Precise cutting control system for offshore oil platform

A control system, precision cutting technology, applied in welding/cutting auxiliary equipment, manufacturing tools, auxiliary devices, etc., can solve the problem of no workpiece installation error, shape error compensation function, inability to intuitively see the position of the processing point, fitting errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

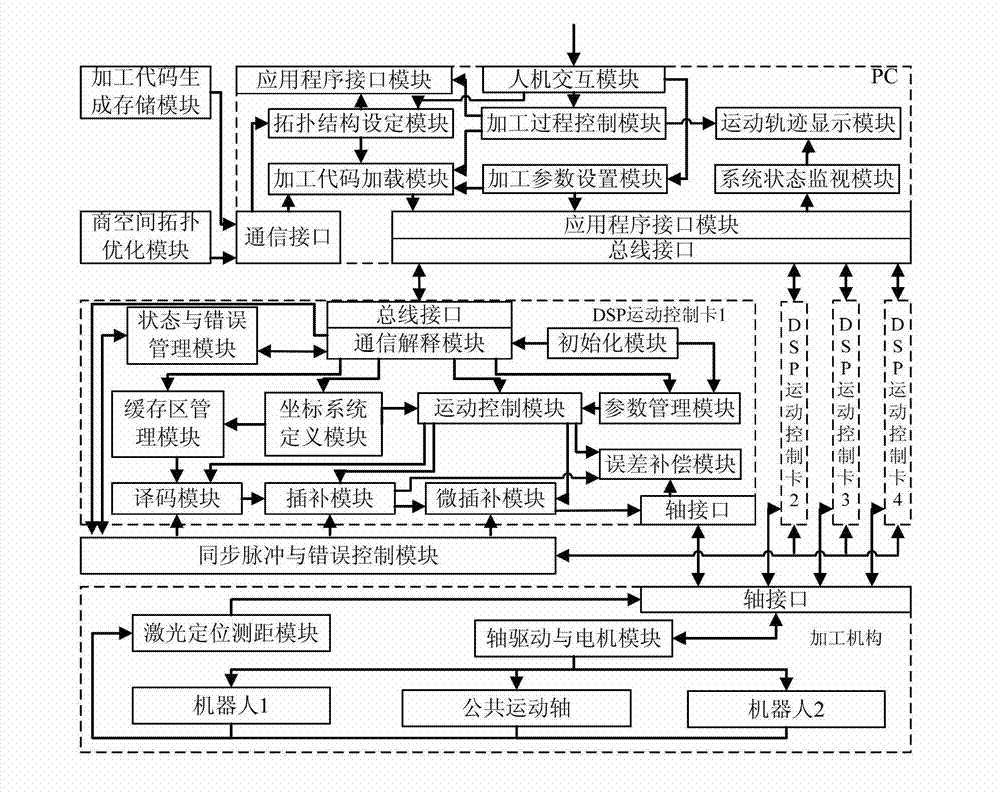

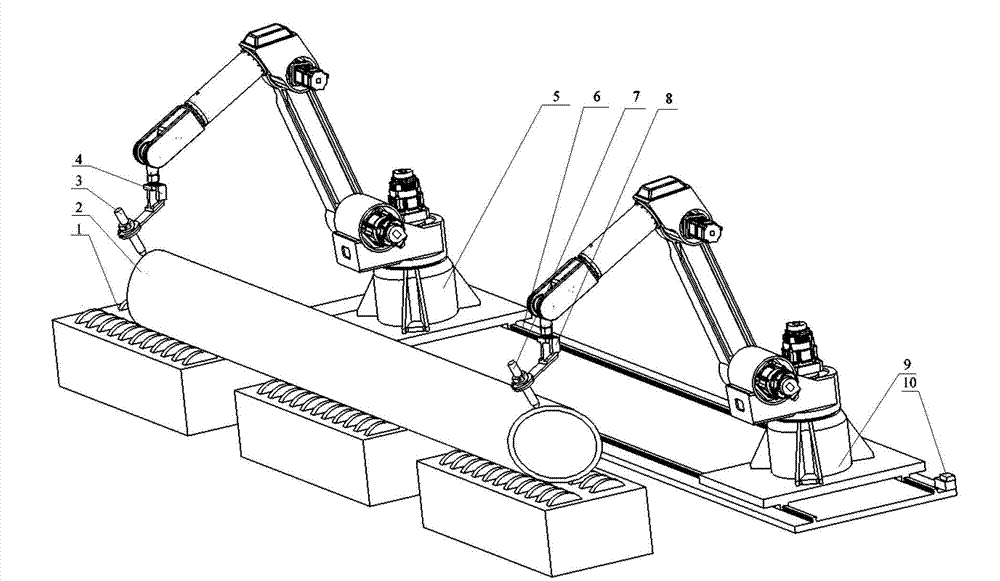

[0038] like figure 1 As shown, the system adopts the structure of PC+DSP motion control card group. The modules in the PC are man-machine interaction module, processing parameter setting module, processing process control module, topology setting module, processing code loading module, system status monitoring module, motion trajectory display module, application program interface module; DSP motion control card The modules include communication interpretation module, initialization module, status and error management module, parameter management module, coordinate system definition module, buffer area management module, motion control module, decoding module, interpolation module, micro interpolation module, error compensation mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com