Quadratic element manipulator

A manipulator and two-dimensional technology, applied in manipulators, metal processing equipment, feeding devices, etc., can solve the problems of slow feeding speed, inability to meet high-speed stamping of stamping dies, and reduced production efficiency of stamping dies, etc., to achieve high production efficiency and workpiece. The effect of high transfer efficiency and automatic continuous high-speed production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

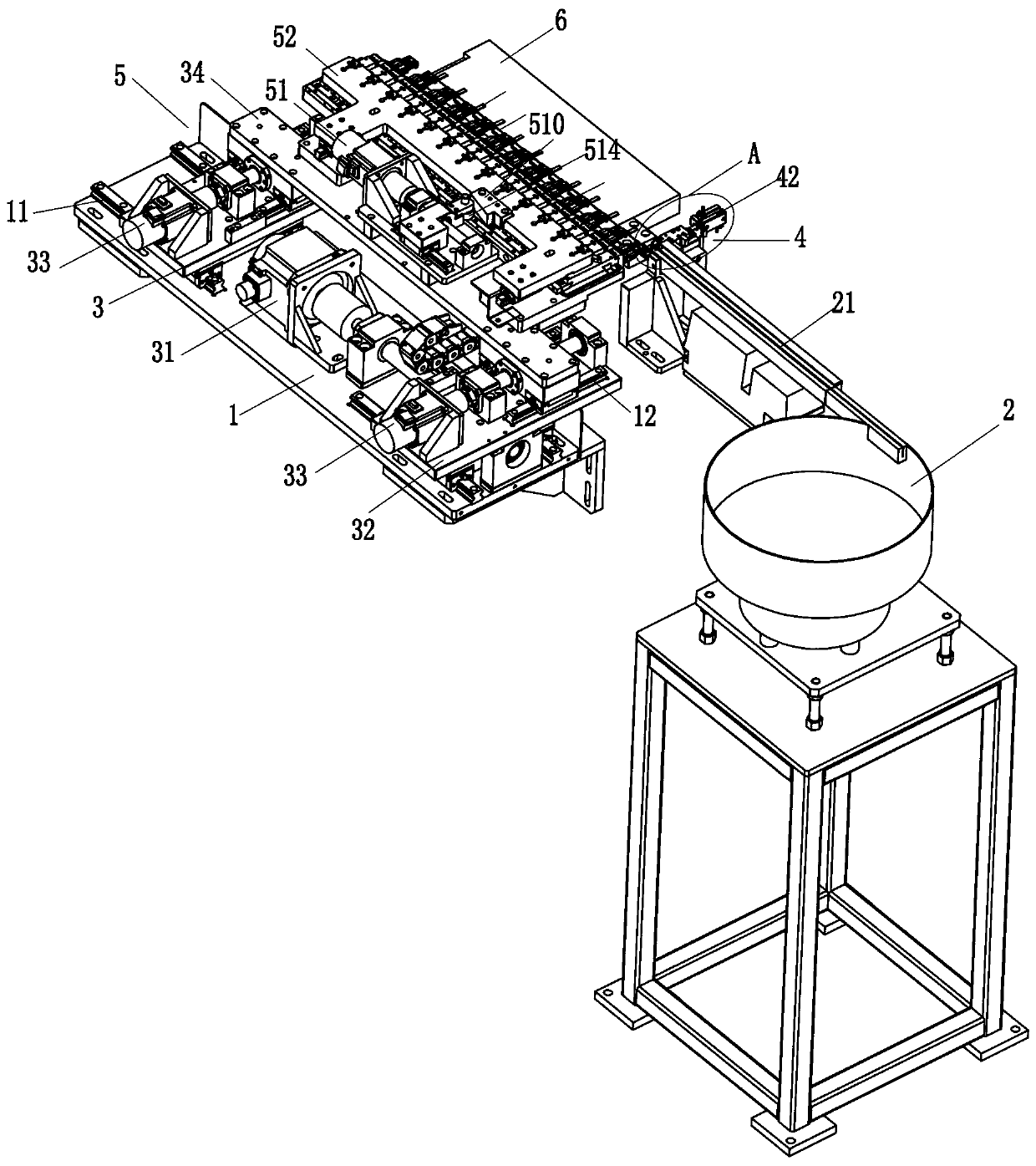

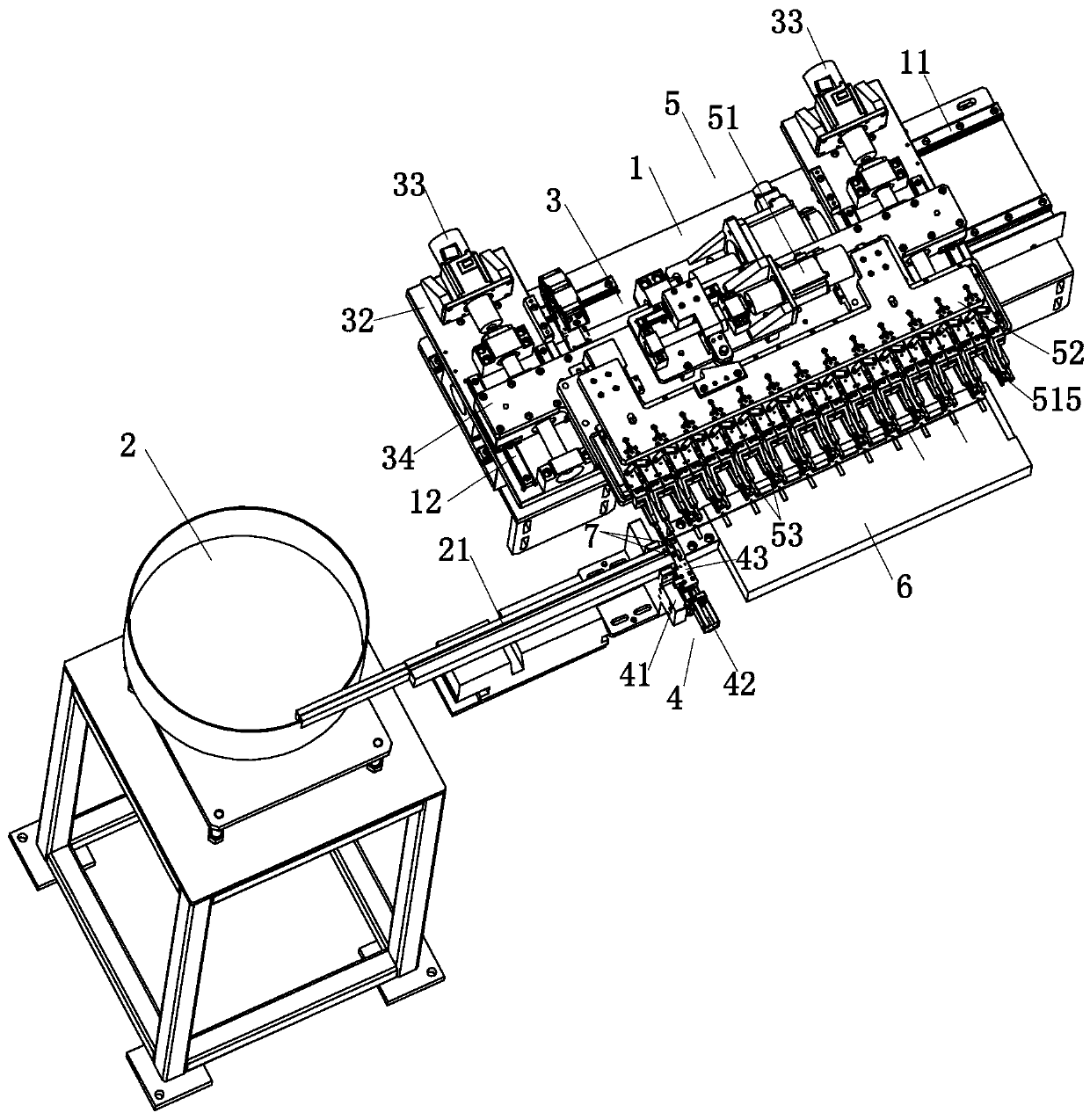

[0033] Embodiment one, such as Figure 1 to Figure 7 As shown, a two-dimensional manipulator includes a vibrating feeding tray 2, a horizontal sliding drive device 3, a material distribution mechanism 4, a workbench 6 and a feeding manipulator 5;

[0034] The vibrating feeding tray 2 is used for vibrating and conveying workpieces to the distributing mechanism 4;

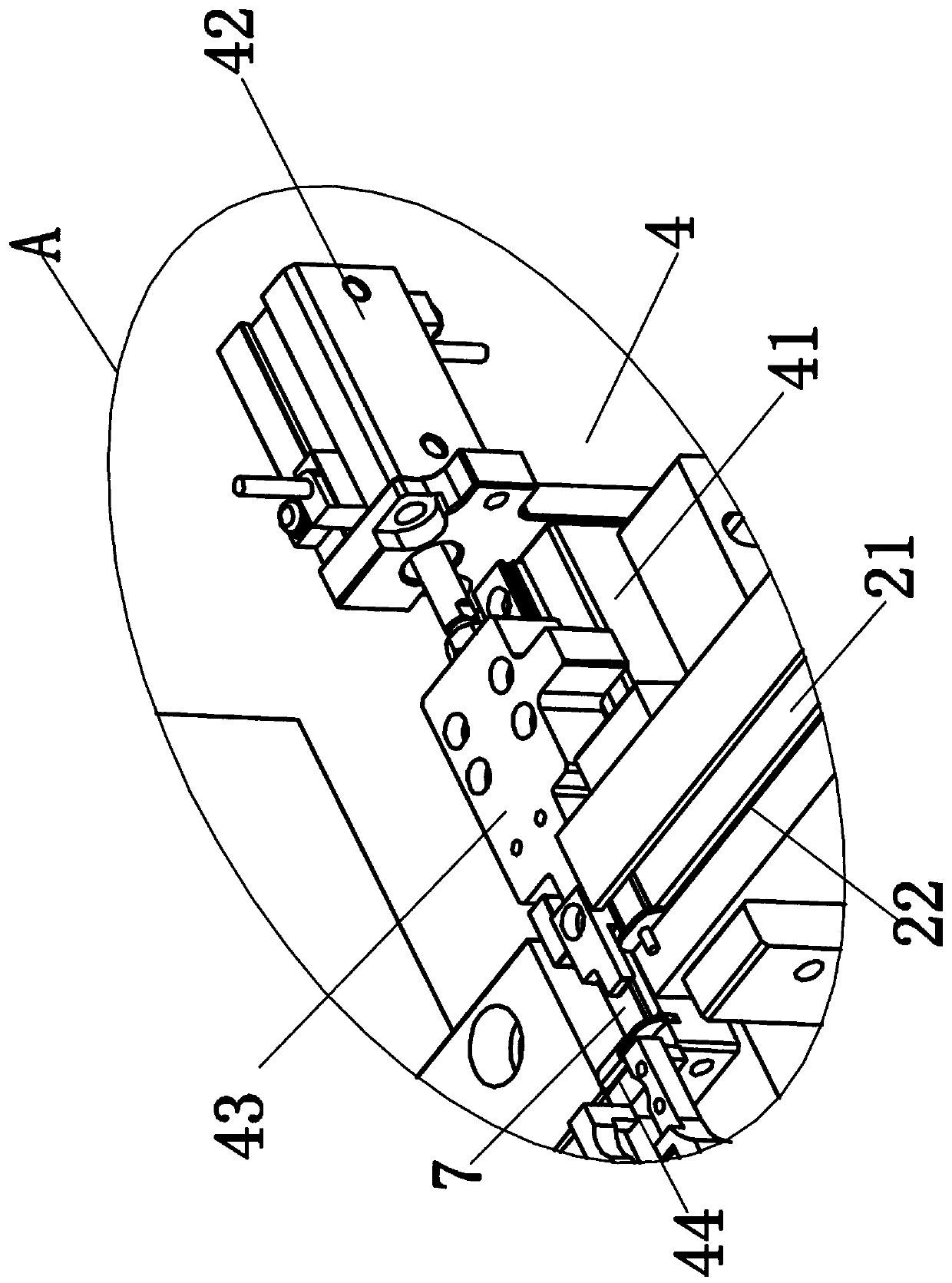

[0035] The material distributing mechanism 4 is arranged on the discharge chute 21 of the vibrating feeding tray 2, and is used to transport the workpieces to the feeding manipulator 5 one by one;

[0036] The horizontal sliding drive device 3 is used to drive the feeding manipulator 5 to move back and forth, left and right;

[0037]The feeding manipulator 5 is arranged on the horizontal slide driving device 3, and is used to grasp and transport multiple workpieces 7 at the same time. The feeding manipulator 5 includes a jaw opening driving device 51, a jaw opening driving plate 52 and multiple A jaw 53, the plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com