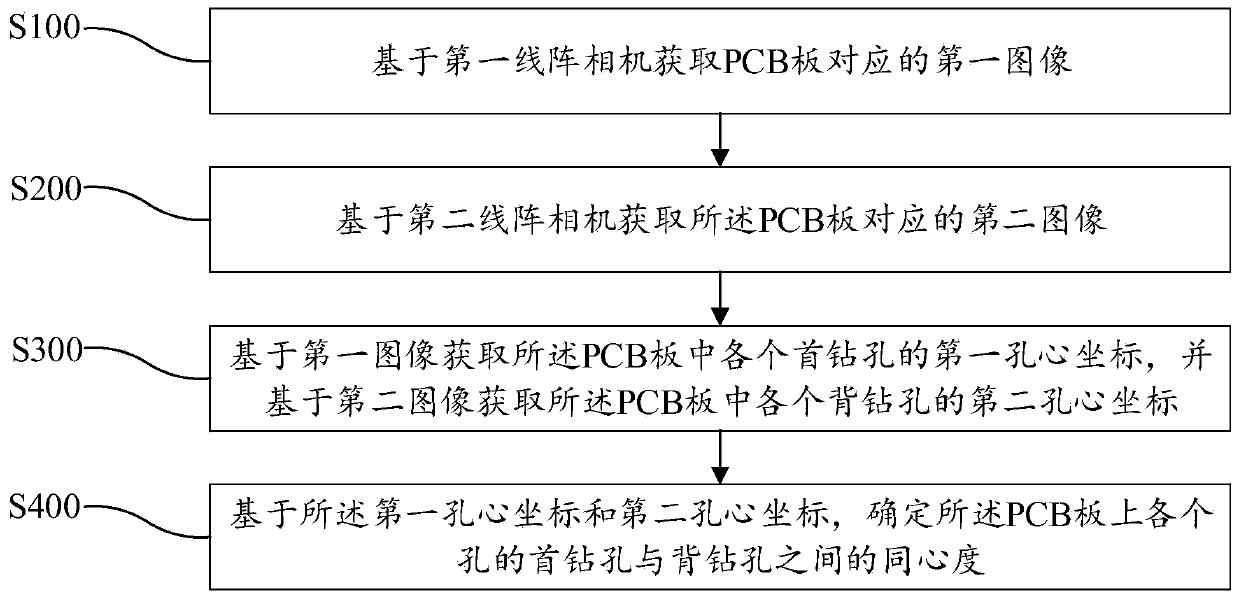

[0098]Based on the first embodiment, the second embodiment of the PCB board detection method of the present invention is proposed. In this embodiment, the PCB board is provided with positioning holes; step S300 includes:

[0099] Step S310, aligning the first image and the second image based on the positioning hole;

[0100] Step S320: Obtain the first hole center coordinates of each first drilled hole in the PCB board based on the first image after alignment, and obtain the second coordinates of each back-drilled hole in the PCB board based on the second image after alignment. Hole center coordinates.

[0101] In this embodiment, after the first image and the second image are obtained, the positioning hole corresponding to the PCB board is obtained, and the first image and the second image are aligned according to the positioning hole, and then according to the aligned first image The first hole center coordinates corresponding to the PCB board are obtained from an image, an...

no. 3 example

[0112] Based on the third embodiment, the fourth embodiment of the PCB detection method of the present invention is proposed. In this embodiment, step S430 includes:

[0113] Step S431, determining whether there is a target distance greater than a preset distance in the minimum distance;

[0114] Step S432, if it does not exist, then determine the coordinates of the first drilled hole and the coordinates of the back drilled hole corresponding to each hole on the PCB based on the distance;

[0115] Step S433, if it exists, then output the first prompt information that the PCB board is unqualified.

[0116] In this embodiment, when determining the minimum distance, it is determined whether there is a target distance greater than the preset distance in the minimum distance, and it has been determined whether the PCB board is an unqualified PCB board according to the preset distance, and there is a target distance greater than the preset distance in the minimum distance. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com