Single-valve core and double-channel solenoid valve

A dual-channel, solenoid valve technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of heavy weight, complex structure, difficult to fully synchronize opening and closing, etc., to reduce volume and weight, and improve safety. the effect of improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

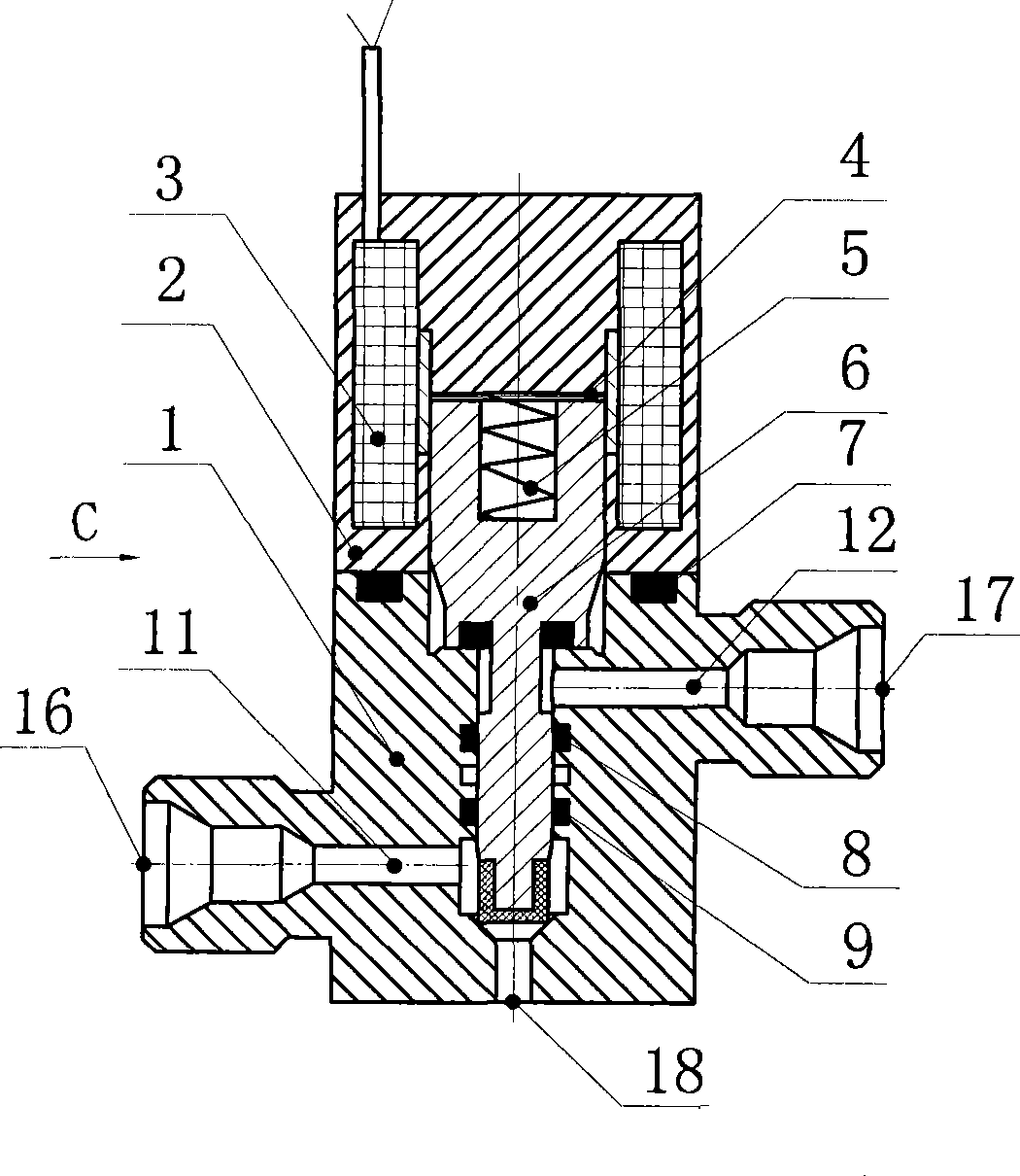

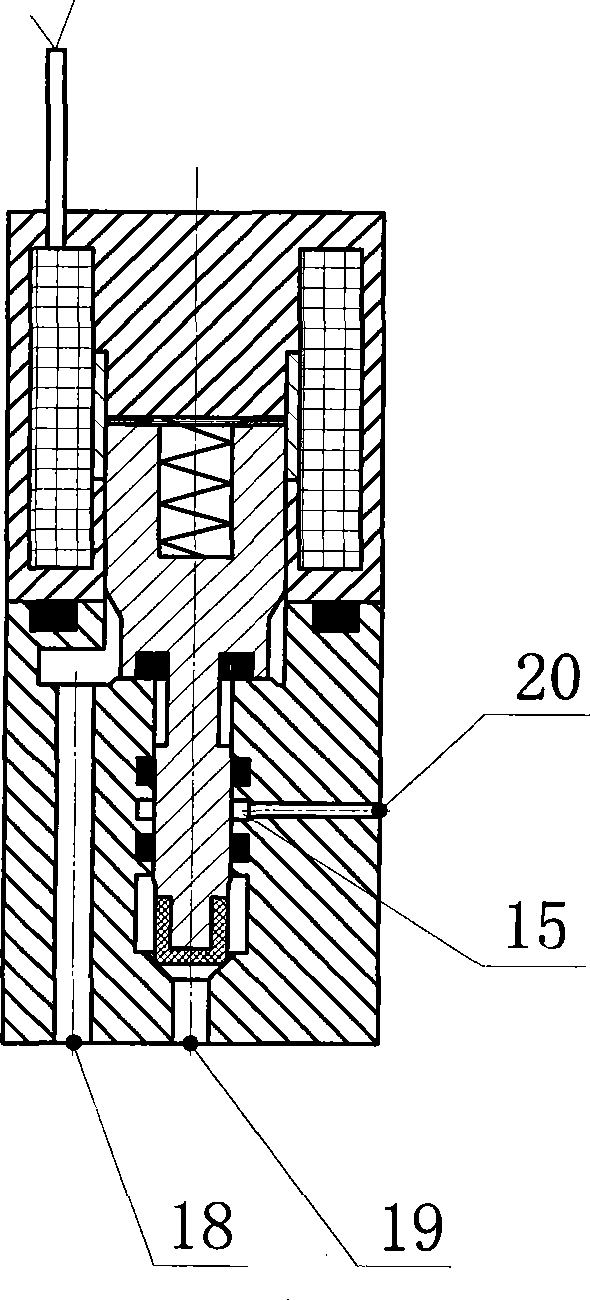

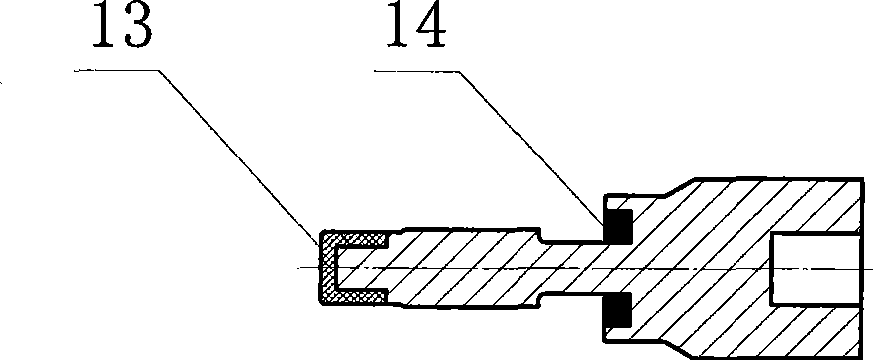

[0024] Such as figure 1 with figure 2 As shown, the single-spool dual-channel solenoid valve of the present invention is composed of a valve body 1, a skeleton 2, a coil 3, a disc spring 4, a cylindrical spring 5, a spool 6, and a rubber O-ring 7. The valve core 6 is co-guided with the valve body 1 in the axial direction; the valve body 1 is provided with a first passage 11 and a second passage 12 which are independent of each other, and the first passage 11 includes a first inlet 16 and a first outlet 18 which communicate with each other. The second channel 12 includes a second inlet 17 and a second outlet 19 that communicate with each other; the valve core 6 is a stepped valve core, and the valve body is provided with a first valve seat 13 and a second valve seat 14, and the first valve seat 13 and the second valve seat 14 are arranged on the valve body. After the spool 6 cooperates, the first channel 11 can be sealed; the second valve seat 14 can seal the second channel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com