Full-cam automatic lathe

A technology of automatic lathes and cams, applied in the field of automatic lathes, can solve the problems of high worker quality requirements, complex operation, high energy consumption, etc., and achieve the effects of low quality requirements, simple operation, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

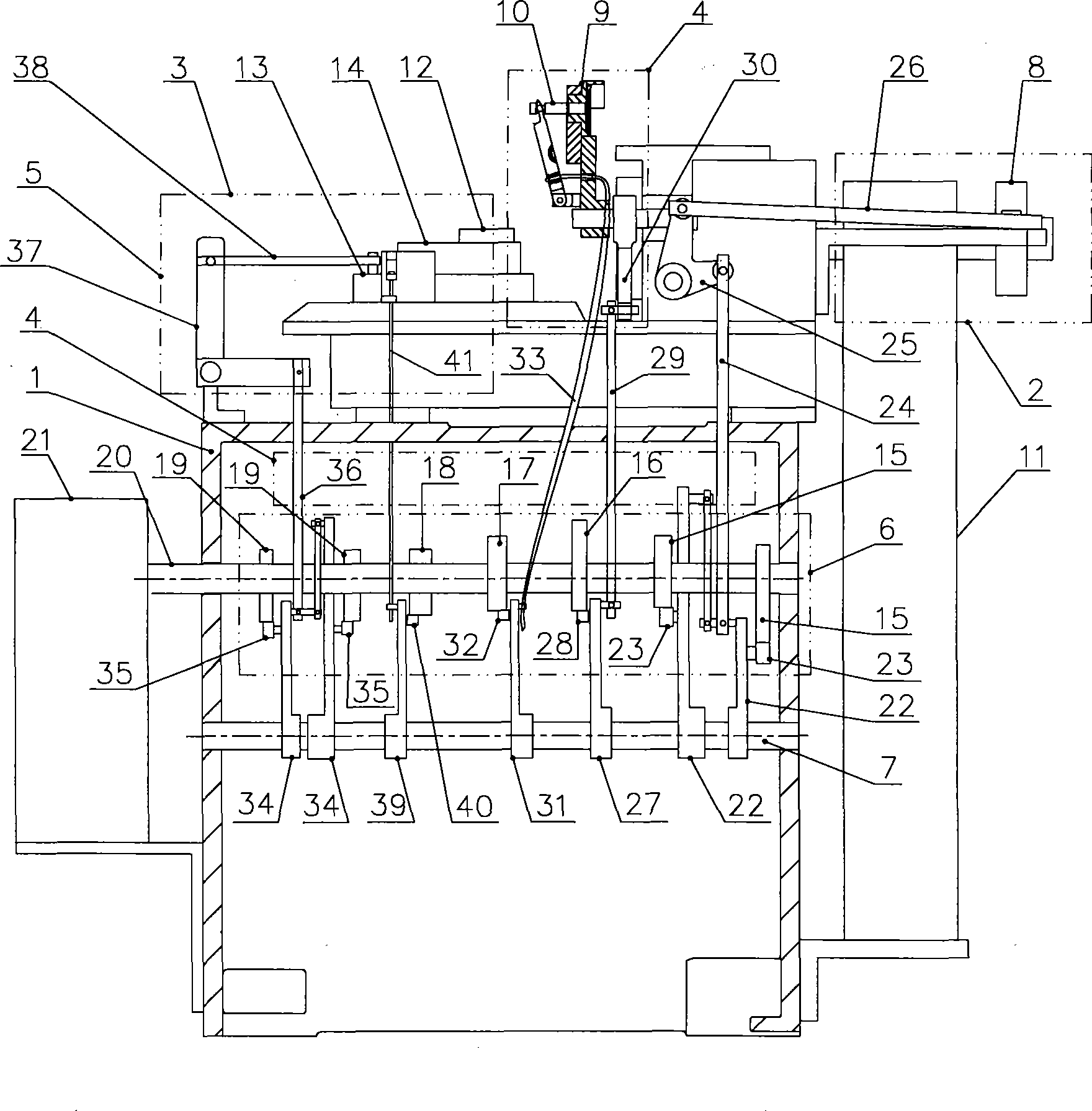

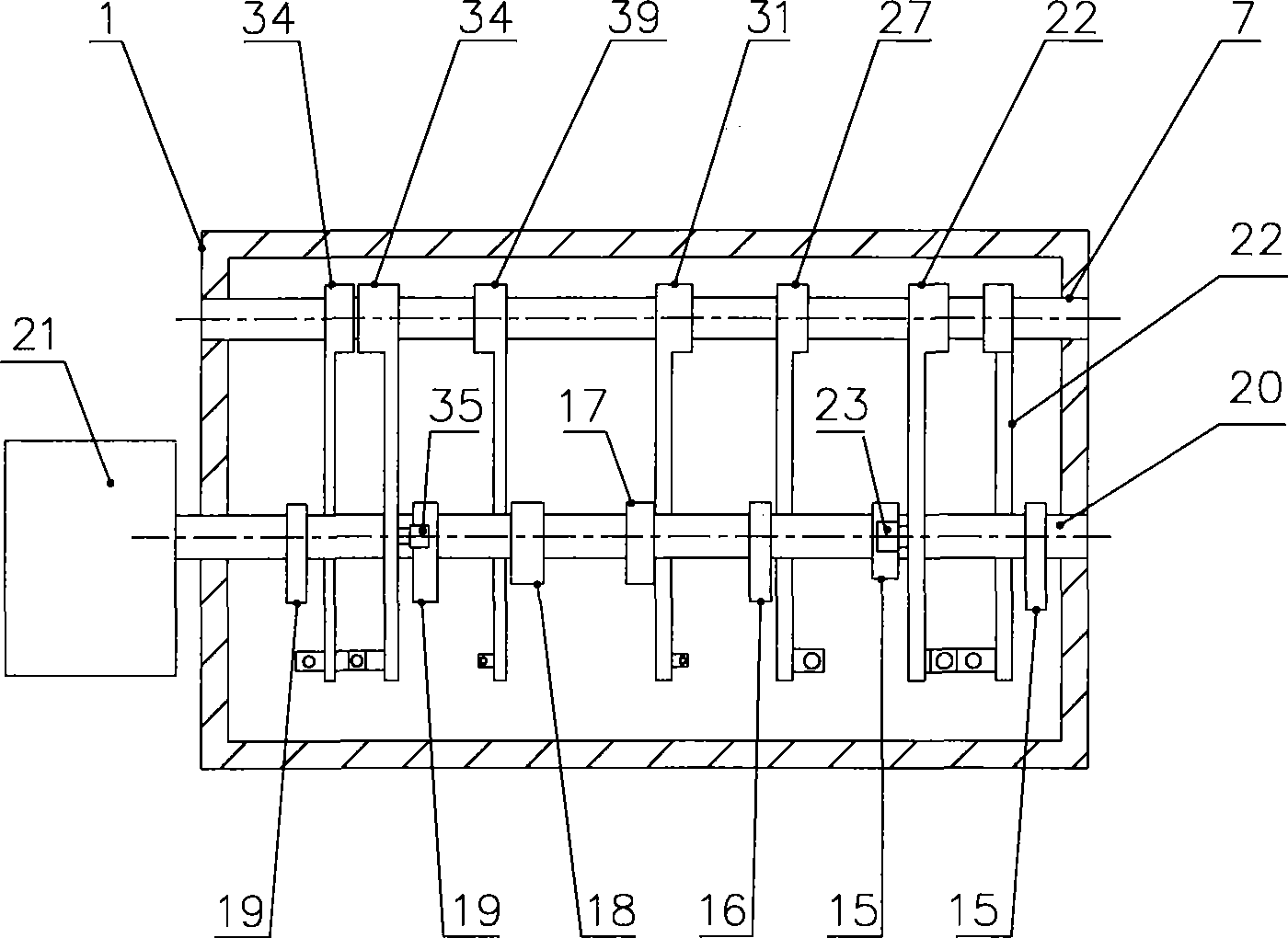

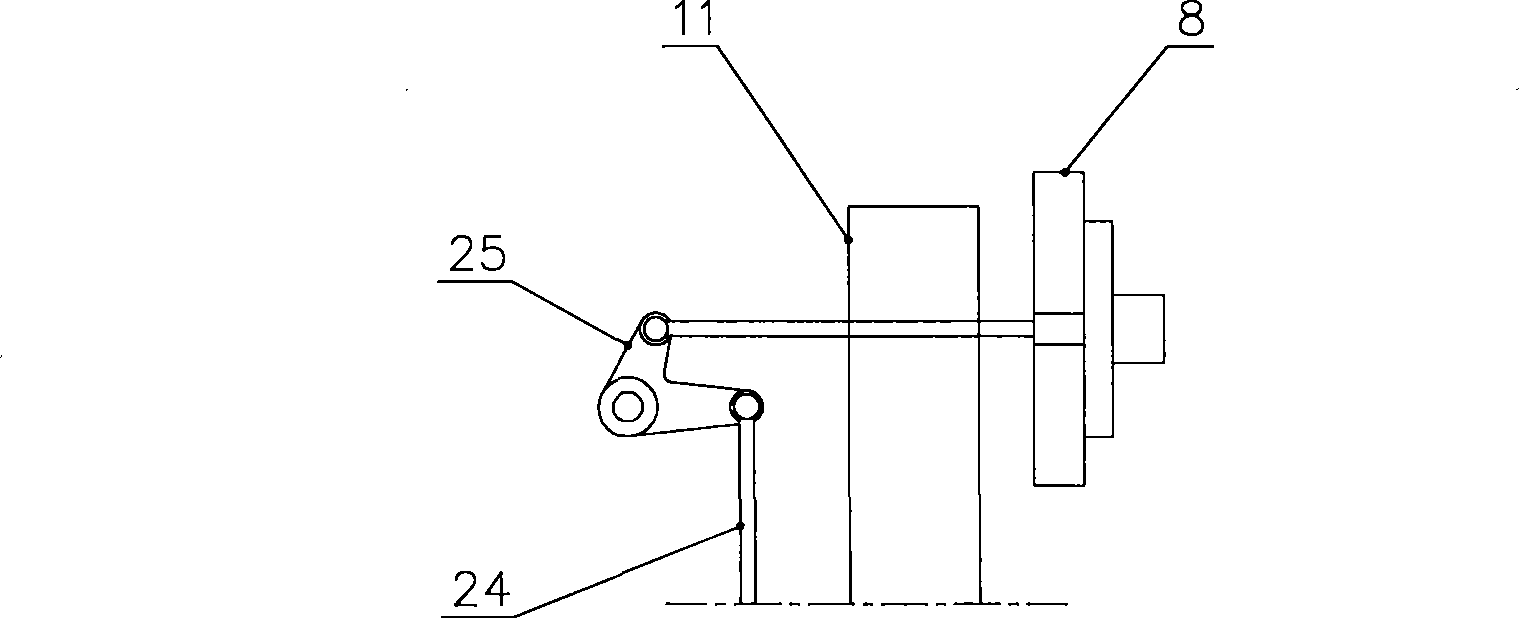

[0021] The present invention will be described in detail below through a preferred embodiment in conjunction with the accompanying drawings.

[0022] like figure 1 As shown, the full-cam automatic lathe includes a bed 1, a workpiece clamping and moving device 2, a tool installation and moving device 3, a workpiece linkage mechanism group 4, a tool linkage mechanism group 5, a cam mechanism 6, and a fixed rod 7. in:

[0023] The bed 1 is a structural member configured according to needs, and is used for installing components of the lathe.

[0024] The fixed rod 7 is arranged on the bed 1 as a fixed support point of all linkage mechanisms mentioned below.

[0025] The tool installation and moving device 3 includes a longitudinal carriage 13, a transverse carriage 14 and a knife rest 12 driven by the two. The tool installation and moving device 3 is connected with a tool link mechanism group 5 for providing several linear reciprocating motions or swings, and the link mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com