Two-dimensional imager

An imager, two-dimensional technology, applied in instruments, measuring devices, optical devices, etc., can solve the problems of wasting adjustment time, difficult to accurately position the workpiece, unable to take into account both rapid movement adjustment and precise movement adjustment, etc., to achieve convenient movement adjustment. , Reasonable design, accurate movement adjustment and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

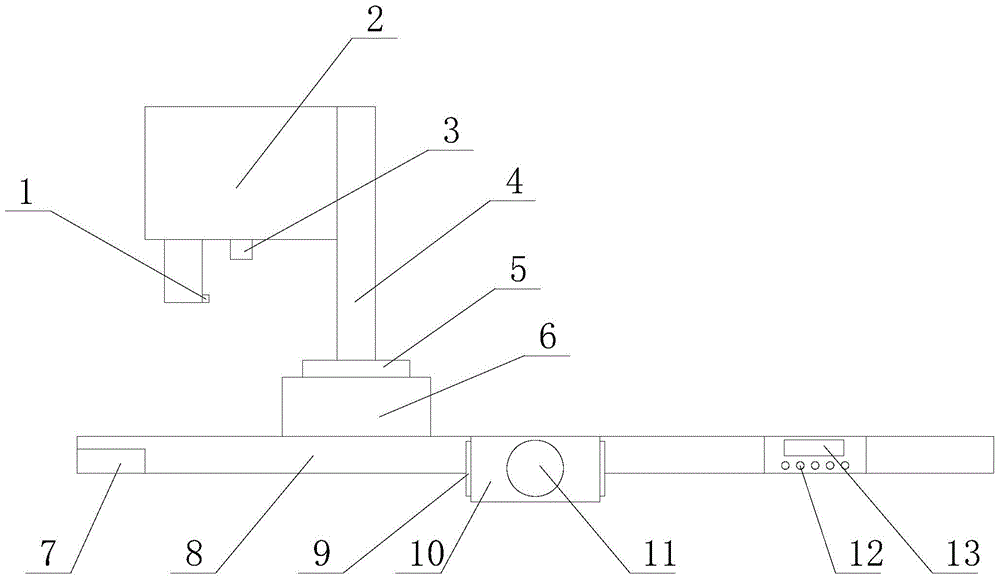

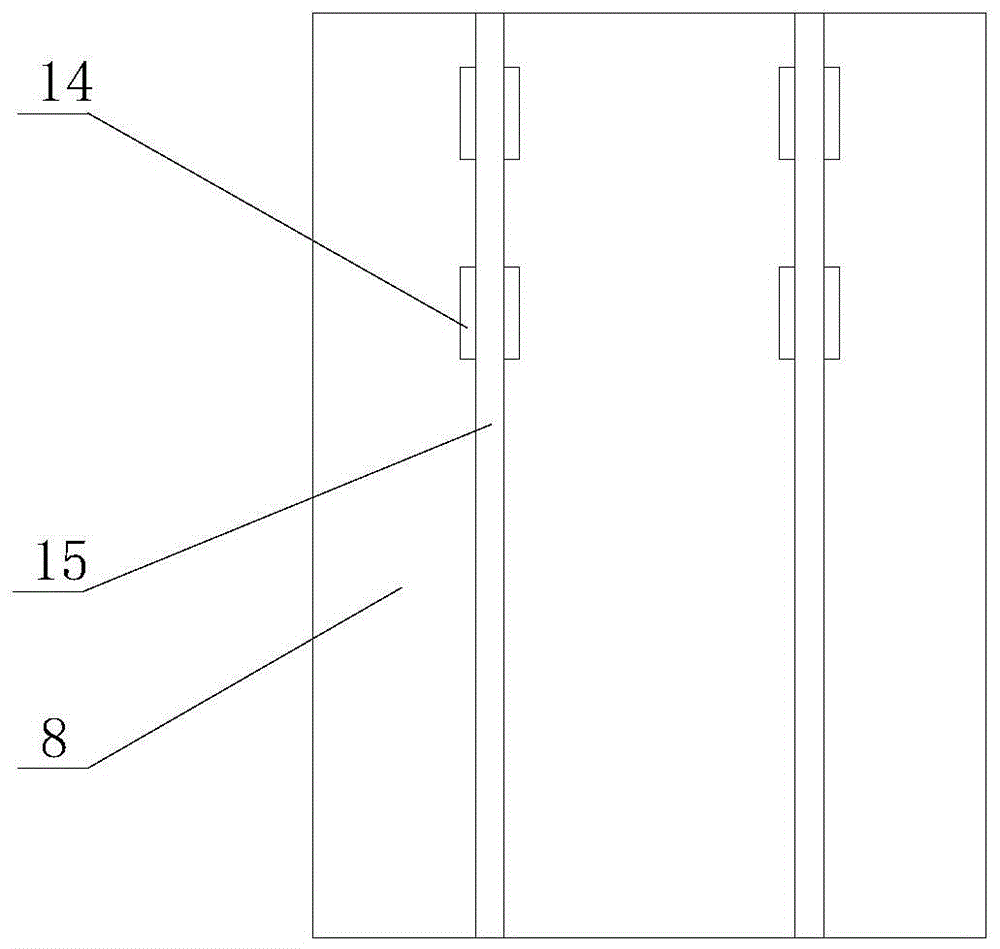

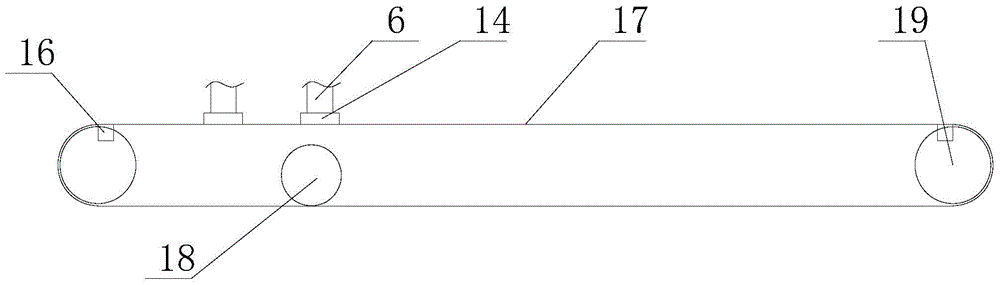

[0016] Such as Figure 1-3 As shown, the two-dimensional imager includes a lens, and the lens is installed on a connecting frame 2, and the connecting frame 2 is installed on a column 4. The column 4 is installed on the rotating mechanism, and the rotating mechanism is installed on the bottom plate 8 through the carrier 6 . The bottom plate 8 is provided with a plurality of parallel chute 15, and a moving mechanism is installed in the chute 15, and the moving mechanism is connected with a transmission mechanism.

[0017] The rotating mechanism includes a rotating motor installed on the platform, and the rotating motor is connected to the column through transmission. In addition, in addition to the above-mentioned use of the rotating motor as the rotating mechanism, it can also be designed in the form of a cylinder and a rotating disk, and the purpose of rotation can also be achieved.

[0018] The moving mechanism includes gears 19 installed at both ends of the chute 15 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com