Method for analyzing borehole deviation of PCB drilling machine

An analysis method and drilling machine technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve problems such as unfavorable machine production debugging, testing, complex structure, and time-consuming, etc., achieving significant technological progress and simple analysis process , Improve the effect of analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for analyzing the deviation of a PCB drilling machine includes the following steps: firstly, the hole position of the drilled hole is measured by a two-dimensional measuring instrument to obtain corresponding hole position data. Specifically, the hole position data includes Cpk (process capability index), Ca (process accuracy, indicating the deviation degree of the center position of the process characteristics), 3Sigma (ie 3σ, σ is the standard deviation, and 3σ is 3 times the standard deviation ) constitutes the engineering coefficient, the deviation data of the hole composed of the deviation value in the X direction and the deviation value in the Y direction of the drilling hole in the actual coordinates, and the deviation value of the tool diameter. Subsequently, the hole position data is imported into the analysis software in text file format.

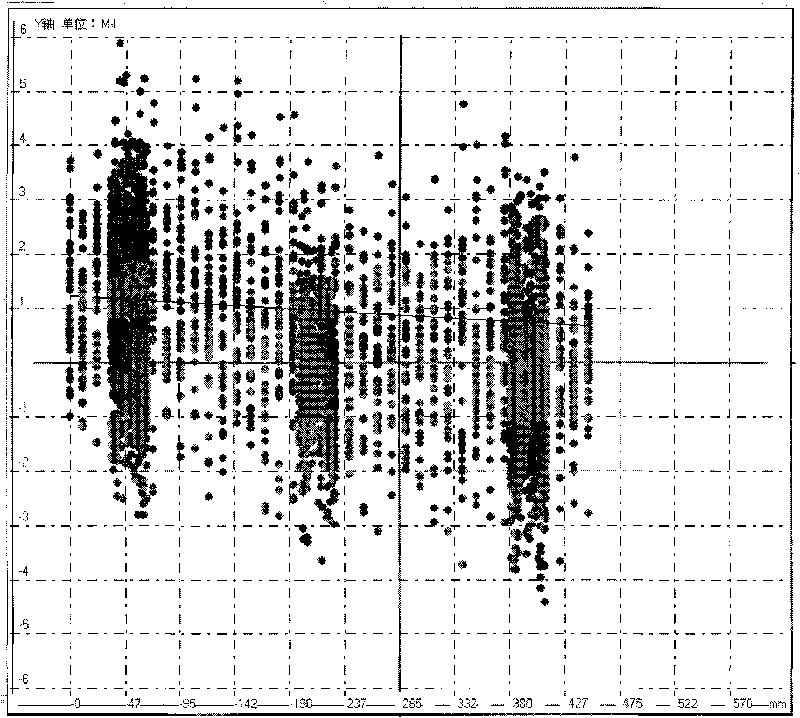

[0030] further combined figure 1 From the point of view, the comparison parameter used is Ex / x, that is, the ...

Embodiment 2

[0033]The method for analyzing the deviation of a PCB drilling machine includes the following steps: firstly, the hole position of the drilled hole is measured by a two-dimensional measuring instrument to obtain corresponding hole position data. Subsequently, the hole position data is imported into the analysis software in text file format.

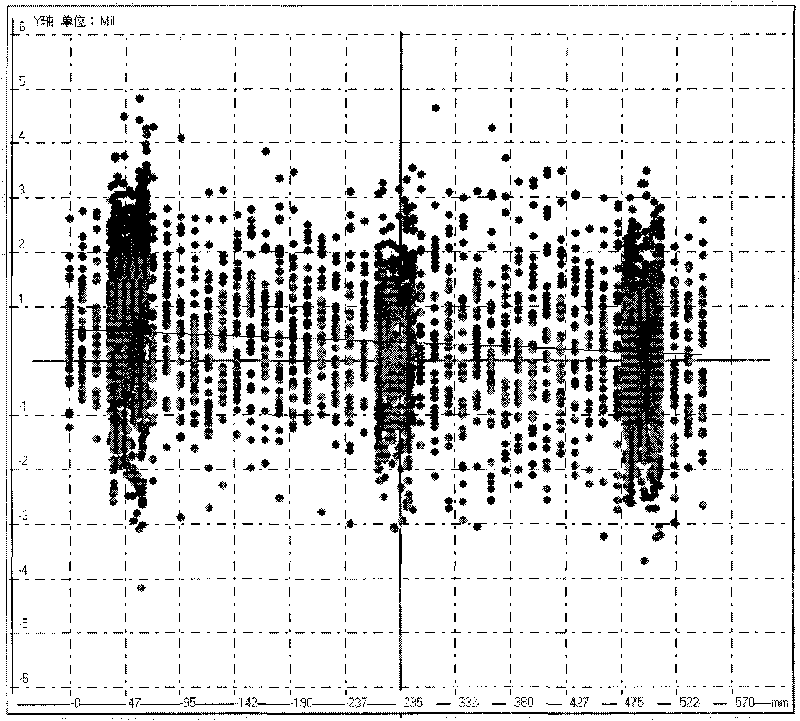

[0034] combine figure 2 According to the hole position data, the comparison parameter used is Ey / y, that is, the deviation data of the coordinates of the actual drilling in the Y direction. The deviation of is the vertical axis, forming a scatter plot. And, combine the average value of multiple drilling deviations under the same Y coordinate value to generate a trend line. In other words, this trend line reflects whether the machine applies laser interferometer compensation in the Y-axis direction to improve drilling accuracy under the condition of small temperature difference (temperature change ±1°C).

[0035] Specifically, if the t...

Embodiment 3

[0037] The method for analyzing the deviation of a PCB drilling machine includes the following steps: firstly, the hole position of the drilled hole is measured by a two-dimensional measuring instrument to obtain corresponding hole position data. Specifically, the hole location data includes the engineering coefficient composed of Cpk, Ca, and 3Sigma, the hole deviation data composed of the deviation value in the X direction and the Y direction deviation value in the actual coordinates of the drilling hole, and the deviation value of the tool diameter . Then, the hole position data is imported into the analysis software in text file format.

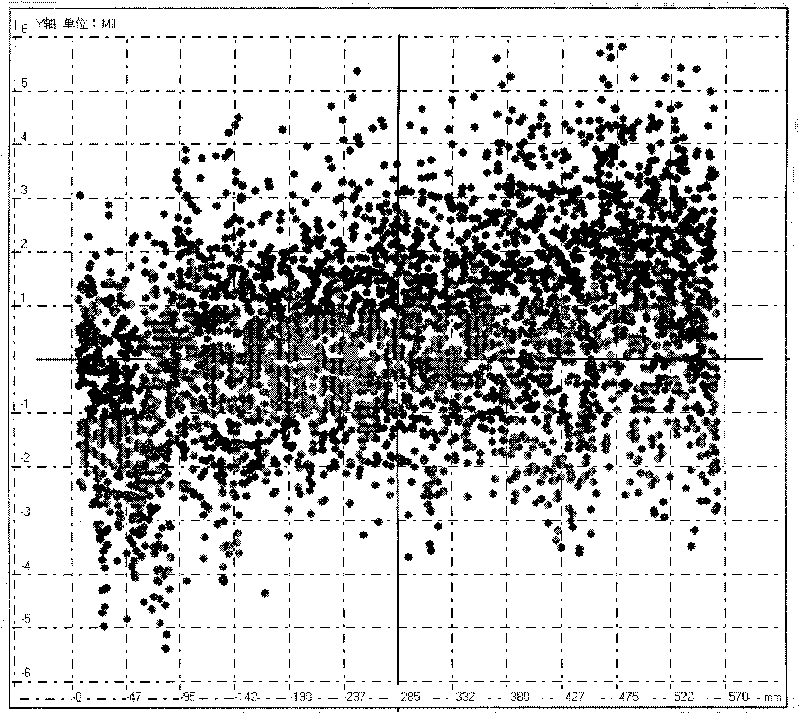

[0038] Finally, according to the hole position data, combined with image 3 From the point of view, a scatter diagram is formed by using Ex / t, that is, the variation data of the deviation in the X direction of the actual drilling hole with time, that is, the order of the drilling holes is used as the abscissa, and the deviation in the X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com