Two-dimensional manipulator feeding in place buffer mechanism

A buffer mechanism and manipulator technology, applied in the field of presses, can solve the problems of not many, the accuracy of feeding cannot be effectively guaranteed, and the structure is complex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

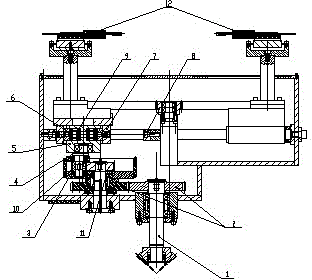

[0011] The present invention includes a transmission shaft 1, the transmission shaft 1 is connected with an eccentric shaft mechanism through a gear set 2, and the eccentric shaft 4 of the eccentric shaft mechanism is connected with a clamping mechanism, and the clamping mechanism includes a base and clamps 12 arranged on both sides of the base, One side of the base is provided with a movable seat connected to the eccentric shaft 4, and the other side of the base is provided with a fixed seat; the front end of the movable seat is provided with a stopper 7, and the front end of the fixed seat is provided with a limit position corresponding to the stopper 7 The distance between block 8, stop block 7 and limit block 8 is preset as the clamping stroke distance.

[0012] The eccentric shaft mechanism includes an eccentric disc 3 that cooperates with the gear set 2 through a key. The eccentric disc 3 is provided with an eccentric shaft 4 and a gear 10 driven by it. The gear 10 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com