Multimachine and multi-engineering automated stamping production line

A multi-engineering, production line technology, applied in the field of stamping processing, can solve the problems of high labor intensity, low production efficiency, low safety factor, etc., and achieve the effect of small footprint, high work efficiency, and high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

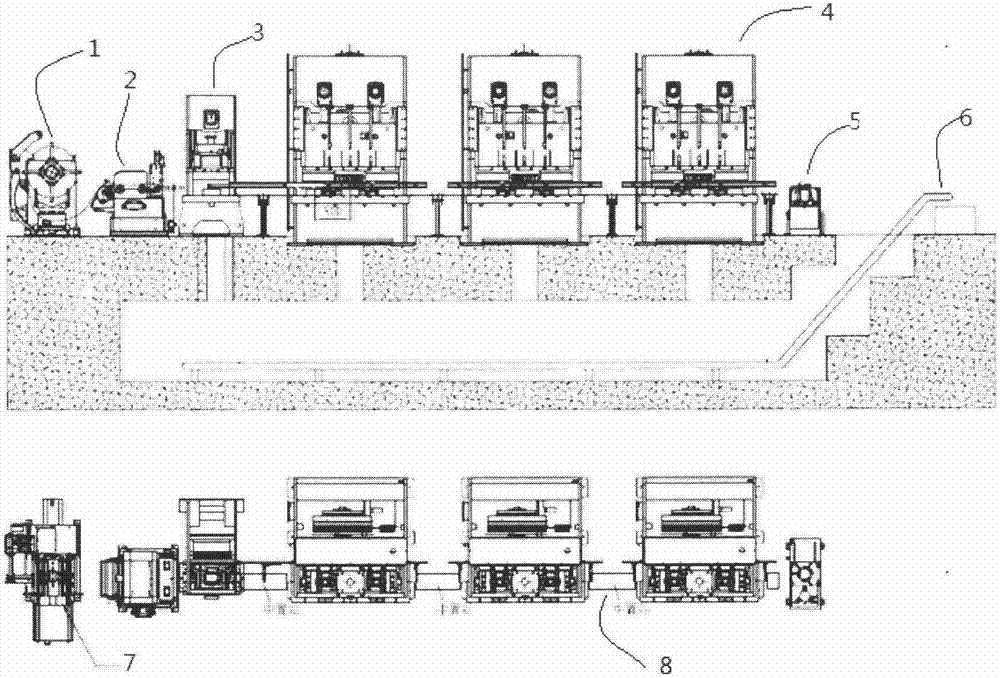

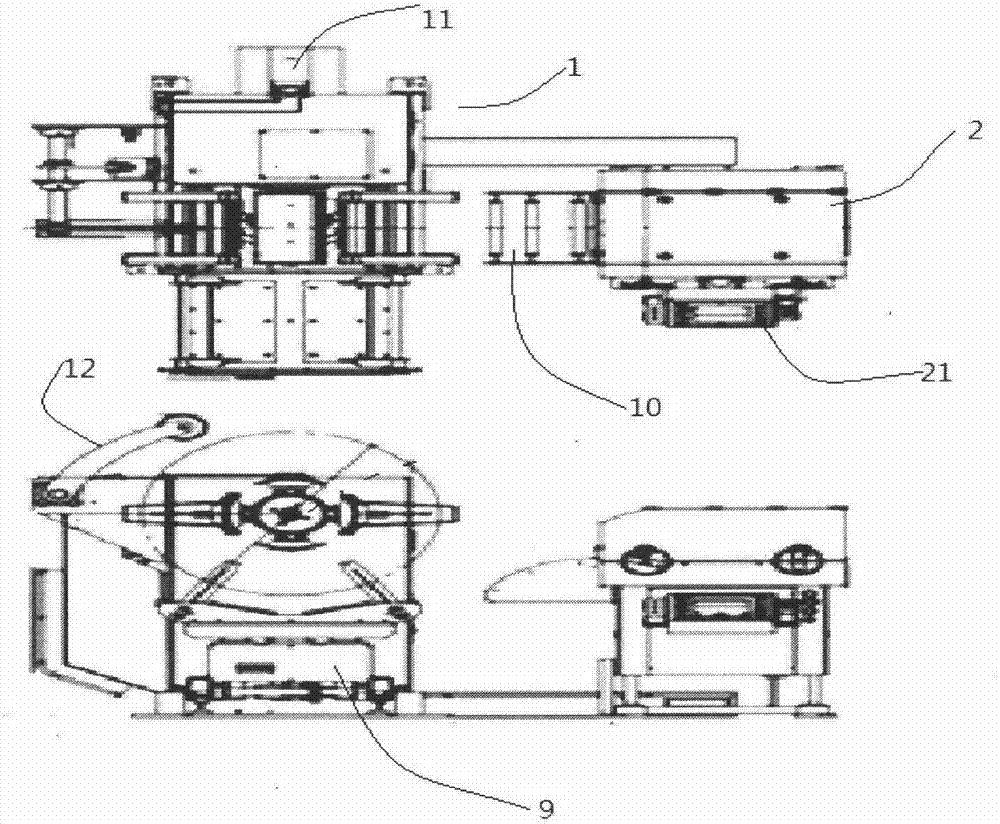

[0026] A multi-machine and multi-engineering automatic stamping production line, which includes a feeding assembly, a stamping assembly, and a receiving assembly; the feeding assembly is connected to the stamping assembly, and the stamping assembly is connected to the receiving assembly and arranged in a straight line; it is characterized in that the stamping The components include 1 open single-point press (3), 3 open double-point presses (4), 1 set of nine-engineering molds, 3 sets of two-dimensional manipulators, and each set of two-dimensional manipulators is set on two presses on the intermediate station (8); the open single-point press (3) is connected to the feeding assembly, and one of the open double-point presses (4) is connected to the receiving assembly; the upper The material assembly includes a feeding trolley (9), a discharge rack (1), a correction roller mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com