Quadratic-element manipulator with small machine table

A two-dimensional, manipulator technology, applied in the direction of manipulators, claw arms, manufacturing tools, etc., can solve the problems of affecting production efficiency, cumbersome workpiece movement, and long time, so as to improve production efficiency, reduce workpiece transfer links, and increase grasping. The effect of the distance the hand can move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

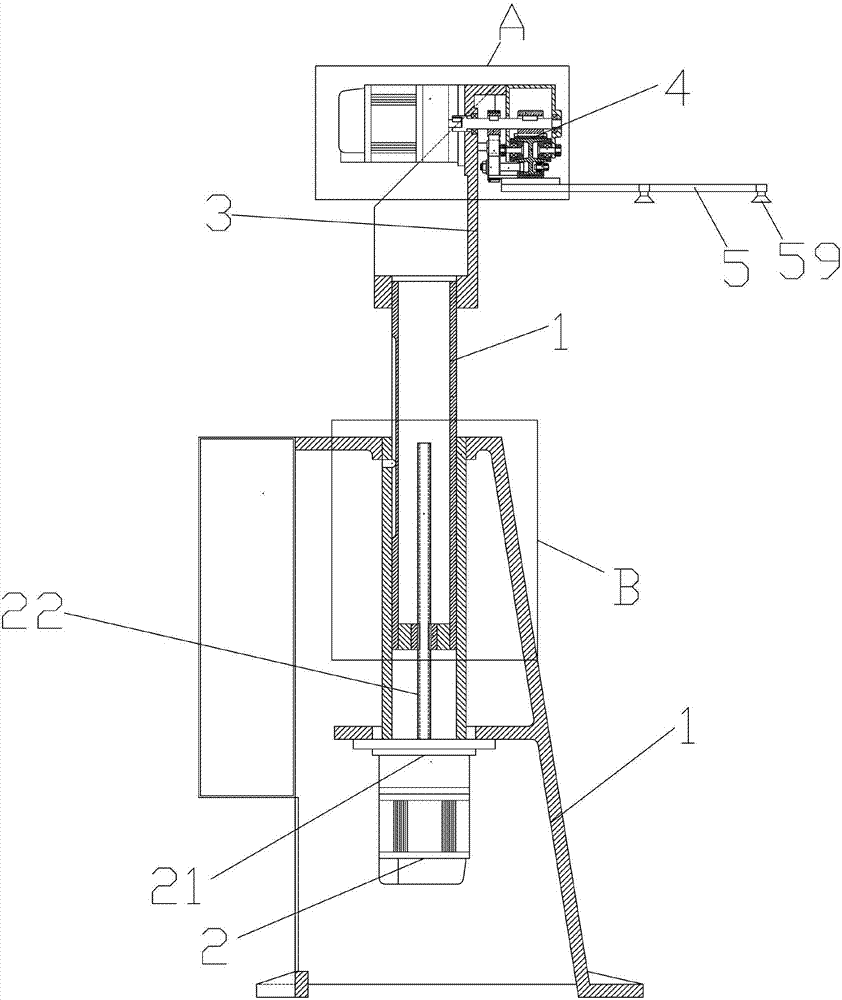

[0035] see Figure 1-Figure 5 , this embodiment shows a small machine two-dimensional manipulator:

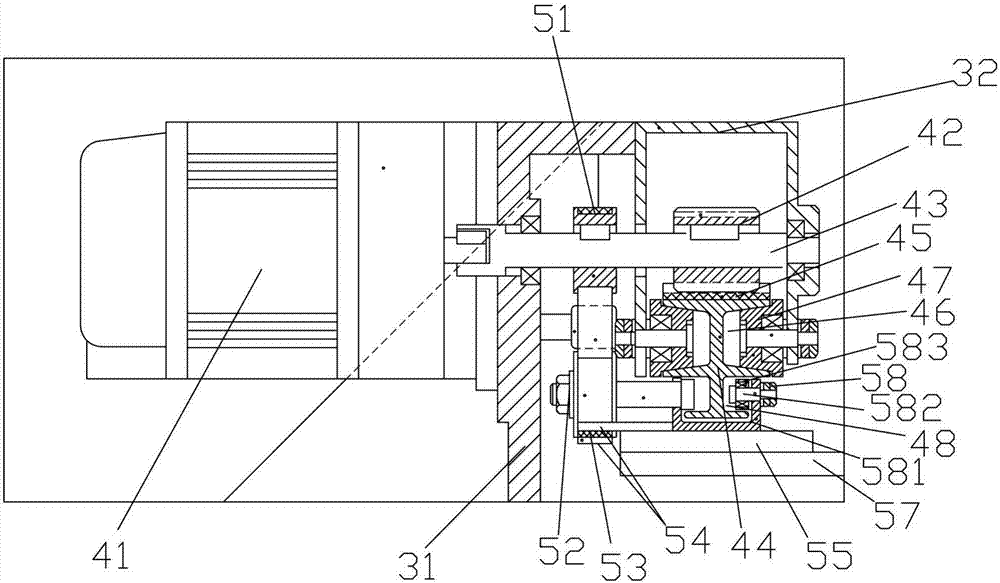

[0036] It includes a base 1, a lifting assembly 2 arranged on the base 1, a moving cross arm fixing frame assembly 3 arranged on the top of the lifting assembly 2, a moving cross arm assembly 4 arranged on the moving cross arm fixing frame assembly 3, and a moving cross arm assembly 4 arranged on the moving The gripper movement assembly 5 on the cross arm assembly 4;

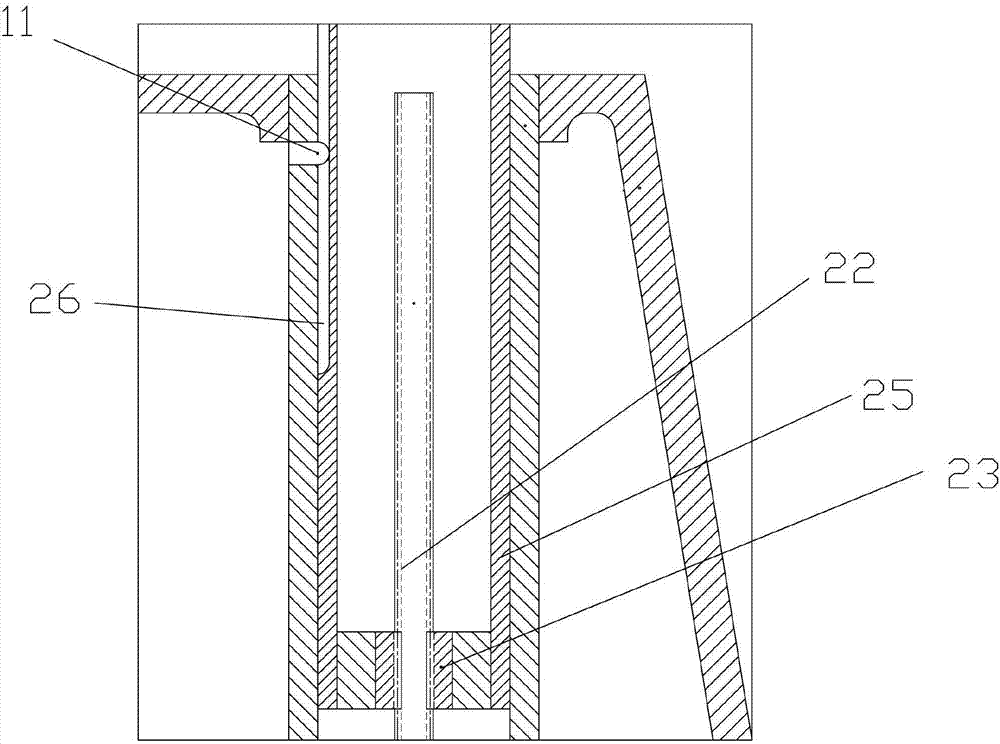

[0037] Lifting assembly 2 comprises the lifting driving device 21 that is made of motor that is arranged on the base 1, is connected to the lifting screw 22 of lifting driving device 21, is arranged on the lifting screw nut 23 on the lifting screw 22, and the lifting screw nut 23 is arranged on Inside the hollow lifting guide rod 24, the moving cross arm fixing frame assembly 3 is arranged on the top of the hollow lifting guide rod 24;

[0038] The base 1 is provided with a lifting bush 25 used in conjunction w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com