Optical quadratic element based profile tolerance measurement method for spherical surface

A profile and two-dimensional technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of not being able to directly use the measurement benchmark of the measured surface and the complexity of the inspection of the machining accuracy of the free-form surface, so as to achieve high practicability and social harmony. value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

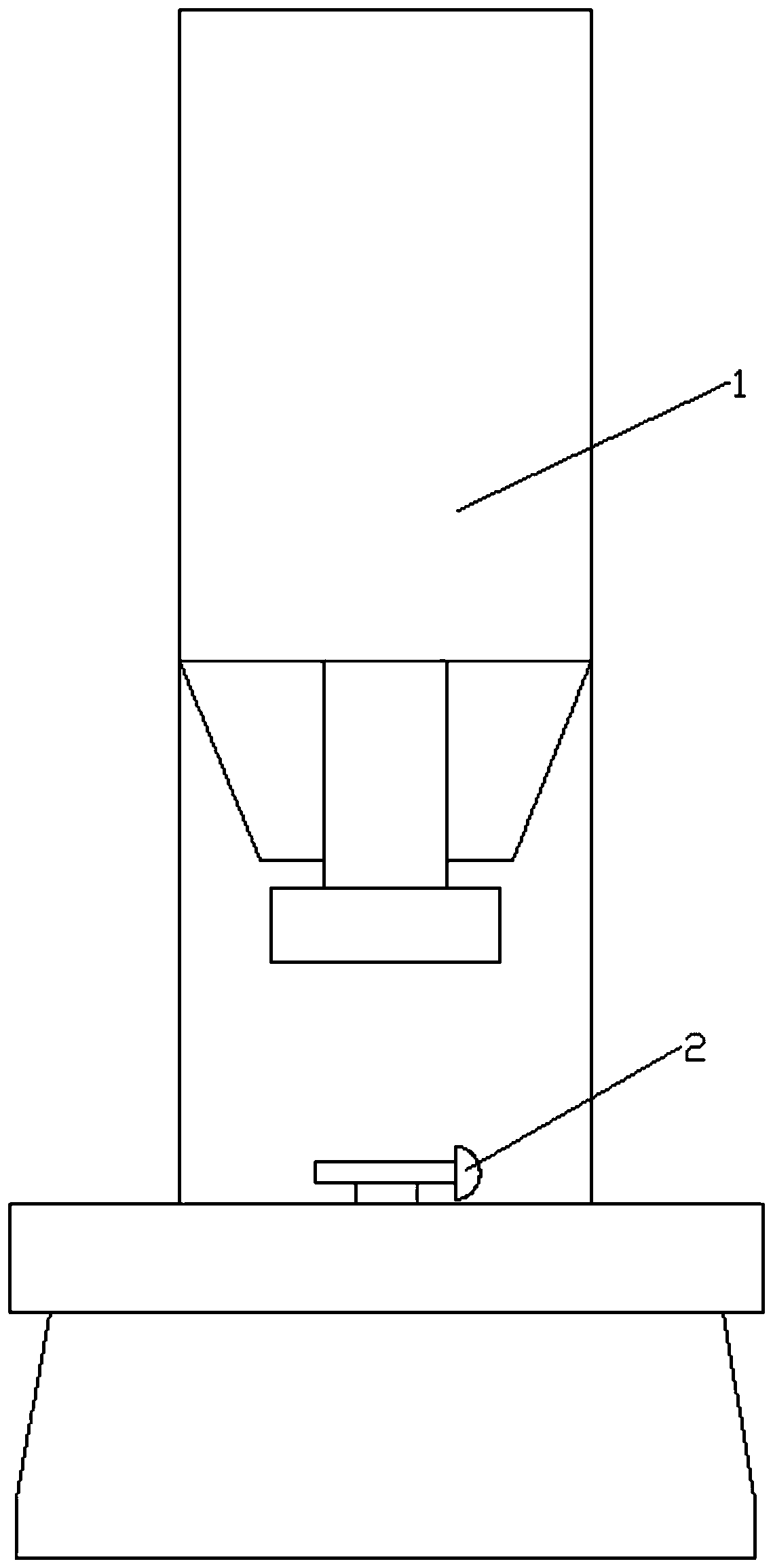

[0025] Embodiment 1, combining figure 1 , a method for measuring the profile of a spherical surface based on an optical quadratic element, comprising steps:

[0026] S1: All parts are arranged in sequence, and placed on the projector to project the two-dimensional surface contour line in sequence;

[0027] S2: Draw the ideal two-dimensional surface contour zone of the part, and make a head model with the tolerance zone of the two-dimensional surface contour of the part;

[0028] S3: Overlap the ideal two-dimensional surface profile band with the measured actual two-dimensional surface profile line, that is, the head model is superimposed on the head of the measured part;

[0029] S4: If the measured actual two-dimensional surface profile line is included in the ideal two-dimensional surface profile band, it is qualified; otherwise, it is unqualified.

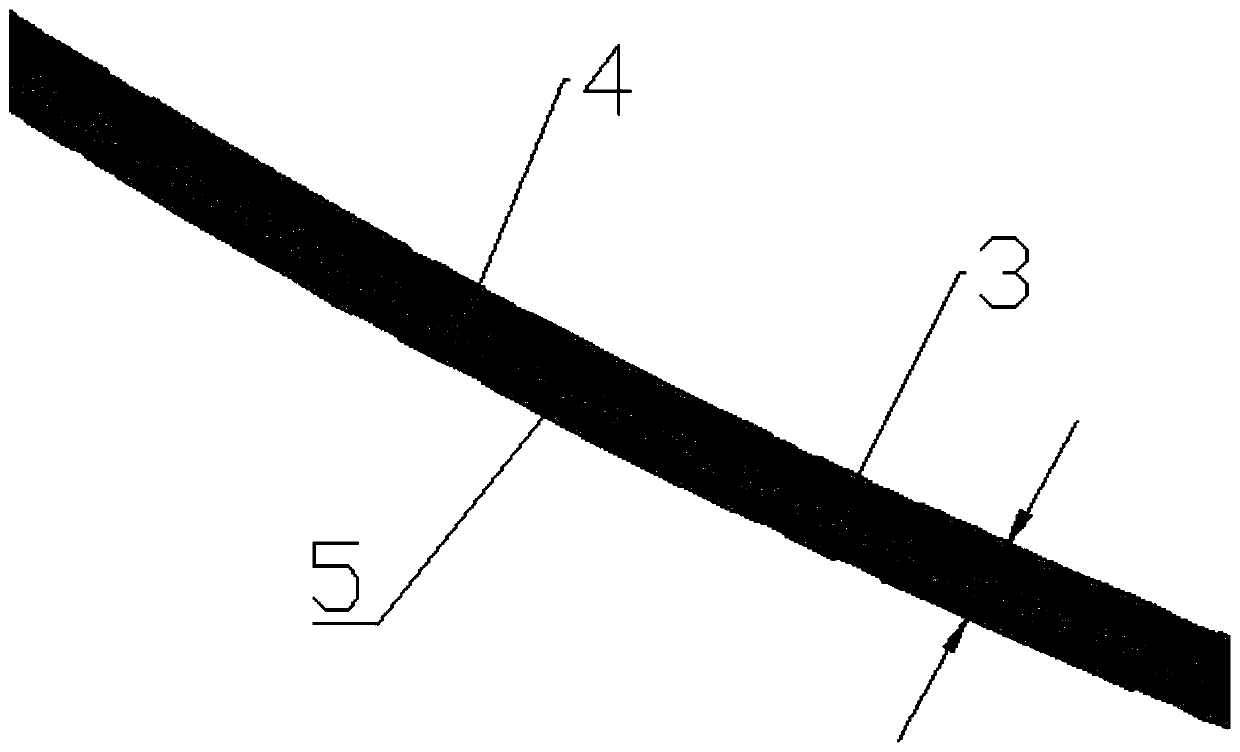

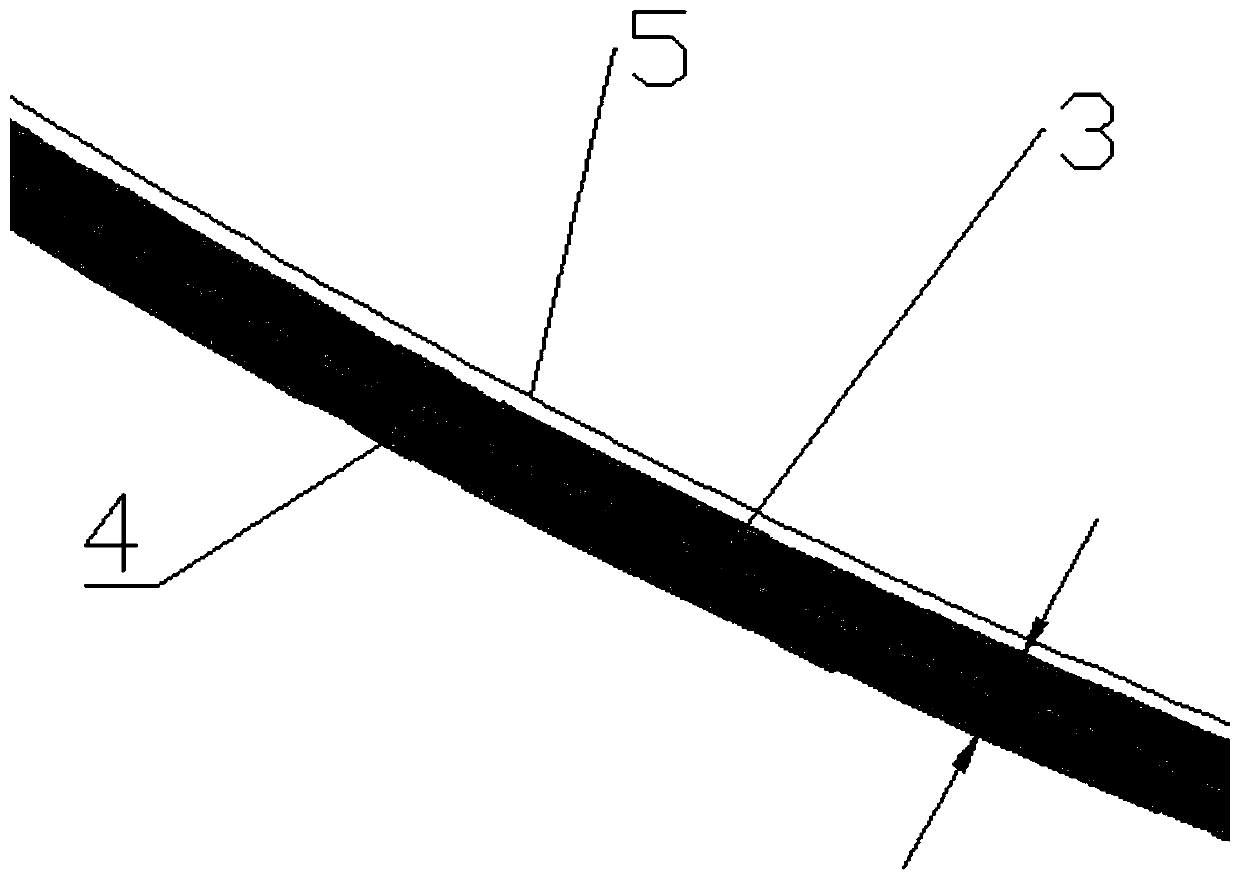

[0030] Further, both the ideal two-dimensional surface profile band and the measured actual two-dimensional surface profile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com